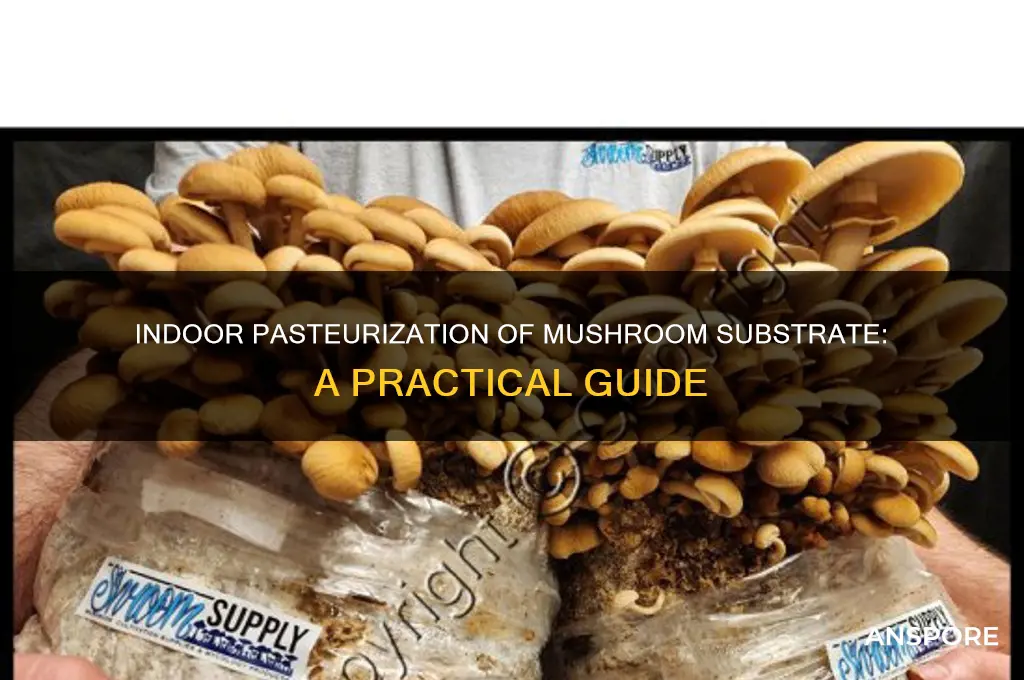

Pasteurizing mushroom substrate indoors is a common practice among home growers and small-scale cultivators seeking to create a sterile environment for mushroom cultivation. This process involves heating the substrate—typically a mixture of materials like straw, wood chips, or compost—to a specific temperature for a set duration to eliminate harmful bacteria, fungi, and pests without killing beneficial microorganisms. Indoor pasteurization is often preferred over sterilization due to its lower temperature requirements and reduced risk of damaging the substrate. Methods such as using a pressure cooker, steam pasteurizer, or hot water bath are popular choices, as they can be adapted to small spaces and controlled environments. However, success depends on precise temperature management, proper equipment, and adherence to safety precautions to avoid contamination or injury.

| Characteristics | Values |

|---|---|

| Feasibility | Yes, pasteurization of mushroom substrate can be done indoors. |

| Purpose | To reduce competing microorganisms and create a suitable environment for mushroom mycelium growth. |

| Methods | Steam pasteurization, hot water bath, or using a pasteurization chamber. |

| Temperature Range | Typically 60-80°C (140-176°F) for 1-2 hours, depending on the method and substrate. |

| Equipment Needed | Large pot, thermometer, steam generator, or pasteurization chamber; gloves and protective gear for safety. |

| Substrate Types | Manure-based, straw, sawdust, or grain substrates can be pasteurized indoors. |

| Advantages | Reduces contamination risk, improves colonization, and is suitable for small-scale or home cultivation. |

| Disadvantages | Requires careful monitoring of temperature and time; improper pasteurization can harm mycelium or leave contaminants. |

| Alternatives | Sterilization (more thorough but requires higher temperatures and pressure) or using pre-sterilized substrates. |

| Safety Precautions | Ensure proper ventilation, avoid inhaling steam, and handle hot materials with care. |

| Cost | Relatively low for DIY setups; higher for specialized equipment like pasteurization chambers. |

| Scalability | Suitable for small to medium-scale operations; larger operations may require more advanced equipment. |

