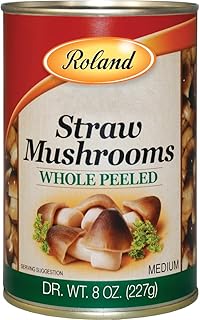

Canned mushrooms are a convenient and versatile pantry staple, but have you ever wondered how they are made? The process begins with the careful selection and harvesting of fresh mushrooms, typically button or cremini varieties, which are then thoroughly cleaned to remove any dirt or debris. After cleaning, the mushrooms are blanched in hot water to preserve their color, texture, and flavor, followed by a quick cooling process to stop the cooking. Next, they are packed into cans, often with a brine or water solution, and sealed airtight. The cans are then subjected to a high-temperature sterilization process, known as retorting, to eliminate any bacteria and ensure a long shelf life. Finally, the cans are labeled and distributed, providing consumers with a ready-to-use ingredient that retains much of the nutritional value and taste of fresh mushrooms.

Explore related products

What You'll Learn

- Harvesting and Selection: Fresh mushrooms are carefully picked, sorted by size, and inspected for quality

- Cleaning Process: Mushrooms are washed thoroughly to remove dirt, debris, and impurities

- Blanching: Briefly boiled to preserve color, texture, and stop enzyme activity

- Canning and Sealing: Packed into cans, brine or water added, then vacuum-sealed

- Sterilization: Cans are heated to kill bacteria, ensuring long shelf life

Harvesting and Selection: Fresh mushrooms are carefully picked, sorted by size, and inspected for quality

The journey of canned mushrooms begins in the fields, where timing is everything. Harvesters must strike at the precise moment when mushrooms reach their peak maturity—neither too young nor overripe. This critical window ensures the mushrooms retain their texture, flavor, and nutritional value. Using sharp knives or handheld tools, workers carefully cut the mushrooms at the base of the stem to avoid damaging the mycelium, allowing for future growth. This meticulous process is often done by hand to preserve the integrity of each mushroom, as mechanical harvesting can bruise or crush the delicate caps.

Once harvested, the mushrooms undergo a rigorous sorting process. Workers categorize them by size, typically into small, medium, and large groups, to ensure uniformity in the final canned product. This step is crucial for both aesthetic appeal and functional consistency, as evenly sized mushrooms cook at the same rate and fit neatly into cans. Sorting also allows for the segregation of mushrooms destined for different products—whole, sliced, or diced—each requiring specific size ranges. For instance, larger mushrooms are often reserved for whole or stuffed varieties, while smaller ones are ideal for slicing or dicing.

Quality inspection is the final gatekeeper before processing. Trained inspectors examine each mushroom for defects such as discoloration, blemishes, or signs of spoilage. Mushrooms with even minor imperfections are discarded to maintain the highest standards. This step is not just about appearance; it’s a safety measure to prevent the inclusion of potentially harmful or off-flavor mushrooms. Advanced facilities may use automated systems with cameras and sensors to detect flaws, but the human eye remains indispensable for nuanced judgment. Only the best mushrooms proceed to the next stage, ensuring consumers receive a premium product.

Practical tips for home growers or small-scale producers can be drawn from this process. When harvesting, use a clean, sharp tool to minimize damage, and handle mushrooms gently to avoid bruising. Sort them immediately after picking to streamline processing and reduce waste. For quality control, establish clear criteria for acceptance and rejection, and train inspectors to recognize subtle defects. By adopting these practices, even small operations can achieve the consistency and quality associated with commercially canned mushrooms.

Visible Range of a Nuclear Mushroom Cloud: Miles and Factors

You may want to see also

Cleaning Process: Mushrooms are washed thoroughly to remove dirt, debris, and impurities

Freshly harvested mushrooms, often covered in soil and forest debris, undergo a rigorous cleaning process before they can be canned. This initial step is critical to ensure the final product is safe, visually appealing, and free from contaminants. The cleaning process begins with a thorough wash, typically in large industrial tanks equipped with high-pressure water jets. These jets dislodge dirt and small particles from the mushroom caps and stems, preparing them for further treatment.

The washing stage is not just about water; it often involves a carefully calibrated solution of water and food-grade sanitizers. Common sanitizers include chlorine-based solutions, which are effective at reducing microbial loads without compromising the mushrooms' integrity. The concentration of sanitizer is crucial—usually around 50–100 ppm of chlorine—to ensure thorough disinfection without leaving residues. After washing, the mushrooms are rinsed again with clean water to remove any traces of sanitizer, ensuring they are safe for consumption.

One challenge in this process is balancing cleanliness with texture preservation. Mushrooms are porous and can absorb excess water, leading to a soggy texture in the final product. To mitigate this, the washing cycle is timed precisely, often lasting no more than 2–3 minutes. Additionally, some manufacturers use air-drying tunnels post-wash to remove surface moisture, maintaining the mushrooms' firm structure. This step is particularly important for button mushrooms, which are more prone to waterlogging than their thicker-skinned counterparts.

