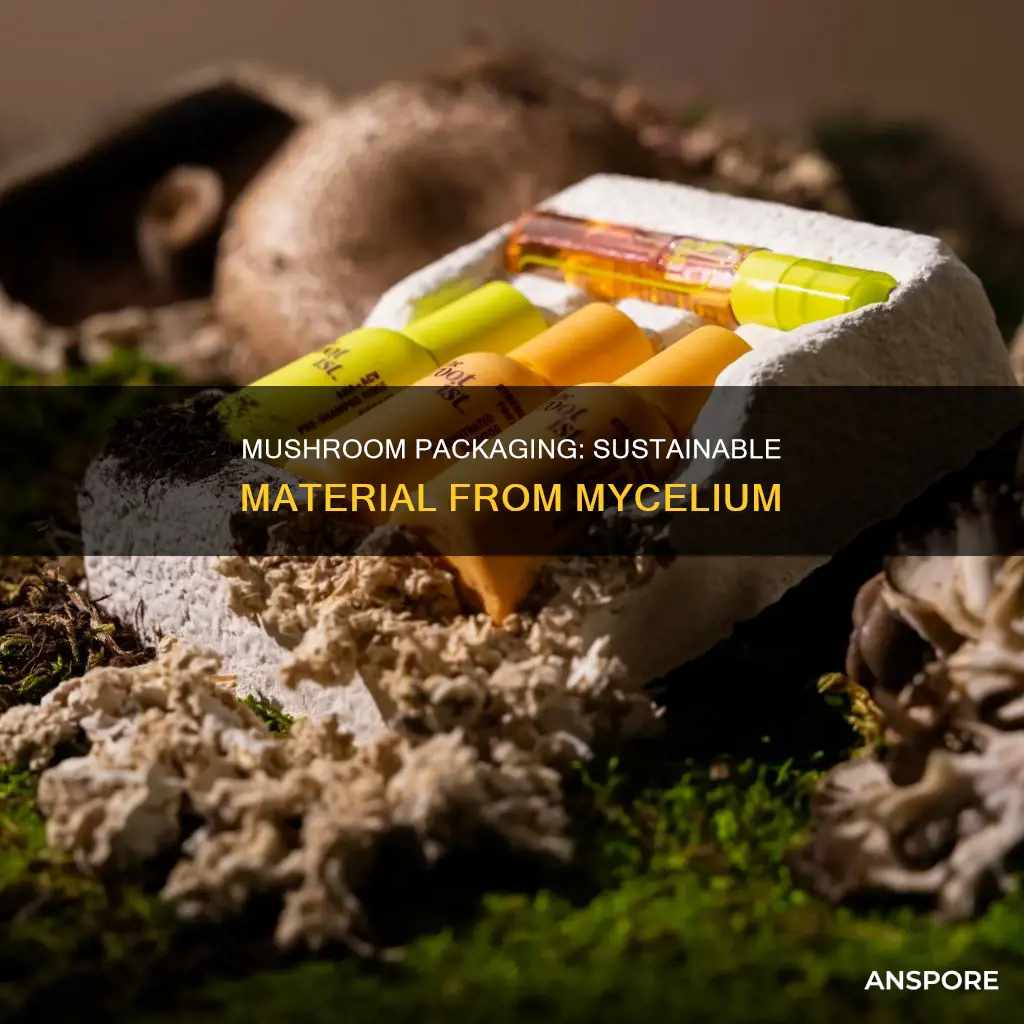

Mushroom packaging is an eco-friendly, sustainable alternative to polystyrene and plastics. It is made from mycelium, the root network of a fungus usually found below the ground. The process involves creating custom moulds that are filled with the MycoComposite™ mix, which takes up to 4–10 days to grow into form. After growth, the pieces are removed from the mould and left for another 2 days to finish developing their velvet-smooth texture. Kiln drying then removes water and renders the mycelium inert, ensuring the packaging stays dry, stable, and strong. Mushroom packaging is biodegradable, renewable, lightweight, strong, inexpensive, and easily moulded, making it an attractive alternative to traditional packaging materials.

