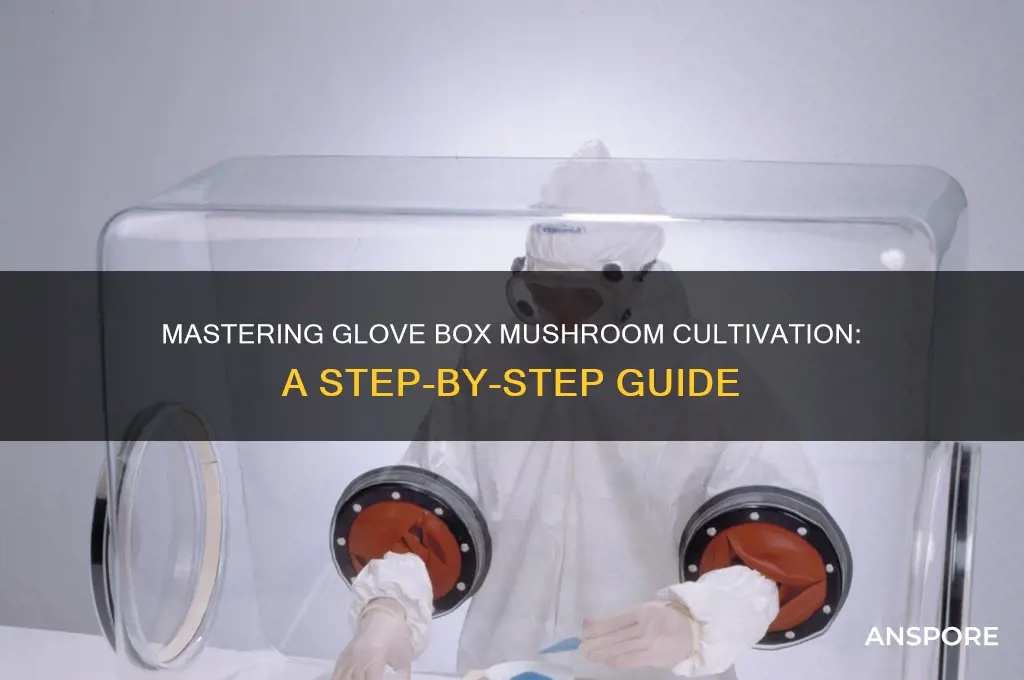

Glove box mushrooms, a fascinating technique in mycology, involves cultivating mushrooms within a controlled, sterile environment using a glove box. This method is particularly useful for growing sensitive or contaminant-prone species, as it minimizes exposure to external pollutants and maintains optimal conditions for fungal growth. The glove box, equipped with gloves for manipulation, allows researchers or enthusiasts to handle substrates, spores, and mycelium without compromising sterility. By mastering this technique, individuals can ensure higher success rates in mushroom cultivation, making it an invaluable skill for both scientific study and hobbyist endeavors.

Explore related products

What You'll Learn

- Sterilize Equipment: Clean tools, jars, and gloves thoroughly to prevent contamination during mushroom cultivation

- Prepare Substrate: Mix and sterilize materials like straw or manure for mushroom growth

- Inoculate Substrate: Inject spore syringe into substrate in a sterile glove box environment

- Maintain Humidity: Use a humidifier or misting to keep conditions optimal for mycelium growth

- Monitor Progress: Regularly check for contamination and mycelium colonization in the glove box

Sterilize Equipment: Clean tools, jars, and gloves thoroughly to prevent contamination during mushroom cultivation

When preparing to cultivate mushrooms in a glove box, the first and most critical step is to sterilize all equipment to prevent contamination. Contaminants such as bacteria, mold, or other fungi can quickly ruin your mushroom cultivation efforts. Begin by gathering all the tools, jars, and gloves you will be using. This includes items like scalpels, tweezers, spore syringes, glass jars, and nitrile gloves. Ensure that every piece of equipment is free from dust, dirt, or any residues from previous use. Start by washing all tools and jars with hot, soapy water, scrubbing thoroughly to remove any visible debris. Rinse everything with clean water to eliminate soap residue, as it can interfere with sterilization.

After cleaning, the next step is to sterilize the equipment. For metal tools like scalpels and tweezers, autoclaving is the most effective method. An autoclave uses high-pressure steam to kill all microorganisms, including spores. If you do not have access to an autoclave, submerging the tools in boiling water for at least 10 minutes can serve as an alternative, though it is less reliable. Glass jars should also be sterilized using an autoclave or pressure cooker. Ensure the jars are completely dry before sterilization to prevent cracking. If using a pressure cooker, process the jars at 15 psi for 30 minutes. Allow the jars to cool completely in a clean, covered area to maintain sterility.

