Building a grow room for mushrooms requires careful planning and attention to detail to create an environment conducive to their growth. The first step is to choose a suitable space, such as a spare room, closet, or basement, ensuring it is clean, dry, and easily controllable in terms of temperature and humidity. Next, you’ll need to set up proper ventilation to maintain fresh air circulation and prevent the buildup of carbon dioxide. Installing a grow tent or constructing a framed room with reflective material can help maximize light efficiency and maintain cleanliness. Temperature and humidity control are critical, so investing in a thermostat, humidifier, and dehumidifier is essential to keep conditions within the optimal range for mushroom cultivation. Additionally, proper lighting, such as LED grow lights, should be used to support the growth of mycelium during the colonization phase. Finally, sterilization and sanitation practices are vital to prevent contamination, including using HEPA filters and regularly cleaning tools and surfaces. With these elements in place, your grow room will provide the ideal conditions for cultivating healthy and abundant mushrooms.

Explore related products

What You'll Learn

Optimal Room Size & Layout

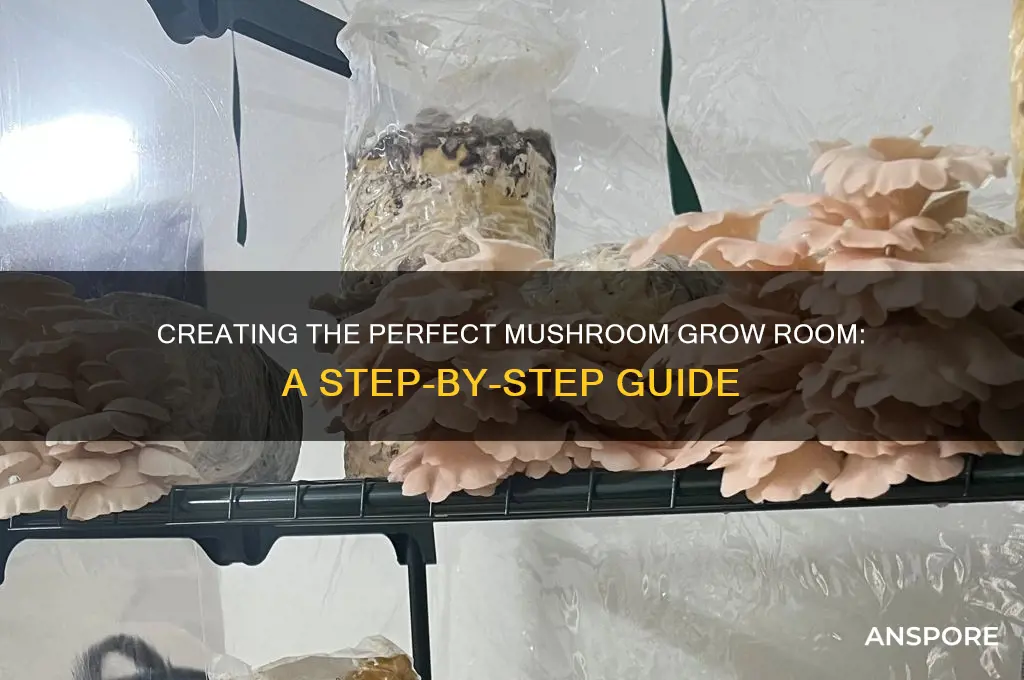

When designing a grow room for mushrooms, the optimal room size and layout are critical factors that influence yield, efficiency, and ease of maintenance. For small-scale growers or hobbyists, a room as compact as 8x8 feet (64 square feet) can suffice, while commercial operations may require spaces of 10x20 feet (200 square feet) or larger. The key is to balance space utilization with accessibility and airflow. A rectangular layout is generally preferred over square shapes because it allows for better air circulation and more efficient placement of shelves or growing racks. Ensure the room’s dimensions accommodate your expected yield and leave enough space for movement and equipment like dehumidifiers, fans, and lighting.

The height of the room is equally important, especially if you plan to use vertical growing systems. A minimum ceiling height of 8 feet is recommended, but 10 feet is ideal for stacking multiple tiers of growing trays or shelves. Vertical space maximizes yield per square foot, particularly for species like oyster mushrooms that grow well in layered setups. If your room has a lower ceiling, consider using shorter racks or focusing on horizontally spreading species like lion’s mane. Always ensure there’s enough clearance for proper air circulation above the highest shelf.

