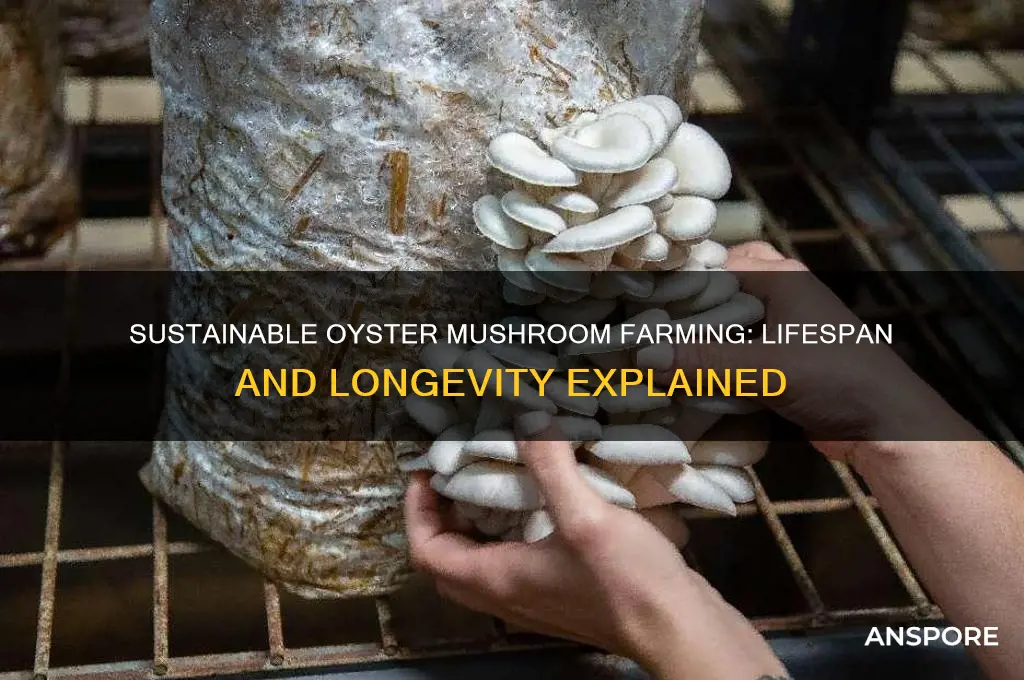

Oyster mushroom farming has gained popularity due to its relatively low startup costs and high yield potential, but understanding the lifespan of such a farm is crucial for long-term planning. Typically, an oyster mushroom farm can last anywhere from 1 to 5 years, depending on various factors such as the growing environment, substrate quality, and disease management practices. Indoor farms with controlled conditions often outlast outdoor setups, as they are less susceptible to pests and weather fluctuations. Additionally, the choice of substrate—whether straw, sawdust, or coffee grounds—plays a significant role in determining the farm's productivity and longevity. Proper maintenance, including regular cleaning and monitoring for contaminants, can significantly extend the farm's operational life, ensuring consistent harvests and a sustainable income stream.

| Characteristics | Values |

|---|---|

| Substrate Lifespan | 1-3 months (depends on substrate type and environmental conditions) |

| Fruiting Cycles | 2-4 flushes (harvests) per substrate block |

| Time Between Flushes | 7-14 days |

| Total Farm Lifespan | 6-12 months (if substrate is replenished and conditions are optimal) |

| Optimal Temperature Range | 55-75°F (13-24°C) for fruiting |

| Humidity Requirement | 80-95% during fruiting |

| Substrate Degradation | Begins after 2-3 months, reducing yield |

| Reusability of Substrate | Limited; often composted after use |

| Factors Affecting Lifespan | Temperature, humidity, contamination, substrate quality |

| Commercial Farm Rotation | 6-12 months (new substrate introduced periodically) |

Explore related products

What You'll Learn

- Initial Setup Lifespan: How long does the initial oyster mushroom farm setup typically last

- Substrate Durability: What is the lifespan of the substrate used in oyster mushroom farming

- Harvest Cycles: How many harvest cycles can an oyster mushroom farm sustain before decline

- Environmental Factors: How do temperature, humidity, and light affect the longevity of an oyster mushroom farm

- Maintenance Impact: Does regular maintenance extend the operational lifespan of an oyster mushroom farm

Initial Setup Lifespan: How long does the initial oyster mushroom farm setup typically last?

