Creating a mushroom dryer is an efficient way to preserve mushrooms while retaining their flavor and nutritional value. The process involves constructing a device that uses controlled heat and airflow to remove moisture from the mushrooms, preventing spoilage and extending their shelf life. To build a mushroom dryer, you’ll need materials like wood or plastic for the frame, mesh screens or racks for holding the mushrooms, a heat source such as a light bulb or heating element, and a fan or vents to ensure proper air circulation. The design should allow for even drying, preventing overheating or under-drying, and can be customized based on the scale of your operation, whether for personal use or small-scale production. Proper sanitation and temperature control are key to ensuring the mushrooms dry safely and effectively.

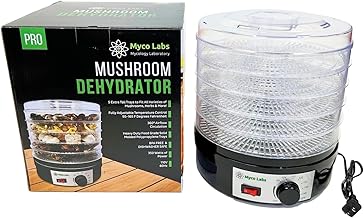

Explore related products

What You'll Learn

- Choosing the Right Materials: Select food-grade mesh, wood, or plastic for safe, durable construction

- Designing Airflow System: Ensure even drying with fans, vents, or natural convection methods

- Temperature Control: Maintain 40-60°C using heaters, thermostats, or solar energy for optimal drying

- Humidity Management: Use dehumidifiers or desiccants to prevent mold and ensure thorough drying

- Assembly and Setup: Build a compact, portable frame with layers for efficient mushroom placement

Choosing the Right Materials: Select food-grade mesh, wood, or plastic for safe, durable construction

When embarking on the construction of a mushroom dryer, selecting the right materials is crucial for ensuring both safety and durability. The primary components of your dryer—mesh, wood, or plastic—must be food-grade to prevent any harmful chemicals from leaching into your mushrooms during the drying process. Food-grade mesh is an excellent choice for the drying surface because it allows for optimal airflow, which is essential for even drying. Look for stainless steel or nylon mesh that is specifically labeled as food-safe. Avoid materials like galvanized steel or untreated metals, as they can corrode or release toxins when exposed to moisture.

Wood is another popular material for building the frame of a mushroom dryer, but not all types of wood are suitable. Opt for hardwoods like maple, oak, or cedar, which are naturally resistant to mold and mildew. Ensure the wood is untreated and free from chemicals like pesticides or preservatives, as these can contaminate your mushrooms. If you’re concerned about longevity, consider sealing the wood with a food-safe finish, such as mineral oil or beeswax, to protect it from moisture without compromising safety.

Plastic can also be a viable option, particularly for trays or components that need to be lightweight and easy to clean. When choosing plastic, prioritize food-grade options like HDPE (high-density polyethylene) or polypropylene, which are durable and resistant to heat. Avoid PVC or other plastics that may contain phthalates or BPA, as these can pose health risks. Ensure the plastic is heat-resistant if you plan to use a warming element in your dryer, as some plastics can warp or release toxins under high temperatures.

In addition to the main materials, consider the fasteners and connectors you’ll use to assemble your dryer. Stainless steel screws, bolts, and hinges are ideal because they are rust-resistant and safe for food contact. Avoid galvanized or coated metals that may chip or degrade over time. If using glue or adhesives, ensure they are food-safe and non-toxic, such as those specifically designed for kitchen or food processing applications.

Finally, think about the overall design and how the materials will interact with your drying environment. For example, if you’re using a dehydrator with a heating element, ensure all materials are heat-resistant and won’t warp or emit fumes. If your dryer will be exposed to humidity, choose materials that are moisture-resistant to prevent mold or degradation. By carefully selecting food-grade mesh, wood, or plastic and ensuring all components are safe and durable, you’ll create a mushroom dryer that is both effective and reliable for long-term use.

Brewing Psilocybin Mushroom Tea: A Step-by-Step Guide for Beginners

You may want to see also

Designing Airflow System: Ensure even drying with fans, vents, or natural convection methods

When designing an airflow system for a mushroom dryer, the primary goal is to ensure even drying across all mushroom surfaces. This can be achieved through a combination of fans, vents, or natural convection methods, depending on your resources and the scale of your operation. Fans are the most common and effective way to create controlled airflow. Positioning fans strategically at the bottom or sides of the dryer ensures a steady stream of air circulates around the mushrooms, preventing moisture buildup and promoting uniform drying. For small-scale setups, a single oscillating fan can suffice, but larger operations may require multiple fans or a ducted system to distribute air evenly.

Vents play a crucial role in maintaining airflow balance within the dryer. Intake vents should be placed at the bottom to allow fresh, dry air to enter, while exhaust vents at the top facilitate the escape of moist air. The size and number of vents should be calculated based on the dryer's volume and the fan's capacity to ensure optimal air exchange. Mesh screens over vents are recommended to keep out pests while allowing unrestricted airflow. Proper vent placement and sizing are essential to prevent stagnant air pockets, which can lead to uneven drying or mold growth.

