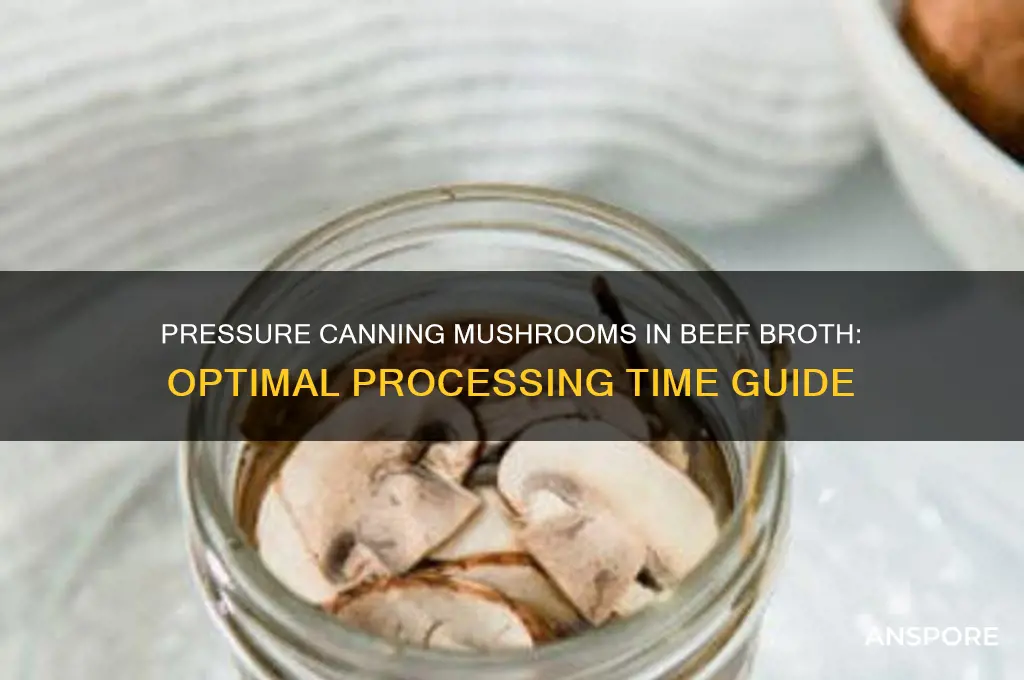

Pressure canning mushrooms in beef broth is a popular method for preserving this flavorful combination, ensuring it remains safe and shelf-stable for extended periods. The process involves placing mushrooms and beef broth into sterilized jars and then processing them in a pressure canner at specific temperatures and times to eliminate harmful bacteria and create a vacuum seal. The exact duration for pressure canning depends on factors such as altitude, jar size, and the type of pressure canner used, but generally, it ranges from 25 to 40 minutes at 10 pounds of pressure for pints and up to 45 minutes for quarts. Following USDA guidelines is crucial to ensure food safety and achieve the desired preservation results.

| Characteristics | Values |

|---|---|

| Processing Time | 75 minutes at 10 lbs pressure (weighted gauge) or 11 lbs pressure (dial gauge) |

| Jar Size | Pints |

| Altitude Adjustments | - 0-1,000 ft: 75 minutes |

| - 1,001-3,000 ft: 80 minutes | |

| - 3,001-6,000 ft: 85 minutes | |

| - Above 6,000 ft: 90 minutes | |

| Headspace | 1 inch |

| Broth Composition | Beef broth (store-bought or homemade) |

| Mushroom Preparation | Fresh, firm mushrooms, washed and sliced |

| Acidification | Not required (beef broth is low-acid, processed as low-acid food) |

| Recommended Equipment | Pressure canner, pint jars, lids, and rings |

| Safety Precautions | Follow USDA guidelines for pressure canning low-acid foods |

| Storage | Store in a cool, dark place for up to 1 year |

| Yield | Varies based on mushroom and broth quantity |

| Reheating Instructions | Boil for 10-15 minutes before consumption |

Explore related products

What You'll Learn

Preparation steps for mushrooms and beef broth

Pressure canning mushrooms in beef broth requires meticulous preparation to ensure safety and flavor. Begin by selecting fresh, firm mushrooms, ideally button or cremini varieties, as their texture holds up well during processing. Clean them gently with a damp cloth or brush to remove dirt, avoiding soaking, which can dilute their earthy flavor. Trim the stems and slice the caps uniformly to promote even cooking and packing.

The beef broth serves as both a preservative and flavor enhancer. Use high-quality, low-sodium broth to control salt levels, or prepare homemade broth for a richer taste. Heat the broth to a simmer before adding it to the jars, ensuring it’s hot enough to create a vacuum seal during processing. For added depth, consider infusing the broth with herbs like thyme or rosemary, but avoid thickening agents like flour or cornstarch, which can compromise food safety.

Packing the jars is a critical step. Sterilize quart or pint jars, lids, and bands in boiling water for 10 minutes before use. Layer the mushrooms into the jars, leaving 1 inch of headspace to allow for expansion. Ladle the hot beef broth over the mushrooms, removing air bubbles with a non-metallic utensil. Wipe the jar rims clean and secure the lids fingertip-tight to prevent contamination.

