Growing oyster mushrooms from oats is a fascinating and accessible method for both novice and experienced cultivators. Oats, being rich in nutrients, provide an excellent substrate for mycelium growth, the vegetative part of the fungus that eventually produces mushrooms. This technique involves sterilizing the oats to eliminate competing microorganisms, inoculating them with oyster mushroom spawn, and maintaining optimal conditions of humidity, temperature, and light. With proper care, the mycelium colonizes the oats, leading to the development of fruiting bodies—the edible oyster mushrooms. This approach not only offers a sustainable way to grow mushrooms at home but also repurposes a common household item, making it an eco-friendly and cost-effective option for mushroom cultivation.

| Characteristics | Values |

|---|---|

| Substrate Suitability | Oats are a suitable substrate for growing oyster mushrooms, as they provide the necessary nutrients and structure. |

| Preparation Method | Oats should be cooked or soaked to break down complex carbohydrates, making them more accessible to the mushroom mycelium. |

| Sterilization Requirement | Sterilization of the oat substrate is recommended to prevent contamination from competing molds or bacteria. |

| Supplementation | Adding supplements like gypsum (calcium sulfate) can improve mushroom yield and quality. |

| pH Level | Oyster mushrooms prefer a slightly acidic to neutral pH range (5.5–7.0), which oats naturally support. |

| Hydration | Oats require proper hydration (around 60-70% moisture content) for optimal mushroom growth. |

| Colonization Time | Mycelium typically colonizes oat substrates within 2-4 weeks, depending on conditions. |

| Fruiting Conditions | After colonization, fruiting requires specific humidity (85-95%), temperature (55-75°F), and light exposure. |

| Yield Potential | Oats can produce moderate to high yields of oyster mushrooms, depending on preparation and environmental control. |

| Cost-Effectiveness | Oats are a relatively inexpensive and readily available substrate, making them a cost-effective option for mushroom cultivation. |

| Sustainability | Using oats as a substrate is sustainable, especially when sourced from organic or waste streams. |

| Common Challenges | Potential issues include contamination, improper hydration, and inadequate sterilization. |

Explore related products

What You'll Learn

- Oat Substrate Preparation: Sterilize oats, moisten, and mix with mushroom spawn for optimal mycelium growth

- Spawn Selection: Choose high-quality oyster mushroom spawn compatible with oat-based substrates

- Growing Conditions: Maintain humidity, temperature (65-75°F), and indirect light for successful fruiting

- Contamination Prevention: Sterilize equipment and use clean techniques to avoid mold or bacteria

- Harvesting Tips: Pick mushrooms when gills are exposed but before spores drop for best yield

Oat Substrate Preparation: Sterilize oats, moisten, and mix with mushroom spawn for optimal mycelium growth

