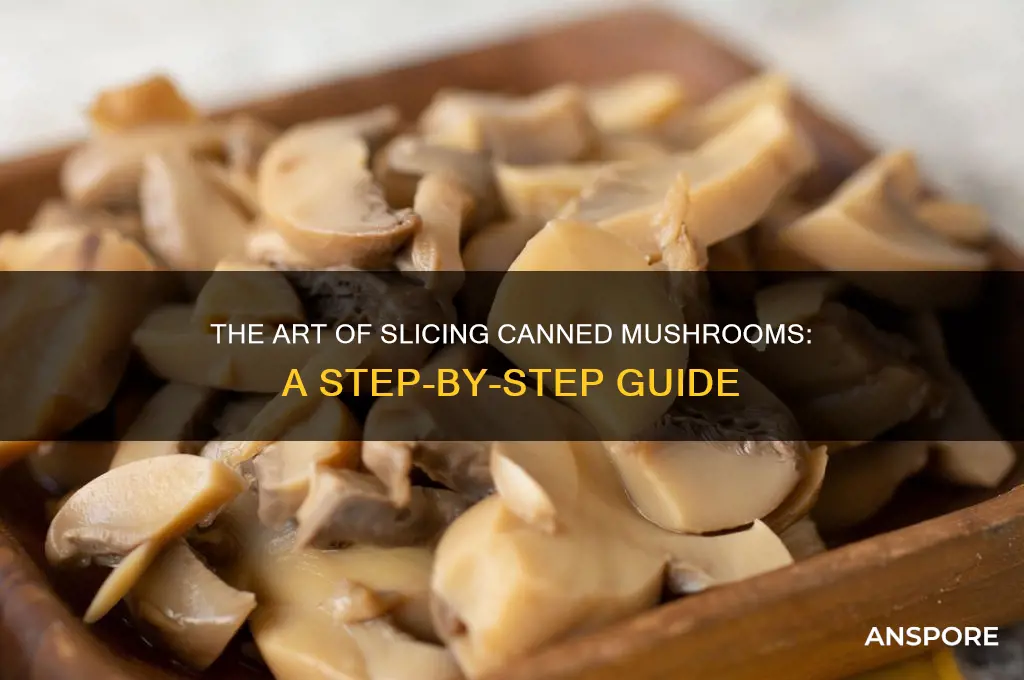

Canned mushrooms are a convenient and versatile ingredient used in countless recipes, but have you ever wondered how they achieve their uniform slices? The process begins with fresh mushrooms, typically button or cremini varieties, which are carefully selected, cleaned, and sorted by size. Once prepared, the mushrooms are placed into a machine specifically designed for slicing, ensuring consistency in thickness. After slicing, the mushrooms are quickly blanched to preserve their texture and color before being canned in a brine or water solution. This method not only extends their shelf life but also maintains their flavor and nutritional value, making them a pantry staple for home cooks and professional chefs alike.

| Characteristics | Values |

|---|---|

| Slicing Method | Machine-sliced using automated equipment |

| Slice Thickness | Typically 1/8 inch (3 mm) to 1/4 inch (6 mm) |

| Uniformity | High consistency due to precision cutting |

| Shape | Circular or slightly oval, depending on mushroom cap size |

| Blade Type | Sharp, stainless steel blades for clean cuts |

| Processing Speed | High-speed slicing (hundreds of mushrooms per minute) |

| Quality Control | Slices inspected for size, thickness, and defects |

| Preservation | Sliced before canning to maintain texture and shape |

| Packaging | Packed in brine, water, or oil to preserve freshness |

| Common Varieties | Button, cremini, or portobello mushrooms |

| Texture After Canning | Slightly softer than fresh but retains firmness |

| Color | Light to medium brown, depending on variety and processing |

| Shelf Life | 2-5 years when stored properly |

| Usage | Ideal for soups, sauces, pizzas, and casseroles |

Explore related products

What You'll Learn

- Slicing Machine Mechanisms: How automated blades precisely cut mushrooms to uniform thickness in high-speed canning lines

- Manual Slicing Techniques: Skilled workers use sharp knives to hand-slice mushrooms for premium canned products

- Blade Types and Materials: Stainless steel or ceramic blades ensure clean cuts and prevent mushroom oxidation during slicing

- Thickness Standards: Industry regulations dictate slice thickness (e.g., 2-3 mm) for consistency in canned mushroom products

- Quality Control Checks: Inspectors verify slice uniformity, texture, and color to meet packaging and consumer expectations

Slicing Machine Mechanisms: How automated blades precisely cut mushrooms to uniform thickness in high-speed canning lines

Automated slicing machines in mushroom canning lines rely on precision-engineered blade mechanisms to achieve uniform thickness at high speeds. These machines typically use circular or reciprocating blades, each designed to minimize mushroom deformation while maintaining consistent cuts. Circular blades, for instance, rotate at speeds up to 1,200 RPM, slicing mushrooms fed through a guided chute. Reciprocating blades, on the other hand, move back and forth at controlled frequencies, often synchronized with the conveyor system to ensure each mushroom is cut at the optimal moment. The blade’s sharpness and material—usually hardened stainless steel—are critical to prevent tearing or crushing the delicate fungi.

