Spent grain, a byproduct of the brewing and distilling processes, is often discarded as waste, but its potential as a sustainable resource is gaining attention. One innovative application is its use as a growing medium for mushrooms. Rich in nutrients and organic matter, spent grain provides an ideal substrate for mushroom cultivation, offering a cost-effective and eco-friendly alternative to traditional materials like straw or sawdust. By repurposing this waste product, not only can mushroom growers reduce their environmental footprint, but breweries and distilleries can also find a valuable second life for their byproducts, creating a circular economy that benefits both industries and the planet.

| Characteristics | Values |

|---|---|

| Suitability | Spent grain is highly suitable as a mushroom growing medium due to its nutrient content and structure. |

| Nutrient Content | Rich in carbohydrates, proteins, and fibers, providing essential nutrients for mushroom mycelium growth. |

| Moisture Retention | Excellent moisture retention properties, which is crucial for mushroom cultivation. |

| Cost-Effectiveness | Low-cost or free byproduct of brewing and distilling processes, making it an economical choice. |

| Sustainability | Reduces waste by repurposing a byproduct, contributing to sustainable agricultural practices. |

| Sterilization Requirement | Requires proper sterilization (e.g., pasteurization or autoclaving) to eliminate competing microorganisms. |

| pH Level | Typically neutral to slightly acidic, which is favorable for many mushroom species. |

| Common Mushroom Species | Suitable for growing oyster mushrooms, shiitake, and other saprophytic mushrooms. |

| Preparation | Must be properly hydrated, sterilized, and supplemented with additional nutrients (e.g., gypsum) if necessary. |

| Bulk Density | Provides a good substrate structure for mycelium colonization and fruiting body formation. |

| Environmental Impact | Eco-friendly alternative to traditional substrates like sawdust or straw. |

| Availability | Readily available from breweries, distilleries, and ethanol production facilities. |

| Potential Drawbacks | Risk of contamination if not properly sterilized; may require additional supplementation for optimal growth. |

Explore related products

What You'll Learn

- Nutrient Content: Spent grain's nutrient profile and its suitability for mushroom mycelium growth

- Preparation Methods: Techniques to sterilize and prepare spent grain for mushroom cultivation

- Mushroom Species: Best mushroom types that thrive on spent grain substrates

- Cost-Effectiveness: Economic benefits of using spent grain as a growing medium

- Environmental Impact: Sustainability and waste reduction through spent grain repurposing

Nutrient Content: Spent grain's nutrient profile and its suitability for mushroom mycelium growth

Spent grain, a byproduct of brewing and distilling processes, is rich in nutrients that can support mushroom mycelium growth. Its composition typically includes carbohydrates, proteins, fibers, and trace minerals, making it a potentially ideal substrate. For instance, the high cellulose and hemicellulose content in spent grain provides a fibrous structure that mushrooms like oyster and shiitake thrive on. However, its nutrient profile varies depending on the grain source (barley, wheat, or rye) and the brewing method, which must be considered when preparing it for mushroom cultivation.

To harness spent grain’s potential, it must be properly prepared to avoid contamination and optimize nutrient availability. Start by pasteurizing or sterilizing the grain to eliminate competing microorganisms. A common method is to soak the spent grain in hot water (180°F/82°C) for 1–2 hours, then drain and cool it before mixing with other substrates like straw or sawdust. For every 5 gallons of substrate, mix in 2–3 gallons of spent grain to balance moisture and nutrient levels. This ratio ensures the mycelium receives sufficient nitrogen and carbon without becoming overly compacted.

Comparatively, spent grain offers advantages over traditional substrates like straw or wood chips due to its higher protein content, typically ranging from 20–25%. This elevated protein level accelerates mycelium colonization, reducing the time between inoculation and fruiting. For example, oyster mushrooms grown on spent grain-enriched substrates often fruit within 2–3 weeks, compared to 4–6 weeks on straw alone. However, its moisture retention properties require careful management to prevent waterlogging, which can lead to mold or bacterial growth.

Practical tips for using spent grain include sourcing it fresh from local breweries to ensure it hasn’t spoiled. If the grain is too wet, spread it thinly to air-dry before use. Supplementing with 5–10% gypsum can improve substrate structure and calcium content, benefiting mushroom development. Always monitor pH levels, aiming for a range of 6.0–6.5, as spent grain’s natural pH can vary. With these adjustments, spent grain transforms from waste into a sustainable, nutrient-rich medium for mushroom cultivation.

