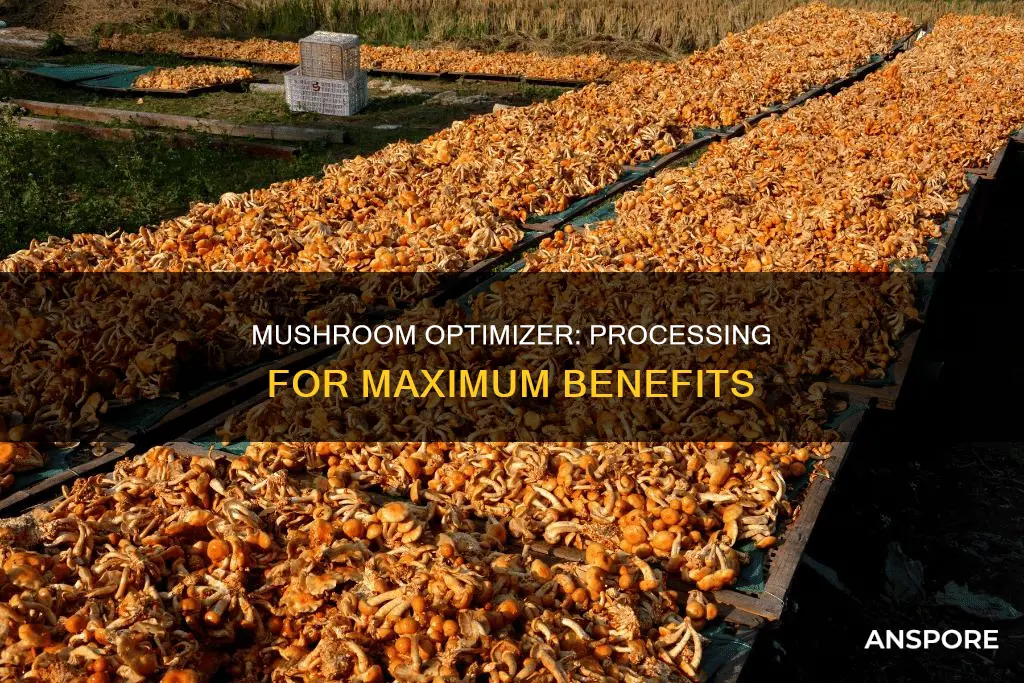

Mushrooms are a well-known food source with a pleasant taste and medicinal benefits. They are increasingly being used in soups, meats, and other processed foods. The global mushroom industry has seen remarkable growth due to its nutritional benefits, increasing market value, and rising consumer demand. Various preservation techniques are employed to extend shelf life and preserve quality, including drying, freezing, canning, high-pressure processing, and modified atmosphere packaging. Cutting-edge technologies such as nuclear magnetic resonance and spectroscopy are also being used to improve post-harvest processing and maintain sensory and nutritional properties.

| Characteristics | Values |

|---|---|

| Preservation Techniques | Drying, freezing, canning, high-pressure processing, modified atmosphere packaging, pickling, steaming, freeze-drying, vacuum freeze-drying, heat pump dehumidifier drying |

| Post-Harvest Processing Techniques | Nuclear magnetic resonance, spectroscopy, automation |

| Pre-Harvest Factors Affecting Quality | Genotype, geographical origin |

| Post-Harvest Factors Affecting Quality | Handling, processing |

| Storage Conditions | Room temperature (1-3 days), refrigerator (8-10 days) |

| Nutritional Benefits | Low sugar and salt content, rich in vitamin D, high quantities of vitamins, minerals, proteins, and dietary fiber |

| Medicinal Benefits | Antioxidant activity, bioactive metabolites with medicinal and nutraceutical properties |

| Use Cases | Soups, meats, processed foods, meat substitutes, ingredients in plant-based sausage, nuggets, salami, wheat |

Explore related products

What You'll Learn

- Pickling: Mushrooms are washed, sliced, and blanched in saltwater, then bottled with vinegar, brine, sugar, and spices

- Drying: Freeze-drying is an effective preservation method, maintaining quality and nutritional value

- Fermentation: This process yields medicinal and nutritional metabolites

- Innovative technologies: Nuclear magnetic resonance and spectroscopy improve post-harvest processing

- Preservation techniques: Canning, freezing, and high-pressure processing extend shelf life and preserve quality

Pickling: Mushrooms are washed, sliced, and blanched in saltwater, then bottled with vinegar, brine, sugar, and spices

Pickling is a popular preservation method for mushrooms, which helps maintain their nutritional value and prolongs their shelf life. The pickling process for mushrooms involves several steps, starting with washing the mushrooms to remove any dirt or debris. After cleaning, the mushrooms are sliced into uniform pieces, ensuring consistent pickling and a more aesthetically pleasing final product. The sliced mushrooms are then blanched in saltwater, typically a 3% salt solution, which helps to preserve their texture and flavour.

