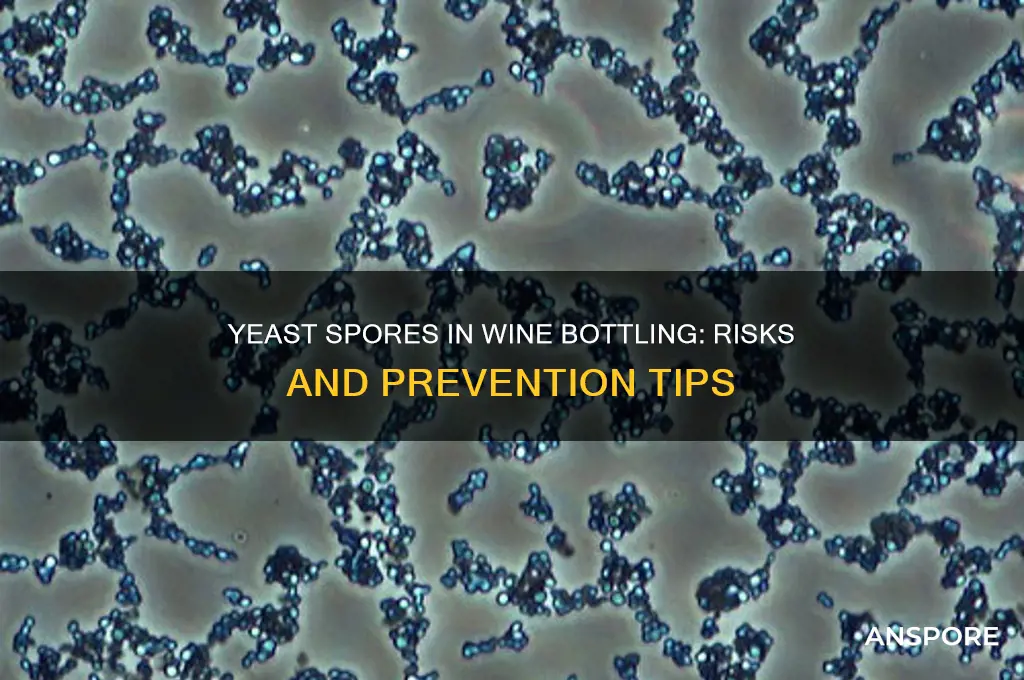

Yeast spores, which are dormant forms of yeast, can indeed pose challenges during the bottling of wine. While yeast plays a crucial role in the fermentation process, converting sugars into alcohol, residual yeast spores or active yeast cells remaining in the wine can lead to unintended secondary fermentation in the bottle. This can result in carbon dioxide production, causing bottles to explode or wine to become excessively fizzy, spoiling the intended still wine. Additionally, yeast autolysis, the breakdown of dead yeast cells, can introduce off-flavors or cloudy appearances, compromising the wine’s quality. Proper clarification, filtration, and stabilization techniques are essential to minimize yeast-related issues during bottling, ensuring the final product remains consistent and enjoyable.

| Characteristics | Values |

|---|---|

| Yeast Spores Presence | Yeast spores can survive in harsh conditions and may remain dormant in wine bottles. |

| Impact on Wine Quality | Can cause refermentation in bottled wine, leading to carbonation, off-flavors, and potential bottle explosions. |

| Refermentation Risk | High if residual sugars are present and spores become active post-bottling. |

| Off-Flavors | Production of undesirable flavors (e.g., sulfur compounds, acetic acid) due to yeast activity. |

| Bottle Integrity | Increased pressure from refermentation can cause bottles to leak, corks to push out, or glass to shatter. |

| Prevention Methods | Proper sterilization, filtration to remove spores, and ensuring complete fermentation before bottling. |

| Detection | Difficult to detect spores pre-bottling; requires rigorous quality control measures. |

| Common Yeast Species | Saccharomyces cerevisiae and wild yeast strains are common culprits. |

| Temperature Influence | Spores may activate in warm storage conditions, accelerating refermentation. |

| Economic Impact | Significant losses due to spoiled batches, recalls, and damaged reputation. |

Explore related products

What You'll Learn

Yeast spore viability in wine bottles

Yeast spores, the dormant survival structures of certain yeast species, can indeed pose challenges during wine bottling. These resilient microorganisms can withstand harsh conditions, including the high alcohol and low pH environment of wine. When present in bottled wine, yeast spores may germinate under favorable conditions, leading to secondary fermentation. This process can result in unwanted carbonation, increased pressure, and potential bottle explosions, compromising wine quality and safety.