Mushrooms and Paranoia: Unraveling the Truth Behind Psychedelic Effects

You may want to see also

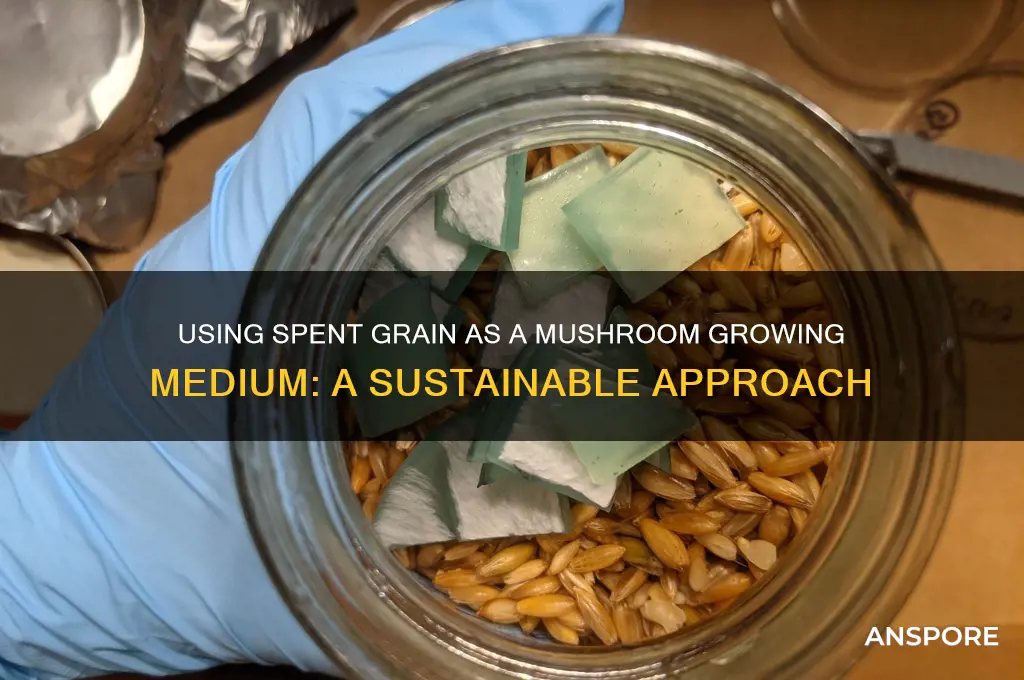

Preparation Methods: Techniques to sterilize and prepare spent grain for mushroom cultivation

Spent grain, a byproduct of brewing, is rich in nutrients and can serve as an excellent substrate for mushroom cultivation. However, its preparation requires careful sterilization to eliminate contaminants that could hinder mushroom growth. Here’s a detailed guide on techniques to sterilize and prepare spent grain for optimal mushroom cultivation.

Step-by-Step Sterilization Process: Begin by collecting spent grain immediately after brewing to minimize bacterial growth. Spread the grain thinly on a clean surface to allow it to cool and reduce moisture content. Once cooled, mix the spent grain with a bulking agent like straw or wood chips in a 3:1 ratio to improve aeration and structure. Next, moisten the mixture to a 60-70% moisture level, ensuring it feels like a wrung-out sponge. Transfer the mixture into autoclavable bags, leaving enough space for expansion. Sterilize the bags in a pressure cooker at 15 psi (121°C) for 90 minutes to kill bacteria, fungi, and spores. Allow the bags to cool completely before inoculating with mushroom spawn to prevent heat damage.

Alternative Sterilization Methods: For those without access to a pressure cooker, pasteurization is a viable option. Soak the spent grain mixture in hot water (80-85°C) for 1-2 hours, stirring occasionally to ensure even heat distribution. While pasteurization doesn’t eliminate all contaminants, it significantly reduces them, making the substrate suitable for less sensitive mushroom species like oyster mushrooms. Another method involves using a steam generator to sterilize the grain in bulk, ideal for larger-scale operations. This method requires precise temperature control to avoid overcooking the substrate.

Inoculation and Incubation: After sterilization, cool the substrate to 25-30°C before introducing mushroom spawn. Mix 1-2 cups of spawn per 5-liter bag of substrate, ensuring even distribution. Seal the bags and place them in a dark, temperature-controlled environment (22-25°C) for colonization. This phase typically lasts 2-4 weeks, depending on the mushroom species. Regularly inspect the bags for signs of contamination, such as mold or unusual odors, and discard any compromised batches.