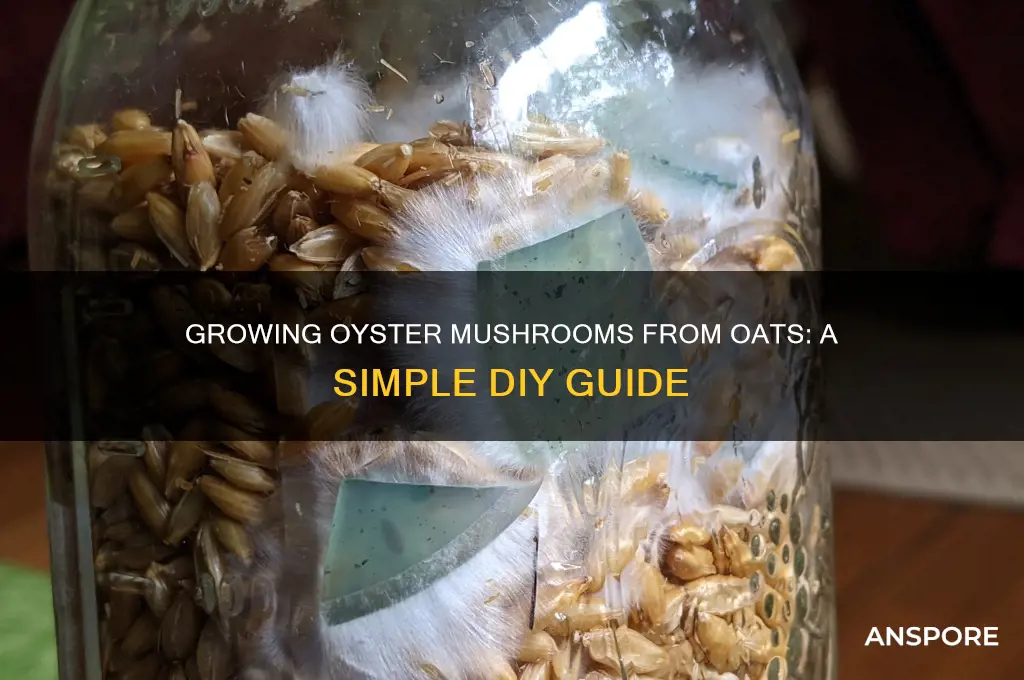

Oats, a humble grain, can be transformed into a thriving habitat for oyster mushrooms with the right preparation. The key to success lies in creating an environment where mycelium, the vegetative part of the fungus, can flourish. This begins with oat substrate preparation, a process that involves sterilizing, moistening, and mixing oats with mushroom spawn. Each step is critical, ensuring the substrate is free from contaminants and provides the necessary nutrients for robust mycelium growth.

Sterilization is the first and most crucial step. Contaminants like bacteria and mold can outcompete the mushroom mycelium, leading to a failed crop. To sterilize oats, start by measuring out 5–10 pounds of oats, depending on the size of your growing container. Place the oats in a large pot and cover them with water, using a ratio of 1 part oats to 2 parts water. Boil the mixture for 30–45 minutes, ensuring the oats are thoroughly cooked and any potential contaminants are eliminated. After boiling, drain the oats and allow them to cool to room temperature. This process not only sterilizes the oats but also begins to break down their structure, making nutrients more accessible to the mycelium.

Once sterilized, the oats must be moistened to the correct consistency. Mycelium requires a damp environment to grow, but too much moisture can lead to anaerobic conditions, stifling growth and encouraging mold. Aim for a moisture content of 60–70%, which feels like a wrung-out sponge. To achieve this, gradually add clean, filtered water to the cooled oats, mixing thoroughly until the desired consistency is reached. A simple test is to squeeze a handful of the mixture—it should hold together briefly before crumbling apart, with no excess water dripping out.

With the oats sterilized and moistened, the next step is to mix in the mushroom spawn. Oyster mushroom spawn, typically sold as grain spawn, is the inoculated material that introduces the mycelium to the substrate. Use a spawn-to-substrate ratio of 1:10 to 1:5, depending on the vigor of the spawn and your growing conditions. Gently combine the spawn and oats in a clean, sterile environment, ensuring even distribution. Overmixing can damage the mycelium, so use light, folding motions to incorporate the spawn.

The final mixture should be transferred to a growing container, such as a plastic bag or tray with small holes for ventilation. Seal the container, leaving enough air space for the mycelium to breathe, and incubate in a dark, warm area (65–75°F) for 2–4 weeks. During this time, the mycelium will colonize the oats, turning the substrate into a dense, white mass. Once fully colonized, introduce light and humidity to trigger fruiting, and soon, oyster mushrooms will begin to emerge. This method, when executed with precision, transforms ordinary oats into a fertile ground for abundant mushroom growth.

Cooking with Shiitake Stems: Delicious Ways to Use Every Part

You may want to see also

Spawn Selection: Choose high-quality oyster mushroom spawn compatible with oat-based substrates

Selecting the right spawn is the cornerstone of successful oyster mushroom cultivation on oat-based substrates. Spawn acts as the seed, containing mycelium—the vegetative part of the fungus—ready to colonize the substrate. For oats, which are nutrient-dense but require careful moisture management, compatibility is key. High-quality spawn ensures vigorous mycelial growth, faster colonization, and higher yields. Inferior spawn may struggle to adapt, leading to contamination or poor fruiting. Thus, investing in reputable, oat-compatible spawn is non-negotiable for optimal results.

Analyzing spawn options reveals two primary types: grain spawn and plug spawn. Grain spawn, typically made from rye or wheat, is often preferred for its high mycelial density and ease of mixing with oats. However, some suppliers offer oat-based spawn, which can enhance compatibility due to its familiarity with the substrate. Plug spawn, while less common for bulk substrates, can be used for inoculating smaller oat-based blocks. The choice depends on your cultivation scale and preference, but always verify the spawn’s compatibility with oats to avoid mismatches.

Instructively, sourcing spawn from trusted suppliers is critical. Look for vendors with positive reviews, transparent production practices, and a history of successful oat-based cultivations. Spawn should be fresh, with active mycelium visible on the grains or plugs. Avoid spawn stored in suboptimal conditions, as it may have weakened mycelium or contamination. For beginners, starter kits often include pre-measured spawn and substrate, simplifying the process. Always follow the supplier’s guidelines for spawn-to-substrate ratios, typically 5-10% spawn by weight for oats.