For those seeking a more energy-efficient or low-tech solution, natural convection can be harnessed to create airflow. This method relies on the principle that warm, moist air rises, creating a natural flow when properly directed. Designing a dryer with a slanted or tiered shelf system encourages air to move upward as it warms, carrying moisture away from the mushrooms. Adding a small chimney or vent at the top enhances this effect by creating a vacuum that pulls air through the system. While natural convection is slower than fan-driven methods, it is cost-effective and ideal for small batches or off-grid setups.

Combining fans and vents in a hybrid system can maximize efficiency and control. Fans can be used to supplement natural convection, ensuring consistent airflow even in humid conditions. Adjustable vents allow you to fine-tune the system based on environmental factors, such as outdoor humidity or temperature. For example, partially closing exhaust vents can slow drying in arid climates, while opening them fully in damp conditions accelerates moisture removal. This flexibility makes hybrid systems versatile for various environments and mushroom types.

Regardless of the method chosen, monitoring airflow is critical to ensuring even drying. Tools like hygrometers and thermometers can help track humidity and temperature levels within the dryer, allowing adjustments to be made as needed. Regularly rearranging mushrooms or rotating trays can also improve uniformity, especially in systems where airflow might be less consistent. By carefully designing and optimizing your airflow system, you can create an efficient mushroom dryer that produces high-quality, evenly dried mushrooms with minimal waste.

Mushrooms' Musical Mystery: Do Fungi Compose Hidden Sonic Symphonies?

You may want to see also

Temperature Control: Maintain 40-60°C using heaters, thermostats, or solar energy for optimal drying

Temperature control is a critical aspect of building an effective mushroom dryer, as maintaining the optimal range of 40-60°C ensures that mushrooms dry efficiently without losing their nutritional value or developing mold. One of the simplest methods to achieve this is by using electric heaters paired with thermostats. Start by selecting a heater suitable for the size of your drying chamber, such as a fan heater or a radiant heater. Install the heater at the base of the dryer to ensure even heat distribution. Connect the heater to a thermostat that allows you to set and maintain the desired temperature range. Place a thermometer inside the drying chamber to monitor the temperature accurately and adjust the thermostat as needed to avoid overheating or underheating.

For a more energy-efficient and eco-friendly approach, consider utilizing solar energy to power your mushroom dryer. Build or purchase a solar dehydrator, which typically consists of a wooden or plastic box with a glass or plastic top to trap sunlight. Inside the box, place a black absorbent material, such as metal sheets or dark fabric, to absorb and radiate heat. Position the mushrooms on trays above this material, ensuring proper airflow. On sunny days, the internal temperature can naturally reach the 40-60°C range. To enhance control, add a small solar-powered fan to circulate air and a thermostat to monitor and regulate the temperature. This method is cost-effective and sustainable, especially in regions with abundant sunlight.

If you prefer a hybrid approach, combine electric heaters with solar energy for consistent temperature control regardless of weather conditions. Install a solar panel system to power the heater and thermostat, reducing reliance on grid electricity. Use a backup electric heater for cloudy or cold days to maintain the required temperature range. This setup ensures reliability while minimizing energy costs. Additionally, insulate the drying chamber with foam or wool to retain heat and reduce the workload on the heating system.

Another innovative method is using heat lamps in conjunction with thermostats for precise temperature control. Position heat lamps above the mushroom trays, ensuring they are far enough to avoid direct contact and potential scorching. Connect the lamps to a thermostat to automatically turn them on or off based on the chamber’s temperature. This setup is particularly useful for small-scale dryers and can be easily adjusted to accommodate different drying needs. Regularly calibrate the thermostat to ensure accuracy and consistency.

Finally, for those with access to wood-fired systems, a wood stove or burner can be integrated into the mushroom dryer design. Install a heat exchanger to transfer heat from the stove to the drying chamber, maintaining the 40-60°C range. Use a thermostat to monitor the temperature and adjust the stove’s intensity as needed. While this method requires more manual intervention, it is a viable option for off-grid or rural settings. Ensure proper ventilation to prevent smoke contamination and maintain air quality within the drying chamber. Each of these methods, when implemented correctly, ensures optimal temperature control for efficient mushroom drying.

Mastering Julienne Mushroom Technique: Easy Steps for Perfectly Cut Fungi

You may want to see also

Explore related products

Humidity Management: Use dehumidifiers or desiccants to prevent mold and ensure thorough drying

Effective humidity management is crucial when building a mushroom dryer, as excessive moisture can lead to mold growth and incomplete drying. One of the most reliable methods to control humidity is by using dehumidifiers. These devices extract moisture from the air, creating an environment conducive to drying mushrooms evenly. When selecting a dehumidifier, consider the size of your drying area and the unit's capacity, measured in pints of water removed per day. Place the dehumidifier near the mushroom dryer, ensuring proper ventilation to maximize efficiency. Regularly empty the dehumidifier’s water collection tank to prevent overflow and maintain consistent performance.

