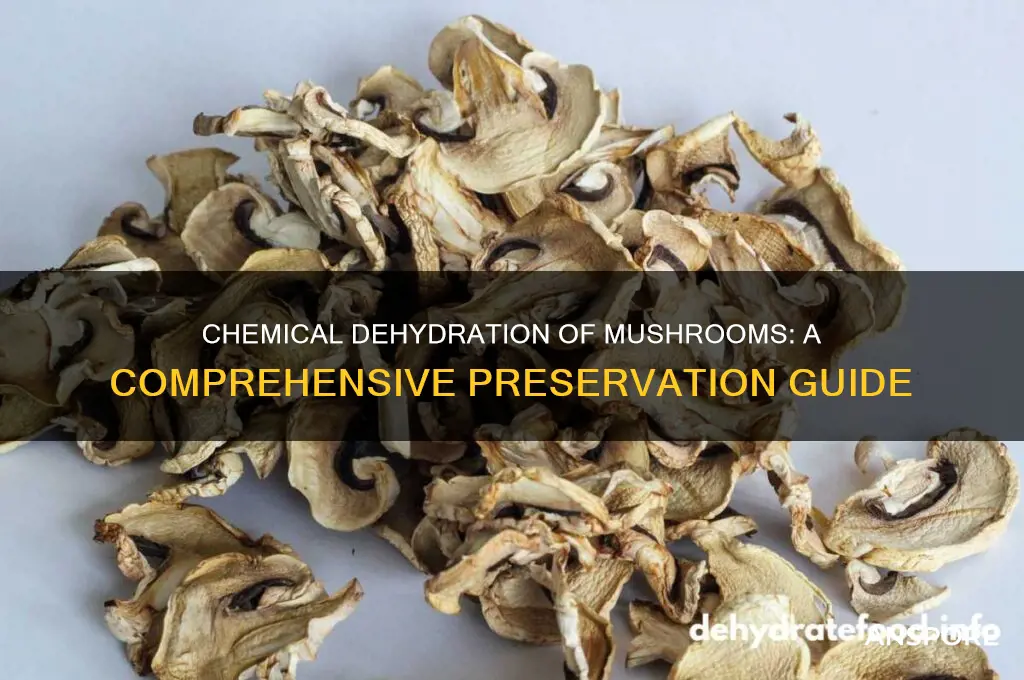

Dehydrating mushrooms through chemical methods involves the use of desiccants or chemical agents to remove moisture efficiently. One common approach is employing calcium chloride or silica gel, which are hygroscopic substances that absorb water from the mushrooms. These chemicals are placed in a sealed container with the mushrooms, creating an environment that accelerates the dehydration process. Another method involves using ethanol or other solvents to extract water, though this requires careful handling due to the flammable nature of such substances. Chemical dehydration offers a faster alternative to traditional air-drying methods, preserving the mushrooms' texture and flavor while significantly reducing drying time. However, it is crucial to ensure that any chemical residues are thoroughly removed to maintain safety and quality for consumption.

| Characteristics | Values |

|---|---|

| Method | Chemical dehydration using a desiccant |

| Desiccants Used | Calcium chloride (CaCl₂), silica gel, or glycerol |

| Mechanism | Desiccants absorb moisture from mushrooms through a process of osmosis or direct absorption |

| Effectiveness | Highly effective in removing moisture quickly |

| Advantages | Faster than air-drying, preserves texture and flavor better, reduces risk of mold growth |

| Disadvantages | Requires handling of chemicals, potential for chemical residue if not properly controlled, higher cost compared to air-drying |

| Application | Industrial-scale dehydration, suitable for large quantities of mushrooms |

| Safety Considerations | Proper ventilation, use of protective gear (gloves, masks), adherence to safety protocols |

| Post-Processing | Mushrooms may require rinsing or further treatment to remove chemical residues |

| Shelf Life of Dehydrated Mushrooms | Significantly extended, up to several years when stored properly |

| Environmental Impact | Chemical disposal must be managed to avoid environmental contamination |

| Common Mushrooms Suitable | Button, shiitake, oyster, and other varieties with high moisture content |

| Rehydration | Mushrooms can be rehydrated in water or broth before use |

| Cost | Higher initial investment due to chemical and equipment costs |

| Scalability | Highly scalable for commercial production |

Explore related products

What You'll Learn

- Using Sulfur Dioxide: Apply SO2 gas to preserve color and dehydrate mushrooms rapidly under controlled conditions