Practical Tips for Success: Always use fresh, uncontaminated spawn to maximize yield. Maintain cleanliness throughout the process, sanitizing tools and work surfaces with a 10% bleach solution. Monitor humidity levels during incubation, aiming for 80-90% relative humidity to support mycelium growth. For fruiting, introduce the colonized substrate to a well-ventilated, humid environment with indirect light. Harvest mushrooms promptly to encourage multiple flushes and extend productivity.

By mastering these preparation methods, spent grain can be transformed into a sustainable and nutrient-rich medium for mushroom cultivation, reducing waste while producing a valuable crop.

Growing Oyster Mushrooms on Soybeans: Feasibility and Cultivation Tips

You may want to see also

Mushroom Species: Best mushroom types that thrive on spent grain substrates

Spent grain, a byproduct of brewing, is rich in nutrients like cellulose, hemicellulose, and proteins, making it an ideal substrate for mushroom cultivation. However, not all mushroom species thrive equally on this medium. Selecting the right species is crucial for maximizing yield and minimizing contamination. Here’s a focused guide on the best mushroom types that excel on spent grain substrates.

Oyster Mushrooms (Pleurotus ostreatus) are the undisputed champions of spent grain cultivation. Their aggressive mycelium colonizes quickly, outcompeting contaminants. Oyster mushrooms are highly adaptable, tolerating a wide range of moisture levels and pH values. To cultivate, mix 50-70% spent grain with 30-50% straw or wood chips for aeration, pasteurize at 65°C (149°F) for 1-2 hours, inoculate with spawn, and maintain humidity at 80-90%. Harvest within 2-3 weeks for optimal texture and flavor.

Lion’s Mane (Hericium erinaceus) is another excellent choice, prized for its medicinal properties and unique texture. This species prefers a slightly denser substrate, so use 60-70% spent grain with 30-40% hardwood sawdust. Pasteurization is critical to prevent contamination, as Lion’s Mane grows slower than oysters. Maintain temperatures between 20-25°C (68-77°F) and humidity above 85%. Fruiting takes 4-6 weeks, but the high market value justifies the patience.

Shiitake (Lentinula edodes) can also be grown on spent grain, though it requires more precise conditions. Shiitake thrives on a substrate with 50-60% spent grain and 40-50% oak sawdust, as it relies on lignin breakdown for nutrition. Steam sterilization is recommended to ensure a sterile environment. After inoculation, incubate at 22-25°C (72-77°F) for 4-6 weeks, then induce fruiting by exposing to fresh air and lowering temperatures to 15-18°C (59-64°F). Harvest when caps are fully opened but still flat.

Comparatively, Button Mushrooms (Agaricus bisporus) are less suited for spent grain alone. They require a more complex substrate with added nitrogen sources like poultry manure. However, blending 30-40% spent grain with traditional compost can reduce costs and improve sustainability. This hybrid approach balances nutrient needs while leveraging spent grain’s structure.

In conclusion, spent grain is a versatile and sustainable substrate, but species selection is key. Oyster mushrooms offer the easiest entry point, while Lion’s Mane and Shiitake provide higher value with more effort. Experimentation with blends and pasteurization techniques can further optimize results, turning brewery waste into a bountiful harvest.

Can Rabbits Safely Eat Baby Bella Mushrooms? A Complete Guide

You may want to see also

Explore related products

Cost-Effectiveness: Economic benefits of using spent grain as a growing medium

Spent grain, a byproduct of brewing and distilling processes, offers a cost-effective solution for mushroom cultivation by repurposing waste into a valuable growing medium. This approach not only reduces disposal costs for breweries but also provides mushroom growers with an affordable substrate alternative. For instance, a small-scale mushroom farm can save up to 40% on substrate costs by using spent grain instead of traditional materials like straw or sawdust. This economic advantage is particularly significant for startups and small businesses operating on tight budgets.

Analyzing the financial benefits, spent grain’s low acquisition cost is a primary driver of its cost-effectiveness. Breweries often give away or sell spent grain at minimal prices, sometimes as low as $0.05 to $0.10 per pound, compared to $0.20 to $0.30 per pound for commercial mushroom substrates. Additionally, spent grain’s high nutrient content reduces the need for supplemental fertilizers, further lowering production expenses. A case study from a Midwest mushroom farm revealed that integrating spent grain into their substrate mix decreased their overall cultivation costs by 35% while maintaining yield quality.

To maximize economic benefits, growers should follow specific steps when using spent grain. First, ensure the grain is properly pasteurized or sterilized to eliminate contaminants, which can be achieved by soaking it in hot water (180°F) for 1–2 hours. Second, mix spent grain with other substrates like straw or wood chips in a 60:40 ratio to balance moisture and aeration. Third, monitor pH levels, as spent grain tends to be slightly acidic (pH 4.5–5.5), and adjust with lime if necessary to reach the optimal range of 6.0–6.5 for mushroom growth. These practices ensure cost savings without compromising productivity.