Explore related products

What You'll Learn

Equipment Needed for Indoor Pasteurization

Pasteurizing mushroom substrate indoors requires precision and the right tools to ensure a sterile environment conducive to mycelium growth. The core equipment includes a large pot or container for holding the substrate, a reliable heat source such as a stove or hot plate, and a thermometer to monitor temperatures accurately. For small-scale operations, a simple kitchen setup can suffice, but larger batches demand more specialized gear like a steam pasteurizer or pressure cooker. The goal is to reach and maintain a temperature of 160–180°F (71–82°C) for 1–2 hours, killing contaminants without damaging beneficial microorganisms.

Beyond the basics, a stirring utensil is essential to distribute heat evenly and prevent substrate from clumping or burning. For those using a pressure cooker, ensure it has a capacity of at least 10–20 quarts to accommodate bulk substrate. Alternatively, a DIY steam pasteurization setup can be constructed using a large metal container with a lid and a steam generator, though this requires careful monitoring to avoid overheating. Insulation materials like blankets or foam boards can help retain heat, reducing energy consumption and maintaining consistent temperatures during the pasteurization process.

For advanced growers, investing in a digital temperature controller can streamline the process, allowing for precise adjustments and automation. This is particularly useful for substrates like straw or manure, which require strict temperature control to avoid over-pasteurization. Additionally, a pH meter can be handy to test substrate acidity post-pasteurization, ensuring optimal conditions for mushroom colonization. While not mandatory, these tools enhance efficiency and reduce the risk of human error.

Safety equipment should not be overlooked. Heat-resistant gloves protect hands during handling, and a mask prevents inhalation of airborne particles. For steam-based methods, a pressure relief valve is critical to prevent accidents. Always pasteurize in a well-ventilated area to disperse moisture and avoid mold growth in the workspace. Proper cleanup tools, such as a brush and disinfectant, ensure the equipment remains sterile for future use.

Finally, consider the scalability of your equipment. Small-scale growers might opt for affordable, multi-purpose kitchen tools, while commercial cultivators may require industrial-grade pasteurizers. Regardless of scale, consistency is key. Regularly calibrate thermometers, clean equipment thoroughly, and document each pasteurization cycle to refine your technique over time. With the right tools and attention to detail, indoor substrate pasteurization becomes a reliable step in the mushroom cultivation process.

Safe Psilocybin Frequency: How Often Can You Trip Mushrooms?

You may want to see also

Safe Temperature Range for Substrate Treatment

Pasteurizing mushroom substrate indoors requires precise temperature control to eliminate contaminants without damaging beneficial microorganisms or the substrate itself. The safe temperature range for this process typically falls between 60°C (140°F) and 80°C (176°F). At these temperatures, harmful bacteria, fungi, and pests are neutralized, while the substrate’s structure and nutrient content remain largely intact. Exceeding 80°C risks denaturing proteins and destroying essential organic matter, while temperatures below 60°C may fail to achieve adequate pasteurization.

To effectively pasteurize substrate indoors, use a reliable thermometer to monitor temperature throughout the process. For small-scale operations, a kitchen oven or large pot on a stovetop can be used, though maintaining consistent heat distribution can be challenging. Alternatively, specialized equipment like steam pasteurizers or insulated containers with heating elements offer more precise control. For example, a steam pasteurizer can uniformly heat substrate to 70°C (158°F) for 1–2 hours, ensuring thorough treatment without overheating.

Comparing methods, steam pasteurization is often preferred for its efficiency and consistency, especially for larger batches. However, it requires access to a steam generator or pressure cooker. Dry heat methods, such as using an oven, are more accessible but carry a higher risk of uneven heating or overheating. Whichever method is chosen, the substrate should be pre-moistened to 60–70% field capacity to facilitate heat penetration and prevent drying.

