When preparing grain for mushroom spawn, the cooking time is a critical step to ensure the grain is properly sterilized and ready for inoculation. Typically, grains like rye, wheat, or millet are used, and they should be cooked until they are fully hydrated and softened but not mushy. The process usually involves boiling the grain in water for about 20-30 minutes, depending on the type and quantity, followed by draining and cooling to the appropriate temperature before introducing the mushroom mycelium. Properly cooked grain provides an ideal substrate for mycelial growth, reducing the risk of contamination and promoting healthy mushroom development.

| Characteristics | Values |

|---|---|

| Grain Type | Typically wheat, rye, or millet (most commonly used for mushroom spawn) |

| Cooking Method | Boiling or pressure cooking |

| Boiling Time | 30-45 minutes (until grains are soft but not mushy) |

| Pressure Cooking Time | 20-30 minutes (reduces cooking time and ensures sterilization) |

| Water-to-Grain Ratio | 3:1 (3 parts water to 1 part grain by volume) |

| Cooling Requirement | Cool to room temperature before inoculation (70-75°F / 21-24°C) |

| Sterilization | Required to kill contaminants (pressure cooking ensures this) |

| pH Adjustment | Optional; some growers adjust pH to 5.5-6.0 for optimal growth |

| Moisture Content | Grains should be moist but not waterlogged after cooking |

| Storage Before Inoculation | Use immediately or store in a sterile environment for up to 24 hours |

| Common Mistakes | Overcooking (mushy grains), undercooking (hard grains), or contamination |

| Alternative Methods | Steam sterilization or using pre-sterilized grain kits |

Explore related products

What You'll Learn

Optimal Grain Moisture Levels

When preparing grain for mushroom spawn, achieving the optimal moisture level is critical for successful colonization by mycelium. The moisture content directly impacts the grain's ability to support mycelial growth while preventing contamination. The ideal moisture range for most mushroom species typically falls between 50% to 65%. This range ensures the grain retains enough water to nourish the mycelium without becoming overly saturated, which could lead to bacterial or mold growth. To measure moisture content accurately, you can use a moisture meter or calculate it by weighing the grain before and after drying a sample in an oven at 105°C (221°F) for 24 hours.

The cooking process plays a significant role in achieving the correct moisture level. Before cooking, the grain should be soaked in water to absorb moisture. The soaking time varies depending on the grain type; for example, rye or wheat typically soaks for 12 to 24 hours. After soaking, drain the excess water thoroughly, as retaining too much moisture at this stage can lead to issues during sterilization and incubation. The goal is to strike a balance where the grain is moist but not waterlogged, ensuring it can be sterilized effectively without drying out during the cooking process.

During cooking, the grain should be hydrated to approximately 60% moisture content. This is achieved by adding the correct ratio of water to grain before pressure cooking or steaming. A common guideline is to use a 1:1 ratio of grain to water by weight, but adjustments may be necessary based on the grain's absorption rate. Cooking times vary, but generally, grains like rye or wheat require 45 to 60 minutes in a pressure cooker at 15 psi to ensure proper hydration and sterilization. Overcooking can lead to mushy grain, while undercooking may leave it too dry or unevenly hydrated.

After cooking, allow the grain to cool and check its moisture level. If the grain feels too wet, spread it out to air dry slightly before transferring it to spawn bags or jars. Conversely, if it feels too dry, lightly mist it with sterile water, ensuring not to oversaturate. Maintaining the optimal moisture level is essential during the cooling and inoculation stages, as fluctuations can introduce contaminants or stress the mycelium. Properly hydrated grain will appear plump and slightly moist to the touch, providing an ideal substrate for mycelial growth.

Finally, consistency in moisture levels across batches is key to repeatable success. Keep detailed records of your soaking, cooking, and water-to-grain ratios to refine your process over time. Environmental factors, such as humidity and grain quality, can also influence moisture absorption, so adaptability is important. By mastering the art of optimal grain moisture levels, you create a foundation for healthy mycelial colonization and robust mushroom yields.

