Mushrooms are a relatively sustainable food to grow, requiring less water and electricity than many vegetables or livestock. They are unique in that they are fungi, and therefore require very different growing conditions to green plants. Commercial mushroom production involves growing and harvesting them in indoor facilities where temperature and humidity can be carefully controlled. They are cultivated from spores, which are collected and used to inoculate grains or seeds to produce spawn, which farms then mix into compost. This mixture is placed in environmentally controlled grow houses, where the mushrooms' root structure, or mycelium, can develop.

| Characteristics | Values |

|---|---|

| Growing conditions | Dark, damp environments without light |

| Cultivated from | Microscopic spores |

| Commercial production | Indoor facilities with controlled temperature and humidity |

| Mushroom spores | Collected and used to inoculate grains or seeds to produce spawn |

| Spawn | Mixed into compost and placed in environmentally controlled grow houses |

| Shiitake mushrooms | Grown on natural or synthetic logs, or plastic bags filled with sawdust and wood chips |

| Mushroom growth | 17-25 days after casing is applied |

| Harvesting | Done by hand, with grow houses steam-sterilized between cycles |

| Post-harvest | Refrigerated, packaged, and shipped to supermarkets, food processors, and restaurants |

| Mushroom substrate | Used for compost, animal feed, biofuel, and construction materials |

| Mushroom cultivation techniques | Trays, logs, bags, bottles, buckets, tubs |

| Commercial techniques | Filling, spawning, casing, bag culture, log culture |

| Organic mushrooms | Must be approved by an independent organic certifier |

| Vitamin D in mushrooms | Requires exposure to sunlight, so artificial light is insufficient |

Explore related products

$14.99

What You'll Learn

- Mushrooms are grown in dark, damp, indoor facilities with controlled temperature and humidity

- Commercially, mushrooms are grown on lignocellulose, e.g. straw, sawdust, and wood chips

- Mushroom spores are collected and used to inoculate grains or seeds to produce spawn

- Grow houses are emptied and steam-sterilized before the next crop is planted

- Mushrooms are a sustainable food to grow, requiring less water and electricity than other produce

Mushrooms are grown in dark, damp, indoor facilities with controlled temperature and humidity

Mushrooms are fungi and, therefore, require very different growing conditions from green plants. Notably, mushrooms thrive in dark, damp environments and do not need light to grow. In fact, mushrooms grown indoors under artificial light are not a source of vitamin D, unlike their wild counterparts, which obtain vitamin D from exposure to sunlight.

Mushroom cultivation involves harnessing the growth of mycelium, the root-like structure of fungi, to promote the growth of mushroom fruiting bodies. In commercial laboratories, mushroom spores are collected and used to inoculate grains or seeds, which then produce spawn—the mushroom farmer's equivalent of a seed. Farms then mix this spawn into compost, which is placed in environmentally controlled grow houses.

Temperature and humidity are carefully regulated to allow the mycelium, a network of lacy white filaments, to develop fully. A casing made of peat moss is spread over the compost mixture to hold in moisture. After about 17 to 25 days, the first mushrooms are ready for harvest. These appear like pins as they push up through the casing, a stage that farmers refer to as "pinning".

Shiitake mushrooms can be grown on natural or synthetic logs, with the latter being made from sterilized and inoculated hardwood sawdust. Plastic bags filled with sawdust and wood chips are another common alternative. These artificial "logs" can produce shiitake mushrooms in just seven weeks.

Mushroom Stamps: A World of Miniature Art

You may want to see also

Commercially, mushrooms are grown on lignocellulose, e.g. straw, sawdust, and wood chips

Commercially, mushrooms are grown on lignocellulose, such as straw, sawdust, and wood chips. Lignocellulose is a material composed of cellulose, hemicellulose, and lignin. It is found in most agro-industrial waste, which is usually disposed of in landfills or burned, causing environmental problems and potential harm to human and wildlife health. However, it can be converted into high-value products like biofuels, value-added fine chemicals, and cheap energy sources for microbial fermentation and enzyme production.