Persuasively, investing in high-quality spawn pays dividends in the long run. While premium spawn may cost more upfront, it reduces the risk of crop failure, saving time and resources. Contamination from low-quality spawn can ruin an entire batch, whereas robust spawn outcompetes contaminants, ensuring a clean grow. Additionally, faster colonization means quicker harvests, maximizing your yield per cycle. For commercial growers, this efficiency translates to higher profitability, making the initial investment well worth it.

Descriptively, imagine opening a bag of high-quality grain spawn: the grains are plump, uniformly colonized by white, healthy mycelium, with no signs of mold or discoloration. When mixed with oats, the spawn integrates seamlessly, creating a vibrant, living medium ready for fruiting. Contrast this with poor-quality spawn, where the grains are shriveled, patchy, or tainted with green or black spots—a recipe for disaster. The difference is palpable, underscoring the importance of meticulous spawn selection for oat-based oyster mushroom cultivation.

Can You Eat Magic Mushroom Stems? Safety and Effects Explained

You may want to see also

Growing Conditions: Maintain humidity, temperature (65-75°F), and indirect light for successful fruiting

Oyster mushrooms thrive in environments that mimic their natural habitat—damp, cool, and shaded forests. To replicate these conditions, maintaining specific humidity, temperature, and light levels is crucial. Humidity should hover between 65-75%, as oyster mushrooms require moisture to develop their fruiting bodies. A hygrometer can help monitor levels, and misting the growing area or using a humidifier ensures consistency. Without adequate humidity, mushrooms may dry out or fail to fruit entirely.

Temperature control is equally vital, with the ideal range falling between 65-75°F (18-24°C). This range encourages mycelium growth and fruiting without stressing the organism. Fluctuations outside this window can stall growth or lead to contamination. For home growers, a thermostat-controlled environment, such as a grow tent or a dedicated room, can provide stability. Avoid placing mushroom kits near drafts, heaters, or windows, as these can cause rapid temperature shifts.

Indirect light plays a subtle but significant role in fruiting. Oyster mushrooms do not require direct sunlight, which can dry them out, but they do need ambient light to signal fruiting. A well-lit room with filtered sunlight or artificial lighting (like LED grow lights set on a timer for 8-12 hours daily) works well. Too little light may delay fruiting, while too much can dehydrate the mycelium. Think of it as creating a forest floor ambiance—dim but not dark.

Practical tips can further optimize these conditions. For humidity, placing a tray of water near the growing substrate or covering the setup with a clear plastic dome can create a microclimate. Temperature regulation can be aided by using insulation around the growing container or choosing a naturally stable location, like a basement. For light, positioning the setup near a north-facing window or using sheer curtains to diffuse sunlight can strike the right balance.

In summary, successful oyster mushroom cultivation from oats hinges on precise environmental control. By maintaining humidity at 65-75%, keeping temperatures within 65-75°F, and providing indirect light, growers can mimic the mushrooms' natural habitat and encourage robust fruiting. These conditions, combined with attentive monitoring and practical adjustments, transform a simple oat substrate into a thriving mushroom garden.

Crafting Red Dye: Mushroom Block's Surprising Potential Revealed

You may want to see also

Explore related products

$2.49

Contamination Prevention: Sterilize equipment and use clean techniques to avoid mold or bacteria

Growing oyster mushrooms from oats is a rewarding endeavor, but success hinges on one critical factor: contamination prevention. Mold and bacteria are the arch-nemeses of mushroom cultivation, capable of swiftly colonizing your substrate and outcompeting your mycelium. To safeguard your harvest, sterilization and clean techniques aren’t optional—they’re mandatory.

The Sterilization Imperative

Sterilization is the cornerstone of contamination prevention. Unlike pasteurization, which reduces microbial populations, sterilization aims to eliminate all living organisms. For oat-based substrates, autoclaving is the gold standard. This process involves subjecting your substrate to high-pressure steam (15 psi) at 121°C (250°F) for 60–90 minutes. If an autoclave isn’t accessible, pressure cooking can suffice, though results may be less consistent. For smaller-scale projects, boiling your oats in water for 30 minutes can work, but it risks altering the substrate’s structure. Always allow sterilized materials to cool in a clean environment before inoculation.

Clean Techniques: The Unseen Defense

Sterilization alone isn’t enough; your workspace and handling practices must also be pristine. Begin by cleaning all equipment—jars, bags, and tools—with a 10% bleach solution or 70% isopropyl alcohol. Work in a clean, clutter-free area, and consider using a still air box or laminar flow hood to minimize airborne contaminants. Wear gloves and a mask during inoculation, and flame-sterilize tools like scalpels or injection needles with a butane torch before use. Even a single spore of mold introduced during this stage can derail your entire project.

