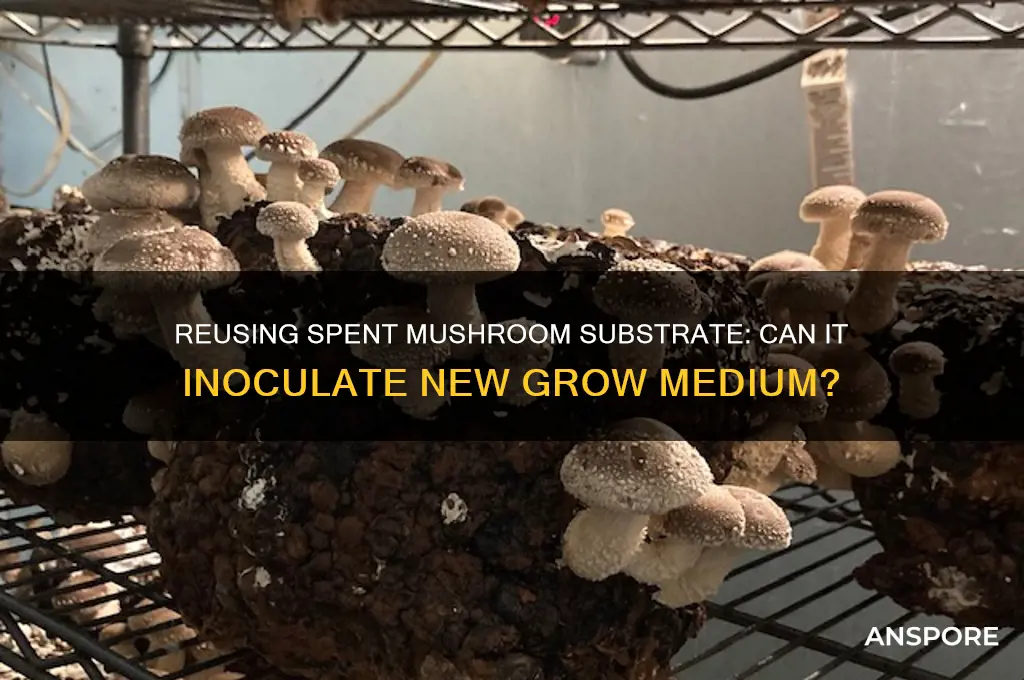

Spent mushroom substrate, the leftover material after mushroom cultivation, is often discarded, but its potential for reuse has sparked interest among growers and researchers. The question of whether spent substrate can be used to inoculate new substrate is particularly intriguing, as it could offer a sustainable and cost-effective method for mushroom production. By leveraging the residual mycelium and nutrients present in the spent material, growers might reduce waste and minimize the need for fresh resources. However, the feasibility of this approach depends on factors such as the viability of the remaining mycelium, potential contamination risks, and the nutritional composition of the spent substrate. Exploring this possibility could pave the way for more circular practices in mushroom farming, aligning with broader goals of sustainability and resource efficiency.

| Characteristics | Values |

|---|---|

| Reusability | Spent mushroom substrate (SMS) can be reused to inoculate new substrate. |

| Cost-Effectiveness | Reduces costs by minimizing the need for new spawn and substrate. |

| Mycelium Presence | SMS often contains residual mycelium, which can colonize new substrate. |

| Contamination Risk | Higher risk of contamination due to exposure to bacteria and molds. |

| Nutrient Depletion | SMS is partially depleted of nutrients, requiring supplementation. |

| Colonization Time | Longer colonization time compared to fresh substrate. |

| Yield | Lower yield potential due to reduced nutrient availability. |

| Species Compatibility | Works best with resilient mushroom species (e.g., oyster mushrooms). |

| Pre-Treatment Required | SMS often requires pasteurization or sterilization before reuse. |

| Environmental Impact | Reduces waste and promotes sustainable mushroom cultivation practices. |

| Consistency | Results may vary due to inconsistent mycelium viability in SMS. |

| Labor Intensity | Requires additional steps for preparation and monitoring. |

| Scalability | Suitable for small-scale growers but may be challenging for large-scale operations. |

Explore related products

What You'll Learn

- Sterilization Methods: Techniques to ensure spent substrate is free from contaminants before inoculation

- Nutrient Retention: Assessing if spent substrate retains enough nutrients for new mycelium growth

- Contamination Risks: Identifying potential risks of using spent substrate for inoculation

- Cost-Effectiveness: Analyzing if reusing spent substrate reduces cultivation costs significantly

- Success Rates: Comparing growth outcomes of new substrate inoculated with spent versus fresh material

Sterilization Methods: Techniques to ensure spent substrate is free from contaminants before inoculation

Spent mushroom substrate, rich in residual nutrients, can be a valuable resource for inoculating new substrate, but only if properly sterilized. Contaminants like bacteria, molds, or competing fungi can compromise the next batch, making sterilization non-negotiable. Here’s how to ensure spent substrate is contaminant-free before reuse.