Perfectly Crispy Frozen Breaded Mushrooms: Optimal Cooking Time Guide

You may want to see also

Sterilization Time for Grain

When preparing grain for mushroom spawn, sterilization is a critical step to ensure a contamination-free environment for mycelium growth. The sterilization time for grain can vary depending on the method used, the type of grain, and the equipment available. Generally, the goal is to eliminate any competing microorganisms while keeping the grain nutritious for the mushroom mycelium. One of the most common methods is pressure cooking, which is both effective and accessible for most growers.

For pressure cooking, the recommended sterilization time for grain is typically 60 to 90 minutes at 15 PSI (pounds per square inch). This duration ensures that the heat penetrates the grain thoroughly, killing bacteria, fungi, and other contaminants. It’s important to note that the timer should only start once the pressure cooker reaches the desired pressure, not from the moment it is turned on. For example, if using a stovetop pressure cooker, allow it to vent steam until the pressure gauge indicates 15 PSI, then begin timing the sterilization process.

The type of grain also influences sterilization time. Harder grains like rye or wheat may require closer to 90 minutes to ensure complete sterilization, while softer grains like millet or sorghum might suffice with 60 minutes. Always err on the side of caution, as under-sterilized grain can lead to contamination, ruining the entire batch. Additionally, pre-soaking the grain for 12 to 24 hours before sterilization can help it absorb more water, making it more hospitable for mycelium growth once inoculated.

Another factor to consider is the amount of grain being sterilized. Overloading the pressure cooker can lead to uneven heating, so it’s best to sterilize grain in smaller batches. A common guideline is to fill the pressure cooker no more than two-thirds full to allow proper steam circulation. If sterilizing larger quantities, extend the sterilization time by 10-15 minutes to ensure all grain is adequately processed.

After sterilization, allow the pressure cooker to cool naturally to room temperature. This gradual cooling process helps prevent contamination by avoiding sudden pressure changes that could draw in external air. Once cooled, the grain is ready for inoculation with mushroom spawn. Proper sterilization time and technique are essential for successful mushroom cultivation, as they lay the foundation for healthy mycelium growth and a bountiful harvest.

Perfectly Crispy Frozen Breaded Mushrooms in Your Power Cooker: Timing Tips

You may want to see also

Cooling Grain Before Inoculation

Cooling the grain properly before inoculation is a critical step in the process of preparing mushroom spawn. After cooking the grain to the appropriate temperature and hydration level, it’s essential to cool it down to a safe range before introducing the mushroom mycelium. The mycelium is highly sensitive to heat, and exposing it to temperatures above 85°F (29°C) can kill it or hinder its growth. Therefore, the cooling process must be handled with care and precision to ensure the success of the inoculation.

The first step in cooling the grain is to remove it from the heat source immediately after cooking. Transfer the cooked grain to a clean, sterile container that allows for good airflow. Spreading the grain in a thin, even layer on a sterile surface or tray can expedite the cooling process, as it maximizes the surface area exposed to the air. Avoid covering the grain tightly during this stage, as it can trap heat and moisture, potentially leading to bacterial or mold contamination. Instead, use a loose cover like a clean cloth or a sterile lid with vents to protect the grain from airborne contaminants while allowing excess heat to escape.

Monitoring the temperature of the grain during cooling is crucial. Use a reliable thermometer to check the internal temperature of the grain periodically. The goal is to bring the grain down to a temperature between 70°F and 80°F (21°C and 27°C), which is the optimal range for inoculation. This process can take anywhere from 1 to 3 hours, depending on the volume of grain and the ambient temperature of the environment. Patience is key, as rushing the cooling process by using fans or refrigerators can introduce unwanted contaminants or uneven cooling.

During the cooling period, maintain a sterile environment to minimize the risk of contamination. Ensure that the area where the grain is cooling is clean and free from drafts that could carry spores or bacteria. If possible, work in a still air box or a laminar flow hood, especially if you’re dealing with small quantities of grain. For larger batches, choose a clean, controlled space with minimal foot traffic and good air quality. Proper hygiene, such as wearing gloves and a mask, is also essential to prevent introducing contaminants during this vulnerable stage.

Once the grain has cooled to the appropriate temperature range, it’s ready for inoculation. However, before proceeding, double-check that both the grain and the inoculation tools (e.g., scalpel, syringe) are sterile. Any oversight in sterilization or cooling can compromise the entire batch. Properly cooled grain provides an ideal substrate for the mycelium to colonize efficiently, setting the stage for healthy mushroom spawn development. Taking the time to cool the grain correctly is a small but vital investment in the success of your mushroom cultivation project.