- Ethanol Extraction: Immerse mushrooms in ethanol to remove moisture, followed by evaporation for dehydration

- Acetic Acid Treatment: Expose mushrooms to acetic acid to reduce water content and enhance shelf life

- Glycol Dehydration: Use propylene glycol to bind water molecules, facilitating efficient moisture removal

- Calcium Chloride Application: Apply calcium chloride to absorb water from mushrooms, aiding in dehydration

Using Sulfur Dioxide: Apply SO2 gas to preserve color and dehydrate mushrooms rapidly under controlled conditions

Sulfur dioxide (SO₂) offers a dual advantage in mushroom dehydration: rapid moisture removal and color preservation. This method is particularly valuable for commercial operations where maintaining the mushroom's natural appearance is as critical as extending shelf life. By leveraging SO₂'s antimicrobial and antioxidant properties, producers can achieve a high-quality, visually appealing product efficiently.

The process begins with exposing mushrooms to controlled concentrations of SO₂ gas, typically ranging from 500 to 2000 ppm (parts per million), depending on the species and desired outcome. The gas is applied in a sealed chamber under specific temperature and humidity conditions—ideally between 20°C and 30°C with low relative humidity. This environment accelerates dehydration while minimizing enzymatic browning, a common issue in mushroom preservation. For optimal results, the exposure time should be carefully monitored, usually lasting between 2 to 6 hours, followed by a ventilation period to remove excess gas.

While effective, this method requires precision and caution. Overuse of SO₂ can lead to off-flavors or health risks, as residual gas may remain in the mushrooms. Regulatory guidelines, such as those set by the FDA, limit SO₂ residues to 1000 ppm in dried mushrooms. Producers must also ensure proper ventilation and personal protective equipment to avoid inhalation risks during application. Despite these challenges, when executed correctly, SO₂ treatment can reduce dehydration time by up to 50% compared to traditional air-drying methods.

A comparative analysis highlights SO₂'s edge over other chemical preservatives. Unlike sodium bisulfite, which requires direct contact with water, SO₂ gas penetrates mushrooms more uniformly, ensuring even preservation. Its ability to inhibit polyphenol oxidase, the enzyme responsible for browning, surpasses that of ascorbic acid, making it a preferred choice for color retention. However, its use is best suited for industrial settings due to the specialized equipment and safety protocols involved.

In practice, small-scale producers can adapt this method by using SO₂ generators designed for food preservation. These devices release controlled amounts of gas, making the process more accessible. Post-treatment, mushrooms should be stored in airtight containers to prevent rehydration and maintain quality. While SO₂ dehydration may not be ideal for organic certification, it remains a powerful tool for those prioritizing efficiency and aesthetics in mushroom preservation.

Where Are Enoki Mushrooms? Tips for Finding This Elusive Fungus

You may want to see also

Ethanol Extraction: Immerse mushrooms in ethanol to remove moisture, followed by evaporation for dehydration

Ethanol extraction offers a precise, chemical-based method for dehydrating mushrooms while preserving their bioactive compounds. This technique leverages ethanol’s ability to displace moisture within the mushroom’s cellular structure, followed by controlled evaporation to achieve a dry state. Unlike air-drying or freeze-drying, ethanol extraction minimizes exposure to heat or oxygen, reducing the risk of nutrient degradation. This method is particularly valuable for mushrooms rich in heat-sensitive compounds like polysaccharides or terpenes, ensuring their integrity remains intact.

To execute ethanol extraction effectively, begin by selecting food-grade ethanol with a concentration of 95% or higher. Lower concentrations may introduce excess water, defeating the dehydration purpose. Clean and slice the mushrooms into uniform pieces to maximize surface area and ensure even moisture removal. Submerge the mushrooms in ethanol at a ratio of 1:4 (mushroom to ethanol by weight) in a glass or food-safe container. Seal the container tightly to prevent ethanol evaporation and allow the mixture to sit for 24–48 hours at room temperature, agitating occasionally to facilitate moisture displacement.