Gloves are another critical component that requires careful attention. Nitrile gloves are preferred over latex due to their durability and resistance to punctures. Before handling any sterilized equipment or inoculating substrates, ensure your gloves are clean and free from contaminants. Wash your hands thoroughly before putting on the gloves, and avoid touching non-sterile surfaces once they are on. If you are working in a glove box, the gloves attached to the box should be sterilized by wiping them down with 70% isopropyl alcohol. This step is essential to maintain the sterile environment inside the glove box.

For additional safety, consider using a disinfectant solution to clean your workspace and any surfaces that will come into contact with your equipment. A mixture of 10% bleach solution or 70% isopropyl alcohol can be used to wipe down tables, counters, and the exterior of the glove box. Allow the disinfectant to sit for at least 10 minutes before wiping it away with a clean cloth. This ensures that the area is free from any potential contaminants that could compromise your mushroom cultivation.

Finally, organize your sterilized equipment in a clean, designated area to maintain sterility until you are ready to use it. Keep jars covered with aluminum foil or sterile lids, and store tools in a sealed container. When working in the glove box, minimize the introduction of external air by working quickly and efficiently. Proper sterilization of equipment is the foundation of successful mushroom cultivation, as it ensures that your mycelium can grow without competition from unwanted microorganisms. By following these steps meticulously, you significantly increase the chances of a successful and contaminant-free mushroom harvest.

Philanemo Mushrooms: Mondstadt's Bountiful Delicacy

You may want to see also

Prepare Substrate: Mix and sterilize materials like straw or manure for mushroom growth

To prepare the substrate for growing mushrooms in a glove box, start by selecting the appropriate materials. Commonly used substrates include straw, manure, or a combination of both. Straw is lightweight and easy to handle, while manure adds essential nutrients that promote mushroom growth. For optimal results, use wheat straw or rye straw, as they have a good balance of cellulose and hemicellulose. If using manure, ensure it is well-aged to avoid introducing harmful pathogens. Mix the straw and manure in a ratio of 80% straw to 20% manure. This blend provides a nutrient-rich environment that supports mycelium colonization.

Once the materials are selected and mixed, the next step is to hydrate the substrate. Proper hydration is crucial for mushroom growth, as it allows the mycelium to spread efficiently. Begin by soaking the straw and manure mixture in water for 1-2 hours. The goal is to achieve a moisture content of around 60-70%. To check hydration, squeeze a handful of the substrate—it should feel damp but not release excess water. After soaking, drain the excess water thoroughly to prevent waterlogging, which can lead to contamination.

After hydration, the substrate must be sterilized to eliminate competing organisms like bacteria and molds. Sterilization is a critical step in ensuring a clean environment for mushroom growth. One common method is pasteurization, which involves heating the substrate to a specific temperature for a set duration. For straw and manure, heat the mixture to 160-180°F (71-82°C) for 1-2 hours. Use a large pot or steam sterilizer for this process. Alternatively, if using a glove box, you can sterilize the substrate in an autoclave at 121°C (250°F) for 1-2 hours. Ensure the substrate cools to room temperature before inoculation to avoid damaging the mushroom spawn.

Another sterilization method suitable for glove box setups is chemical treatment. This involves using a disinfectant like lime or hydrogen peroxide to treat the substrate. For example, sprinkle agricultural lime (calcium hydroxide) over the hydrated substrate at a rate of 2-3% by weight, then mix thoroughly. Let the substrate sit for 24 hours to allow the lime to neutralize potential contaminants. While chemical treatment is less precise than pasteurization or autoclaving, it can be effective when done correctly. Always wear protective gear, such as gloves and a mask, when handling chemicals.

Finally, once the substrate is sterilized and cooled, it is ready for inoculation with mushroom spawn. Transfer the substrate into sterile containers or bags, leaving enough space for the mycelium to grow. Introduce the spawn evenly throughout the substrate, ensuring good contact between the spawn and the material. Seal the containers or bags to maintain a sterile environment. Place the inoculated substrate in the glove box, maintaining optimal conditions of temperature (70-75°F or 21-24°C) and humidity (90-95%). Regularly monitor the substrate for signs of contamination or mycelium growth, and adjust conditions as needed to support healthy mushroom development.