The cleaning process also includes a manual inspection phase. Trained workers sort through the washed mushrooms, removing any that are damaged, discolored, or still visibly dirty. This human touch ensures that only the highest-quality mushrooms proceed to the next stage of canning. For larger operations, optical sorting machines may assist, using cameras to detect imperfections that the human eye might miss. This dual approach guarantees consistency and quality in every can.

Finally, the cleaned mushrooms are briefly blanched in hot water (around 90°C for 2–3 minutes) to halt enzymatic activity and further reduce microbial contamination. This step also helps firm up the mushrooms, making them easier to handle during the subsequent slicing or whole-packing process. The blanching water is often recycled and treated to minimize waste, aligning with modern sustainability practices in food production. By the end of this meticulous cleaning process, the mushrooms are ready to be sealed in cans, preserving their freshness and flavor for months to come.

Magic Mushrooms and Casino Wins: Myth or Mind-Altering Advantage?

You may want to see also

Blanching: Briefly boiled to preserve color, texture, and stop enzyme activity

Blanching is a critical step in the canning process for mushrooms, serving as a safeguard against the natural processes that degrade their quality. When mushrooms are harvested, enzymes within their cells remain active, continuing to break down tissues and alter flavor, texture, and color. By briefly boiling the mushrooms in water—typically for 2 to 5 minutes—blanching halts these enzymatic reactions, effectively preserving the mushrooms’ freshness. This step is particularly vital for canned mushrooms, as it ensures they retain their firm texture, vibrant color, and earthy flavor even after months on a shelf.

The science behind blanching is straightforward yet ingenious. Enzymes, which thrive in the mushroom’s cellular environment, are denatured when exposed to high temperatures. A short boil at temperatures between 180°F and 200°F (82°C and 93°C) is sufficient to deactivate these enzymes without overcooking the mushrooms. This precise timing is crucial; too short, and the enzymes may remain active; too long, and the mushrooms lose their crispness and absorb excess water, becoming mushy. Blanching also helps remove air from the mushroom tissues, reducing the risk of oxidation and discoloration during storage.

From a practical standpoint, blanching requires careful attention to detail. Mushrooms should be sorted and cleaned before blanching to remove dirt and debris, ensuring the process is hygienic. Once blanched, the mushrooms are immediately plunged into ice water to halt the cooking process—a technique known as shocking. This rapid cooling preserves the mushrooms’ structural integrity and prevents them from becoming overcooked. Properly blanched mushrooms will have a slightly softened exterior but remain firm and resilient, ideal for the canning process.

Comparing blanching to other preservation methods highlights its efficiency. Unlike drying or freezing, blanching is a quick, energy-efficient step that prepares mushrooms for canning without altering their sensory qualities significantly. It also complements the subsequent steps in canning, such as brining and sealing, by creating a stable base product. While blanching alone does not extend shelf life indefinitely, it is indispensable in the canning process, ensuring the final product meets consumer expectations for quality and consistency.

In conclusion, blanching is a simple yet transformative step in the journey from fresh mushroom to canned delicacy. By briefly boiling the mushrooms, producers preserve their color, texture, and flavor while halting enzymatic activity that would otherwise degrade them. This method, when executed with precision, ensures that canned mushrooms remain a convenient, reliable ingredient for kitchens worldwide. Whether used in soups, stir-fries, or sauces, blanched and canned mushrooms retain the essence of their fresh counterparts, thanks to this essential preprocessing technique.

Can You Eat Raw Champignon Mushrooms? Safety and Tips

You may want to see also

Explore related products

Canning and Sealing: Packed into cans, brine or water added, then vacuum-sealed

The canning process for mushrooms begins with packing the pre-cooked or blanched mushrooms into sterile cans. This step is crucial, as it sets the foundation for the preservation process. The mushrooms are carefully arranged to maximize space without damaging their delicate structure. Once packed, a liquid—either brine or water—is added to the can. Brine, a saltwater solution, is often preferred for its ability to enhance flavor and act as a natural preservative. The ratio of salt to water in brine typically ranges from 3% to 5% by weight, ensuring both taste and safety. Water, on the other hand, is a simpler option that maintains the mushroom’s natural flavor. The choice between brine and water depends on the desired end product and consumer preferences.

After the liquid is added, the can undergoes vacuum sealing, a critical step that removes air and creates an airtight environment. This process involves heating the can to expel air and then sealing it while still hot. Vacuum sealing is essential because it prevents the growth of microorganisms that require oxygen to thrive, such as mold and bacteria. The absence of air also slows enzymatic activity, which can cause spoilage. For optimal results, the vacuum sealing process should achieve a vacuum level of at least 28 inches of mercury (Hg), ensuring a tight seal that prolongs shelf life.