Mushrooms are cultivated from spores rather than seeds. In commercial laboratories, mushroom spores are collected and used to inoculate grains or seeds to produce spawn, which farms buy and mix into their compost. The compost mixture is placed in environmentally controlled grow houses, where temperature and humidity are carefully regulated to allow the mushrooms' root structure, or mycelium, to develop fully.

Lignocellulose is a suitable substrate for the solid-state fermentation process involving mushrooms. Mushrooms can degrade lignocellulosic substrates through lignocellulolytic enzyme production and then use the degraded products to produce their fruiting bodies. This process can be used to produce high-quality food from low-quality waste streams, such as straw, which would otherwise be burned.

The use of lignocellulose in mushroom cultivation can also improve sustainability. For example, the spent mushroom substrate (SMS) produced during cultivation can be used as compost, as animal feed, or to produce packaging and construction materials, biofuels, and enzymes. Additionally, the CO2 emissions and heat from mushroom cultivation may be used to promote plant growth in greenhouses.

Mellow Mushroom's Dessert Delights: What to Expect

You may want to see also

Mushroom spores are collected and used to inoculate grains or seeds to produce spawn

Mushrooms are cultivated from microscopic spores, not seeds. A mature mushroom can produce as many as 16 billion spores. These spores are collected in sterile laboratory conditions and used to inoculate grains or seeds to produce spawn—the mushroom farmer's equivalent of a seed. This process is similar to how people grow apples from grafted wood instead of planting seeds.

Spawn is a living fungal culture, called mycelium, grown onto a substrate. It is the backbone of any mushroom-growing operation. Unlike seeds, mushroom spawn is grown from selected genetics and cloned for consistent production of a particular mushroom cultivar. This ensures that a particular set of genetics produces a consistent variety of mushrooms.

To create spawn, companies specialising in its manufacture sterilise a mixture of millet grain, water and chalk. Rye, wheat, and other small grains may be substituted for millet. This mixture is then inoculated with spores.

Farms buy spawn and mix it into their compost. The compost mixture is placed in environmentally controlled grow houses. The temperature and humidity must be carefully regulated for the mushrooms' root structure, or mycelium, to develop fully.

Mushrooms: Do They Ever Expire?

You may want to see also

Explore related products

$29.99

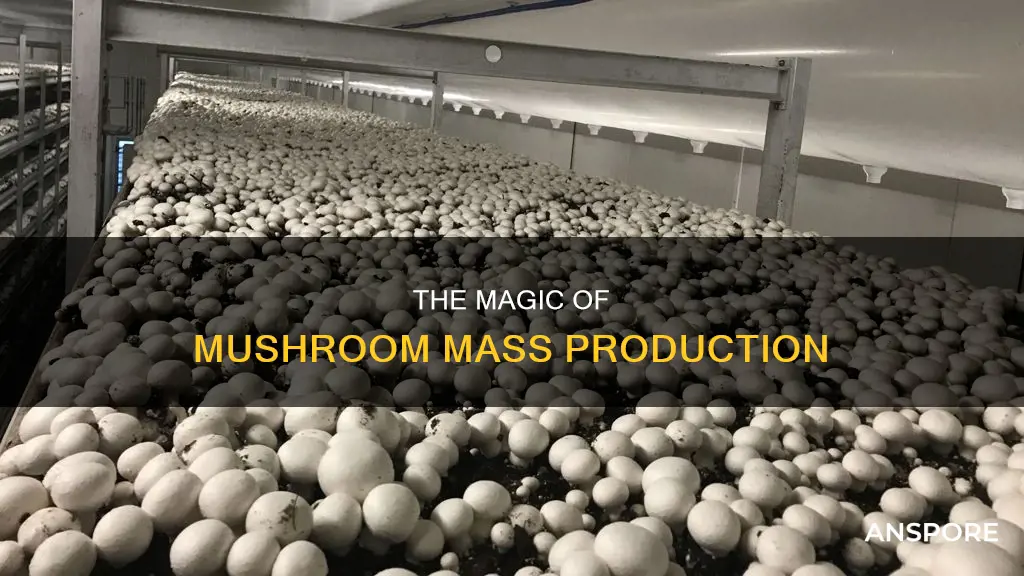

Grow houses are emptied and steam-sterilized before the next crop is planted

The process of growing mushrooms involves a series of carefully monitored steps to ensure optimal conditions for their growth. One crucial aspect of mushroom cultivation is maintaining a sterile environment, as fungi are sensitive to their surroundings. This is particularly important when transitioning between crop cycles.

