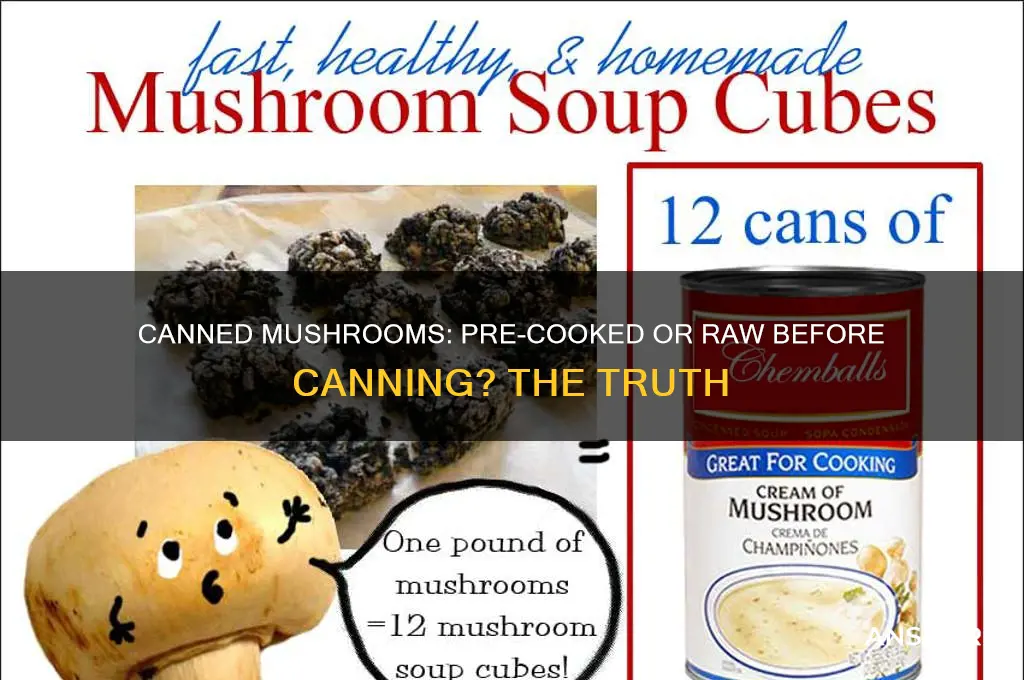

When it comes to canned mushrooms, the question of whether they are cooked before canning is a common one. The process typically involves harvesting fresh mushrooms, which are then cleaned, trimmed, and often blanched or lightly cooked to preserve their texture and flavor. This preliminary cooking step also helps to eliminate any potential microorganisms that could cause spoilage. After this, the mushrooms are packed into cans, covered with a brine or other preserving liquid, and then subjected to a high-temperature canning process that ensures their safety and extends their shelf life. This combination of pre-cooking and canning ensures that the mushrooms remain edible and maintain their quality until they are opened and consumed.

| Characteristics | Values |

|---|---|

| Cooking Before Canning | Yes, mushrooms are typically blanched or steamed before canning. |

| Purpose of Cooking | To destroy enzymes, remove excess moisture, and improve shelf life. |

| Blanching Method | Briefly immersed in boiling water (1-2 minutes). |

| Steaming Method | Exposed to steam for a short duration (2-3 minutes). |

| Temperature Control | Cooked at temperatures between 180°F to 212°F (82°C to 100°C). |

| Cooling Process | Quickly cooled to stop the cooking process and preserve texture. |

| Brine or Liquid | Packed in brine (saltwater), vinegar, or oil after cooking. |

| Sterilization | Cans are sterilized post-packing to ensure safety and longevity. |

| Texture After Canning | Slightly softer than fresh mushrooms due to heat treatment. |

| Nutrient Retention | Some water-soluble vitamins may be lost during blanching/steaming. |

| Common Canning Varieties | Button, cremini, and shiitake mushrooms are often canned after cooking. |

| Shelf Life | Canned mushrooms last 1-5 years when stored properly. |

| Safety Standards | Follows FDA or regional food safety guidelines for low-acid foods. |

Explore related products

What You'll Learn

Pre-canning mushroom preparation

Mushrooms destined for canning undergo a precise preparation process to ensure safety, texture, and flavor preservation. This begins with selecting firm, fresh mushrooms free from blemishes or signs of spoilage. Button, cremini, and portobello varieties are commonly chosen for their versatility and ability to withstand the canning process. After sorting, the mushrooms are thoroughly cleaned to remove dirt and debris, often involving a gentle rinse or brushing technique to avoid water absorption, which can dilute their flavor.