After immersion, separate the mushrooms from the ethanol using a fine-mesh strainer or cheesecloth. The ethanol can be reclaimed through distillation for future use, making this method cost-effective and sustainable. The mushrooms, now saturated with ethanol, must undergo evaporation to complete the dehydration process. Spread them in a thin layer on a drying rack or parchment paper and place them in a well-ventilated area with a temperature of 35–40°C (95–104°F). Avoid higher temperatures to prevent ethanol combustion or mushroom scorching. Allow 12–24 hours for the ethanol to fully evaporate, leaving behind dehydrated mushrooms with minimal volume and weight.

While ethanol extraction is efficient, it requires careful handling due to ethanol’s flammability and potential toxicity in high concentrations. Always work in a well-ventilated area, away from open flames or heat sources. For safety, consider using a fume hood or wearing protective gloves and goggles. Additionally, ensure the final product is free of residual ethanol by testing with a flame—if it ignites, further drying is necessary. When executed correctly, this method yields dehydrated mushrooms with preserved potency, ideal for long-term storage or use in tinctures, powders, or supplements.

In comparison to traditional dehydration methods, ethanol extraction stands out for its ability to maintain mushroom quality while accelerating moisture removal. While it demands more precision and caution, its advantages in preserving bioactive compounds make it a superior choice for medicinal or culinary applications. For enthusiasts seeking a scientific, controlled approach to mushroom dehydration, ethanol extraction provides a reliable and repeatable process that bridges chemistry and practicality.

Can Dogs Safely Eat Chaga Mushrooms? A Pet Owner's Guide

You may want to see also

Acetic Acid Treatment: Expose mushrooms to acetic acid to reduce water content and enhance shelf life

Acetic acid, the active component in vinegar, offers a unique chemical method for dehydrating mushrooms while potentially enhancing their flavor profile. This method leverages the acid's ability to both draw out moisture and act as a natural preservative.

By exposing mushrooms to a controlled concentration of acetic acid, typically around 5-10% diluted in water, you create an environment that encourages water loss from the mushroom cells. This process, known as osmosis, occurs as the higher concentration of acetic acid outside the mushroom cells draws water out through the cell membranes.

The application method is straightforward. Submerge sliced or whole mushrooms in the diluted acetic acid solution for a period of 15-30 minutes. The duration depends on the desired level of dehydration and the mushroom variety. Softer varieties like shiitake may require less time compared to denser types like portobello. After soaking, thoroughly rinse the mushrooms with water to remove excess acid and pat them dry.

This treatment not only reduces water content but also imparts a subtle tangy flavor to the mushrooms, making them suitable for various culinary applications.

While acetic acid treatment is effective, it's crucial to consider potential drawbacks. Prolonged exposure to high concentrations of acetic acid can alter the mushroom's texture, making them overly soft. Additionally, the tangy flavor may not be desirable for all dishes. It's essential to experiment with different concentrations and soaking times to achieve the desired balance of dehydration and flavor enhancement.

For optimal results, combine acetic acid treatment with other dehydration methods like air-drying or oven drying at low temperatures. This multi-step approach ensures thorough dehydration while allowing for better control over the final texture and flavor of the mushrooms.

Mushrooms and Digestion: How They Impact Your Stool Consistency

You may want to see also

Explore related products

$69.99 $75.99

Glycol Dehydration: Use propylene glycol to bind water molecules, facilitating efficient moisture removal

Propylene glycol, a versatile chemical compound, offers a unique approach to mushroom dehydration by leveraging its hygroscopic nature. Unlike traditional methods that rely on heat or air circulation, glycol dehydration targets water molecules directly, binding them through chemical affinity. This process not only accelerates moisture removal but also preserves the mushroom’s texture and flavor more effectively than heat-intensive techniques, which can degrade delicate compounds. By immersing mushrooms in a controlled concentration of propylene glycol, typically 50-70% by volume, the solution draws out water through osmosis, leaving behind a dehydrated product ready for further processing or storage.

The mechanism of glycol dehydration hinges on propylene glycol’s ability to form hydrogen bonds with water molecules, effectively "trapping" them within its structure. This chemical interaction is reversible, allowing for the subsequent removal of bound water through evaporation or distillation. For optimal results, mushrooms should be pre-treated by blanching or slicing to increase surface area and reduce dehydration time. A 1:2 ratio of mushroom weight to propylene glycol solution is recommended, with immersion times ranging from 6 to 12 hours depending on mushroom thickness. Careful monitoring of the solution’s viscosity is crucial, as excessive water absorption can render it ineffective.