The initial setup of an oyster mushroom farm is a critical phase that lays the foundation for the entire operation. Typically, the lifespan of the initial setup can vary depending on several factors, including the materials used, environmental conditions, and maintenance practices. On average, a well-constructed initial setup can last anywhere from 6 months to 2 years before requiring significant upgrades or replacements. This duration is largely influenced by the choice of growing medium, substrate containers, and the overall infrastructure of the farm.

One of the key components of the initial setup is the substrate containers, which are often made from materials like plastic bags, buckets, or trays. High-quality, durable plastic bags can last through multiple grow cycles, typically up to 1-2 years, before showing signs of wear and tear. However, cheaper or thinner materials may degrade faster, especially when exposed to moisture and temperature fluctuations. Proper handling and cleaning between cycles can significantly extend the lifespan of these containers.

Another important aspect is the growing environment, which includes structures like grow rooms, tents, or outdoor beds. If the farm is set up indoors, the infrastructure—such as shelving units, humidity control systems, and ventilation—can last several years with minimal maintenance. Outdoor setups, however, may face more rapid degradation due to weather exposure. For instance, wooden beds or frames might last only 1-2 years before rotting, while metal structures can endure for 5 years or more with rust prevention measures.

The substrate itself, often a mixture of straw, sawdust, or coffee grounds, is a consumable component and does not contribute to the lifespan of the setup. However, the methods and equipment used to pasteurize or sterilize the substrate can impact longevity. Autoclaves or steamers, for example, can last 5-10 years if maintained properly, ensuring consistent substrate preparation throughout the farm’s initial setup phase.

Finally, the lifespan of the initial setup is also tied to the farmer’s ability to manage pests, diseases, and contamination. Regular sanitation practices, such as cleaning tools and surfaces, can prevent the buildup of harmful pathogens that might otherwise shorten the setup’s usability. By investing in quality materials and adopting rigorous maintenance routines, farmers can maximize the lifespan of their initial oyster mushroom farm setup, ensuring productivity and efficiency for at least 1-2 years before major overhauls are needed.

Fresh Portobello Mushrooms Shelf Life: Storage Tips for Maximum Freshness

You may want to see also

Substrate Durability: What is the lifespan of the substrate used in oyster mushroom farming?

The lifespan of the substrate used in oyster mushroom farming is a critical factor that directly influences the overall productivity and longevity of the farm. Substrates, which are the materials on which mushrooms grow, typically consist of agricultural by-products like straw, sawdust, or coffee grounds. The durability of these substrates varies depending on several factors, including the type of material, environmental conditions, and the mushroom cultivation technique employed. Generally, a well-prepared substrate can support multiple flushes of oyster mushrooms, but its effectiveness diminishes over time due to nutrient depletion and degradation.

For straw-based substrates, which are commonly used for oyster mushrooms, the lifespan typically ranges from 2 to 4 months. During this period, the substrate can produce 2 to 3 flushes of mushrooms, with each flush occurring approximately 10 to 14 days apart. After the final flush, the substrate begins to break down, losing its structural integrity and nutrient content. At this point, it is no longer suitable for mushroom growth and must be replaced or recycled. Proper sterilization and hydration of the substrate at the beginning of the process can maximize its durability and yield.

Sawdust-based substrates, often used in more controlled environments like indoor farms, tend to have a slightly longer lifespan, lasting up to 6 months or more. These substrates are denser and retain moisture better, allowing for slower nutrient release. However, they still degrade over time due to fungal activity and microbial breakdown. Regular monitoring of moisture levels and pH is essential to ensure the substrate remains viable for as long as possible. Additionally, supplementing the substrate with nutrients between flushes can extend its productive life.

Environmental factors play a significant role in substrate durability. High humidity and temperature can accelerate decomposition, while proper ventilation and temperature control can slow it down. Contamination by competing molds or bacteria can also reduce substrate lifespan, making sterilization and hygiene critical during preparation. Farmers must balance these factors to optimize substrate use and minimize waste.

In summary, the lifespan of the substrate in oyster mushroom farming depends on the material used, environmental conditions, and cultivation practices. Straw substrates typically last 2 to 4 months, supporting 2 to 3 flushes, while sawdust substrates can endure up to 6 months. Understanding and managing these variables is key to maximizing substrate durability and ensuring consistent mushroom yields. After its productive life, the spent substrate can be repurposed as compost or soil amendment, adding value to the farming cycle.

Slow Cooker Mushroom Magic: Perfect Cooking Times Revealed

You may want to see also

Harvest Cycles: How many harvest cycles can an oyster mushroom farm sustain before decline?