A critical caution is to avoid overheating, as temperatures above 80°C can sterilize the substrate, eliminating beneficial microbes needed for mushroom colonization. Additionally, always allow the substrate to cool to below 30°C (86°F) before inoculating with spawn, as higher temperatures can kill the mycelium. Practical tips include stirring the substrate halfway through pasteurization to ensure even heat distribution and using a digital probe thermometer for accurate readings.

In conclusion, mastering the safe temperature range for substrate treatment is key to successful indoor mushroom cultivation. By adhering to the 60°C–80°C range and employing appropriate techniques, growers can effectively pasteurize substrate while preserving its viability for healthy mushroom growth. Whether using steam or dry heat, precision and attention to detail ensure a contaminant-free environment for optimal mycelial development.

Mushroom Hunting in State Parks: Rules, Safety, and Best Practices

You may want to see also

Time Duration for Effective Pasteurization

Effective pasteurization of mushroom substrate indoors hinges on precise time management, as duration directly influences the elimination of contaminants while preserving beneficial microorganisms. For most substrates, such as straw or manure, a pasteurization time of 60 to 90 minutes at temperatures between 160°F to 180°F (71°C to 82°C) is standard. This range ensures that harmful bacteria, fungi, and pests are neutralized without overheating, which could degrade the substrate’s nutritional value. Shorter durations may fail to eliminate contaminants, while longer periods risk sterilizing the substrate, removing essential microbes needed for mycelial growth.

The specific time required can vary based on substrate type and moisture content. For example, denser materials like wood chips may require closer to 90 minutes to ensure heat penetration, whereas lighter substrates like straw may suffice with 60 minutes. Monitoring internal temperature with a probe thermometer is critical, as surface temperature alone can be misleading. Consistency in heat application is key—fluctuations can lead to uneven pasteurization, leaving pockets of contamination.

Instructively, the process begins by hydrating the substrate to 60-70% moisture content, then placing it in a pasteurization vessel, such as a steam box or hot water bath. Heat is applied gradually to reach the target temperature, and timing starts once the core temperature stabilizes. Stirring or agitating the substrate halfway through can improve heat distribution, particularly for larger batches. After pasteurization, the substrate must cool to 80°F to 90°F (27°C to 32°C) before inoculation to avoid damaging the mycelium.

Comparatively, pasteurization differs from sterilization in both time and outcome. Sterilization, typically lasting 1 to 2 hours at higher temperatures (250°F or 121°C), is more aggressive and eliminates all microorganisms, beneficial or not. Pasteurization, with its shorter duration, strikes a balance, reducing contaminants while retaining a microbiome conducive to mushroom growth. This makes it a preferred method for indoor cultivation, where precision and control are paramount.

Practically, home cultivators can optimize pasteurization by pre-soaking substrates overnight to ensure even moisture distribution, using a reliable thermometer to monitor temperature, and maintaining a consistent heat source. For small-scale operations, a large pot with a lid or a DIY steam box can suffice. Larger setups may require specialized equipment like electric pasteurizers. Always test the process with a small batch to fine-tune timing and temperature for your specific substrate and equipment.

Canning Sheepshead Mushrooms: A Step-by-Step Preservation Guide

You may want to see also

Explore related products

Preventing Contamination During the Process

Pasteurizing mushroom substrate indoors is a delicate process where contamination risks lurk at every step. Even a single spore or bacterium can derail weeks of effort. Understanding the enemies—mold, bacteria, and competing fungi—is the first line of defense. These invaders thrive in the same warm, nutrient-rich environment that mushrooms love, making vigilance critical.

Sterilize Your Workspace and Tools: Begin by treating your indoor area like a mini-laboratory. Wipe down surfaces with a 10% bleach solution or 70% isopropyl alcohol. Autoclave or boil metal tools (thermometers, tongs) for 20 minutes. For non-metal items, use a flame sterilizer or soak in disinfectant. Wear gloves and a mask to minimize human-borne contaminants. Even a hair follicle can introduce unwanted microbes.

Control Temperature and Humidity: Pasteurization typically occurs between 140°F and 160°F (60°C–71°C), but precision matters. Use a digital thermometer to monitor substrate temperature, ensuring it reaches the target range without exceeding it. High humidity (70–80%) is equally vital during cooling to prevent drying, but avoid creating condensation, which can introduce airborne contaminants. A dehumidifier or proper ventilation can balance moisture levels.