If a dehumidifier is not feasible, desiccants offer a cost-effective alternative for humidity control. Silica gel, calcium chloride, or activated charcoal are popular desiccants that absorb moisture from the air. Place these materials in breathable containers near the drying mushrooms, ensuring they are not in direct contact with the produce. Desiccants must be replaced or regenerated once they reach their moisture absorption limit. For example, silica gel can be reactivated by heating it in an oven, while calcium chloride dissolves as it absorbs moisture and needs to be replaced entirely.

Combining dehumidifiers and desiccants can provide a dual-layer defense against humidity, especially in high-moisture environments. Position desiccants in strategic locations around the dryer to target localized humidity pockets that the dehumidifier might miss. Monitor the drying area regularly with a hygrometer to ensure humidity levels remain below 50%, the threshold at which mold growth becomes a risk. Adjust the placement and quantity of desiccants or the dehumidifier’s settings as needed to maintain optimal conditions.

Proper airflow is essential to complement humidity management efforts. Ensure your mushroom dryer has adequate ventilation, such as fans or vents, to circulate air and assist in moisture removal. Pairing dehumidifiers or desiccants with good airflow prevents moisture from settling on mushroom surfaces, promoting even drying. Avoid overcrowding the drying racks, as this can trap humidity and create microenvironments where mold thrives.

Finally, consider the climate of your location when planning humidity management. In naturally humid regions, rely more heavily on dehumidifiers and use larger quantities of desiccants. In drier climates, desiccants alone may suffice, but always monitor humidity levels to avoid over-drying. By integrating dehumidifiers, desiccants, and proper airflow, you can create a mushroom dryer that effectively prevents mold and ensures thorough, consistent drying of your mushrooms.

Jarrow vs. MRM: Which Brand Offers the Best Mushroom Supplement?

You may want to see also

Assembly and Setup: Build a compact, portable frame with layers for efficient mushroom placement

To build a compact and portable mushroom dryer with layers for efficient mushroom placement, start by selecting a lightweight yet sturdy material for the frame. Aluminum or PVC pipes are excellent choices due to their durability and ease of assembly. Cut the pipes to your desired dimensions, typically around 2 feet in width and 3 feet in height, to create a frame that is both portable and spacious enough for multiple layers. Use connectors or elbows to join the pipes, forming a rectangular or square structure. Ensure the joints are secure by applying adhesive or tightening screws, depending on the material. This frame will serve as the backbone of your dryer, supporting the layers where mushrooms will be placed.

Next, construct the layers for mushroom placement using fine mesh screens or food-grade plastic trays with small perforations. These layers should fit snugly within the frame, allowing for adequate airflow while preventing mushrooms from falling through. If using mesh screens, stretch and secure them onto wooden or PVC frames that match the inner dimensions of the main structure. For trays, ensure they are lightweight and stackable, with enough spacing between them to allow warm air to circulate evenly. Attach small legs or supports to the bottom of each layer to maintain consistent spacing and airflow.

Incorporate a heating element to facilitate the drying process. A small, portable fan with a heating function or a string of low-wattage incandescent bulbs can be installed at the base of the frame. Position the fan or bulbs to direct warm air upward through the layers, ensuring even drying. If using bulbs, wrap them in a protective mesh to prevent direct contact with the mushrooms. Alternatively, a small thermostat-controlled heating pad can be placed at the bottom, covered with a heat-resistant barrier to diffuse the warmth evenly.

Add a top cover to retain heat and protect the mushrooms from dust or contaminants. Use a clear plastic sheet or lightweight mesh that fits securely over the frame, allowing moisture to escape while maintaining the internal temperature. Attach hinges or Velcro strips to make the cover easily removable for loading and unloading mushrooms. Ensure the cover is vented with small openings to prevent condensation buildup, which can hinder the drying process.

Finally, test the setup by placing a single layer of mushrooms inside and running the heating element for a short period. Monitor the temperature and airflow, making adjustments as needed to ensure optimal drying conditions. Once satisfied, expand to multiple layers, ensuring each tray or screen is evenly loaded to maintain consistent drying across all levels. This compact, portable mushroom dryer is now ready for use, providing an efficient and controlled environment for preserving your mushroom harvest.

Crafting Mushroom Capsules: A Step-by-Step DIY Guide for Beginners

You may want to see also

Frequently asked questions

You’ll need a wooden or plastic frame, mesh or wire racks, a heat source (like a light bulb or heating element), a thermometer, a fan for airflow, and insulation material to retain heat.

Use a thermostat or manually adjust the heat source to keep the temperature between 120°F and 140°F (49°C and 60°C). Monitor with a thermometer and ensure proper airflow.

Drying time varies but typically takes 6 to 12 hours, depending on mushroom thickness, humidity, and dryer efficiency. Check regularly for crispness.

Yes, a food dehydrator works well for drying mushrooms. Set it to 125°F to 135°F (52°C to 57°C) and place mushrooms on the trays for 6 to 12 hours.