Preventing spores from germinating in food is crucial for ensuring food safety and extending shelf life, as spores from bacteria like *Clostridium botulinum* and *Bacillus cereus* can survive harsh conditions and cause foodborne illnesses when they germinate and multiply. Effective strategies include proper heat treatment, such as pasteurization or sterilization, to destroy spores, maintaining low temperatures during storage to inhibit germination, controlling water activity through dehydration or the addition of salts and sugars, and using preservatives like sodium benzoate or nitrites to suppress spore activation. Additionally, minimizing oxygen exposure through vacuum packaging or modified atmosphere packaging can further prevent spore germination, ensuring that food remains safe and free from spoilage.

| Characteristics | Values |

|---|---|

| Temperature Control | Keep food below 4°C (39°F) or above 60°C (140°F) to inhibit spore germination. Spores are most likely to germinate between 25°C and 40°C (77°F and 104°F). |

| pH Level | Maintain food pH below 4.6 to prevent spore germination. Acidic conditions inhibit spore growth. |

| Water Activity (aw) | Reduce water activity to below 0.92. Spores require moisture to germinate, so controlling water content is crucial. |

| Oxygen Availability | Use vacuum packaging or modified atmosphere packaging (MAP) to reduce oxygen levels, as many spores require oxygen for germination. |

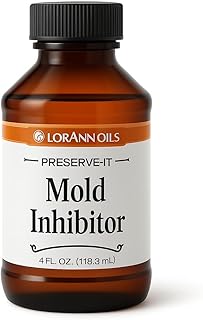

| Preservatives | Add preservatives like sodium benzoate, sorbic acid, or nitrites to inhibit spore germination and growth. |

| Heat Treatment | Apply heat treatments such as pasteurization, sterilization (e.g., autoclaving), or thermal processing to destroy spores or prevent germination. |

| Irradiation | Use ionizing radiation to inactivate spores and prevent germination, commonly used in spices and herbs. |

| Fermentation | Encourage the growth of beneficial microorganisms through fermentation, which can create conditions unfavorable for spore germination. |

| Hurdle Technology | Combine multiple preservation methods (e.g., heat, pH, aw, preservatives) to create synergistic effects that prevent spore germination. |

| Proper Storage | Store food in clean, dry, and airtight containers to minimize contamination and moisture, which can trigger spore germination. |

| Avoid Cross-Contamination | Prevent spores from entering food by maintaining hygiene, using clean equipment, and separating raw and cooked foods. |

| Chemical Treatments | Use antimicrobial agents like hydrogen peroxide or ozone to inhibit spore germination in specific food processing steps. |

Explore related products

What You'll Learn

- Control Temperature: Keep food below 4°C or above 60°C to inhibit spore germination

- Reduce Moisture: Use dehydration or dry storage to limit water availability for spores

- Adjust pH Levels: Acidic or alkaline environments can prevent spore activation in food

- Add Preservatives: Incorporate chemicals like sodium benzoate to suppress spore growth

- Proper Packaging: Use airtight, vacuum-sealed, or modified atmosphere packaging to block spore germination

Control Temperature: Keep food below 4°C or above 60°C to inhibit spore germination

Spores, the resilient survival forms of certain bacteria, can withstand extreme conditions and germinate when conditions are favorable, leading to food spoilage or foodborne illnesses. Temperature control is a critical strategy to prevent spore germination, as it directly influences the metabolic activity of these microorganisms. By maintaining food temperatures below 4°C or above 60°C, you create an environment hostile to spore activation, effectively halting their growth and potential hazards.

Understanding the Temperature Zones:

Imagine a thermal spectrum, with a danger zone nestled between 4°C and 60°C. Within this range, spores find the warmth and moisture they need to awaken from dormancy. Below 4°C, metabolic processes slow down significantly, rendering spores inactive. Above 60°C, the heat becomes destructive, denaturing proteins and disrupting cellular structures, effectively killing spores.

This principle underpins food safety guidelines worldwide. Refrigeration, aiming for temperatures below 4°C, is a cornerstone of food preservation, slowing down bacterial growth and keeping spores dormant. Conversely, cooking food to temperatures exceeding 60°C ensures the destruction of any vegetative bacteria and spores present.