Processing times vary by altitude and jar size. For a dial-gauge pressure canner, process quart jars at 11 pounds of pressure for 90 minutes and pint jars for 85 minutes. For a weighted-gauge canner, process at 10 pounds of pressure for the same durations. Always consult the USDA guidelines for your specific region to ensure safety. Once processed, let the jars cool undisturbed for 12–24 hours before checking seals and storing in a cool, dark place for up to one year.

Baking Morel Mushrooms: Tips, Recipes, and Delicious Results

You may want to see also

Recommended pressure canning times and PSI levels

Pressure canning mushrooms in beef broth requires precise timing and PSI levels to ensure safety and quality. The USDA recommends processing pints for 50 minutes and quarts for 85 minutes at 10 pounds PSI for weighted-gauge canners, or 11 pounds PSI for dial-gauge canners, at altitudes of 0 to 2,000 feet. Adjustments are necessary for higher elevations: add 0.5 pounds PSI for each 1,000 feet above sea level. These parameters are critical because mushrooms are low-acid foods, making them susceptible to botulism if not processed correctly. Always consult altitude-specific guidelines to avoid underprocessing.

The science behind these times and pressures lies in destroying *Clostridium botulinum* spores, which thrive in low-acid, anaerobic environments. At 240°F (116°C), the temperature achieved under 10-11 pounds PSI, spores are effectively eliminated. Pints process faster due to their smaller volume, allowing heat to penetrate more quickly, while quarts require additional time to ensure uniform heating. Failure to meet these standards can result in spoilage or dangerous toxins, emphasizing the importance of adhering strictly to recommended protocols.

Practical tips can enhance your canning success. Preheat the canner with 2-3 inches of water before adding jars to reduce processing time. Ensure mushrooms are fully submerged in hot beef broth, leaving 1-inch headspace to allow for expansion. After processing, let the canner cool naturally; forcing cooling can cause seal failure. Test seals by pressing the lid center—if it doesn’t flex, the jar is sealed. Label jars with the date and contents for easy reference, and store in a cool, dark place for up to 18 months.

Comparing pressure canning to other preservation methods highlights its efficiency for low-acid foods. Water bath canning, for instance, is insufficient for mushrooms in beef broth due to its lower temperature (212°F). Freezing is an alternative but requires significant storage space and risks texture degradation over time. Pressure canning, while more equipment-intensive, offers shelf-stable results without additives or electricity, making it ideal for long-term storage and emergency preparedness.

In conclusion, mastering pressure canning times and PSI levels is essential for safely preserving mushrooms in beef broth. By following USDA guidelines, understanding the science, and applying practical techniques, you can achieve reliable, high-quality results. This method not only extends the life of your harvest but also provides a convenient, flavorful ingredient for future meals. Precision and patience are key—invest in the process, and your pantry will thank you.

Can Mushrooms Harm Dogs? Risks, Symptoms, and Safety Tips

You may want to see also

Proper jar sterilization and sealing techniques

Sterilizing jars is a critical step in pressure canning mushrooms in beef broth, as it eliminates microorganisms that could spoil the food or pose health risks. The USDA recommends sterilizing jars by submerging them in boiling water for 10 minutes, ensuring they remain hot until filled. This process is essential for low-acid foods like mushrooms and meat broths, which are prone to botulism-causing bacteria. Always use a wire rack at the bottom of the canner to prevent jars from cracking due to direct heat contact.

Sealing techniques are equally vital to ensure a vacuum seal, which locks out air and contaminants. After filling jars with mushrooms and broth, remove air bubbles by sliding a non-metallic spatula between the food and jar. Wipe the jar rim with a clean, damp cloth to remove residue, as any debris can interfere with sealing. Center the lid on the jar and screw the band on fingertip-tight—overtightening can cause seal failure. Process the jars in a pressure canner at 10 lbs of pressure for 30 minutes (for pints) or 35 minutes (for quarts), adjusting for altitude as per USDA guidelines.

A comparative analysis of sealing methods reveals that two-piece lids with a flat disc and screw band are superior to one-piece lids for pressure canning. The flexible rubber gasket in two-piece lids creates a tighter seal under high heat and pressure. Avoid reusing lids, as their gaskets lose elasticity, but bands can be reused if they show no signs of rust or warping. For best results, purchase new lids for each canning session.

Practical tips include preheating jars in a 200°F oven for 10 minutes if boiling water is impractical. Always handle hot jars with a jar lifter to prevent burns. After processing, let jars cool undisturbed for 12–24 hours before testing seals. A properly sealed lid will not flex when pressed; if it does, reprocess within 24 hours or refrigerate immediately. Label jars with the canning date and consume within 1–5 years for optimal quality and safety.

In conclusion, proper jar sterilization and sealing are non-negotiable steps in pressure canning mushrooms in beef broth. By following precise techniques and adhering to USDA guidelines, you ensure the longevity and safety of your preserved food. Attention to detail in these steps not only prevents spoilage but also safeguards against foodborne illnesses, making the process both a science and an art.