The uniformity of sliced mushrooms hinges on the machine’s feed system and thickness adjustment mechanisms. Mushrooms are first aligned on a vibrating conveyor to ensure they enter the slicing zone in a consistent orientation. Thickness is controlled by adjustable guides that position the mushroom relative to the blade. For example, a 3mm slice is achieved by setting the guide 3mm above the blade’s cutting edge. Advanced systems use laser or optical sensors to measure mushroom diameter and adjust blade height dynamically, compensating for variations in size. This ensures every slice meets the target thickness, typically ranging from 2mm to 5mm for canned mushrooms.

Blade maintenance is a critical factor in sustaining precision and efficiency. Dull or damaged blades not only compromise slice quality but also slow down production. Automated systems often incorporate self-sharpening mechanisms, where a grinding stone periodically hones the blade edge during operation. Additionally, blades are replaced every 8–12 hours of continuous use, depending on the machine’s throughput and mushroom density. Regular cleaning with food-safe sanitizers prevents residue buildup, which can affect slice consistency and hygiene standards.

Comparing manual slicing to automated systems highlights the advantages of mechanized precision. Hand-sliced mushrooms, while feasible for small batches, often exhibit thickness variations of up to ±1mm, whereas automated lines achieve tolerances within ±0.2mm. This consistency is essential for canned products, where uniform slices ensure even cooking and texture in the final product. Moreover, automated systems can process up to 10,000 mushrooms per minute, a throughput unattainable by manual labor. The integration of robotics and AI in newer models further enhances efficiency, with predictive maintenance algorithms minimizing downtime.

In practice, operators must balance speed with quality to optimize slicing performance. Overfeeding the machine can lead to jams, while underfeeding reduces output. Ideal mushroom moisture content (60–70%) is crucial, as overly dry or wet mushrooms can clog blades or produce uneven slices. Temperature control in the slicing area is also vital; blades operate best at 15–20°C to prevent thermal expansion affecting precision. By adhering to these parameters, canning facilities can achieve both high-speed production and the uniform slice thickness demanded by consumers and regulatory standards.

Can Bulldogs Safely Eat Mushrooms? A Complete Guide for Owners

You may want to see also

Manual Slicing Techniques: Skilled workers use sharp knives to hand-slice mushrooms for premium canned products

In the realm of premium canned mushrooms, the art of manual slicing is a testament to the value of human precision. Skilled workers, armed with sharp knives, meticulously hand-slice each mushroom to achieve uniformity and quality that machines often struggle to replicate. This technique is reserved for high-end products where consistency and texture are paramount. The process begins with selecting fresh, firm mushrooms, ensuring they are free from blemishes. Workers then use a straight-edged knife, typically with an 8-inch blade, to create slices of precise thickness—usually 2-3 millimeters—ideal for even cooking and presentation.

The skill required for manual slicing extends beyond mere cutting. Workers must maintain a steady hand and keen eye to ensure each slice is identical in thickness and shape. This level of precision is particularly crucial for gourmet applications, where the visual appeal of the mushroom slices can elevate a dish. For instance, in upscale restaurants, hand-sliced mushrooms are often used in sauces, pizzas, or as a garnish, where their uniform appearance enhances the overall dining experience. The tactile feedback of a knife against the mushroom’s flesh allows workers to adjust their pressure and angle in real-time, something automated machines cannot achieve.

While manual slicing is labor-intensive, it offers advantages that justify its use in premium products. Unlike machine-sliced mushrooms, which can be uneven or damaged by the mechanical process, hand-sliced mushrooms retain their structural integrity. This is especially important for canned mushrooms, as the slicing method directly impacts how well they hold up during the canning process and subsequent reheating. Additionally, the human touch ensures that any defects or subpar mushrooms are discarded, maintaining a higher standard of quality. For consumers, this translates to a product that not only looks better but also performs consistently in recipes.