Practical Application: A Two-Pronged Approach

Implementing this temperature control strategy involves a two-pronged approach:

- Chilling: Promptly refrigerate perishable foods within two hours of purchase or preparation. Use airtight containers to prevent cross-contamination and maintain consistent temperatures throughout the refrigerator. Aim for a refrigerator temperature of 3°C or below.

- Heating: Cook foods thoroughly, ensuring internal temperatures reach at least 74°C (165°F) for poultry, 71°C (160°F) for ground meats, and 63°C (145°F) for whole meats. Use a food thermometer to ensure accuracy. Reheat leftovers to at least 74°C (165°F) before consumption.

Beyond the Basics: Considerations and Cautions

While temperature control is a powerful tool, it's not foolproof. Some spores, like those of Clostridium botulinum, can survive boiling temperatures. Additionally, temperature fluctuations can create opportunities for spore germination. Avoid leaving food at room temperature for extended periods, and never partially cook food with the intention of finishing it later.

Remember, temperature control is just one aspect of food safety. Combining it with proper hygiene, safe food handling practices, and careful storage is crucial for preventing foodborne illnesses. By understanding the role of temperature in spore germination and implementing these practical measures, you can significantly reduce the risk of food spoilage and protect yourself and others from potential harm.

How to Play Spore on LAN: A Step-by-Step Multiplayer Guide

You may want to see also

Reduce Moisture: Use dehydration or dry storage to limit water availability for spores

Spores, the resilient survival structures of certain bacteria, fungi, and plants, can withstand harsh conditions, including extreme temperatures and chemicals. However, they require moisture to germinate and pose a threat to food safety. Depriving them of water is a proven strategy to keep them dormant, making dehydration and dry storage essential techniques in food preservation.

The Science Behind Dehydration: Dehydration involves removing moisture from food, creating an environment inhospitable to spore germination. When water activity (aw) in a product drops below 0.6, most spores enter a state of dormancy. This process can be achieved through various methods, including sun drying, oven drying, or using specialized dehydrators. For instance, drying fruits and vegetables at temperatures between 130-140°F (54-60°C) can reduce their moisture content to levels that inhibit spore growth.

Practical Dehydration Techniques: To effectively dehydrate food, follow these steps: 1. Prepare the food by washing and slicing it into uniform pieces. 2. Arrange the pieces on dehydrator trays, ensuring adequate air circulation. 3. Set the dehydrator to the recommended temperature and time, typically 12-24 hours for most fruits and vegetables. 4. Check for doneness by testing the food's flexibility; it should be leathery but not brittle. 5. Store the dehydrated food in airtight containers in a cool, dry place.

Dry Storage Strategies: Proper storage is crucial to maintaining the low-moisture environment achieved through dehydration. Use glass jars or plastic containers with tight-fitting lids to store dehydrated foods. For added protection, include desiccant packets, such as silica gel, to absorb any residual moisture. Regularly inspect stored items for signs of spoilage, and discard any packages with visible mold or off-odors.

Comparative Advantages: Dehydration and dry storage offer several benefits over other preservation methods. Unlike canning or freezing, dehydration requires no special equipment or energy-intensive processes, making it accessible and cost-effective. Additionally, dehydrated foods are lightweight and have a long shelf life, often lasting for years when stored properly. This method is particularly useful for preserving seasonal produce, ensuring a year-round supply of nutritious foods while minimizing the risk of spore-related contamination.

Cautions and Limitations: While dehydration is effective against spore germination, it's not a foolproof method. Some spores may still survive, especially in low-acid foods. To mitigate this risk, combine dehydration with other preservation techniques, such as fermentation or the addition of natural preservatives like salt or vinegar. Furthermore, always follow established food safety guidelines, including proper hand hygiene and sanitation practices, to prevent contamination during the dehydration and storage processes. By understanding the principles of moisture control and implementing these strategies, you can significantly reduce the likelihood of spore germination in your food.

Ozone Machines vs. Mold Spores: Effective Solution or Myth?