Within the room, the layout should prioritize functionality and cleanliness. Position the entrance opposite the work area to minimize contamination risks, and install a small antechamber or airlock if possible. Shelving units or growing racks should be placed along the walls, leaving a central aisle for easy access. If using bulk substrate beds, arrange them in rows with at least 2-3 feet of space between them for airflow and maintenance. Avoid overcrowding, as poor air circulation can lead to mold or uneven growth.

Lighting requirements are minimal for mushrooms, but the layout should account for indirect natural light or artificial LED strips. Place lights above or between shelves, ensuring they don’t obstruct airflow. If using natural light, position windows or translucent panels on the north side to avoid overheating. Electrical outlets should be strategically placed to power fans, dehumidifiers, and lights without creating tripping hazards.

Finally, consider the placement of environmental control equipment. Dehumidifiers, humidifiers, and air exchange systems should be positioned near the center or along walls, depending on their size and airflow direction. A thermostat and hygrometer should be mounted at mushroom height to monitor conditions accurately. Proper zoning of equipment ensures uniform environmental conditions throughout the room, which is essential for consistent mushroom growth. Thoughtful planning of room size and layout not only optimizes yield but also simplifies daily care and reduces the risk of contamination.

Psilocybe Mushrooms in Colorado: Where and How They Grow

You may want to see also

Temperature & Humidity Control

Mushrooms thrive in specific environmental conditions, and precise temperature and humidity control are critical for successful cultivation. The ideal temperature range for most mushroom species is between 65°F and 75°F (18°C and 24°C). To maintain this, consider installing a thermostat-controlled heating and cooling system in your grow room. Portable heaters, air conditioners, or heat exchangers can be effective, depending on your climate and the size of the space. Insulating the grow room is also essential to minimize temperature fluctuations and reduce energy costs. Use materials like foam boards or reflective insulation to maintain a stable internal environment.

Humidity control is equally vital, as mushrooms require a relative humidity (RH) level between 85% and 95% for optimal growth. A humidifier is a must-have tool for any mushroom grow room, especially in drier climates or during winter months. Ultrasonic or evaporative humidifiers are popular choices, but ensure they are sized appropriately for your room. Pair the humidifier with a hygrometer to monitor RH levels accurately. If humidity exceeds 95%, mold and bacteria can become issues, so consider adding a dehumidifier or improving ventilation to balance the environment.

Ventilation plays a dual role in temperature and humidity control. Proper airflow helps regulate temperature and prevents stagnant air, which can lead to humidity imbalances. Install exhaust fans with adjustable speeds to remove excess heat and moisture, and use intake vents to bring in fresh, filtered air. A timer or controller can automate this process, ensuring consistent air exchange without overcooling or drying the room. Additionally, using oscillating fans inside the grow room promotes even humidity distribution and prevents pockets of damp air where contaminants can thrive.

For advanced control, invest in an environmental controller that integrates temperature, humidity, and ventilation management. These devices can automatically adjust settings based on real-time data, providing a hands-off approach to maintaining ideal conditions. Some controllers also offer remote monitoring and alerts, allowing you to address issues before they impact your crop. When selecting equipment, prioritize energy efficiency and reliability, as these systems will run continuously throughout the growing cycle.

Finally, consider the microclimate within your grow room, especially if using shelving or racks to maximize space. Temperature and humidity can vary at different heights, so place sensors at multiple levels to ensure uniform conditions. If needed, add supplemental heaters, humidifiers, or fans to target specific areas. Regularly calibrate your sensors and equipment to maintain accuracy, as even small deviations can affect mushroom development. By meticulously managing temperature and humidity, you create an environment where mushrooms can flourish, leading to healthier yields and fewer cultivation challenges.

Mastering Mushroom Cultivation: A Beginner’s Guide to Growing Mushrooms at Home

You may want to see also

Lighting Requirements for Growth

Mushrooms have unique lighting requirements compared to plants, as they do not rely on photosynthesis for growth. However, light still plays a crucial role in their development, particularly in fruiting body formation and orientation. When designing a grow room for mushrooms, understanding and implementing the correct lighting conditions is essential for optimal yields. The primary purpose of lighting in a mushroom grow room is to signal the mycelium that it’s time to fruit and to help mushrooms grow upright and healthy.