Steam Sterilization: The Gold Standard

Steam sterilization, or autoclaving, is the most reliable method for eliminating contaminants. Heat the spent substrate to 121°C (250°F) under 15 psi pressure for 60–90 minutes. This process penetrates dense organic material, killing spores and microorganisms. For home growers, a pressure cooker can serve as a makeshift autoclave, though maintaining consistent temperature and pressure is critical. Always allow the substrate to cool completely before inoculation to avoid damaging mycelium.

Chemical Sterilization: A Practical Alternative

When autoclaving isn’t feasible, chemical sterilization offers a viable option. Hydrogen peroxide (3–6% solution) or lime (calcium hydroxide) can be mixed into the spent substrate to raise pH levels, creating an inhospitable environment for contaminants. For example, adding 2–3 tablespoons of agricultural lime per 5 liters of substrate can effectively suppress bacterial growth. However, chemical methods may leave residues, so thorough rinsing or dilution is essential before inoculation.

Solarization: Harnessing Natural Heat

For low-tech operations, solarization leverages sunlight to sterilize substrate. Spread the spent material in a clear plastic bag, seal it tightly, and expose it to direct sunlight for 4–6 weeks. Temperatures inside the bag can exceed 50°C (122°F), sufficient to kill many pathogens. This method is cost-effective but time-consuming and less reliable in cooler climates. Regularly monitor for condensation, which can foster mold growth, and ensure the substrate is completely dry before use.

Pasteurization: A Milder Approach

Pasteurization reduces contaminants without the intensity of sterilization, making it suitable for spent substrate with lower contamination risk. Heat the material to 60–70°C (140–158°F) for 1–2 hours, either in a water bath or oven. While this method doesn’t eliminate all spores, it significantly reduces their numbers, allowing mycelium to outcompete remaining contaminants. Pasteurization is best paired with vigorous mycelium cultures for optimal results.

Cautions and Best Practices

Regardless of the method, always inspect spent substrate for visible mold or off-odors before sterilization. Avoid reusing substrate from failed batches, as it may harbor persistent contaminants. After sterilization, work in a clean environment and use sterile tools to prevent recontamination. While sterilization methods vary in efficacy, consistency and attention to detail are key to successfully reusing spent substrate.

Overcooking Shiitake Mushrooms: Risks, Texture Changes, and Flavor Impact

You may want to see also

Nutrient Retention: Assessing if spent substrate retains enough nutrients for new mycelium growth

Spent mushroom substrate, often discarded after harvest, may still harbor residual nutrients that could support new mycelium growth. However, the viability of this approach hinges on the extent to which essential elements like nitrogen, phosphorus, and carbon remain available. Studies suggest that up to 30-50% of initial nutrients can persist in spent substrate, depending on the mushroom species and cultivation conditions. For instance, oyster mushrooms (*Pleurotus ostreatus*) are known to deplete substrate more efficiently than shiitake (*Lentinula edodes*), leaving behind varying nutrient profiles. This residual nutrient content raises the question: can spent substrate be repurposed effectively, or does it fall short of supporting robust mycelial colonization?

To assess nutrient retention, a systematic analysis of spent substrate is essential. Begin by collecting samples from different depths of the substrate, as nutrient distribution can vary. Conduct laboratory tests to measure nitrogen (N), phosphorus (P), and potassium (K) levels, using methods like the Kjeldahl procedure for N and colorimetric assays for P. Compare these values to the nutrient requirements for mycelium growth, typically 1-2% N, 0.5-1% P, and 0.5-1% K on a dry weight basis. If the spent substrate meets or exceeds 50% of these thresholds, it may be suitable for inoculation after supplementation with organic matter like wheat bran or cottonseed meal. For example, adding 10-20% (by weight) of a high-nitrogen amendment can bridge the nutrient gap, ensuring adequate resources for mycelium development.

A comparative study between fresh and spent substrate highlights the trade-offs of reusing materials. While fresh substrate guarantees optimal nutrient availability, spent substrate offers cost savings and reduces waste. However, spent substrate often lacks sufficient simple sugars and starches, which mycelium relies on for rapid colonization. To mitigate this, pre-treating spent substrate with a 5-10% molasses solution can replenish carbohydrates, enhancing its viability. Additionally, pasteurizing the spent substrate at 60-70°C for 6-8 hours can eliminate competing microorganisms, giving mycelium a competitive advantage during inoculation.