Once the mushrooms are prepared, they are bottled or jarred with a brine solution, vinegar, sugar, and various spices. The brine solution is typically made with water and salt, providing a salty flavour and further preserving the mushrooms. Vinegar, often a key ingredient in pickling, adds a tangy flavour and helps to inhibit bacterial growth, enhancing preservation. Sugar is also added to the mixture, balancing the salty and tangy flavours with a touch of sweetness. Lastly, spices are included to enhance the flavour profile and aroma of the pickled mushrooms. Common spices used in pickling include black peppercorns, bay leaves, mustard seeds, coriander seeds, and red pepper flakes, among others.

The combination of vinegar, brine, sugar, and spices not only enhances the flavour of the mushrooms but also acts as a preservative, inhibiting microbial growth and extending the shelf life of the product. The specific proportions and types of ingredients used in the pickling solution can vary depending on regional preferences and the desired flavour profile. Some recipes may also include additional ingredients such as herbs, garlic, or other aromatics to further enhance the flavour of the pickled mushrooms.

Additionally, combining drying and pickling methods can further extend the shelf life of mushrooms while providing a meat substitute suitable for soups and stews. Before the pickling process, mushrooms can be pre-treated with an ascorbate solution, resulting in optimal chemical composition and improved sensory properties. This combination of drying and pickling techniques can effectively preserve mushrooms for an extended period.

Mushrooms: Nature's Plastic-Eating Superheroes

You may want to see also

Drying: Freeze-drying is an effective preservation method, maintaining quality and nutritional value

Drying is a popular preservation technique used to extend the shelf life of mushrooms. Of the various drying methods, freeze-drying is particularly effective in maintaining the quality and nutritional value of mushrooms.

Mushrooms are highly perishable, with a very short shelf life of 1-3 days at room temperature and 8-10 days in the refrigerator. Their quality deteriorates rapidly after harvest due to their high water content, rapid respiratory rate, and lack of cuticular structure. Therefore, drying is an essential step in preserving mushrooms for longer periods.

Freeze-drying, also known as lyophilization, is a process that involves freezing the mushrooms and then removing the ice through sublimation under low pressure. This method minimizes the loss of quality and nutritional content compared to other drying techniques. Optimal freeze-drying parameters can produce dried mushrooms with chemical characteristics similar to those of raw mushrooms. For example, freeze-drying can retain up to 86% of the ascorbic acid content in mushrooms, according to a study by Giri and Prasad (2007).

Freeze-drying is especially suitable for mushrooms as it maintains the nutrients and original shape of various mushroom species. For instance, Luo et al. (2022) and Xu et al. (2021) found that vacuum freeze-drying produces high-quality dehydrated shiitake, Pleurotus eryngii, and Agaricus bisporus mushrooms. This technique helps extend the shelf life of mushrooms while preserving their sensory and nutritional properties.

Combining drying with other preservation methods, such as pickling, can further enhance the shelf life and provide meat substitutes for soups and stews. Pickling involves washing, slicing, and blanching mushrooms in salted water before transferring them to jars or bottles with brine, vinegar, sugar, and spices. Pretreatment with an ascorbate solution before pickling can also help achieve optimal chemical composition and sensory properties.

Nitrogen Fertilizer: Friend or Foe to Mushrooms?

You may want to see also

Fermentation: This process yields medicinal and nutritional metabolites

Mushrooms are a well-known food source, valued for their pleasant taste, low sugar and salt content, and rich vitamin D content. They are also known for their medicinal properties. However, their commercialization is challenging due to their perishability and the fluctuations in their chemical composition in response to factors such as genotype, geographical origin, and pre- and post-harvest handling.

To address these challenges, various preservation techniques are employed in the mushroom industry, including traditional drying methods such as hot air, microwave, vacuum freeze, and infrared drying. Among these methods, hot air drying is the simplest and most cost-efficient, enhancing the unique flavor of shiitake mushrooms. On the other hand, vacuum freeze drying maintains the nutrients and original shape of various mushroom species, resulting in high-quality dehydrated mushrooms. Heat pump dehumidifier drying has been identified as the optimal process for producing top-quality mushroom products.

Additionally, pickling mushrooms with spices, brine solution, and vinegar is a straightforward method to preserve their nutritional value and extend their shelf life. Combining drying and pickling methods can further prolong shelf life while providing a meat substitute suitable for soups and stews. The pickling process involves washing, slicing, and blanching mushrooms in salted water before transferring them to jars or bottles with brine, vinegar, sugar, and spices.