However, manual slicing is not without its challenges. The process is time-consuming, requiring a skilled workforce and a significant investment in training. Workers must be adept at handling sharp knives safely, and the repetitive nature of the task demands physical endurance. Despite these hurdles, many premium brands insist on manual slicing as a hallmark of their commitment to quality. For those interested in replicating this technique at home, investing in a high-quality chef’s knife and practicing consistent slicing motions can yield similar results, though on a smaller scale.

In conclusion, manual slicing techniques represent a blend of artistry and functionality in the production of premium canned mushrooms. By prioritizing precision and quality, skilled workers create a product that stands out in both appearance and performance. While the method may be labor-intensive, its benefits—uniformity, durability, and superior texture—make it a worthwhile choice for discerning consumers and chefs alike. For those seeking the best in canned mushrooms, the presence of hand-sliced products is a clear indicator of excellence.

Transforming Dried Magic Mushrooms: Creative Processing Methods and Forms

You may want to see also

Blade Types and Materials: Stainless steel or ceramic blades ensure clean cuts and prevent mushroom oxidation during slicing

The choice of blade material is critical in the slicing of canned mushrooms, as it directly impacts the quality and shelf life of the final product. Stainless steel and ceramic blades are the preferred options due to their unique properties. Stainless steel blades, for instance, are prized for their durability and resistance to corrosion, making them ideal for high-volume production environments. They can be sharpened to a precise edge, ensuring clean, consistent cuts that minimize damage to the mushroom tissue. This is essential, as crushed or torn mushrooms can release enzymes that accelerate oxidation, leading to discoloration and off-flavors.

Ceramic blades, on the other hand, offer a different set of advantages. They are inherently sharper than stainless steel and retain their edge longer, reducing the need for frequent sharpening. Ceramic is also non-reactive, meaning it won’t interact with the mushrooms’ natural acids or the canning liquid, further preventing oxidation. However, ceramic blades are more brittle and require careful handling to avoid chipping. For manufacturers, the decision between stainless steel and ceramic often comes down to balancing durability, sharpness, and cost-effectiveness.

In practice, the slicing process involves feeding whole or pre-cut mushrooms through a blade assembly, which may consist of multiple blades to achieve uniform thickness. Stainless steel blades are typically used in heavy-duty slicers designed for continuous operation, while ceramic blades are more common in precision machines where edge retention is paramount. The speed of the blades and the pressure applied must be carefully calibrated to avoid compressing the mushrooms, which can force out juices and create a messy, uneven cut.

One practical tip for ensuring optimal performance is to maintain blade temperature. Overheating can dull edges and increase friction, leading to subpar cuts. Cooling systems integrated into slicing machinery can mitigate this, particularly when using stainless steel blades. For ceramic blades, regular inspection for micro-fractures is crucial, as even small chips can compromise the quality of the slice.

Ultimately, the selection of stainless steel or ceramic blades depends on the specific needs of the production line. Stainless steel is versatile and cost-effective, making it suitable for most operations, while ceramic offers superior sharpness and chemical inertness for premium applications. By understanding the strengths and limitations of each material, manufacturers can ensure that their canned mushrooms are sliced with precision, maintaining both texture and freshness.

Canned Straw Mushrooms vs. Fresh White Mushrooms: A Substitute Guide

You may want to see also

Explore related products

Thickness Standards: Industry regulations dictate slice thickness (e.g., 2-3 mm) for consistency in canned mushroom products

Canned mushrooms, a pantry staple in many households, owe their uniformity to precise industry standards, particularly in slice thickness. Regulations typically mandate slices between 2-3 mm, ensuring consistency across brands and batches. This narrow range is not arbitrary; it balances texture, flavor release, and visual appeal, critical factors for consumer satisfaction. Thicker slices might retain a meatier bite but risk uneven cooking, while thinner ones can become mushy or disintegrate. The 2-3 mm standard strikes a practical compromise, making canned mushrooms versatile for soups, stir-fries, and sauces.

Achieving this uniformity requires specialized machinery. Slicing equipment is calibrated to cut mushrooms with precision, often using laser-guided blades or automated systems that account for variations in mushroom size and shape. Quality control checks are frequent, with samples measured to ensure compliance. Deviations, even by fractions of a millimeter, can lead to product rejection, highlighting the industry’s commitment to consistency. For manufacturers, adhering to these standards is non-negotiable, as it directly impacts consumer trust and brand reputation.