To mitigate the risk of yeast spore-related issues, winemakers employ various strategies. One common approach is to ensure complete fermentation before bottling, minimizing the presence of residual sugars that could fuel spore germination. Additionally, filtration techniques, such as sterile filtration (0.45-0.65 μm), can effectively remove yeast spores from the wine. However, this method may also strip the wine of desirable sensory compounds, requiring careful consideration of the filtration process. Chemical treatments, like the addition of sulfur dioxide (SO2) at recommended levels (50-100 mg/L for red wines, 100-150 mg/L for white wines), can also inhibit yeast spore germination.

A comparative analysis of yeast spore viability in different wine styles reveals interesting trends. For instance, sweet wines with higher residual sugar content are more susceptible to yeast spore-related issues, as the sugars provide a readily available energy source for spore germination. In contrast, dry wines with lower pH and higher alcohol content create a less hospitable environment for yeast spores. Furthermore, the age of the wine plays a crucial role, as older wines may have a higher likelihood of containing viable yeast spores due to potential contamination during aging or bottling.

From a practical standpoint, winemakers can implement several measures to minimize yeast spore viability in wine bottles. Firstly, maintaining strict hygiene practices throughout the winemaking process is essential, including regular cleaning and sanitization of equipment. Secondly, monitoring the wine's chemical parameters, such as pH, alcohol content, and SO2 levels, can help identify potential risks. Lastly, conducting routine microbiological analyses, including yeast spore counts, can provide valuable insights into the wine's microbial stability. By adopting these strategies, winemakers can significantly reduce the likelihood of yeast spore-related issues, ensuring the production of high-quality, stable wines.

In the context of wine bottling, understanding yeast spore viability is crucial for producing consistent, high-quality products. By considering the unique characteristics of different wine styles, implementing effective control measures, and monitoring key parameters, winemakers can minimize the risk of yeast spore-related issues. As the wine industry continues to evolve, ongoing research and innovation in this area will be essential to developing new strategies for managing yeast spore viability, ultimately contributing to the production of exceptional wines that meet the highest standards of quality and safety.

Can Flood Spores Wait? Understanding Their Survival and Dormancy Mechanisms

You may want to see also

Impact of spores on wine flavor

Yeast spores, particularly those from wild or spoilage strains, can significantly alter wine flavor during bottling. Unlike active yeast cells, spores are dormant and resilient, surviving harsh conditions like high alcohol content and low pH. However, under favorable conditions, they can germinate, leading to secondary fermentation or spoilage. This process introduces off-flavors such as acetic acid (vinegar-like), ethyl acetate (nail polish remover), or sulfur compounds (rotten egg), overshadowing the wine’s intended profile. Even in small quantities, these compounds can render a wine undrinkable, making spore control critical in bottling.

To mitigate spore-induced flavor issues, winemakers must adopt rigorous sanitation practices. Spores can survive on equipment, bottles, and corks, so all materials should be sterilized with sulfur dioxide or peracetic acid solutions. Additionally, filtering wine through 0.45-micron membranes can physically remove spores, though this may strip some desirable compounds. For natural winemakers avoiding filtration, maintaining a free SO₂ level of 20–30 mg/L post-fermentation is essential to inhibit spore germination. Regular testing for spore presence using malt agar plates can also help identify risks early, allowing for corrective action before bottling.

Comparing wines affected by spores to pristine samples reveals stark differences in sensory experience. A wine contaminated with *Brettanomyces* spores, for instance, may develop "barnyard" or "band-aid" aromas, while *Zygosaccharomyces* spores can cause refermentation, leading to overcarbonation and off-flavors. In contrast, wines bottled under sterile conditions retain their varietal character, acidity, and intended aging potential. This highlights the importance of spore management not just for quality but also for preserving the winemaker’s artistic intent.