For most mushroom species, indirect or low-intensity lighting is sufficient. A standard recommendation is to provide 8–12 hours of light per day, mimicking natural daylight cycles. This can be achieved using LED grow lights, fluorescent tubes, or even natural light through a window, though controlled artificial lighting is preferred for consistency. The light intensity should be relatively low, around 200–500 lux, as mushrooms do not require high-intensity light like plants. Overly bright light can stress the mycelium and hinder fruiting.

The color temperature of the light also matters. Cool white or full-spectrum LED lights with a color temperature of 4000–6500K are ideal, as they closely resemble natural daylight. Avoid red or blue spectrum lights, as they are not necessary for mushroom growth and may disrupt the fruiting process. Additionally, ensure the lighting setup is energy-efficient, as the lights will be on for several hours daily. LED lights are highly recommended for their low heat output and energy efficiency.

Positioning the lights correctly is another critical aspect. Lights should be placed above the growing area, evenly distributing light across the substrate or fruiting bags. Avoid placing lights too close to the mushrooms, as excessive heat can dry out the growing environment and damage the mycelium. A distance of 12–18 inches between the light source and the mushrooms is generally adequate. If using multiple light fixtures, ensure they are spaced evenly to avoid shadowed areas.

Finally, consistency in lighting schedules is key. Mushrooms thrive in predictable environments, so maintaining a regular light-dark cycle is essential. Use timers to automate the lighting schedule, ensuring the grow room receives the same amount of light each day. During the pinning and fruiting stages, some growers introduce short periods of darkness or "nighttime" to encourage mushroom formation. However, complete darkness is not necessary, and a consistent low-light environment is often sufficient for healthy fruiting. By carefully managing these lighting requirements, you can create an optimal environment for mushroom growth in your dedicated grow room.

Cultivating Psychedelic Mushrooms: A Comprehensive Guide to Growing Techniques

You may want to see also

Explore related products

Sterilization & Cleanliness Tips

Maintaining a sterile and clean environment is crucial for successful mushroom cultivation, as contaminants like bacteria, mold, and other fungi can quickly ruin your crop. The grow room must be designed and maintained with meticulous attention to sterilization and cleanliness to ensure optimal conditions for mushroom growth. Here are some essential tips to achieve this.

Air Filtration and Circulation: Start by installing a high-quality HEPA (High-Efficiency Particulate Air) filter in your grow room’s ventilation system. This filter will capture airborne particles, including spores and dust, preventing them from settling on your mushroom substrate. Ensure proper air circulation by using fans to maintain a consistent airflow, which helps prevent stagnant air pockets where contaminants can thrive. Regularly clean or replace the filters to maintain their efficiency.

Surface Sterilization: All surfaces within the grow room, including walls, floors, shelves, and equipment, should be regularly cleaned and sterilized. Use a 10% bleach solution or a commercial disinfectant specifically designed for sterile environments. Pay special attention to corners, crevices, and areas around equipment, as these spots can harbor hidden contaminants. After cleaning, allow the surfaces to dry completely before reintroducing any mushroom cultures or substrates to avoid dilution of sterilizing agents.

Personal Hygiene and Protective Gear: Anyone entering the grow room must follow strict hygiene protocols. Wear sterile gloves, a lab coat or coveralls, a hairnet, and a face mask to minimize the introduction of external contaminants. Before entering, use a disinfectant footbath to clean footwear or, ideally, change into dedicated cleanroom shoes. Showering before work and using antimicrobial soaps can further reduce the risk of contamination from skin and hair.

Substrate and Spawn Sterilization: The substrate (the material on which mushrooms grow) and spawn (the mushroom mycelium) must be sterilized before use. Autoclaving is the most reliable method, where the substrate is subjected to high-pressure steam at 121°C (250°F) for at least 30 minutes. Alternatively, pressure cooking can be used for smaller batches. Ensure that all containers and tools used in this process are also sterilized. After sterilization, handle the substrate and spawn in a still-air box or laminar flow hood to maintain sterility during the inoculation process.