You may want to see also

Adjust pH Levels: Acidic or alkaline environments can prevent spore activation in food

Spores, the resilient survival forms of certain bacteria, can withstand extreme conditions, making them a persistent threat to food safety. However, their ability to germinate and cause spoilage or illness is not invincible. One effective strategy to prevent spore activation is manipulating the pH levels of the food environment.

The Science Behind pH and Spore Inhibition:

Acidic or alkaline conditions can disrupt the delicate balance required for spore germination. Spores are particularly sensitive to pH extremes during the early stages of germination. When exposed to highly acidic environments (low pH), the spore's inner membrane becomes more permeable, leading to the leakage of essential ions and nutrients, ultimately inhibiting growth. On the other hand, alkaline conditions (high pH) can denature proteins and disrupt the spore's metabolic processes, preventing successful germination.

Practical Application in Food Preservation:

To harness the power of pH adjustment, food manufacturers and home preservers can employ specific techniques. For instance, adding organic acids like citric, acetic, or lactic acid to food products can lower the pH, creating an inhospitable environment for spores. A common example is the use of vinegar (acetic acid) in pickling, which not only adds flavor but also inhibits spore germination, ensuring the safety of preserved vegetables. Similarly, in the dairy industry, the addition of lactic acid bacteria during fermentation lowers the pH of milk, preventing the growth of spoilage spores.

Dosage and Safety Considerations:

The effectiveness of pH adjustment lies in precision. The target pH range for spore inhibition typically falls below 4.6 for acidic conditions and above 9.0 for alkaline environments. However, it's crucial to note that extreme pH levels can also affect the sensory qualities of food, such as taste and texture. Therefore, finding the optimal pH range that ensures spore inhibition without compromising food quality is essential. For instance, in fruit preserves, a pH of around 3.5 is often targeted, achieved through the natural acidity of fruits or the addition of citric acid, ensuring both safety and palatability.

A Comparative Advantage:

Compared to other preservation methods, pH adjustment offers a natural and cost-effective solution. Unlike thermal processing, which can alter food texture and nutrient content, pH manipulation preserves the sensory attributes of food while targeting spores specifically. This method is particularly advantageous for heat-sensitive products, such as certain fruits and dairy items, where traditional sterilization techniques may not be feasible. By understanding the pH preferences of different spores, food producers can tailor their preservation strategies, ensuring both safety and consumer satisfaction.

In the battle against food spoilage and contamination, adjusting pH levels emerges as a powerful tool. This technique showcases how a simple scientific principle can be harnessed to create effective and natural preservation methods, ensuring the safety and quality of our food supply.

Can Agar Plates Accurately Detect C. Diff Spores in Lab Tests?

You may want to see also

Explore related products

Add Preservatives: Incorporate chemicals like sodium benzoate to suppress spore growth

Spores, particularly those from bacteria like Clostridium botulinum, can survive harsh conditions and germinate under favorable environments, posing a significant risk to food safety. To combat this, the strategic use of preservatives like sodium benzoate emerges as a potent solution. This chemical, commonly recognized as E211, is a sodium salt of benzoic acid, widely utilized in the food industry for its antimicrobial properties. Its effectiveness lies in disrupting the cellular functions of microorganisms, including spores, by inhibiting their energy production and metabolic processes.

Incorporating sodium benzoate into food products requires careful consideration of dosage and application. The FDA permits its use at levels up to 0.1% by weight in acidic foods, where it is most effective due to its reliance on low pH environments (below 4.5) to convert into benzoic acid, its active form. For instance, in beverages like sodas or fruit juices, a concentration of 0.05% to 0.1% is typically sufficient to suppress spore germination and growth. However, in less acidic foods, combining sodium benzoate with other preservatives or adjusting the product’s pH may be necessary to enhance its efficacy.

While sodium benzoate is generally recognized as safe (GRAS) by regulatory bodies, its use is not without considerations. Over-reliance on chemical preservatives can lead to consumer concerns about artificial additives, prompting the need for transparency in labeling. Additionally, some studies suggest potential health risks when sodium benzoate is combined with certain food colorings, forming benzene, a known carcinogen. Manufacturers must therefore adhere to recommended dosages and avoid pairing it with incompatible ingredients to mitigate such risks.