For home winemakers, preventing spore contamination starts with sourcing clean fruit and using cultured yeast strains. If wild fermentation is desired, monitor the process closely and stabilize the wine with SO₂ before bottling. Aging wines in spore-prone environments (e.g., humid cellars) requires vigilant humidity control and regular inspection for mold. Finally, if off-flavors appear post-bottling, consider blending affected batches with clean wine or using fining agents like activated carbon to mitigate, though this is a last resort and not always effective. Proactive measures are always superior to reactive fixes.

Can Mold Spores Trigger Skin Hives? Understanding the Allergic Reaction

You may want to see also

Preventing spore contamination during bottling

Yeast spores, particularly those of Brettanomyces, can survive in harsh conditions and contaminate wine during bottling, leading to off-flavors like barnyard or bandaid aromas. To prevent this, wineries must adopt rigorous sanitation protocols. Start by ensuring all bottling equipment—fillers, corkers, and conveyors—is thoroughly cleaned with a food-grade sanitizer. Use a solution of 200 ppm chlorine or 70% isopropyl alcohol, allowing contact for at least 10 minutes to kill spores. Rinse equipment with sterile water afterward to avoid chemical residue in the wine.

Temperature control is another critical factor in spore prevention. Yeast spores thrive in warm environments, so maintain bottling areas below 68°F (20°C). Chill the wine to 50–55°F (10–13°C) before bottling to inhibit spore activation. Additionally, filter the wine through a 0.45-micron membrane to physically remove spores, though this step may not eliminate all contaminants. Combine filtration with sterile bottling practices for maximum effectiveness.

Instruct bottling staff to wear sterile clothing, including hairnets, gloves, and lab coats, to minimize human contamination. Limit access to the bottling area to essential personnel only. Implement a "no-return" policy for partially filled bottles, as these can harbor spores and reintroduce them into the production line. Regularly audit sanitation procedures and train staff to recognize signs of contamination, such as sediment or haze in the wine.

For added protection, consider using inert gases like nitrogen or argon to flush bottles before filling. This displaces oxygen, creating an environment hostile to spore germination. Apply 1–2 psi of gas for 2–3 seconds per bottle, ensuring complete coverage. While this step adds time and cost, it significantly reduces the risk of post-bottling spoilage. Pair this technique with rigorous sanitation for a comprehensive contamination prevention strategy.

Can Botulism Spores Survive Fermentation? Uncovering the Risks and Facts

You may want to see also

Explore related products

Spoilage risks from yeast spores

Yeast spores, particularly those of wild or unwanted strains, pose a significant risk to the bottling process of wine. These dormant cells can survive harsh conditions, including high alcohol levels and low pH, only to activate later when conditions become favorable. Once awakened, they can initiate secondary fermentation in the bottle, leading to unwanted carbonation, off-flavors, and even bottle explosions. This spoilage not only compromises the wine’s quality but also poses safety risks due to increased pressure in sealed containers.

To mitigate these risks, winemakers must adopt rigorous sanitation practices. All equipment, from fermenters to bottling lines, should be cleaned with sulfites or other sanitizers to eliminate spore presence. Additionally, filtering wine through 0.45-micron filters can physically remove spores, though this method may strip some desirable compounds. Winemakers should also monitor sulfur dioxide levels, maintaining at least 30–50 ppm of free SO₂ to inhibit spore germination without affecting flavor.

A comparative analysis reveals that certain yeast strains, such as *Brettanomyces*, are particularly resilient and can produce volatile phenols, giving wine a "barnyard" aroma. Unlike *Saccharomyces* strains used in fermentation, these spoilage yeasts thrive in high-alcohol environments, making them a persistent threat. In contrast, *Zygosaccharomyces* species can tolerate extremely high sugar concentrations, often found in sweet wines, and produce off-flavors like acetic acid. Understanding these differences helps winemakers tailor their prevention strategies.