Comparing vacuum sealing to other sealing methods highlights its superiority in preserving canned mushrooms. Unlike simple heat sealing, which may leave residual air in the can, vacuum sealing guarantees a complete removal of oxygen. This makes it far more effective in preventing spoilage and maintaining quality. Additionally, vacuum-sealed cans are less prone to bulging or leakage, common issues with improperly sealed products. For home canners, investing in a reliable vacuum sealer is a practical tip to ensure professional-grade results.

From a practical standpoint, understanding the canning and sealing process empowers consumers to make informed choices. When purchasing canned mushrooms, look for intact seals and avoid cans with dents or bulges, as these may indicate compromised sealing. For those interested in home canning, follow USDA guidelines for safe processing times and temperatures. For instance, low-acid foods like mushrooms require processing in a pressure canner at 240°F (116°C) for 30 minutes to ensure safety. Properly canned and sealed mushrooms can last up to five years when stored in a cool, dry place, making them a convenient and long-lasting pantry staple.

Can Dogs Safely Eat Cooked Mushrooms in the UK?

You may want to see also

Sterilization: Cans are heated to kill bacteria, ensuring long shelf life

The sterilization process is a critical step in canning mushrooms, ensuring that the final product remains safe and edible for years. This process involves heating the sealed cans to a specific temperature, typically between 240°F to 250°F (115°C to 121°C), for a predetermined duration, often 20 to 40 minutes. The exact time and temperature depend on the size of the can and the type of mushroom being processed. This heat treatment effectively eliminates bacteria, yeast, and mold, which are the primary culprits behind food spoilage. By destroying these microorganisms, the sterilization process significantly extends the shelf life of canned mushrooms, making them a convenient and reliable pantry staple.

Consider the science behind this process: when cans are heated, the high temperature causes the destruction of bacterial cell walls and the denaturation of essential proteins, rendering the microorganisms incapable of survival or reproduction. This method, known as thermal processing, is a standard practice in the food preservation industry. It’s worth noting that the heat treatment must be carefully controlled to avoid overcooking the mushrooms, which could compromise their texture and flavor. Manufacturers often use retort machines, specialized equipment designed to apply uniform heat and pressure to multiple cans simultaneously, ensuring consistency across batches.

From a practical standpoint, home canners can replicate this process using a pressure canner, though it’s essential to follow guidelines meticulously. For instance, low-acid foods like mushrooms require processing at 10 pounds of pressure (at an altitude of 1,000 feet or below) for 30 minutes for pint-sized jars and 45 minutes for quart-sized jars. Always consult reliable sources, such as the USDA’s Complete Guide to Home Canning, for specific instructions tailored to your equipment and environment. Improper sterilization can lead to botulism, a severe foodborne illness caused by the toxin produced by Clostridium botulinum, so precision is non-negotiable.

Comparing sterilization in mushroom canning to other preservation methods highlights its efficiency. While methods like dehydration or freezing can also extend shelf life, they often require additional storage conditions (e.g., low humidity or sub-zero temperatures) and may alter the product’s texture or flavor more significantly. Canning, on the other hand, preserves mushrooms in a ready-to-use state, with minimal changes to their taste and consistency. This makes sterilized canned mushrooms particularly versatile, suitable for soups, stir-fries, and sauces without the need for rehydration or thawing.

Finally, the sterilization step underscores the balance between food safety and sensory quality. While heat treatment is indispensable for eliminating pathogens, it must be optimized to preserve the mushrooms’ natural attributes. Manufacturers often blanch mushrooms before canning to deactivate enzymes that could cause discoloration or off-flavors, further enhancing the final product’s appeal. For consumers, understanding this process not only builds trust in canned goods but also highlights the ingenuity behind a product that seamlessly blends convenience with safety.

Detecting Magic Mushrooms: Methods, Accuracy, and Legal Implications Explained

You may want to see also

Frequently asked questions

Mushrooms are first cleaned to remove dirt and debris, then trimmed to ensure uniformity. They are often blanched in hot water or steam to preserve color, texture, and flavor before canning.

After preparation, mushrooms are packed into sterilized cans, and a brine or water solution is added. The cans are then sealed and heated under high pressure (retort process) to kill bacteria and other microorganisms, ensuring long shelf life.

Yes, mushrooms are typically blanched or lightly cooked before canning to preserve their texture and flavor. The final cooking occurs during the retort process after the cans are sealed.

Canned mushrooms often contain added salt (in brine) or citric acid to enhance flavor and act as natural preservatives. Some brands may also use minimal additives like calcium chloride to maintain firmness.

When stored in a cool, dry place, canned mushrooms can last for 2–5 years. Once opened, they should be refrigerated in a separate container and consumed within 3–4 days.