The next critical step is blanching, a brief heat treatment that halts enzymatic activity responsible for spoilage and color degradation. Mushrooms are typically blanched in boiling water for 3-5 minutes, followed by an immediate ice bath to stop the cooking process. This step not only preserves their vibrant color but also firms their texture, making them better suited for the rigors of canning. Blanching also helps remove any remaining impurities, ensuring a cleaner final product.

After blanching, mushrooms are often treated with an acid solution, such as a mixture of water, lemon juice, or vinegar, to further enhance safety and shelf life. This step lowers the pH of the mushrooms, creating an environment hostile to bacteria and other pathogens. The acid treatment also helps maintain the mushrooms' color and texture during the canning process. For example, a common ratio is 1 tablespoon of lemon juice per pint of water, in which the mushrooms are soaked for 2-3 minutes before packing.

Packing the mushrooms into sterilized jars requires careful attention to detail. They are tightly arranged to minimize air pockets, which can lead to spoilage. A brine or marinade, often consisting of water, salt, and spices, is then added to cover the mushrooms completely. This liquid not only adds flavor but also acts as a barrier against microorganisms. Proper headspace—typically ½ inch—is left at the top of the jar to allow for expansion during processing.

Finally, the filled jars undergo a pressure canning process, which is essential for low-acid foods like mushrooms to eliminate any remaining bacteria, including Clostridium botulinum. Jars are processed at 240°F (116°C) for 30 minutes (for pints) or 45 minutes (for quarts), depending on altitude adjustments. This step ensures the mushrooms are safe for long-term storage. Once cooled, the jars are checked for proper sealing, and any unsealed jars are refrigerated and used immediately. This meticulous preparation guarantees that canned mushrooms retain their quality and safety for up to 18 months.

Magic Mushrooms Peak Time: Understanding the Onset and Duration

You may want to see also

Heat treatment in canning process

Heat treatment is a critical step in the canning process, particularly for mushrooms, to ensure safety, extend shelf life, and maintain quality. This process involves exposing the mushrooms to high temperatures for a specific duration, effectively eliminating microorganisms that could cause spoilage or pose health risks. The heat treatment must be carefully calibrated to kill pathogens like *Clostridium botulinum* without overcooking the mushrooms, which could degrade their texture and flavor. For example, commercial canning operations often use a retort process where mushrooms are heated to temperatures between 240°F and 250°F (115°C to 121°C) for 20 to 40 minutes, depending on the container size and mushroom density.

The method of heat treatment can vary based on the type of mushroom and the desired end product. For instance, whole mushrooms typically require longer processing times compared to sliced or diced varieties due to their larger size and denser structure. Home canners should follow USDA guidelines, which recommend using a pressure canner for low-acid foods like mushrooms. This ensures the internal temperature reaches the necessary level to destroy spores and bacteria. Boiling water bath canning is insufficient for mushrooms because it does not achieve the high temperatures required for safe preservation.

One common misconception is that mushrooms are fully cooked before canning. In reality, the heat treatment during the canning process itself serves as the primary cooking method. Mushrooms are usually cleaned, trimmed, and blanched briefly before canning, but the final "cooking" occurs in the retort or pressure canner. This dual purpose of heat treatment—both preserving and cooking—is what makes it a cornerstone of the canning process. Properly canned mushrooms retain their nutritional value, with minimal loss of vitamins and minerals, making them a convenient and healthy pantry staple.

For those attempting home canning, precision is key. Overprocessing can lead to mushy mushrooms, while underprocessing risks contamination. Always use a tested recipe from a reliable source, such as the National Center for Home Food Preservation, and monitor the canner’s pressure and temperature closely. Additionally, ensure jars are sterilized and seals are airtight to prevent recontamination after processing. With the right technique, heat treatment transforms fresh mushrooms into a shelf-stable product that can be enjoyed year-round, preserving their earthy flavor and firm texture.