After a crop of mushrooms has been harvested, the grow houses are emptied. The harvested mushrooms are then refrigerated and packaged for distribution to supermarkets, food processors, and restaurants. The remaining compost from the previous crop is recycled for potting soil, contributing to sustainable practices in mushroom farming.

Before the next crop is planted, the grow houses undergo a thorough steam sterilisation process. This step is essential to prevent contamination and ensure a clean environment for the new crop. The sterilisation process eliminates any potential pests, pathogens, or unwanted microorganisms that could hinder the growth of the next batch of mushrooms.

Steam sterilisation effectively kills any remaining spores, bacteria, or fungi that may be present in the grow house. It involves using steam under high pressure to sanitise all surfaces, equipment, and structures within the growing area. This process ensures that any residual organic matter or potential sources of infection are eradicated, creating a sterile environment for the next crop.

By emptying and steam-sterilising the grow houses between crop cycles, mushroom farmers can maintain optimal conditions for the next batch of mushrooms. This practice helps prevent diseases, promotes healthy mushroom growth, and ensures the consistent production of high-quality mushrooms. It is a critical step in the mass production of mushrooms, contributing to efficient and successful farming practices.

Mellow Mushroom's Quesadilla Offerings: What's Available?

You may want to see also

Mushrooms are a sustainable food to grow, requiring less water and electricity than other produce

Commercial mushroom production involves growing and harvesting them in indoor facilities where temperature and humidity can be carefully controlled. In commercial laboratories, mushroom spores are collected and used to inoculate grains or seeds to produce spawn—the mushroom farmer's equivalent of a seed. Farms buy this spawn and mix it into their compost. The compost mixture is placed in environmentally controlled grow houses, where temperature and humidity must be carefully regulated for the mushrooms' root structure, a network of lacy white filaments called mycelium, to develop fully.

The process of growing mushrooms is highly efficient in terms of land, water, and energy use compared to other forms of protein production. For example, growing one pound of mushrooms only requires 1.8 gallons of water and 1.0 KWH of electricity—very low numbers compared to many vegetable and livestock production requirements.

Mushroom-forming fungi can also be grown on agricultural waste streams, such as straw, sawdust, and wood chips, converting low-quality waste into high-quality food. This makes mushroom cultivation a valuable part of the transition to a circular economy, where waste streams are considered valuable resources. The spent mushroom substrate (SMS) can be used as compost, as animal feed, or to produce packaging and construction materials, biofuels, and enzymes.

Why You Should Avoid Reheating Mushrooms

You may want to see also

Frequently asked questions

Mushrooms are fungi and require very different conditions from green plants to grow. They thrive in dark, damp environments and are cultivated from microscopic spores rather than seeds. Commercial production of mushrooms involves growing and harvesting them in indoor facilities where temperature and humidity can be carefully controlled.

In commercial laboratories, mushroom spores are collected and used to inoculate grains or seeds to produce spawn. Farms buy this spawn and mix it into compost. The compost mixture is placed in environmentally controlled grow houses. A casing made of peat moss is spread over the compost mixture to hold in moisture. After 17 to 25 days, the first mushrooms are ready for harvest. Each crop is harvested by hand. The grow houses are then emptied and steam-sterilized before the process is repeated.

Mushrooms are grown on lignocellulose such as straw, sawdust, and wood chips. They can also be grown on natural or synthetic logs, or in trays.

Mushrooms are a relatively sustainable food to grow compared to other fruits and vegetables or livestock. Growing one pound of mushrooms only requires 1.8 gallons of water and 1.0 KWH of electricity. They can also be grown on waste products such as straw, which would otherwise be burned.