Routine Monitoring and Maintenance: Implement a regular cleaning schedule and stick to it rigorously. Daily tasks might include wiping down surfaces, checking and replacing filters, and inspecting for any signs of contamination. Weekly or bi-weekly deep cleaning sessions should involve more thorough disinfection of all areas. Keep a log of cleaning activities and any observed issues to track patterns and address potential problems early. Additionally, use agar plates or other testing methods to monitor the air and surfaces for microbial activity, allowing you to take corrective action before contamination spreads.

By following these sterilization and cleanliness tips, you can create a grow room environment that minimizes the risk of contamination, setting the stage for healthy and productive mushroom cultivation.

Exploring Florida's Forests: Do Psilocybin Mushrooms Grow Here?

You may want to see also

Substrate Preparation & Spawning

Substrate preparation is a critical step in mushroom cultivation, as it provides the nutrients and environment necessary for mycelium growth. Begin by selecting an appropriate substrate material, such as straw, wood chips, or a grain-based mixture, depending on the mushroom species you intend to grow. For example, oyster mushrooms thrive on straw, while shiitake mushrooms prefer hardwood sawdust. Sterilize or pasteurize the substrate to eliminate competing microorganisms. Sterilization, typically done in an autoclave or pressure cooker, is essential for grain substrates, while pasteurization, involving soaking in hot water, is sufficient for straw or wood-based substrates. Ensure the substrate cools to around 70-80°F (21-27°C) before proceeding, as excessive heat can kill the mycelium.

Once the substrate is prepared, it’s time for spawning, which involves introducing mushroom spawn (colonized grain or sawdust) into the substrate. Calculate the correct spawn-to-substrate ratio, usually 1:10 to 1:5 by weight, depending on the mushroom species and substrate type. Mix the spawn thoroughly into the substrate using a sanitized tool to ensure even distribution. This step requires a clean environment to minimize contamination, so work in a still air box or a clean room if possible. After mixing, transfer the inoculated substrate into grow bags, trays, or containers, leaving enough headspace for the mycelium to expand. Seal the containers with a breathable material, such as micropore tape or a small hole in the bag, to allow gas exchange while preventing contaminants from entering.

Maintaining proper environmental conditions during colonization is crucial. Store the inoculated substrate in a dark, temperature-controlled area, ideally between 70-75°F (21-24°C), depending on the mushroom species. Humidity should be moderate to prevent drying, but not so high that it encourages mold growth. Monitor the substrate regularly for signs of contamination, such as unusual colors or smells, and discard any affected containers immediately. Colonization time varies by species and substrate but typically takes 2-4 weeks for grain-based substrates and 4-6 weeks for straw or wood-based substrates. Patience is key, as rushing this stage can compromise the entire grow cycle.

As the mycelium colonizes the substrate, it will turn the material white or slightly off-white, indicating healthy growth. Once fully colonized, the substrate is ready for the next phase, which often involves introducing light and adjusting humidity to initiate fruiting. Avoid disturbing the substrate during colonization, as this can introduce contaminants or set back the growth process. Proper substrate preparation and spawning lay the foundation for a successful mushroom harvest, so attention to detail and cleanliness are paramount in this stage of building your grow room.

Do Magic Mushrooms Thrive Under Pine Trees? Exploring the Myth

You may want to see also

Frequently asked questions

The essential components include a controlled environment with proper ventilation, humidity, and temperature regulation. You’ll need a grow tent or insulated room, humidifiers or misters, a thermostat-controlled heater or air conditioner, LED or fluorescent grow lights, and shelving or racks for mushroom substrates.

Use a hygrometer and thermometer to monitor conditions. Ideal humidity is typically 80-95%, maintained with humidifiers, misters, or a humidification system. Temperature should be kept between 65-75°F (18-24°C), controlled with heaters, air conditioners, or fans.

Mushrooms don’t require intense light, but they need a light cycle to trigger fruiting. LED or fluorescent lights are ideal because they’re energy-efficient and emit minimal heat. Provide 12 hours of indirect light daily to simulate natural conditions.

Maintain cleanliness by sterilizing all equipment and surfaces before use. Use HEPA filters for air intake, wear gloves and a mask when handling substrates, and avoid introducing foreign organisms. Regularly clean the room and ensure proper airflow to minimize contamination risks.