Isolate the Process: Designate a separate room or enclosure for pasteurization to minimize cross-contamination. If using a pressure cooker or oven, ensure it’s dedicated solely to substrate preparation. For larger batches, consider a DIY pasteurization chamber with a heating element and thermometer. Seal all openings with tape or insulation to maintain temperature and exclude external spores.

Post-Pasteurization Handling: Once pasteurized, the substrate is in a vulnerable state. Transfer it to a sterile container immediately, using gloved hands and flame-sterilized tools. Cover it with a breathable material (e.g., microwave-sterilized paper towel) to allow gas exchange while blocking contaminants. Inoculate within 24 hours to prevent opportunistic microbes from colonizing the cooled substrate.

By treating each step as a potential contamination point, you transform pasteurization from a risky endeavor into a controlled, repeatable process. The goal isn’t just to heat the substrate—it’s to create an environment where only your chosen mycelium can thrive.

Mushroom and Paneer Combo: A Delicious Pairing or Culinary Clash?

You may want to see also

Cost-Effective Methods for Small-Scale Operations

Pasteurizing mushroom substrate indoors is feasible for small-scale growers, but cost-effectiveness hinges on efficient methods and resource optimization. One of the most accessible techniques is the hot water bath, which requires minimal equipment. Fill a large pot or container with water, heat it to 160–180°F (71–82°C), and submerge your substrate (e.g., straw or sawdust) in mesh bags for 1–2 hours. This method eliminates most contaminants without the need for expensive machinery. However, it’s labor-intensive and requires careful monitoring to avoid overheating, which can damage the substrate.

For growers seeking a more automated approach, the pressure cooker method offers precision and consistency. A 22-quart pressure cooker can pasteurize 5–10 pounds of substrate at a time, making it ideal for small batches. Set the cooker to 15 psi and process for 45–60 minutes, ensuring the internal temperature reaches 170°F (77°C). While the initial investment in a pressure cooker ($100–$200) may seem steep, it pays off in time savings and reliability. Pair this with reusable substrate bags to further reduce costs.

Another cost-effective strategy is steam pasteurization, which can be DIY-adapted using a large pot with a steamer basket and a lid. Place the substrate in the basket, seal the pot, and steam for 1.5–2 hours. This method is energy-efficient, as it uses less water than a full bath, and can be scaled up with larger pots or multiple batches. However, it requires careful monitoring to maintain consistent steam levels and avoid dry spots.

Comparatively, chemical pasteurization using lime (calcium hydroxide) is a low-tech, low-cost alternative. Mix 2–4% lime by weight into your substrate, moisten it, and let it sit for 2–3 weeks. While this method is inexpensive and requires no heat, it’s slower and less reliable for complete pasteurization. It’s best suited for growers with ample time and patience, not those on tight schedules.

The takeaway for small-scale operations is to balance initial investment with long-term efficiency. Hot water baths and steam pasteurization offer low upfront costs but require more hands-on effort. Pressure cookers provide consistency and speed but demand a higher initial outlay. Chemical methods are the cheapest but come with trade-offs in time and reliability. By choosing the method that aligns with your resources and goals, you can pasteurize substrate indoors effectively without breaking the bank.

Browning Canned Mushrooms: Tips for Enhancing Flavor and Texture

You may want to see also

Frequently asked questions

Yes, you can pasteurize mushroom substrate indoors using methods like hot water baths, steam sterilization, or a pressure cooker, depending on the scale of your operation.

The easiest method for small-scale indoor pasteurization is using a hot water bath, where the substrate is soaked in water heated to 160-180°F (71-82°C) for 1-2 hours.

Pasteurization reduces but does not eliminate all contaminants, making it less effective than sterilization. However, it is sufficient for many mushroom species and is easier to perform indoors.

You’ll need a large pot or container, a thermometer, and optionally a pressure cooker or steam generator. For small batches, a kitchen setup is often sufficient.

Yes, you can pasteurize substrate without specialized equipment by using a hot water bath or oven method, though results may vary depending on the technique and temperature control.