The lifespan of an oyster mushroom farm and the number of harvest cycles it can sustain are closely related, influenced by factors such as substrate quality, environmental conditions, and farm management practices. Typically, an oyster mushroom farm can produce multiple harvest cycles before the substrate is exhausted or contaminated. On average, a well-managed farm can sustain 3 to 6 harvest cycles per substrate batch, with each cycle lasting around 7 to 14 days depending on the mushroom variety and growing conditions. For example, a single batch of straw or sawdust substrate, when properly pasteurized and inoculated, can yield mushrooms repeatedly over several weeks to months.

The first harvest cycle usually produces the highest yield, as the substrate is fresh and nutrient-rich. Subsequent cycles tend to decrease in yield as the substrate's nutrients are depleted. After the third or fourth cycle, the decline becomes more noticeable, and the mushrooms may grow smaller or take longer to mature. This decline is a natural part of the process, as the mycelium exhausts the available resources in the substrate. To maximize the number of cycles, farmers often ensure optimal humidity, temperature, and ventilation, as these factors directly impact mushroom growth and substrate longevity.

The type of substrate used also plays a critical role in determining how many harvest cycles a farm can sustain. Straw and sawdust are commonly used substrates for oyster mushrooms, and they typically support 3 to 5 cycles before becoming spent. Coffee grounds or agricultural waste can also be used but may have a shorter lifespan due to their varying nutrient content and structure. Reusing substrate is possible but requires careful management to avoid contamination, which can prematurely end the farm's productivity.

Contamination is a significant factor that can reduce the number of harvest cycles. Mold, bacteria, or competing fungi can quickly degrade the substrate and outcompete the oyster mushroom mycelium. To mitigate this, farmers often pasteurize the substrate before inoculation and maintain sterile conditions during the growing process. Regular monitoring and prompt removal of contaminated areas can extend the farm's lifespan and increase the number of successful cycles.

Finally, the decision to replace the substrate depends on the farmer's goals and resources. While some farms may continue beyond 6 cycles with diminishing returns, others may choose to refresh the substrate after 3 to 4 cycles to maintain consistent yields. With proper planning and management, an oyster mushroom farm can remain productive for several months, providing a steady supply of mushrooms while minimizing waste and maximizing efficiency. Understanding these dynamics allows farmers to optimize their operations and plan for substrate replacement or farm rejuvenation in a timely manner.

Perfectly Sautéed Mushrooms: Timing and Seasoning Tips for Delicious Results

You may want to see also

Explore related products

Environmental Factors: How do temperature, humidity, and light affect the longevity of an oyster mushroom farm?

Temperature plays a critical role in determining how long an oyster mushroom farm can remain productive. Oyster mushrooms thrive in a specific temperature range, typically between 55°F and 75°F (13°C to 24°C). If temperatures consistently fall below 50°F (10°C) or rise above 80°F (27°C), mycelial growth slows, and fruiting bodies may fail to develop. Prolonged exposure to extreme temperatures can stress the mycelium, reducing its vitality and shortening the farm's lifespan. For instance, cold temperatures can delay fruiting, while excessive heat can cause the mycelium to degrade. Maintaining optimal temperature through controlled environments, such as greenhouses or indoor farms, is essential for maximizing the farm's longevity.

Humidity is another pivotal factor influencing the sustainability of an oyster mushroom farm. Oyster mushrooms require high humidity levels, ideally between 70% and 90%, to support proper fruiting. Insufficient humidity can lead to stunted growth, small or deformed mushrooms, and increased susceptibility to contaminants. Conversely, excessive humidity can create a breeding ground for mold and bacteria, which compete with the mycelium for resources. Consistent monitoring and regulation of humidity levels, often achieved through misting systems or humidifiers, are crucial for maintaining a healthy and long-lasting farm. Neglecting humidity control can significantly reduce the farm's productive lifespan.

Light, while not as critical as temperature or humidity, still impacts the longevity of an oyster mushroom farm. Oyster mushrooms do not require direct sunlight for photosynthesis, as they are heterotrophic organisms. However, indirect or diffused light is necessary to signal the mycelium to initiate fruiting. Complete darkness can delay or inhibit fruiting, while excessive light can stress the mushrooms and reduce their quality. Providing a balanced light environment, such as 12 hours of low-intensity light per day, encourages consistent fruiting cycles and prolongs the farm's productivity. Ignoring light requirements can disrupt the farm's rhythm and shorten its overall lifespan.

