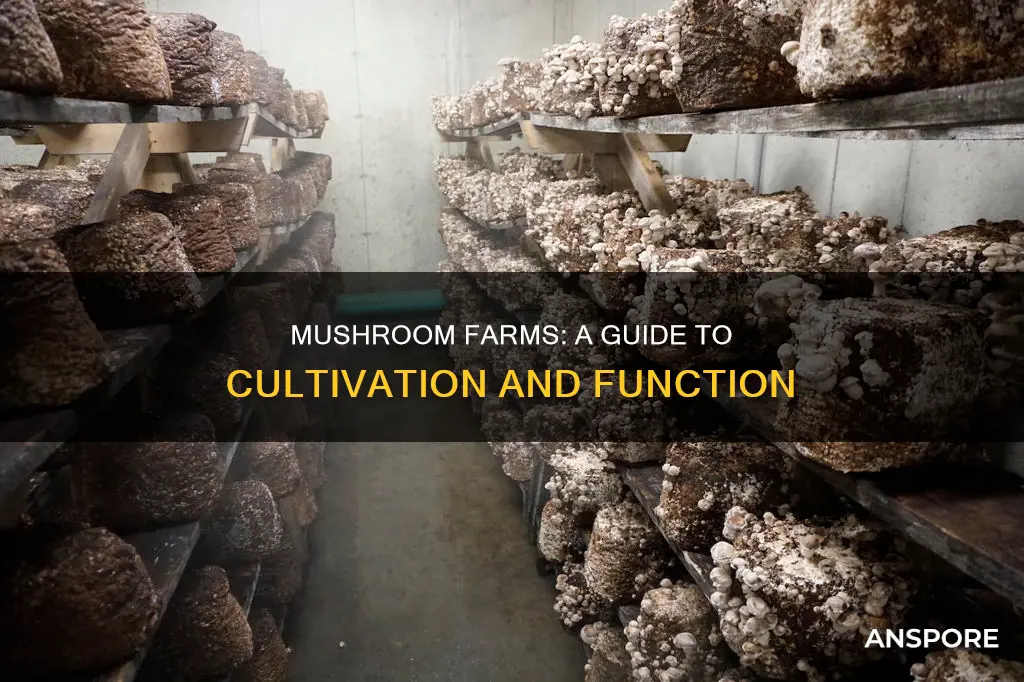

Mushroom farming, or fungiculture, is the cultivation of mushrooms for food, medicine, and other products. It is an environmentally friendly, sustainable, and space-efficient alternative to traditional agriculture. The process of mushroom farming can be broken down into five stages, from spawning to harvest. Mushrooms are grown in a substrate, which can include straw, wood chips, or even coffee grounds, and require specific temperature and humidity conditions to thrive. Harvest times vary depending on the species of mushroom, and each has its own indicators of maturity. Oyster mushrooms, for example, should be picked before the caps start to flatten. Overall, the process of mushroom farming is accessible to those interested, and small-scale operations can be profitable.

| Characteristics | Values |

|---|---|

| Mushroom farming method | Indoor or outdoor |

| Mushroom species | Oyster, Shiitake, etc. |

| Spawn | Mycelium propagated on grains or agar |

| Substrate | Straw, sawdust, wood chips, etc. |

| Temperature | 57° to 62°F |

| Humidity | Controlled, moisture added through mist or steam |

| Ventilation | Ducting installation |

| Harvesting | Every 3-5 days, for 35-42 days |

| Packaging | Non-waxed paper bags |

| Lighting | Not required, but can be used for harvesting |

Explore related products

$14.99

Spawn and substrate

Spawn is a blend of spores and nutrient sources like grains, straw, or wood chips. It acts as the mushroom equivalent of a sourdough starter in bread baking, providing initial nourishment that helps speed up the rest of the growing process. Commercial mushroom farmers purchase spawn from companies specialising in its manufacture. The spawn-making process involves sterilising a mixture of millet grain, water, and chalk. Rye, wheat, and other small grains may be substituted for millet.

Mushroom spawn is used to propagate mycelium, which is a network of thin, thread-like cells that make up the vegetative part of a fungus. Mycelium can be propagated on various grains or agars, and it is from this that mushrooms eventually grow.

The substrate is the growing medium in which the spawn is placed to initiate mushroom growth. The most popular substrate for growing gourmet edible mushrooms indoors is sterilised sawdust, either purchased as pre-inoculated blocks (ready-to-fruit) or prepared using spawn. Many other substrates can be used to grow mushrooms indoors, including straw, but these are not recommended for commercial production by industry leaders.

Oyster mushrooms, for example, are grown in a substrate that comprises sterilised wheat, paddy straw, and even used coffee grounds. They do not require much space compared to other crops, and the per-unit production and profit are comparatively higher. An ideal substrate will contain enough nitrogen and carbohydrates for rapid mushroom growth. Mushrooms metabolise complex carbohydrates in their substrate into glucose, which is then transported through the mycelium as needed for growth and energy.

How Mushrooms Dry: Techniques and Tips

You may want to see also

Harvesting

The timing of the harvest also follows a specific cycle. The terms "flush," "break," or "bloom" refer to the 3- to 5-day harvest periods during the cropping cycle, followed by a few days when no mushrooms are available for harvest. This cycle repeats itself, and harvesting can continue as long as mushrooms mature. The ideal air temperature during cropping is between 57° to 62°F, as it favours mushroom growth and deters pests.