A comparative analysis highlights the long-term economic advantages of spent grain over conventional substrates. While straw and sawdust require frequent replenishment and incur higher transportation costs, spent grain is often locally sourced, reducing carbon footprints and logistics expenses. Moreover, its reuse aligns with circular economy principles, enhancing a farm’s sustainability profile and potentially attracting eco-conscious consumers willing to pay a premium for responsibly grown mushrooms. This dual benefit of cost reduction and market differentiation positions spent grain as a strategic choice for economically and environmentally minded growers.

Finally, practical tips can further amplify the economic benefits of using spent grain. For example, establishing partnerships with local breweries can secure a consistent and low-cost supply. Growers can also experiment with different mushroom varieties, such as oyster or shiitake, which thrive on spent grain-based substrates, to diversify their product offerings. By integrating these strategies, mushroom farmers can transform a brewery’s waste into a profitable resource, turning cost-effectiveness into a cornerstone of their business model.

Can Guinea Pigs Eat Mushrooms? A Safe Diet Guide

You may want to see also

Environmental Impact: Sustainability and waste reduction through spent grain repurposing

Spent grain, a byproduct of brewing and distilling processes, often ends up as waste, contributing to environmental strain through disposal costs and methane emissions from landfills. However, repurposing this organic material as a mushroom growing medium offers a sustainable solution. Mushrooms thrive on nutrient-rich substrates, and spent grain provides an ideal base due to its high cellulose and protein content. By diverting spent grain from waste streams, breweries and distilleries can significantly reduce their carbon footprint while creating a circular economy model.

To implement this practice, start by collecting spent grain immediately after the brewing process to maintain its moisture content, typically around 70-80%. This moisture level is crucial for mushroom cultivation, as it reduces the need for additional hydration. Next, pasteurize the spent grain at 65-70°C (149-158°F) for 1-2 hours to eliminate competing microorganisms. Once cooled, mix the grain with mushroom spawn at a ratio of 5:1 (grain to spawn) and place it in a sterilized growing container. Maintain a controlled environment with temperatures between 20-25°C (68-77°F) and humidity above 85% for optimal mycelium growth.

Comparatively, traditional mushroom substrates like straw or sawdust require additional amendments and processing, making spent grain a more resource-efficient alternative. Its repurposing not only reduces waste but also lowers the demand for virgin materials, aligning with principles of regenerative agriculture. For instance, a medium-sized brewery producing 10,000 liters of beer weekly generates approximately 2,000 kg of spent grain. If repurposed, this could yield up to 400 kg of mushrooms, providing both environmental and economic benefits.

Persuasively, the environmental impact of this approach extends beyond waste reduction. By integrating spent grain into mushroom cultivation, businesses can enhance their sustainability credentials and appeal to eco-conscious consumers. Additionally, the process generates a secondary product—mushroom compost—which can be used to enrich soil, further closing the loop in agricultural systems. This dual-purpose repurposing exemplifies how innovative solutions can transform waste into value, fostering a more resilient and sustainable food system.

Descriptively, imagine a brewery partnering with local mushroom farmers to create a symbiotic relationship. The brewery supplies spent grain, reducing its disposal costs, while the farmer produces mushrooms for local markets, minimizing transportation emissions. This collaborative model not only reduces environmental impact but also strengthens community ties and supports local economies. By adopting such practices, industries can move toward a zero-waste future, proving that sustainability and profitability can coexist harmoniously.

Probiotics and Mushroom Cultivation: Unlocking Growth Potential with Beneficial Bacteria

You may want to see also

Frequently asked questions

Yes, spent grain, a byproduct of brewing, can be used as a growing medium for mushrooms. It is rich in nutrients and provides a suitable substrate for many mushroom species.

Oyster mushrooms, shiitake, and lion's mane mushrooms are among the species that grow well on spent grain due to its nutrient content and structure.

Yes, spent grain typically needs to be pasteurized or sterilized to eliminate competing microorganisms and ensure a clean environment for mushroom growth.

Spent grain can be used alone, but it is often mixed with supplements like gypsum, vermiculite, or straw to improve aeration, moisture retention, and nutrient balance.

Yes, using spent grain for mushroom cultivation reduces waste from the brewing industry, provides a sustainable growing medium, and supports a circular economy by repurposing byproducts.