| Characteristics | Values |

|---|---|

| Main Ingredient | Mycelium |

| Other Ingredients | Low-value agricultural feedstock, hemp, hurd, corn husks |

| Properties | Insulative, lightweight, strong, durable, cheap to produce, eco-friendly, compostable, biodegradable, versatile, thermally insulating |

| Benefits | Sustainable alternative to polystyrene and plastics, protective, shock absorption, reduces landfill waste and pollution |

| Downsides | Carbon footprint in production, not as widely available as plastics, more expensive than styrofoam |

| Manufacturers | Ecovative, Mushroom Material, Mushroom Packaging |

| Clients | Ikea, Dell, eco-conscious luxury consumer brands |

Explore related products

$22.95

What You'll Learn

Mycelium is a natural, self-assembling glue

Mushroom packaging is an innovative, eco-friendly alternative to traditional packaging materials such as polystyrene and plastic. It is made from mycelium, the root structure of mushrooms, and agricultural waste. Mycelium is a natural, self-assembling glue that binds together the mushroom roots, creating a strong and lightweight composite.

Mycelium is a network of thread-like cells that form the root structure of mushrooms. It grows underground and consists of branching, interconnected fine threads that can grow into any shape. This natural material is lightweight yet strong, and it is also cheap to produce, making it an attractive alternative to fossil fuel-derived materials. One of the unique properties of mycelium is its ability to self-assemble, acting like a natural glue. This glue-like property allows mycelium to bind together the mushroom roots and any agricultural waste, creating a cohesive and durable composite material.

The process of creating mushroom packaging typically involves mixing mycelium with agricultural waste to form a MycoComposite mix. This mix is then placed into custom moulds, where it grows into the desired shape within 4-7 days, without the need for light or water. The mycelium digests the agricultural by-products and binds together to form a cohesive mass. After growth, the pieces are removed from the moulds and left to develop a smooth texture. The material then undergoes a dehydration and heat treatment process to stop growth and remove any spores or allergens, resulting in a dry, stable, and strong final product.

Mushroom packaging offers several advantages over traditional packaging materials. It is fully biodegradable, breaking down naturally in the ground within 45 days, and can be disposed of with food waste or composted at home. It is also environmentally friendly, reducing landfill waste and pollution while providing the same durability and protective properties as polystyrene. Additionally, mushroom packaging is thermally insulating, naturally water-resistant, and can be produced quickly and cost-effectively.

The versatility of mycelium has led to its use in various industries beyond packaging. It is being explored as a sustainable alternative for skincare sponges, leather, and even alt-protein substitutes, showcasing the potential for mycelium to revolutionise multiple sectors. Overall, mushroom packaging and the self-assembling nature of mycelium offer a promising solution for eco-conscious businesses seeking sustainable alternatives to traditional packaging materials.

Mushroom Caps: Nature's Magic Unveiled

You may want to see also

The packaging is compostable and thermally insulating

Mushroom packaging is an eco-friendly and cost-effective alternative to polystyrene and plastics. It is made from mycelium, the root network of a fungus, and agricultural waste. Mycelium is a network of branching, interconnected fine threads that can grow into any shape and has no size limit. This makes it a versatile, lightweight, and strong material that is cheap to produce.

Mushroom packaging is created by filling molds with a MycoComposite mix, which takes up to four days to grow into form. The pieces are then removed from the mold and left for two more days to develop their natural velvet-smooth texture. Kiln drying is then used to remove water and render the mycelium inert, ensuring the packaging stays dry, stable, and strong.

The final product is fully compostable and biodegradable, breaking down naturally in the ground within 45 days without the need for chemicals or industrial composting facilities. It can be added to food waste, broken down and dispersed in the garden, or even mixed with seeds to grow wildflowers. Mushroom packaging is also thermally insulating, with similar insulative properties to traditional foam coolers, and can withstand temperatures from 70°C down to -25°C.

Mushroom packaging provides an environmentally friendly way to protect products during shipping, with excellent shock absorption and durability. It is a popular choice for eco-conscious brands and has been adopted by companies such as Ikea and Dell for furniture and computer packaging. By using mushroom packaging, businesses can meet the growing demand for sustainable solutions while also saving costs.

Are Sliced Mushrooms Prewashed? Know Before You Cook!

You may want to see also

It's lightweight, strong and inexpensive to produce

Mushroom packaging is an innovative and eco-friendly alternative to traditional packaging materials such as polystyrene and plastic. It is lightweight, strong, and inexpensive to produce, making it an attractive option for businesses seeking sustainable solutions.