Practical implementation of sodium benzoate involves more than just adding it to a product. It requires thorough testing to ensure compatibility with other ingredients and stability over the product’s shelf life. For instance, in baked goods, sodium benzoate can be incorporated into the dough or batter, but its effectiveness may diminish over time due to exposure to heat. In such cases, combining it with heat-stable preservatives or applying it post-baking could yield better results. By understanding its mechanisms and limitations, sodium benzoate becomes a valuable tool in the arsenal against spore germination, ensuring safer, longer-lasting food products.

Vaping and Fungus: Uncovering the Truth About Throat Spores

You may want to see also

Proper Packaging: Use airtight, vacuum-sealed, or modified atmosphere packaging to block spore germination

Spores, the resilient survival structures of certain bacteria, can withstand extreme conditions and lie dormant until they find the right environment to germinate. In food, this means spoilage, potential illness, and wasted resources. Proper packaging acts as a critical line of defense, disrupting the conditions spores need to awaken and multiply. Airtight, vacuum-sealed, or modified atmosphere packaging (MAP) are powerful tools in this fight, each working in distinct ways to create an inhospitable environment for spore germination.

Airtight packaging, the simplest and most common method, eliminates oxygen exposure, a crucial factor for many spore-forming bacteria. By creating a hermetic seal, it deprives spores of the oxygen they need for metabolic processes, effectively stalling germination. This method is particularly effective against aerobic bacteria like *Bacillus cereus*, a common culprit in foodborne illness. Vacuum sealing takes this a step further by removing air entirely, creating a high-pressure environment that further inhibits spore activation. This method is widely used in packaging meats, cheeses, and other perishable items, extending their shelf life significantly.

Modified atmosphere packaging (MAP) goes beyond simply removing oxygen. It involves replacing the air inside the package with a carefully controlled gas mixture, typically consisting of carbon dioxide, nitrogen, and sometimes oxygen in specific ratios. This tailored atmosphere can directly inhibit spore germination by creating conditions that are unfavorable for bacterial growth. For example, high carbon dioxide levels can lower the pH of the food, making it more acidic and hostile to spore activation. MAP is particularly effective for fresh produce, baked goods, and ready-to-eat meals, where maintaining quality and safety is paramount.

While these packaging methods are powerful tools, they are not foolproof. Proper implementation is crucial. Any breaches in the packaging, even microscopic ones, can compromise its effectiveness. Additionally, some spore-forming bacteria, like *Clostridium botulinum*, can thrive in anaerobic environments, making MAP potentially counterproductive in certain cases. Therefore, combining proper packaging with other preservation techniques like refrigeration, pasteurization, or fermentation is essential for comprehensive food safety.

Ultimately, airtight, vacuum-sealed, and modified atmosphere packaging are not just about keeping food fresh; they are about safeguarding health and preventing foodborne illnesses. By understanding the specific needs of spore-forming bacteria and tailoring the packaging environment accordingly, we can effectively block spore germination and ensure the safety and quality of our food supply.

Can Mold and Spores Survive Underwater? Exploring Aquatic Microbial Life

You may want to see also

Frequently asked questions

Effective methods include proper heating (e.g., boiling or pressure cooking) to kill spores, maintaining low temperatures (refrigeration or freezing) to inhibit growth, and controlling moisture levels through drying or using preservatives like salt or sugar.

Some spores, like those from *Clostridium botulinum*, can survive boiling temperatures. To ensure elimination, use methods like pressure cooking (121°C/250°F for 3 minutes) or commercial sterilization processes, which are specifically designed to destroy spores.

Spores generally struggle to germinate in highly acidic environments (pH below 4.6). Using acidic ingredients like vinegar or citrus juices, or fermenting foods to lower pH, can help prevent spore germination and ensure food safety.

![Shiragiku Koji [Aspergillus oryzae] Spores Gluten-Free Vegan - 200g/8oz](https://m.media-amazon.com/images/I/81hDfq6QDPL._AC_UL320_.jpg)