Can Jains Eat Mushrooms? Exploring Dietary Guidelines and Beliefs

You may want to see also

Explore related products

Safety guidelines to prevent botulism risks

Botulism, caused by the toxin produced by *Clostridium botulinum*, is a severe and potentially fatal illness. When pressure canning mushrooms in beef broth, the risk of botulism arises if the process fails to eliminate spores or if the environment allows toxin production. To mitigate this, follow these safety guidelines rigorously.

Step 1: Acidify the Broth

C. botulinum thrives in low-acid, anaerobic environments. Since beef broth is low in acidity, add an acidifying agent like lemon juice or citric acid to lower the pH below 4.6. For every quart of broth, add 2 tablespoons of bottled lemon juice or ½ teaspoon of citric acid. This simple step creates an inhospitable environment for botulism spores to germinate.

Step 2: Use a Tested Recipe and Processing Time

Rely only on recipes from reputable sources like the USDA or university extension services. These recipes specify processing times and pressures tailored to your altitude. For mushrooms in beef broth, a common guideline is 25 minutes at 10 pounds of pressure for pints and 30 minutes for quarts, adjusted for altitudes above 1,000 feet. Deviating from these times can leave spores intact or allow toxin production.

Step 3: Inspect Equipment and Seals

Before canning, ensure your pressure canner is in good condition. Check the vent pipe for clogs, the gauge for accuracy, and the sealing ring for cracks. A faulty seal or inaccurate gauge can lead to underprocessing, leaving spores alive. Test the canner with water to confirm it reaches and maintains the required pressure.

Step 4: Cool and Store Properly

After processing, allow the canner to cool naturally; never force-cool it. Once opened, remove jars and check seals. Wipe jars, label with contents and date, and store in a cool, dark place. Inspect stored jars regularly for signs of spoilage, such as bulging lids, leaks, or off odors. Discard any questionable jars immediately.

Takeaway: Precision Saves Lives

Botulism prevention in pressure canning hinges on precision—acidifying the broth, following tested recipes, using reliable equipment, and storing jars correctly. These steps transform a risky process into a safe, rewarding way to preserve mushrooms in beef broth. Always prioritize safety over shortcuts.

Raw Mushrooms: Safe to Eat or Cooking Required? Expert Insights

You may want to see also

Storage tips for canned mushroom beef broth

Proper storage is crucial for maintaining the safety and quality of canned mushroom beef broth. Once processed, allow the jars to cool undisturbed for 12–24 hours. Check seals by pressing the center of each lid; if it doesn’t flex, the jar is properly sealed. Label jars with the canning date and contents, using a permanent marker or adhesive label resistant to moisture. Store in a cool, dark place with consistent temperatures between 50°F and 70°F, avoiding areas prone to temperature fluctuations like above stoves or near windows.

Humidity and light exposure can degrade both the container and contents over time. Keep jars away from direct sunlight or damp environments, such as basements prone to moisture. For optimal flavor retention, use canned mushroom beef broth within 12–18 months. While properly processed jars may remain safe beyond this period, the broth’s texture and taste may deteriorate. Rotate stock by using older jars first, a practice especially important for home canners who process in large batches.

Inspect jars periodically for signs of spoilage, such as bulging lids, off odors, or visible mold. These indicate improper sealing or bacterial contamination, rendering the contents unsafe for consumption. Unsealed jars should be refrigerated immediately and used within 2–3 weeks, or reprocessed within 24 hours if the contents are still safe. For those using pressure canners, ensure processing times align with altitude adjustments—typically 100 minutes at 10 pounds of pressure for pints, and 110 minutes for quarts, at altitudes below 1,000 feet.

For long-term storage, consider using dark-colored jars or wrapping clear jars in foil to protect against light. Stack jars only if the lids are flat and secure, avoiding pressure on the seals. If storing in a pantry, use shelves with lips to prevent jars from rolling or falling. In earthquake-prone areas, secure jars with non-slip liners or store in lower cabinets. Proper storage not only preserves the broth’s integrity but also ensures a safe, flavorful product when opened.

Finally, integrate canned mushroom beef broth into meal planning to avoid waste. Use it as a base for soups, stews, or gravies, or as a flavorful liquid for cooking grains like rice or barley. For smaller households, consider canning in pint jars instead of quarts to reduce the risk of spoilage after opening. By following these storage tips, home canners can enjoy their mushroom beef broth at its best, maximizing both safety and culinary potential.

Freezing Cream of Mushroom: Tips for Safe and Easy Storage

You may want to see also

Frequently asked questions

Process quart jars for 90 minutes and pint jars for 75 minutes at 10 lbs of pressure for a weighted-gauge canner or 11 lbs for a dial-gauge canner.

Use 10 lbs of pressure for a weighted-gauge canner or 11 lbs for a dial-gauge canner, adjusted for altitude if necessary.

No, reducing the processing time can compromise food safety. Always follow the recommended 75 minutes for pints and 90 minutes for quarts.

Yes, increase the pressure by 1 lb for every 2,000 feet above sea level, and follow altitude-specific processing time guidelines for safety.