Practical tips include storing wine bottles in cool, dark environments to discourage spore activation. For home winemakers, using sterile bottling equipment and avoiding cross-contamination during transfers is crucial. Commercial producers may benefit from implementing a Hazard Analysis and Critical Control Points (HACCP) system to identify and control spore risks at every stage of production. Regular testing for yeast viability post-bottling can also provide early detection of potential spoilage.

In conclusion, while yeast spores are microscopic, their impact on bottled wine can be catastrophic. By combining preventive measures, such as sanitation, filtration, and chemical control, with vigilant monitoring, winemakers can safeguard their products against spoilage. The key lies in understanding the specific threats posed by different yeast strains and adapting strategies to neutralize them effectively.

Are All Gram-Positive Bacteria Non-Spore Forming? Unraveling the Myth

You may want to see also

Detecting yeast spores in bottled wine

Yeast spores in bottled wine can lead to secondary fermentation, causing carbonation, off-flavors, or even bottle explosions. Detecting these spores before they become active is crucial for winemakers to ensure product quality and safety. While yeast spores are naturally present in vineyards and wineries, their presence in bottled wine indicates a breach in sterilization or filtration processes. Early detection methods can prevent costly recalls and maintain brand reputation.

Analytical Approach: Understanding Detection Methods

Instructive Guide: Practical Steps for Winemakers

To detect yeast spores, start by collecting representative samples from bottles across different batches. Filter 100 mL of wine through a 0.45 µm membrane to capture spores, then analyze the filtrate using PCR or plating on yeast-selective media like YPD agar. For PCR, use species-specific primers targeting *Saccharomyces cerevisiae* or wild yeast like *Brettanomyces*. Incubate agar plates at 28°C for 48–72 hours to observe colony growth. If spores are detected, assess filtration systems, cleaning protocols, and bottling equipment for contamination sources. Regular monitoring during production can preempt issues, ensuring spores never reach the bottling stage.

Comparative Analysis: Traditional vs. Modern Techniques

Traditional methods like microscopic examination and plating rely on visual identification and culturing, which are labor-intensive and prone to human error. Modern techniques, such as PCR and flow cytometry, offer faster, more accurate results but require specialized equipment and expertise. For small wineries, investing in PCR kits or outsourcing to labs may be cost-effective compared to the long-term risks of undetected spores. Larger operations might integrate real-time monitoring systems, such as ATP bioluminescence tests, to detect microbial contamination instantly. The choice depends on budget, scale, and the desired level of precision.

Descriptive Insight: The Impact of Undetected Spores

Imagine opening a bottle of wine only to find it foaming uncontrollably or emitting a vinegar-like aroma. This is the reality when yeast spores activate post-bottling. In still wines, spores can ferment residual sugars, producing CO₂ that pressurizes bottles until they burst. In aged wines, *Brettanomyces* spores can metabolize alcohol into acetic acid, ruining years of work. Even dormant spores pose a risk, as they can revive under favorable conditions, such as temperature fluctuations during storage. Detecting spores early not only saves product but also protects consumers from potential hazards like glass shards from exploding bottles.

Persuasive Argument: Investing in Detection Pays Off

While implementing spore detection methods may seem costly upfront, the alternative is far more expensive. A single contaminated batch can lead to recalls, lawsuits, and irreparable damage to a winery’s reputation. For instance, a 2018 case saw a renowned winery lose $2 million due to undetected *Brettanomyces* spores. By contrast, investing in PCR kits or flow cytometry systems costs a fraction of that, offering long-term savings and peace of mind. Proactive detection is not just a quality control measure—it’s a strategic investment in sustainability and consumer trust.

Are Psilocybin Spores Legal to Sell? Understanding the Laws

You may want to see also

Frequently asked questions

Yes, yeast spores can affect bottling if they are active and continue fermenting in the bottle, potentially causing carbonation, off-flavors, or bottle explosions.

Yeast spores can survive in wine if it is not properly stabilized or filtered, or if contamination occurs during the bottling process from equipment or the environment.

Yes, active yeast spores can lead to secondary fermentation in the bottle, producing unwanted carbonation, off-flavors, or spoilage, ruining the wine’s quality.

To prevent issues, ensure the wine is fully stabilized through filtration, pasteurization, or sulfite addition before bottling, and maintain strict sanitation of bottling equipment.