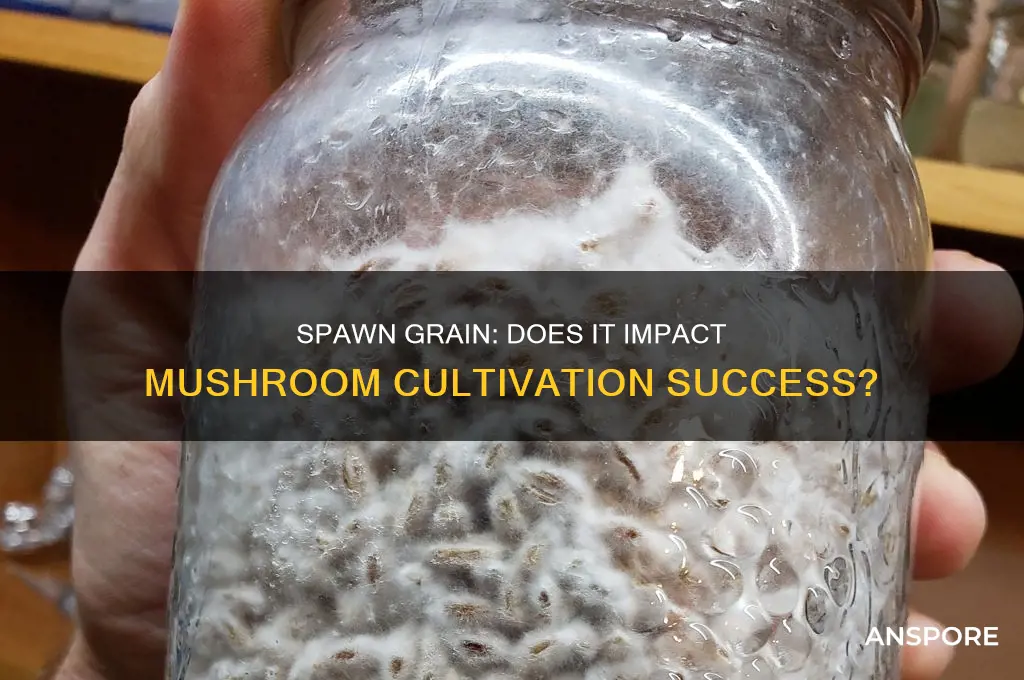

Grain spawn is an essential ingredient in mushroom cultivation. It is a substrate composed of sterilized grains, such as rye or wheat, that have been inoculated with mushroom mycelium. This mycelium forms a network of fungal cells that completely colonizes the grains, resulting in a highly concentrated source of mushroom spores. The type of grain used for spawn can vary, including wheat, rye, brown rice, white rice, wild bird seed, and even popcorn. However, rye is the most common due to its water-absorbing qualities and nutrient composition. The process of creating grain spawn involves preparing the substrate, sterilizing or pasteurizing it, inoculating the grain, and providing optimal conditions for incubation. Grain spawn plays a vital role in establishing healthy mushroom cultures, offering essential nutrients and an environment for fungi to thrive.

| Characteristics | Values |

|---|---|

| Purpose | Grain spawn provides the necessary nutrients for the fungi to grow and acts as a seed for mushroom growth. |

| Composition | A mixture of grains like rye, wheat, barley, millet, and popcorn, inoculated with mushroom mycelium. |

| Scalability | Grain spawn can be easily scaled up to meet the demands of larger mushroom cultivation operations. |

| Compatibility | Compatible with various mushroom species, including gourmet, medicinal, and dung-loving mushrooms. |

| Preparation | Grains are rinsed, soaked, cooked, dried, and then sterilized before inoculation with mushroom culture. |

| Contamination Control | Grain jars are sterilized to reduce the risk of contamination during incubation. |

| Yield | Grain spawn provides a highly concentrated source of mushroom spores, resulting in bountiful mushroom growth. |

| Substrate Requirement | Grain spawn must be mixed with a bulk substrate, such as manure, hardwood, or straw, before fruiting. |

| Advantages | Grain spawn offers efficiency, reliability, and versatility, making it the industry standard for mushroom cultivation. |

Explore related products

What You'll Learn

The role of grain spawn in mushroom cultivation

Grain spawn is an essential ingredient in mushroom cultivation. It is a mixture of grains like rye, wheat, and barley, meticulously inoculated with mushroom mycelium. The grains are sterilized and prepared before inoculation, and the subsequent creation of an optimal environment for incubation is crucial.