Perfectly Crispy Air Fryer Frozen Mushrooms: Cooking Time Guide

You may want to see also

Explore related products

Inoculation to Colonization Time

For most common mushroom species, such as oyster or shiitake mushrooms, the inoculation to colonization time ranges from 10 to 21 days. During this period, the mycelium grows through the grain, breaking down the nutrients and establishing a strong network. Optimal temperature for colonization is usually between 75°F and 80°F (24°C to 27°C), as this range promotes rapid mycelial growth without encouraging contamination. It’s crucial to maintain sterile conditions during inoculation, as contaminants like bacteria or mold can outcompete the mycelium and ruin the spawn.

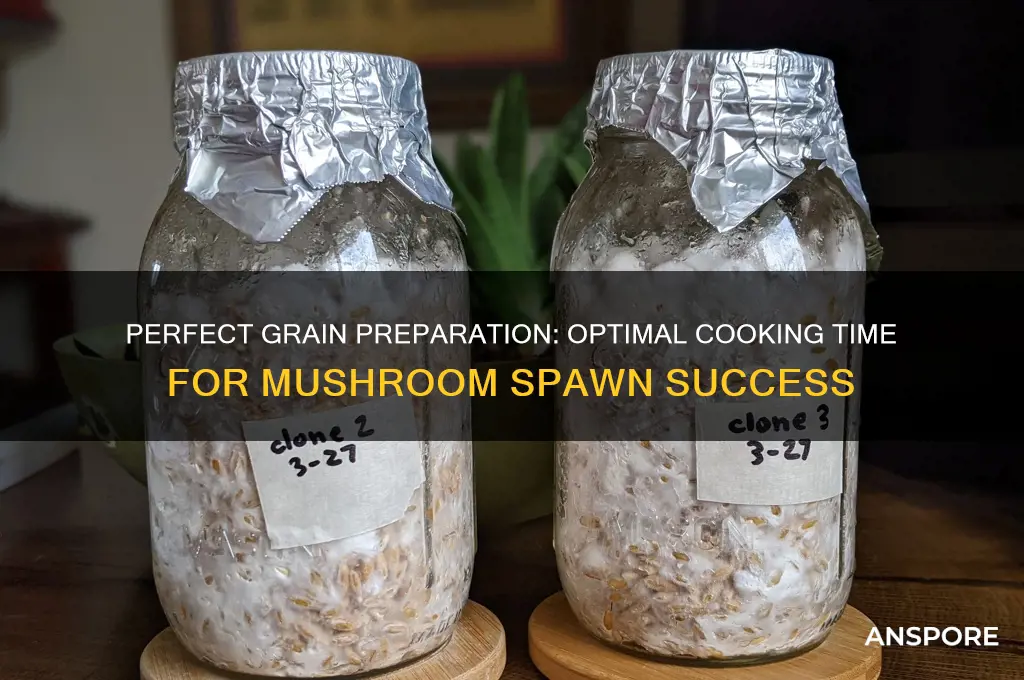

The first few days after inoculation are particularly important, as the mycelium begins to establish itself. You may notice small patches of white mycelium appearing on the grain within 3-5 days. These patches will gradually spread and merge until the entire substrate is colonized. Monitoring the progress daily is recommended, but avoid opening the container unnecessarily, as this can introduce contaminants. Patience is key, as rushing the process or disturbing the environment can lead to failed colonization.

Environmental factors play a significant role in determining how quickly colonization occurs. Humidity levels should be kept relatively high, around 60-70%, to support mycelial growth. Proper airflow is also important, as stagnant air can create pockets of carbon dioxide that hinder growth. If conditions are optimal, colonization can occur on the faster end of the timeline, while suboptimal conditions may extend the process. For example, lower temperatures or insufficient moisture can slow mycelial growth, delaying full colonization.

Once the grain is fully colonized, it turns completely white and appears fluffy or cotton-like, indicating that the mycelium has consumed the available nutrients. At this point, the grain spawn is ready for the next step, whether it’s transferring to bulk substrate for fruiting or storing for later use. It’s important not to wait too long after full colonization, as the mycelium can begin to degrade the grain if left without additional nutrients. Proper timing ensures the spawn remains healthy and viable for mushroom production.