Practical implementation requires careful consideration of substrate age and storage conditions. Spent substrate older than 4 weeks may experience nutrient leaching or microbial degradation, reducing its effectiveness. Store spent substrate in a cool, dry place (15-20°C) and use within 2 weeks of harvesting for best results. When inoculating, use a higher spawn-to-substrate ratio (e.g., 5-10% instead of the typical 2-5%) to compensate for lower nutrient availability. Monitor colonization closely, as slower growth rates are expected compared to fresh substrate. With proper supplementation and management, spent substrate can serve as a sustainable medium for mycelium cultivation, balancing resource conservation with productivity.

Can Dogs Eat Cooked Mushrooms? Safety Tips for Pet Owners

You may want to see also

Contamination Risks: Identifying potential risks of using spent substrate for inoculation

Spent mushroom substrate, though rich in nutrients, harbors a complex microbial ecosystem that can compromise new inoculations. While reusing substrate may seem cost-effective, the residual bacteria, fungi, and spores from previous grows pose significant contamination risks. These microorganisms, including competing molds and bacteria, can outpace mycelium growth, leading to failed batches. Understanding these risks is crucial for anyone considering this practice.

One of the primary contamination risks lies in the survival of competing fungi. Spent substrate often contains remnants of the mushroom species previously cultivated, along with other fungi that may have colonized during the grow cycle. When used to inoculate new substrate, these fungi can dominate the environment, stifling the growth of the desired mushroom species. For instance, *Trichoderma* spp., a common contaminant, thrives in nutrient-rich environments and can rapidly overtake mycelium, rendering the substrate unusable.

Bacterial contamination is another critical concern. Spent substrate frequently contains bacteria such as *Escherichia coli* or *Pseudomonas* spp., which can proliferate in the warm, moist conditions ideal for mushroom cultivation. These bacteria not only compete for nutrients but can also produce toxins that inhibit mycelium growth. To mitigate this risk, pasteurization or sterilization of the spent substrate is essential, though these processes can degrade its structural integrity, reducing its effectiveness as a growing medium.

Physical contaminants, such as insect eggs or larvae, also pose a threat. Pests like fungus gnats or mites may have infested the spent substrate during the previous grow, and their eggs can survive dormant until conditions are favorable. Introducing these pests into new substrate can lead to widespread infestation, damaging both the mycelium and the fruiting bodies. Careful inspection and treatment of spent substrate, such as freezing for 48 hours, can help eliminate these risks, but such steps add complexity and time to the process.

Finally, the nutrient profile of spent substrate can inadvertently encourage contamination. While it provides essential organic matter, its depleted state may create an imbalance that favors opportunistic microorganisms over mycelium. Supplementing with fresh nutrients can help, but this approach requires precise calibration to avoid overfeeding contaminants. For those determined to reuse substrate, a cautious, stepwise approach—including testing small batches and monitoring for signs of contamination—is recommended to minimize risks.

Can Sniffer Dogs Detect Mushrooms in Australia? Exploring Their Abilities

You may want to see also

Explore related products

Cost-Effectiveness: Analyzing if reusing spent substrate reduces cultivation costs significantly

Reusing spent mushroom substrate to inoculate new batches is a practice gaining traction among cultivators, but its cost-effectiveness remains a critical question. At first glance, the potential savings seem obvious: reducing the need for fresh substrate and inoculants could significantly lower material costs. However, the devil is in the details. Spent substrate often retains residual mycelium, which could act as a natural inoculant, but its viability and contamination risks must be weighed against the upfront savings. To determine if this method truly reduces cultivation costs, a deeper analysis of both direct and indirect expenses is necessary.

From an analytical perspective, the cost-effectiveness of reusing spent substrate hinges on three key factors: mycelial viability, contamination risk, and labor intensity. Studies suggest that up to 30% of spent substrate can retain viable mycelium, depending on the mushroom species and cultivation conditions. For example, oyster mushrooms (*Pleurotus ostreatus*) are known to leave behind robust mycelial networks, making their spent substrate a promising candidate for reuse. However, contamination from competing molds or bacteria can render the substrate unusable, negating any potential savings. Additionally, the process of sterilizing or pasteurizing spent substrate adds labor and energy costs, which must be factored into the equation.

Instructively, cultivators interested in reusing spent substrate should follow a structured approach to maximize cost-effectiveness. First, assess the condition of the spent substrate by inspecting it for signs of contamination or excessive breakdown. If it appears healthy, pasteurize it at 60–70°C (140–158°F) for 1–2 hours to kill contaminants while preserving mycelial viability. Mix the pasteurized spent substrate with fresh substrate at a ratio of 1:3 to 1:5, ensuring sufficient nutrients for new growth. Monitor the inoculated substrate closely for signs of contamination during the initial colonization phase. This method, when executed correctly, can reduce substrate costs by 20–30%, depending on the scale of operation.