To harvest oyster mushrooms, you twist the stem off as close to the growing block as possible just before the caps are fully uncurled. Oyster mushrooms are a popular crop due to their high per-unit production and profit, and they can be grown indoors in kits or columns, or outdoors on logs. Indoor growing provides the advantage of year-round production, higher yields, and less time between harvests.

After harvesting, mushrooms must be kept refrigerated at 35° to 45°F. To prolong shelf life, mushrooms should be stored in a non-waxed paper bag to allow them to "breathe" after harvest, as plastic bags can reduce airflow.

Mushroom Powder: Superfood or Super-Hype?

You may want to see also

Ventilation and humidity

Ventilation is essential for mushroom growing, and it is necessary to control humidity and temperature. Moisture can be added to the air by a cold mist, live steam, or by wetting the walls and floors. To remove moisture from the growing room, farmers can admit a greater volume of outside air, introduce drier air, or move the same amount of outside air and heat it to a higher temperature, as warmer air holds more moisture and thus lowers relative humidity.

Temperature control in a mushroom growing room is similar to temperature control in a home. Heat can originate from hot water circulated through pipes mounted on walls, or hot, forced air blown through a ventilation duct. Some mushroom farms are located in limestone caves, where the rock acts as a heating and cooling surface depending on the time of year.

Indoor mushroom cultivation allows for control of light, temperature, and humidity, while excluding contaminants and pests, enabling consistent production. This is why indoor cultivation is more common than outdoor farms, despite the latter being more cost-effective to set up.

The Magic of Growing Button Mushrooms

You may want to see also

Explore related products

$29.99

Pests and diseases

Mushrooms are susceptible to a number of pests and diseases that can negatively impact crop quality and yield. The most common fungal disease among commercially cultivated white button mushrooms is Verticillium dry bubble, which is characterised by a globe-like mass of mushroom tissue. Green mold is another prevalent disease, typically found on the casing surface of Agaricus, Pleurotus, and shiitake mushrooms. It is caused by poor hygiene and poorly prepared growth substrates. Bacterial blotch disease, caused by the Pseudomonas tolaasii bacterium, is also common and results in brown, sunken lesions on the mushroom cap.

Mushrooms are also susceptible to pests such as mites, sciarid flies, phorid flies, and fungus gnats. These pests can directly damage the mushrooms, leaving holes or bite marks, or spread diseases. Nematodes are another common pest, found in almost all soils and straw and manure. They can cause the death of the mycelium and subsequent yield losses.

To prevent and control pests and diseases, mushroom farmers can implement a range of strategies. Proper sterilization and environmental controls are key preventative measures. This includes proper pasteurization of the compost, planting beds, and equipment, as well as maintaining the appropriate temperature and humidity levels for mushroom growth. Integrated Pest Management (IPM) practices, such as exclusion techniques and the use of disinfectants and sanitizers, can also help prevent and reduce the spread of pests. Biological controls, such as introducing natural predators like ladybugs, lacewings, and parasitic wasps, can effectively control pests without the use of toxic chemicals. Companion plantings, such as aromatic herbs, flowers, or vegetables, can also be used to repel insect pests and attract beneficial insects.

Mushroom Mystery: Unwanted Guests in My Terrarium

You may want to see also

Storage

Storing mushrooms is a crucial part of the mushroom farming process. Freshly harvested mushrooms should be refrigerated at 34° to 45°F within an hour of picking. It is important to allow the mushrooms to breathe by storing them in a non-waxed paper bag or a container that allows airflow. Stainless steel hotel pans are also a good option for storage, with paper towels at the bottom to control moisture and the top left open for airflow.

To prolong the shelf life of mushrooms, it is important to prevent them from drying out and losing weight. Mushrooms can be dried in a dehydrator, an oven, or the sun, but this process should be carefully controlled to avoid over-drying or contamination by insects. Dried shiitake mushrooms, for example, should be stored in sealed polyethylene bags in a dry, cool, dark place.

Freezing is another option for storing mushrooms, but they must be treated to stop maturation first by steaming or sauteing. Soaking mushrooms in a mixture containing lemon juice or citric acid before steaming can help reduce darkening. After cooling and draining, the mushrooms should be packaged with a 1/2-inch headspace and placed in the freezer for fast cooling.

On a commercial mushroom farm, the harvested mushrooms are typically placed into cold storage, and the substrate can be used for additional fruiting or composted. Some farms focus on selling ready-to-fruit blocks, which require storage in a walk-in cooler before being brought into fruiting conditions over a 3-4 week schedule.

Overall, proper storage methods are essential to maintaining the quality and prolonging the shelf life of mushrooms, whether they are fresh, dried, or frozen.

Microdosing Mushrooms: A Natural Remedy for Depression?

You may want to see also

Frequently asked questions

Mushroom farming involves several steps, including preparing spawn, controlling light, temperature and humidity, harvesting, and packaging.

Mushrooms require specific conditions to grow, such as controlled light, temperature and humidity. The ideal temperature range is between 57° to 62°F (20° to 24°C), and humidity can be adjusted using various methods.

Mushroom farming offers several advantages over traditional agriculture, including environmental sustainability, efficient space usage, low labour costs, and the ability to yield profits within a few weeks. Additionally, it is a popular choice for consumers seeking locally sourced food options.