While glycol dehydration is efficient, it requires strict adherence to safety protocols. Propylene glycol is generally recognized as safe (GRAS) by the FDA, but its use in food processing demands purity levels of 99.5% or higher to avoid contaminants. After dehydration, residual glycol must be removed through rinsing or further drying to meet regulatory standards. This method is particularly advantageous for industrial-scale operations, where consistency and speed are paramount. However, small-scale producers may find the cost of high-purity glycol and the complexity of post-processing steps less feasible compared to conventional drying methods.

A comparative analysis highlights glycol dehydration’s edge in preserving bioactive compounds like polysaccharides and antioxidants, which are often compromised by high-temperature drying. For instance, studies show that mushrooms dehydrated using propylene glycol retain up to 85% of their original antioxidant capacity, compared to 60% with hot air drying. This makes glycol dehydration ideal for functional food applications or nutraceutical production. However, its environmental impact, including glycol disposal and energy consumption during distillation, warrants consideration, especially in sustainability-focused operations.

In practice, integrating glycol dehydration into a mushroom processing workflow involves a series of precise steps. Begin by preparing a 60% propylene glycol solution in food-grade containers, ensuring thorough mixing to avoid concentration gradients. Submerge pre-treated mushrooms and agitate periodically to enhance water extraction. Post-dehydration, rinse the mushrooms with distilled water to eliminate surface glycol, followed by a final drying step at low temperatures (40-50°C) to remove residual moisture. This hybrid approach combines the efficiency of chemical dehydration with the safety of traditional drying, yielding a superior product tailored for premium markets.

Adding Mushrooms to Your New Saltwater Tank: Timing Tips

You may want to see also

Calcium Chloride Application: Apply calcium chloride to absorb water from mushrooms, aiding in dehydration

Calcium chloride, a highly hygroscopic salt, excels at drawing moisture from its surroundings, making it a potent tool for dehydrating mushrooms. Its effectiveness stems from its ability to form hydrates, chemically bonding with water molecules and locking them away from the mushroom tissue. This process not only removes moisture but also helps preserve the mushroom's texture and flavor profile compared to traditional air-drying methods.

When applying calcium chloride for mushroom dehydration, precision is key. A recommended dosage ranges from 10-20% calcium chloride solution by weight of the mushrooms. This solution can be prepared by dissolving food-grade calcium chloride flakes in water at a ratio of 1:4 (calcium chloride to water). Submerge the mushrooms in this solution for 10-15 minutes, allowing the salt to penetrate the cellular structure and draw out moisture.

While calcium chloride dehydration is efficient, it requires careful handling. The salt's corrosive nature necessitates the use of gloves and eye protection during preparation and application. Additionally, thorough rinsing of the dehydrated mushrooms is crucial to remove any residual salt, ensuring a palatable end product. This method is particularly suitable for dehydrating mushrooms intended for soups, stews, or other dishes where the salt content can be balanced by other ingredients.

For optimal results, consider the mushroom variety. Delicate mushrooms like chanterelles may require shorter soaking times to prevent excessive texture loss. Heartier varieties like shiitakes can withstand longer exposure. Experimentation with soaking times and calcium chloride concentrations allows for tailoring the dehydration process to achieve the desired texture and moisture content.

Can Mushrooms Grow in Your Bed? Uncovering the Truth and Risks

You may want to see also

Frequently asked questions

The chemical method involves using a desiccant like calcium chloride or silica gel to absorb moisture from mushrooms. These chemicals create a dry environment, drawing out water through osmosis or adsorption.

Yes, when using food-grade desiccants like silica gel or calcium chloride, the method is safe. However, ensure the chemicals do not come into direct contact with the mushrooms to avoid contamination.

The process typically takes 24–48 hours, depending on the mushroom type, humidity, and the amount of desiccant used. Regularly check the progress to ensure thorough dehydration.

Yes, desiccants like silica gel can be reused after regeneration (heating to remove absorbed moisture). Calcium chloride, however, may need replacement once it dissolves into a brine solution. Always inspect the chemicals before reuse.