Persuasively, the environmental benefits of reusing spent substrate further strengthen its case as a cost-effective strategy. By reducing waste and minimizing the need for fresh materials, cultivators can lower their carbon footprint while cutting costs. For small-scale growers, this dual advantage can be particularly appealing, as it aligns with sustainable practices without requiring significant investment. However, large-scale operations must consider the logistical challenges of handling and processing spent substrate, which could offset some of the financial benefits.

Comparatively, reusing spent substrate stacks up well against traditional methods when both cost and sustainability are prioritized. While purchasing fresh substrate and inoculants guarantees consistency, it comes with higher material and disposal costs. In contrast, reusing spent substrate introduces variability but offers long-term savings and environmental benefits. For instance, a case study of a commercial oyster mushroom farm found that incorporating 25% spent substrate into new batches reduced substrate costs by 15% annually, with minimal impact on yield. This balance of cost reduction and sustainability makes it a compelling option for forward-thinking cultivators.

In conclusion, reusing spent mushroom substrate to inoculate new batches can significantly reduce cultivation costs, but success depends on careful execution and risk management. By assessing mycelial viability, managing contamination, and optimizing the mixing ratio, cultivators can achieve substantial savings while minimizing waste. While not a one-size-fits-all solution, this approach offers a practical and sustainable alternative for those willing to invest time and effort into refining the process.

Mushrooms and Keppra: Potential Interactions and Safety Concerns Explored

You may want to see also

Success Rates: Comparing growth outcomes of new substrate inoculated with spent versus fresh material

Spent mushroom substrate, often discarded after harvest, retains residual mycelium and nutrients, making it a potential inoculant for new substrate. However, success rates vary significantly when comparing growth outcomes between spent and fresh inoculum. Fresh inoculum, typically grain or agar-based, offers a high concentration of active mycelium, ensuring rapid colonization and robust fruiting. In contrast, spent substrate contains lower mycelial density and may harbor contaminants, which can hinder growth. To maximize success with spent substrate, pasteurization or sterilization is essential to eliminate competing organisms while preserving viable mycelium.

A comparative study reveals that fresh inoculum consistently achieves colonization rates above 90% within 7–10 days, whereas spent substrate inoculation often results in 60–70% colonization over 14–21 days. For instance, using 10–20% spent substrate by volume mixed with fresh, sterilized substrate can improve outcomes, but exceeding this ratio increases contamination risk. Practical tips include blending spent substrate thoroughly to distribute mycelium evenly and maintaining optimal humidity (60–70%) and temperature (22–25°C) during incubation. This approach balances resource efficiency with growth reliability.

From an analytical perspective, the lower success rate of spent substrate inoculation stems from its reduced mycelial vigor and nutrient depletion. Fresh inoculum, rich in active mycelium and nutrients, outpaces spent substrate in both speed and yield. However, spent substrate offers economic and environmental advantages, reducing waste and material costs. For hobbyists or small-scale growers, a hybrid approach—using 15% spent substrate mixed with 85% fresh, sterilized substrate—can yield acceptable results with minimal investment. Commercial growers, prioritizing consistency, may find this method too variable for large-scale application.

Persuasively, spent substrate inoculation is not a replacement for fresh inoculum but a supplementary strategy. Its success hinges on meticulous preparation and controlled conditions. For example, pasteurizing spent substrate at 65°C for 1 hour can eliminate most contaminants while preserving mycelium. Pairing this with a small inoculation rate (e.g., 10% spent substrate) minimizes risks while leveraging residual resources. While yields may be 20–30% lower than fresh inoculum, the method aligns with sustainable practices, making it a viable option for environmentally conscious growers.

In conclusion, the success of spent substrate inoculation depends on balancing resource efficiency with growth reliability. Fresh inoculum remains superior in speed, yield, and consistency, but spent substrate offers a cost-effective, eco-friendly alternative with careful management. By optimizing ratios, pasteurizing, and maintaining ideal conditions, growers can achieve satisfactory results while reducing waste. This approach underscores the importance of experimentation and adaptation in mushroom cultivation, turning a byproduct into a valuable resource.

Can Mushrooms Grow on Mushrooms? Exploring Fungal Growth Dynamics

You may want to see also

Frequently asked questions

Yes, spent mushroom substrate can be used to inoculate new substrate, as it often still contains viable mycelium that can colonize fresh material.

Spent substrate is generally less effective than spawn because the mycelium may be weaker or less concentrated, but it can still work for low-cost inoculation.

Spent substrate should be crumbled and mixed thoroughly into the new substrate to ensure even distribution of mycelium, and it should be pasteurized to reduce contamination risks.

Yes, spent substrate may carry contaminants or competing organisms, so proper sterilization or pasteurization of the new substrate is crucial to minimize risks.