The interplay between temperature, humidity, and light must be carefully managed to ensure the longevity of an oyster mushroom farm. For example, high temperatures combined with low humidity can rapidly dehydrate the substrate, halting mycelial growth. Similarly, optimal temperature and humidity without adequate light can prevent fruiting, rendering the farm unproductive. Farmers must adopt a holistic approach, using tools like thermostats, hygrometers, and timers to create a stable environment. By addressing these environmental factors proactively, growers can extend the lifespan of their oyster mushroom farm, often achieving multiple harvests over several months or even years.

Finally, environmental consistency is key to maximizing the lifespan of an oyster mushroom farm. Fluctuations in temperature, humidity, or light levels can stress the mycelium, making it more vulnerable to contaminants and reducing its ability to recover. For outdoor farms, seasonal changes pose a significant challenge, as natural conditions often deviate from the ideal range. Indoor or controlled environments offer greater stability but require continuous monitoring and adjustment. By prioritizing environmental control and responding promptly to deviations, farmers can create conditions that support long-term mushroom production, ensuring their farm remains viable and productive over an extended period.

Perfectly Baked Mushrooms: Timing Tips at 350 Degrees

You may want to see also

Maintenance Impact: Does regular maintenance extend the operational lifespan of an oyster mushroom farm?

Regular maintenance plays a pivotal role in extending the operational lifespan of an oyster mushroom farm. Oyster mushroom cultivation relies on specific environmental conditions, substrate quality, and hygiene to ensure consistent yields. Without routine upkeep, factors such as contamination, equipment degradation, and environmental imbalances can significantly shorten the farm's productivity. For instance, mycelium contamination from bacteria, molds, or pests can render growing substrates unusable, necessitating costly replacements and downtime. Regular maintenance, including sterilizing equipment, monitoring humidity and temperature, and inspecting substrates, mitigates these risks, ensuring the farm remains viable for a longer period.

One critical aspect of maintenance is the management of growing substrates. Oyster mushrooms thrive on organic materials like straw, sawdust, or coffee grounds, which degrade over time. Regularly assessing substrate quality and replacing spent materials prevents nutrient depletion and maintains optimal conditions for mycelium growth. Additionally, proper composting and recycling of used substrates can reduce waste and lower operational costs, contributing to the farm's sustainability. Neglecting substrate management can lead to poor yields and increased susceptibility to diseases, ultimately reducing the farm's lifespan.

Environmental control systems, such as humidifiers, fans, and temperature regulators, are essential for oyster mushroom cultivation. Over time, these systems can wear out or become less efficient, leading to suboptimal growing conditions. Routine maintenance, including cleaning filters, calibrating sensors, and replacing worn parts, ensures these systems function reliably. For example, a malfunctioning humidifier can cause dry conditions that hinder mushroom fruiting, while a broken fan can lead to stagnant air and increased contamination risk. By addressing these issues proactively, farmers can avoid disruptions and maintain consistent production cycles.

Hygiene is another cornerstone of oyster mushroom farm maintenance. Contamination from spores, bacteria, or pests can spread rapidly in the humid, nutrient-rich environment of a mushroom farm. Regular cleaning of growing rooms, tools, and containers, coupled with the use of disinfectants, minimizes the risk of outbreaks. Implementing biosecurity measures, such as restricting access to growing areas and using protective clothing, further safeguards the farm. Without such practices, contamination can devastate crops, requiring extensive decontamination efforts and potentially rendering the farm unviable.

Finally, record-keeping and monitoring are integral to effective maintenance. Tracking environmental conditions, yield data, and maintenance activities provides insights into the farm's performance and identifies potential issues before they escalate. For example, noticing a gradual decline in humidity levels or an increase in contamination incidents allows farmers to take corrective action promptly. This data-driven approach not only extends the farm's lifespan but also optimizes productivity and profitability. In summary, regular maintenance is not just a task but an investment in the long-term success of an oyster mushroom farm.

Maximizing Mushroom Freshness: Optimal Storage Tips and Shelf Life Guide

You may want to see also

Frequently asked questions

An oyster mushroom farm can last between 3 to 6 months, depending on factors like substrate quality, environmental conditions, and farming practices.

Yes, oyster mushroom farms can often produce multiple flushes, usually 2 to 4, before the substrate is exhausted, typically within 3 to 6 months.

The lifespan is influenced by substrate type, humidity, temperature, ventilation, and contamination prevention measures.

Oyster mushrooms typically take 2 to 4 weeks to grow from spawn to harvest, depending on conditions.

No, oyster mushroom farms are not indefinite; the substrate will eventually deplete nutrients, and contamination risks increase over time, limiting the farm's lifespan to a few months.