The Magic of Mushroom Spores: A Replication Guide

You may want to see also

Inoculate Substrate: Inject spore syringe into substrate in a sterile glove box environment

Inoculating the substrate with a spore syringe in a sterile glove box environment is a critical step in cultivating mushrooms. Begin by preparing your glove box, ensuring it is clean and sanitized to maintain a sterile workspace. The glove box should be equipped with gloves attached to the interior, allowing you to manipulate items inside without compromising sterility. Preheat the glove box to the appropriate temperature, typically around 70-75°F (21-24°C), to ensure optimal conditions for the inoculation process. Gather all necessary materials, including the spore syringe, substrate jars or bags, alcohol wipes, and a lighter or torch for sterilizing tools.

Once the glove box is ready, place the spore syringe and substrate inside. Before proceeding, sterilize the needle of the spore syringe by passing it through a flame or wiping it with a 70% isopropyl alcohol pad. This step is crucial to prevent contamination. Next, carefully open the substrate jar or bag within the glove box, minimizing exposure to the external environment. If using jars, remove the lid and set it aside on a clean surface inside the box. For bags, open the injection port while keeping the rest of the bag sealed. Ensure the substrate is properly hydrated and ready for inoculation, as dry substrate will not support mycelium growth effectively.

With the substrate exposed, insert the sterilized needle of the spore syringe into the substrate. Aim to distribute the spores evenly throughout the material. For jars, inject the spores in multiple locations, typically 2-4 points around the jar, to ensure thorough colonization. If using bags, inject the spores through the designated port, squeezing the bag slightly to create space for the needle. Each injection should dispense approximately 1-2 cc of spore solution, depending on the substrate volume. Work methodically to avoid over-injecting in one area, which can lead to uneven growth.

After injecting the spores, promptly seal the substrate container to maintain sterility. For jars, replace the lid and secure it with a piece of micropore tape to allow gas exchange while preventing contaminants from entering. For bags, close the injection port tightly. Gently agitate the substrate by swirling the jar or massaging the bag to distribute the spores more evenly. This step enhances the chances of successful colonization. Once completed, remove the inoculated substrate from the glove box and place it in a dark, temperature-controlled environment, such as a closet or cabinet, to encourage mycelium growth.

Finally, clean and sanitize the glove box after use to prepare it for future inoculations. Dispose of any waste properly, and ensure all tools are sterilized and stored correctly. Monitoring the substrate for signs of contamination or mycelium growth is essential in the following days. If done correctly, the inoculated substrate should show signs of colonization within 7-14 days, marked by white, thread-like mycelium spreading throughout the material. This process requires patience and attention to detail, but mastering it is key to successful mushroom cultivation in a glove box environment.

The Ultimate Guide to Cleaning Mushrooms

You may want to see also

Explore related products

Maintain Humidity: Use a humidifier or misting to keep conditions optimal for mycelium growth

Maintaining optimal humidity is critical for successful mycelium growth in a glove box mushroom setup. Mycelium, the vegetative part of a fungus, thrives in environments with high humidity levels, typically between 90-95%. Without adequate moisture, the mycelium can dry out, stunting growth and reducing yields. To achieve this, a humidifier is an excellent tool. Place a small, adjustable humidifier inside the glove box, ensuring it’s positioned away from direct contact with the substrate to prevent waterlogging. Set the humidifier to maintain the desired humidity range, and regularly monitor the levels using a hygrometer to make adjustments as needed. This method provides a consistent and controlled environment for the mycelium to flourish.

If a humidifier is not available or feasible, misting is a practical alternative to maintain humidity. Use a fine-mist spray bottle filled with distilled or filtered water to lightly mist the inside of the glove box, focusing on the walls and air space rather than directly on the substrate. Misting should be done 2-3 times daily, or as often as necessary to keep humidity levels stable. Be cautious not to over-mist, as excessive moisture can lead to contamination or mold growth. Pair this method with a hygrometer to ensure the humidity remains within the optimal range, and always allow excess moisture to settle before closing the glove box to maintain a balanced environment.

Combining both humidification methods can yield even better results. Use a humidifier as the primary source of humidity control, and supplement with misting during periods of rapid evaporation or when humidity levels drop unexpectedly. This dual approach ensures a stable and consistent environment for mycelium growth. Additionally, consider using a humidity controller with the humidifier to automate the process, reducing the need for manual intervention. This setup is particularly useful for larger glove box systems or when growing multiple mushroom varieties with similar humidity requirements.