Cooked Stuffed Mushrooms Shelf Life: Storage Tips and Freshness Guide

You may want to see also

Raw vs. cooked mushroom canning

Mushrooms destined for cans often undergo a heat treatment before sealing, a process that sparks debate among canning enthusiasts. This preliminary cooking step, typically a blanching or steaming process, serves multiple purposes. Firstly, it helps to reduce the mushroom's natural enzyme activity, which can cause undesirable changes in color, texture, and flavor during storage. Secondly, heat treatment can destroy potential microorganisms, ensuring a safer product with an extended shelf life. This method is particularly crucial for low-acid foods like mushrooms, as it prevents the growth of harmful bacteria, including Clostridium botulinum, which can cause botulism.

The decision to cook mushrooms before canning is not merely a matter of preference but a critical factor in food safety and quality. Raw-pack canning, where fresh, uncooked mushrooms are packed directly into jars, is a riskier endeavor. While it may preserve a more vibrant color and firmer texture, it requires precise processing times and pressures to ensure safety. The United States Department of Agriculture (USDA) recommends a specific process for raw-pack mushrooms, involving a weighted pressure canner and processing times ranging from 50 to 90 minutes, depending on the jar size and altitude. This method demands attention to detail and adherence to guidelines to prevent potential health hazards.

In contrast, hot-pack canning, where mushrooms are pre-cooked, offers a more forgiving process. By simmering mushrooms in a brine or water bath for a few minutes before packing, you significantly reduce the risk of spoilage. This method is especially advantageous for home canners, as it allows for a more flexible processing time and a wider safety margin. The heat treatment also helps to concentrate the mushroom's flavor, resulting in a more intense taste experience. For instance, a simple recipe might involve sautéing sliced mushrooms in butter until golden, then packing them into sterilized jars with a hot broth, leaving a 1-inch headspace, and processing in a boiling water bath for 20 minutes.

The choice between raw and cooked mushroom canning ultimately depends on the desired outcome and the canner's expertise. Raw-pack methods can yield a more aesthetically pleasing product, ideal for those seeking a natural, fresh appearance. However, it demands strict adherence to processing guidelines and is better suited for experienced canners. Cooked mushrooms, on the other hand, provide a safer, more beginner-friendly option, ensuring a delicious, shelf-stable product with a longer lifespan. For those new to canning, starting with hot-pack methods is advisable, gradually building confidence and skills before attempting raw-pack techniques.

In the realm of mushroom canning, the raw vs. cooked debate highlights the delicate balance between preserving freshness and ensuring safety. While raw-pack methods offer a visually appealing result, they require meticulous attention to processing details. Cooked mushrooms, though slightly altered in texture and color, provide a more forgiving and flavorful option, making them a popular choice for both commercial and home canning operations. Understanding these nuances empowers canners to make informed decisions, ensuring their mushroom preserves are both delicious and safe for consumption.

Discovering Reishi Mushrooms in The Long Dark: Survival Guide

You may want to see also

Explore related products

$37.49

Safety of canned mushrooms

Canned mushrooms undergo a rigorous process to ensure safety, starting with a thermal treatment that eliminates harmful microorganisms. This step is crucial because mushrooms, like many fresh produce items, can harbor bacteria, yeasts, and molds. The heat processing not only cooks the mushrooms but also creates a vacuum seal, preventing recontamination. For instance, commercial canning operations typically heat mushrooms at temperatures between 240°F and 250°F (115°C to 121°C) for several minutes, a process known as sterilization. This method is so effective that properly canned mushrooms can have a shelf life of up to five years when stored in a cool, dry place.

One common concern is the presence of toxins, particularly from wild mushrooms. However, commercially canned mushrooms are cultivated varieties, such as button, cremini, or shiitake, which are grown in controlled environments to minimize toxin risks. The canning process further reduces any potential toxins by breaking down unstable compounds through heat. For example, studies show that heat treatment significantly reduces hydrazine levels, a naturally occurring compound in mushrooms that can be harmful in high concentrations. Despite this, it’s essential to inspect cans for signs of damage, such as bulging or leaks, which could indicate bacterial growth like *Clostridium botulinum*, the cause of botulism.