Grain spawn is a substrate that provides the necessary nutrients for the fungi to grow. It is a highly concentrated source of mushroom spores, acting as a seed for mushroom growth. The mycelium forms a network of fungal cells that completely colonizes the grains, providing the backbone for any mushroom-growing operation. This process is similar to grafting in horticulture, where a particular selected set of genetics produces a consistent variety.

The choice of grain is important, with popular options including rye, wheat, barley, and millet. Each type offers unique advantages and suitability for specific mushroom species. For example, rye is the most common grain used for mushroom cultivation due to its water-absorbing qualities, nutrient composition, and preference among mushrooms.

Grain spawn can be easily scaled up to meet the demands of larger mushroom cultivation operations. It can be used in various ways, including indoor and outdoor growing, and it is compatible with different mushroom species. However, it is important to note that grain spawn is not suitable for log inoculation or fruiting mushrooms without mixing it with a bulk substrate.

Overall, understanding the process of creating and utilizing grain spawn is paramount for successful mushroom cultivation. It plays a vital role in establishing healthy mushroom cultures and is widely embraced in the industry.

Mushrooms' Magical Impact: How They Affect Your Body and Mind

You may want to see also

Advantages of using rye grain spawn

The type of grain used in mushroom spawn significantly impacts the success of the grow. It affects colonisation speed, contamination risk, how well the grain breaks up, and how evenly it mixes into the substrate. Rye grain spawn is a popular option due to its unique advantages and suitability for specific mushroom species. Here are some advantages of using rye grain spawn:

High Nutritional Value

Rye grain is composed of high protein content and starch, making it easily digestible for most mushrooms. This makes it a great source of nutrition for the mycelium to feed on and spread through.

Scalability

Rye grain spawn can be easily scaled up to meet the demands of larger mushroom cultivation operations. It can be used for both indoor and outdoor growing.

Speed and Reliability

Rye offers a good balance of speed and reliability, especially when conditions aren't perfect. It colonises quickly and evenly, providing a substantial amount of spawn with low risk of contamination.

Moisture Retention

Rye grain has excellent moisture retention properties. It can hold more moisture than any other grain, which is beneficial for hydration, a crucial step in the grain spawn production process.

Structure

Rye grain has the right combination of size and density. It breaks apart easily when shaken, aiding in the distribution of the mycelium through the substrate. It is also less prone to clumping or turning mushy during preparation.

Psilocybin Mushrooms: Can They Enhance Your Vision?

You may want to see also

Preparing the substrate

One common substrate is straw, which is inexpensive and effective. It can be purchased at farm shops, pet stores, or other locations that sell animal feed or bedding. Similar agricultural products, such as corn stalks, can also be used. You can choose to grow in a 100% straw substrate or add supplements to provide additional nutrients. Before using straw as a substrate, it needs to be pasteurized to reduce the population of bacteria and give the mushrooms a better chance to grow. This can be done by cutting the straw into 3-4 inch lengths and then pasteurizing it using hot water, lime water, or peroxide solutions.

Another option for a substrate is coffee grounds, which is a straightforward and inexpensive method. Combine a kilogram of coffee grounds with 100 grams of mushroom spawn, and optionally add 20% straw to improve air exchange and speed up colonization. Coffee grounds are already pasteurized due to the brewing process, so you can skip this step. However, it is important to use fresh coffee grounds within 24 hours of brewing.

For certain types of mushrooms, you can also use cut logs as a substrate since many varieties of fungi feed on dead wood. Most hardwood tree species, such as beech, poplar, maple, oak, birch, and elm, can be used. The ideal log size for growing mushrooms is around 1 meter long and 15 cm in diameter.

Once you have selected and prepared your substrate, it is important to sterilize or pasteurize it to minimize the risk of mold and bacteria growth and give your mycelium a head start. This can be done through various methods, including heating, chemicals, or fermentation. After sterilization or pasteurization, the substrate is ready for inoculation with mushroom spores or spawn to begin the growing process.