From a culinary perspective, the regulated thickness of canned mushroom slices offers reliability in recipes. Chefs and home cooks alike can predict how the mushrooms will perform, whether they’re sautéed, baked, or simmered. For instance, a 2-3 mm slice will caramelize evenly in a pan, adding depth to a dish without overpowering other ingredients. This predictability is especially valuable in commercial kitchens, where consistency is key to maintaining menu quality. It also simplifies recipe development, as cooks can rely on canned mushrooms to behave uniformly across different preparations.

However, the focus on thickness standards isn’t without challenges. Mushrooms, being natural products, vary in size, moisture content, and texture, which can complicate slicing. Manufacturers must invest in advanced technology and rigorous processes to meet regulations. Additionally, while consistency is beneficial, some consumers may crave variety, such as thicker slices for heartier dishes or thinner ones for delicate recipes. Balancing standardization with innovation remains an ongoing industry dialogue, as companies explore ways to cater to diverse preferences without compromising quality.

In practice, understanding these thickness standards can enhance how canned mushrooms are used. For example, if a recipe calls for a specific texture—say, a tender bite in a creamy pasta—knowing the slice thickness helps in selecting the right product or adjusting cooking times. Home canners, too, can benefit from this knowledge, using 2-3 mm as a benchmark when preparing their own preserves. Ultimately, these industry regulations are more than just technical requirements; they’re a foundation for the reliability and versatility that make canned mushrooms a go-to ingredient.

Mixing Alcohol and Magic Mushrooms: Risks, Effects, and Safety Tips

You may want to see also

Quality Control Checks: Inspectors verify slice uniformity, texture, and color to meet packaging and consumer expectations

Canned mushrooms undergo rigorous quality control checks to ensure they meet both packaging standards and consumer expectations. Inspectors focus on three critical attributes: slice uniformity, texture, and color. These checks are not arbitrary; they are rooted in industry standards and consumer preferences. For instance, slice uniformity is measured using calibrated tools to ensure each slice falls within a 1-2 mm thickness range, as deviations can affect cooking consistency and visual appeal. This precision is essential because consumers expect uniformity, especially in recipes where even slicing matters, such as stir-fries or pizzas.

Texture is another non-negotiable aspect of quality control. Inspectors assess the firmness and mouthfeel of the mushroom slices, ensuring they are neither too soft nor too rubbery. A texture analyzer, a device that measures the force required to compress the mushroom, is often used to quantify this attribute. The ideal texture score falls between 4.5 and 5.5 on a 10-point scale, where 1 is overly mushy and 10 is unacceptably tough. This range is determined through consumer panels, where participants rate the texture based on their sensory experience. Maintaining this standard ensures the mushrooms retain their integrity during cooking and provide a satisfying bite.

Color consistency is equally critical, as it directly influences consumer perception of freshness and quality. Inspectors use colorimeters to measure the hue, saturation, and brightness of the mushroom slices, comparing them to a predefined color standard. Deviations of more than 5% from the benchmark can lead to rejection of the batch. For example, a lighter shade might suggest underprocessing, while a darker tone could indicate overcooking or oxidation. Packaging labels often include phrases like "naturally preserved color," which requires strict adherence to these color standards to avoid misleading consumers.

The interplay between these three attributes—uniformity, texture, and color—creates a holistic quality control framework. Inspectors often cross-reference these parameters to identify underlying issues. For instance, inconsistent slicing might correlate with uneven texture, suggesting a problem with the cutting machinery. Similarly, color variations could indicate temperature fluctuations during the canning process. By addressing these interdependencies, manufacturers can pinpoint and rectify issues before they reach the consumer, ensuring every can meets the highest standards.

Practical tips for manufacturers include regular calibration of slicing machines, routine maintenance of processing equipment, and continuous monitoring of canning temperatures. Additionally, incorporating real-time feedback from quality control checks into production workflows can prevent batch rejections and reduce waste. For consumers, understanding these quality control measures reinforces trust in the product. When selecting canned mushrooms, look for brands that highlight their quality assurance processes, as this transparency often correlates with superior product consistency and safety.

Can Cats Safely Eat Psychedelic Mushrooms? Risks and Facts Revealed

You may want to see also

Frequently asked questions

Canned mushrooms are typically sliced using automated machinery that cuts them into uniform pieces after they have been cleaned, blanched, and prepared for canning.

Canned mushrooms are usually sliced before the canning process, as part of the preparation stage, to ensure consistency and even cooking during preservation.

Specialized industrial slicers with sharp blades are used to slice canned mushrooms, ensuring precision and uniformity in the thickness and shape of the slices.

Canned mushrooms are available in both sliced and whole forms, depending on consumer preference and intended use. Sliced mushrooms are more common for convenience in recipes.