For home canners, following USDA guidelines is critical to ensure safety. Mushrooms must be washed, sliced, and blanched before packing into sterilized jars. A pressure canner is required to achieve the necessary temperature for low-acid foods like mushrooms, processing at 11 pounds of pressure for 30 minutes for pints and 45 minutes for quarts. Failure to follow these steps can result in insufficient heat penetration, leaving harmful bacteria intact. Even a small mistake, such as underprocessing or using improper sealing techniques, can render the product unsafe for consumption.

Comparatively, canned mushrooms offer a safer alternative to fresh mushrooms in certain scenarios, particularly for individuals with weakened immune systems. Fresh mushrooms can carry pathogens like *Listeria monocytogenes*, which thrive in refrigerated conditions. Canned mushrooms, once heated, are free from such risks, making them a reliable option for vulnerable populations. However, once opened, canned mushrooms should be treated like fresh produce—refrigerated and consumed within three to four days to prevent spoilage.

In conclusion, the safety of canned mushrooms hinges on proper processing and handling. Whether commercially produced or home-canned, the combination of heat treatment, vacuum sealing, and adherence to guidelines ensures a safe product. By understanding these processes and risks, consumers can confidently incorporate canned mushrooms into their diets, enjoying their convenience without compromising health. Always prioritize inspecting cans and following storage recommendations to maximize safety and quality.

How Long Are Mushrooms Good After Best Buy Date?

You may want to see also

Texture changes after canning

Canned mushrooms undergo a transformation in texture due to the heat processing involved in canning. This process, known as thermal processing, typically involves heating the mushrooms to temperatures between 240°F and 250°F (115°C to 121°C) for a specific duration, often around 20 to 40 minutes. The heat breaks down the mushrooms' cell walls, releasing enzymes and softening their structure. As a result, the once-firm, slightly spongy texture of fresh mushrooms gives way to a more tender, almost silky consistency in their canned counterparts.

The extent of texture change depends on various factors, including the mushroom variety, its initial freshness, and the specific canning process used. For instance, button mushrooms, with their denser flesh, may retain a bit more bite after canning compared to the more delicate oyster mushrooms, which can become quite soft. The brining solution, typically a mixture of water, salt, and sometimes acid, also plays a role. A higher salt concentration can draw out moisture from the mushrooms, contributing to a slightly firmer texture, while acidic solutions may accelerate the softening process.

From a culinary perspective, understanding these texture changes is crucial for recipe adaptation. Canned mushrooms, with their softer texture, are ideal for dishes where they will be cooked further, such as soups, stews, and sauces. Their tenderness allows them to blend seamlessly into these dishes without requiring additional cooking time. However, for recipes that call for a more substantial mushroom presence, such as stir-fries or salads, fresh or quickly sautéed mushrooms might be a better choice to maintain that desirable bite.

To mitigate excessive softening, some canners employ a technique called 'hot-filling,' where the mushrooms are heated separately before being added to the cans. This method reduces the overall processing time, minimizing the heat's impact on texture. Additionally, using mushrooms with a naturally firmer texture, like shiitake or portobello, can result in a canned product that retains more of its original mouthfeel. For home canners, experimenting with different mushroom varieties and processing times can lead to a more tailored texture, ensuring the final product meets specific culinary needs.

In summary, the canning process inevitably alters the texture of mushrooms, but this change can be managed and even leveraged in cooking. By considering the factors influencing texture and employing specific techniques, both commercial and home canners can produce canned mushrooms that are not only safe and shelf-stable but also texturally suitable for a variety of culinary applications. This knowledge empowers cooks to make informed decisions, ensuring that the convenience of canned mushrooms doesn't come at the expense of texture and, ultimately, flavor.

Perfectly Oven-Cooked Portobello Mushrooms: A Simple, Flavorful Recipe Guide

You may want to see also

Frequently asked questions

Yes, mushrooms are typically blanched or lightly cooked before canning to preserve their texture, color, and flavor while eliminating any potential bacteria.

Cooking mushrooms before canning helps to destroy enzymes that can cause spoilage, ensures even heating during the canning process, and enhances their shelf life.

Canned mushrooms are partially cooked during the canning process but are not fully cooked. They are safe to eat straight from the can but are often heated or cooked further in recipes.

Minimal cooking before canning retains most of the mushrooms' nutrients, though some water-soluble vitamins may be lost during the blanching process.

It is not recommended to can raw mushrooms as they may not heat evenly or reach the necessary temperature to kill harmful bacteria, increasing the risk of spoilage or foodborne illness.