While these traditional methods have their benefits, fermentation is a process that yields medicinal and nutritional metabolites. Mushroom mycelia exhibit significant antioxidant activity and can enhance the levels of beneficial compounds in other foods, such as fermented soybeans. The fermentation process produces bioactive metabolites with medicinal and nutraceutical properties. Additionally, mushroom fermentation can be used to create a fully fermented bacterial cellulose membrane that incorporates mushroom fermentation extract, resulting in natural, safe, and multifunctional products. Furthermore, mushroom fermentation can be employed to produce bio-organic fertilizers, optimizing fermentation conditions for microorganisms and reducing fermentation time.

Mushroom Consumption: Weight Gain or Loss?

You may want to see also

Explore related products

Innovative technologies: Nuclear magnetic resonance and spectroscopy improve post-harvest processing

Nuclear Magnetic Resonance (NMR) and spectroscopy are innovative technologies that are revolutionizing mushroom processing, particularly in post-harvest treatment.

NMR is a versatile technique that can be applied to a wide range of liquid and solid matrices without altering the sample or creating hazardous waste. It is a non-invasive and non-destructive method that provides highly resolved spatial information about the distribution and magnetic environment of water in soft tissues. This makes it particularly useful for examining the quality, histology, histochemistry, and structural characteristics of samples.

Spectroscopy, a type of NMR technology, is a robust method for rapidly analyzing mixtures at the molecular level without requiring separation or purification steps. It is commonly used by chemists and biochemists to identify molecular structures and study chemical reactions. Spectroscopy has been applied in food science to analyze the phenolic compounds and triterpenic acids in oregano, detect refined olive oil adulteration, and determine the composition of extra virgin olive oils.

Combining NMR relaxation spectroscopy and magnetic resonance imaging (MRI) techniques has proven effective in characterizing the aging and salting effects on caviar during storage. MRI, another type of NMR technology, is widely used in medical radiology to obtain soft tissue images for diagnostics. In the context of mushroom processing, MRI can provide visual observations of the interior of mushrooms, offering information about their chemical composition and internal structure. This is especially useful for monitoring compositional and structural modifications that occur during post-harvest processing.

The application of NMR and MRI technologies in mushroom processing helps to maintain the sensory properties, nutritional content, and quality of mushrooms. These innovative techniques contribute to advancements in mushroom production and quality worldwide, supporting the growing demand for mushrooms in various food products.

Psychedelic Mushrooms: Medication Interactions and Side Effects

You may want to see also

Preservation techniques: Canning, freezing, and high-pressure processing extend shelf life and preserve quality

Canning, freezing, and high-pressure processing are effective preservation techniques that extend the shelf life and maintain the quality of mushrooms. These methods involve specific procedures to ensure food safety and preserve the sensory qualities of the mushrooms.

Canning mushrooms requires careful preparation and processing. The process typically involves selecting and cleaning the mushrooms, cutting them into appropriate sizes, and boiling or steaming them before packing them into hot jars with a salt solution. The jars are then sealed and processed in a pressure cooker or boiling water canner for a specified duration. The canning process helps to kill microorganisms and prevent spoilage, preserving the mushrooms for extended periods.

Freezing is another popular preservation method for mushrooms. It involves cleaning and preparing the mushrooms, heat treatment through steam blanching or sautéing, and then cooling them in ice water before freezing. Freezing mushrooms individually or in small batches helps maintain their quality. Freezing is a convenient way to store mushrooms for future use, and frozen mushrooms can be easily incorporated into various dishes.

High-pressure processing (HPP) is a non-thermal technology widely used in the food industry, including for mushrooms. HPP employs mechanical forces to apply high pressure to food products, inactivating microorganisms and extending shelf life. This method effectively preserves the sensory and nutritional qualities of mushrooms while ensuring food safety. HPP is an innovative technique that contributes to advancements in mushroom production and quality worldwide.

Additionally, other preservation techniques, such as drying, pickling, and modified atmosphere packaging, are also employed in the mushroom industry. These methods offer alternative ways to extend the shelf life of mushrooms and maintain their nutritional content. Overall, the choice of preservation technique depends on various factors, including safety, quality, and convenience.

Mushroom Handling: Avoiding Bruises and Damage

You may want to see also

Frequently asked questions

Traditional methods of processing mushrooms include pickling, drying, freezing, canning, and high-pressure processing.

Innovative techniques in mushroom processing include nuclear magnetic resonance, spectroscopy, and automation. These methods help to maintain sensory properties, nutritional content, and improve efficiency.

Metabolomics is a technique used to understand how mushroom metabolites respond to various pre- and post-harvest conditions such as genotype, storage condition, drying, and packaging. This helps to optimize the quality of culinary mushrooms by clarifying the impact of metabolite changes on their physicochemical and organoleptic profiles, including color, aroma, taste, and flavor.

Freeze-drying is an effective method for preserving mushrooms while maintaining their nutritional value. It can be used alone or in combination with other processing methods. Freeze-drying produces high-quality dehydrated mushrooms that closely resemble the chemical characteristics of the raw material.