Proper ventilation is also essential when maintaining humidity in a glove box. While the goal is to keep humidity high, stagnant air can lead to issues like mold or bacterial growth. Ensure the glove box has a passive ventilation system, such as small vents or a slightly open seal, to allow for air exchange without significantly dropping humidity levels. If using a humidifier, position it near the ventilation source to help distribute moisture evenly. Regularly inspect the glove box for signs of condensation or water accumulation, and address any issues promptly to prevent contamination.

Lastly, monitor the substrate’s moisture content in conjunction with humidity control. While the air humidity is crucial, the substrate should also retain adequate moisture for mycelium colonization. Use a moisture meter to check the substrate periodically, ensuring it remains damp but not waterlogged. If the substrate dries out, gently mist it with water, taking care not to disturb the mycelium. By maintaining both air humidity and substrate moisture, you create an ideal environment for robust mycelium growth and successful mushroom fruiting in your glove box setup.

Mushrooms: A Kingdom of Their Own

You may want to see also

Monitor Progress: Regularly check for contamination and mycelium colonization in the glove box

Monitoring the progress of your mushroom cultivation in a glove box is crucial to ensure a successful harvest and to catch any issues early. Regular checks for contamination and mycelium colonization are essential steps in this process. Here’s how to effectively monitor progress:

Establish a Checking Schedule: Set a consistent schedule for inspecting your glove box, ideally every 2-3 days during the initial stages of colonization. Mycelium growth can be rapid, and contamination can spread quickly if left unchecked. Use a notebook or digital tool to log each inspection, noting the date, observed conditions, and any actions taken. This record will help you track progress and identify patterns over time.

Inspect for Contamination: During each check, carefully examine the substrate and mycelium for any signs of contamination, such as mold, discoloration, or unusual smells. Contaminants often appear as green, black, or fuzzy patches that differ from the white or light-colored mycelium. If detected, isolate the contaminated area immediately to prevent spread. Use a sterile tool to remove the affected portion if possible, and ensure the glove box environment remains clean and sterile during this process.

Assess Mycelium Colonization: Monitor the spread of mycelium across the substrate to gauge colonization progress. Healthy mycelium appears as a dense, white network. Calculate the percentage of colonization by comparing the area covered by mycelium to the total substrate area. Aim for at least 70-80% colonization before proceeding to the next stage, such as fruiting. Inconsistent or slow colonization may indicate issues with humidity, temperature, or substrate quality, requiring adjustments to optimize conditions.

Maintain Sterility During Checks: Each time you open the glove box, ensure you follow strict sterile procedures to minimize the risk of introducing contaminants. Wear sterile gloves, use a mask to avoid breathing onto the substrate, and sanitize any tools or equipment before use. Keep the glove box environment clean and organized, and work quickly but carefully to reduce exposure time. After each inspection, clean the glove box interior with a suitable disinfectant to maintain a sterile environment.

Adjust Conditions as Needed: Based on your observations, make necessary adjustments to the glove box environment. If contamination is recurring, review your sterilization techniques and consider using a more effective disinfectant. If mycelium growth is slow, check and adjust humidity and temperature levels to create optimal conditions. Regular monitoring allows you to fine-tune the environment, ensuring the best possible conditions for healthy mycelium development and minimizing the risk of failed crops.

By diligently monitoring progress and addressing issues promptly, you can significantly increase the chances of a successful mushroom cultivation in your glove box. Consistent checks and proactive management are key to achieving a thriving mycelium network and a bountiful harvest.

Mushrooms: Saving Bees, Our Food Heroes

You may want to see also

Frequently asked questions

A glove box is a sealed container with built-in gloves, allowing users to manipulate items inside without exposing them to external contaminants. It’s used for growing mushrooms to maintain a sterile environment, preventing mold, bacteria, or other contaminants from interfering with the mushroom cultivation process.

You’ll need a glove box, a HEPA filter, a vacuum pump, sterile gloves, a pressure gauge, and a way to maintain humidity and temperature control inside the box. Additionally, you’ll require sterile substrates, mushroom spawn, and tools for inoculation, such as scalpels or syringes.

Before use, sterilize the glove box interior with a disinfectant like 70% isopropyl alcohol. Ensure all tools and materials are sterilized before entering the box. Work slowly and deliberately to avoid contamination, and use a HEPA filter to continuously purify the air inside the glove box.