In summary, the inoculation to colonization time for grain spawn typically spans 10 to 21 days, depending on mushroom species and environmental conditions. Maintaining optimal temperature, humidity, and sterile practices is crucial for successful and timely colonization. Monitoring the progress and understanding the signs of full colonization ensures that the spawn is ready for the next stage of mushroom cultivation. This phase requires patience and attention to detail but is a rewarding step in the journey of growing mushrooms from spawn.

Perfectly Roasted Garlic Mushrooms: Oven Cooking Time Guide

You may want to see also

Grain Type Cooking Durations

When preparing grain for mushroom spawn, the cooking duration varies significantly depending on the type of grain used. Each grain has unique characteristics that influence how long it needs to be cooked to achieve the right texture and sterilization necessary for mushroom cultivation. Properly cooked grains provide an ideal substrate for mycelium growth while minimizing the risk of contamination. Below is a detailed guide on cooking durations for commonly used grains.

Wheat Berries: Wheat is a popular choice for mushroom spawn due to its availability and nutrient content. To prepare wheat berries, rinse them thoroughly and soak for 8–12 hours to reduce cooking time. After soaking, drain the water and add the grains to a pot with fresh water in a 1:2 grain-to-water ratio. Bring to a boil, then reduce to a simmer. Cook for 45–60 minutes, or until the grains are tender but not mushy. Overcooking can lead to a substrate that is too soft, which may retain excess moisture and increase contamination risk.

Rye Berries: Rye is another favored grain for mushroom cultivation, particularly for growing species like oyster mushrooms. Like wheat, rye berries should be soaked for 8–12 hours before cooking. After soaking, drain and add the grains to a pot with fresh water in a 1:2.5 ratio. Boil, then simmer for 60–75 minutes. Rye requires a slightly longer cooking time than wheat to achieve the desired texture. Ensure the grains are fully cooked but still firm to provide a stable substrate for mycelium colonization.

Millet: Millet is a smaller grain that cooks more quickly than wheat or rye. It does not require soaking but should be rinsed thoroughly before cooking. Use a 1:3 grain-to-water ratio and bring to a boil. Simmer for 20–30 minutes, or until the grains are tender. Millet’s short cooking time makes it a convenient option, but care must be taken to avoid overcooking, as it can become too soft and clump together.

Sorghum: Sorghum is a hardy grain that works well for mushroom spawn, especially for outdoor cultivation. Soak sorghum grains for 12–16 hours to reduce cooking time. After soaking, drain and add to a pot with fresh water in a 1:2.5 ratio. Boil, then simmer for 60–90 minutes. Sorghum’s tough outer layer requires longer cooking to ensure it softens adequately. Test the grains for tenderness before removing them from heat.

Barley: Barley is often used for mushroom spawn due to its nutritional profile and availability. Soak barley grains for 8–12 hours, then drain and add to a pot with fresh water in a 1:3 ratio. Boil, then simmer for 45–60 minutes. Pearl barley cooks faster than hulled barley, so adjust the time accordingly. The grains should be chewy but not hard, providing a suitable texture for mycelium growth.

Understanding the specific cooking durations for each grain type is crucial for successful mushroom cultivation. Always sterilize the cooked grains before inoculation to prevent contamination. Properly prepared grains will serve as a robust foundation for healthy mycelium development and abundant mushroom yields.

Perfectly Cooked Frozen Stuffed Mushrooms: Timing Tips for Delicious Results

You may want to see also

Frequently asked questions

Grain for mushroom spawn should be cooked for about 45–60 minutes. This ensures the grains are fully hydrated and sterilized, creating an ideal substrate for mushroom mycelium to colonize.

The ideal temperature for cooking grain is between 200°F (93°C) and 212°F (100°C). This range ensures proper sterilization without burning or overcooking the grains.

Yes, pressure cooking is recommended for sterilizing grain. Cook the grain at 15 PSI for 45–60 minutes to ensure all contaminants are eliminated and the grains are ready for inoculation.

The grain is fully cooked when it is soft, fully hydrated, and has absorbed most of the water. It should not be mushy or burnt. Allow it to cool before inoculating with mushroom spawn.