Death Cap Mushrooms: A Common Deadly Threat

You may want to see also

Explore related products

The incubation process

Incubation is the third step in the mushroom cultivation process, after strain selection and substrate preparation. It is a crucial stage where the mycelium is left to grow, spread, and colonize a new food source. This process typically begins around four days after inoculation, with the "leap off" phase, where the mycelium initially leaps off the spawn and onto the new substrate. The mycelium then expands through the substrate in a three-dimensional sphere, fusing together until the entire substrate becomes one mycelial organism.

During incubation, it is essential to provide the optimal conditions for the mycelium to thrive. This primarily involves maintaining the preferred temperature range for the species being cultivated. The ideal temperature for many species is around 70°F (16°C). However, it is important to consider that fungi produce heat, and their internal temperatures may be slightly higher than the ambient air temperature. Therefore, it is recommended to avoid placing bags or buckets of incubating mushrooms too close together to prevent overheating. While fresh air exchange (FAE) and humidity are less crucial during incubation compared to fruiting, maintaining low levels can help deter early pinning in some species.

The duration of the incubation process varies depending on the mushroom species and the substrate used. For example, shiitake mushrooms, the most cultivated specialty mushroom, require a longer incubation period of six to ten weeks. In contrast, most other specialty mushrooms, except maitake and reishi, typically incubate in about two weeks. It is important to monitor the development of the mushroom block during incubation to recognize when full colonization has been achieved, marking the transition from incubation to the fruiting stage.

While incubation is a relatively hands-off step, it is crucial to provide the necessary conditions and monitor the process to ensure successful mushroom cultivation. Without proper conditions, mycelial growth can slow down, and contamination can occur. Therefore, the role of the mushroom grower during incubation is critical in creating an optimal environment for the mycelium to flourish.

How Chanterelles Transform into Lobster Mushrooms

You may want to see also

Scaling up grain spawn for larger operations

Grain spawn is a mixture of grains like rye, wheat, and barley, inoculated with mushroom mycelium. It is a crucial step in cultivating healthy mushrooms, as it provides the necessary nutrients for the fungi to grow. The scalability of grain spawn allows it to meet the demands of larger mushroom cultivation operations.

To scale up grain spawn for larger operations, several factors need to be considered:

Efficient Production Methods

Utilizing automated equipment and streamlining processes can increase efficiency, enabling the production of larger grain spawn quantities in less time. This includes implementing reliable sterilization procedures and incubation techniques.

Consistent Quality Control

Strict quality control measures are essential to ensure that each batch of grain spawn meets the desired standards. This prevents issues when scaling up production and helps maintain the health and viability of the spawn.

Reliable Sourcing of Raw Materials

Establishing relationships with reliable grain suppliers is crucial for consistent and uninterrupted access to raw materials. It ensures a steady supply of high-quality grains suitable for mushroom cultivation, such as rye, wheat, and barley.

Spawn to Bulk Ratios

Adjusting the spawn to bulk ratio can influence the speed of colonization, resistance to contamination, and harvesting time. For larger-scale operations, experienced cultivators can use higher ratios, such as 1:4 or even 1:5, to optimize spawn health and environmental control.

Customization and Species Compatibility

Different types of grains offer unique advantages and suitability for specific mushroom species. For example, rye is popular due to its water-absorbing qualities and nutrient composition. Wheat grain spawn is favored for its ability to support uniform growth and control contamination. Customization options, including grain types and specialty mycelium-based spawns, can be explored to meet the specific needs of the mushroom species being cultivated.

By implementing these strategies and maintaining a thorough understanding of the grain spawn process, cultivators can successfully scale up their operations to meet the demands of larger mushroom cultivation endeavors.

Mushrooms and Mucus: Is There a Link?

You may want to see also

Frequently asked questions

Grain spawn, also known as mushroom spawn, is an essential ingredient used in mushroom cultivation. It is a substrate composed of sterilized grains, such as rye or wheat, that have been inoculated with mushroom mycelium.

Grain spawn provides the necessary nutrients for the fungi to grow and flourish, ultimately giving rise to mushrooms. It is also easily scalable and can be used in a wide variety of ways, including indoor and outdoor growing.

The first step is to select and prepare the grain for sterilization. This involves rinsing and cleaning the grains, soaking them in water for 12-24 hours, and then cooking them for 15-20 minutes. Next, drain and dry the grains to remove excess moisture. Finally, load the grains into mason jars, sterilize them, and they are ready for inoculation.