The key component of mushroom packaging is mycelium, which is the root network of a fungus. Mycelium consists of fine, thread-like cells that form a natural, self-assembling glue. This glue-like property of mycelium allows it to bind together and create a strong, cohesive material. The mycelium grows without the need for light or water, making it a low-maintenance option. Additionally, it can grow into any shape or size, providing versatility in packaging design.

The process of creating mushroom packaging is straightforward and cost-effective. Custom moulds are created to grow the packaging solution. These moulds are filled with a MycoComposite™ mix, which takes up to four days to grow into the desired form. After growth, the pieces are removed from the mould and left for two more days to develop their natural, velvet-smooth texture. The kiln-drying process then removes water and renders the mycelium inert, ensuring the packaging is dry, stable, and strong.

The lightweight nature of mushroom packaging translates to cost savings during shipping and delivery. Less fuel is consumed due to the reduced weight, resulting in increased efficiency and lower transportation costs. Additionally, the raw materials needed to cultivate mycelium are inexpensive and readily available, further contributing to the cost-effectiveness of mushroom packaging production.

Mushroom packaging offers a sustainable and eco-friendly alternative to traditional packaging materials. It is fully compostable and biodegradable, breaking down within weeks when buried in soil. By using mushroom packaging, businesses can reduce their environmental impact and contribute to a more circular economy.

Mushrooms: Super Nutritious, Super Delicious?

You may want to see also

Explore related products

The material is grown in custom moulds

Mushroom packaging is a mycelium-based packaging alternative to polystyrene and plastics. Mycelium is the root network of a fungus, usually found below the ground. It consists of a network of branching, interconnected fine threads that can grow into any shape, from delicate structures to tightly packed masses.

The moulds can be reused to produce multiple batches of packaging. The final sample products are fit-tested and shipped for approval. The same 3D file used for prototyping is then used to make more durable hard tools.

Mushroom packaging is a cost-effective, economical, compostable, and eco-friendly alternative to polystyrene. It has the same protective properties as polystyrene, ensuring items remain safe and secure during transit. It is also fully biodegradable, breaking down naturally in the ground in around 45 days.

Mushrooms and Mitosis: The Cell Division Mystery

You may want to see also

The final product is dry, stable and strong

Mushroom packaging is a mycelium-based alternative to polystyrene and plastics. Mycelium is the root network of a fungus, usually found below the ground. It is a network of branching, interconnected fine threads that can grow into any shape. It is a completely natural material that is lightweight, strong, and cheap to produce.

The process of making mushroom packaging involves using custom moulds that are filled with the MycoComposite™ mix, which takes up to four days to grow into form. After growth, the pieces are removed from the mould and left for another two days to finish developing their velvet-smooth texture, which is characteristic of mycelium.

The final product is dry, stable, and strong. Kiln drying is used to remove water and render the mycelium inert, ensuring that the packaging stays dry. This process also stops the growth of the mycelium, making the packaging stable and inert. The final product is strong due to the natural strength of mycelium, which has been compared to the strength of polystyrene and other foams.

Mushroom packaging is fully biodegradable, breaking down naturally in the ground within 45 days without the need for chemicals or industrial composting facilities. It is also compostable and can be added to food waste, broken down in the garden, or mixed with seeds to grow wildflowers. The packaging is compatible with food waste collection at the end of its life for anaerobic digestion processing.

Mushrooms: A Dash Diet Superfood?

You may want to see also

Frequently asked questions

Mushroom packaging is an eco-friendly and compostable packaging material made from the root structure of mushrooms, known as mycelium.

The mushroom root structure, or mycelium, is grown into a custom mould, which takes around 4-7 days. After growth, the pieces are removed from the mould and left to develop a velvet-smooth texture. Kiln drying then removes water and renders the mycelium inert, so the packaging stays dry and strong.

Mushroom packaging is a natural, biodegradable, and sustainable alternative to polystyrene and plastic packaging. It is also cost-effective, with similar protective properties to polystyrene, including excellent shock absorption and durability.

Mushroom packaging is gaining popularity with eco-conscious brands, including furniture giant Ikea, and computer company Dell.

Mushroom packaging is commercially available from companies such as Ecovative and Mushroom Material.