The Role of Environmental Control

Contamination prevention extends beyond equipment. Maintain a controlled environment for incubation and fruiting. Ideal incubation temperatures for oyster mushrooms range from 22–28°C (72–82°F), with humidity levels around 60–70%. Avoid placing your grow bags or containers in drafty areas, as air movement can introduce contaminants. Regularly inspect your substrate for signs of mold—discoloration, unusual smells, or fuzzy growth—and isolate any contaminated units immediately to prevent spread.

Practical Tips for Success

Small details make a big difference. Label all containers with dates and contents to track progress and avoid confusion. Use transparent grow bags or jars to monitor mycelial growth and detect contamination early. If reusing equipment, thoroughly clean and sterilize it between batches. For added protection, incorporate a layer of vermiculite or perlite into your substrate to retain moisture without creating water pockets that foster bacteria. Consistency in these practices will dramatically increase your chances of a healthy, contaminant-free mushroom harvest.

Contamination prevention is a meticulous but essential art in mushroom cultivation. By combining rigorous sterilization, clean techniques, and environmental vigilance, you’ll create a fortress against mold and bacteria, ensuring your oat-based oyster mushrooms thrive.

Post-Mushroom Insomnia: Why Can't You Sleep After Eating Mushrooms?

You may want to see also

Harvesting Tips: Pick mushrooms when gills are exposed but before spores drop for best yield

Oyster mushrooms grown from oats, a method favored by both hobbyists and small-scale farmers, reach their peak flavor and texture when harvested at the right moment. The key lies in observing the gills—those delicate, radiating structures beneath the cap. Harvest when the gills are fully exposed but still light in color, indicating the mushroom is mature yet hasn’t begun releasing spores. This timing ensures maximum yield and quality, as spores, once dropped, signal the mushroom’s energy shifting from growth to reproduction, diminishing its culinary appeal.

To master this timing, inspect your oat-based oyster mushroom substrate daily once fruiting bodies appear. Look for caps that have flattened or curled upward, exposing the gills completely. A subtle change in gill color from pale to slightly darker is your cue—harvest immediately. Use a sharp knife or scissors to cut the stem at the base, avoiding pulling, which can damage the mycelium and reduce future flushes. Proper timing not only preserves the mushroom’s firm texture but also encourages the substrate to produce additional crops.

Comparing this to other mushroom varieties, oyster mushrooms are more forgiving in their harvest window but still demand attention. Unlike shiitakes, which can be left longer without significant spore drop, oysters mature rapidly, often within 5–7 days after pinning. This quick turnaround means a missed day can result in overripe mushrooms with a slimy texture and reduced flavor. For optimal results, aim to harvest within 24 hours of gill exposure, especially in warmer growing environments where spore release accelerates.

A practical tip for oat-based grows is to maintain humidity between 80–90% during fruiting, as this slows spore release while promoting healthy growth. If you notice the gills darkening significantly or a fine dust (spores) accumulating on the substrate, you’ve waited too long. While these mushrooms are still edible, their shelf life decreases, and their texture becomes softer, less ideal for sautéing or grilling. For those growing in bulk, consider harvesting in batches, starting with the most mature mushrooms to extend the overall harvest period.

Finally, understanding the biology behind this timing enhances your success. Oyster mushrooms, when grown on oats, thrive in nutrient-rich conditions but follow a natural lifecycle dictated by spore dispersal. By interrupting this cycle at the right moment, you not only enjoy superior mushrooms but also optimize your substrate’s productivity. For instance, a 5-gallon bucket of oat-based substrate can yield up to 2–3 pounds of mushrooms over 2–3 flushes if harvested correctly. This method turns a simple oat base into a sustainable, high-yielding mushroom farm, proving that timing truly is everything in the world of fungi cultivation.

Can Mushroom Mulch Cause E. Coli Infections? Facts and Risks

You may want to see also

Frequently asked questions

Yes, you can grow oyster mushrooms using oats as a substrate. Oats provide a nutritious base for mushroom mycelium to colonize and fruit.

First, sterilize the oats to eliminate contaminants. Mix the sterilized oats with oyster mushroom spawn, place the mixture in a sterile container, maintain proper humidity and temperature, and wait for the mycelium to colonize before inducing fruiting.

Oats should be properly hydrated and sterilized to prevent contamination. Additionally, ensure the oats are not overcooked, as this can affect their ability to support mushroom growth. Proper ventilation and environmental conditions are also crucial for success.