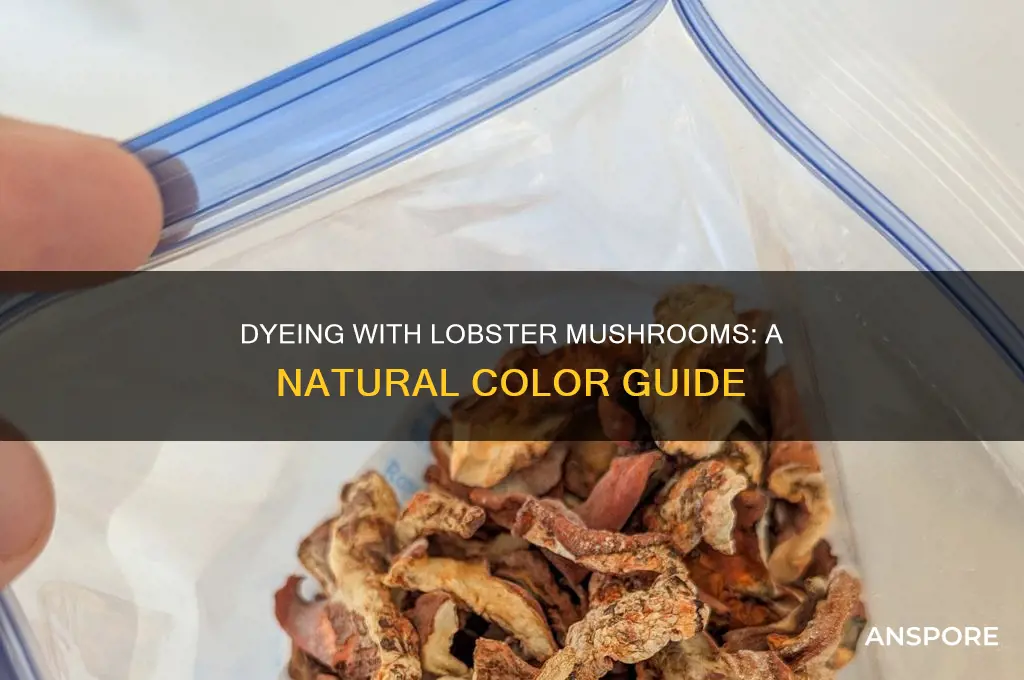

Dyeing with lobster mushroom, a unique and vibrant fungus known for its striking orange and red hues, offers a natural and sustainable way to create beautiful, earthy tones on fabrics and fibers. This fascinating mushroom, scientifically named *Lactarius deliciosus* or *Hypomyces lactifluorum*, contains pigments that can be extracted and used as a dye, resulting in rich, warm colors ranging from golden yellow to deep orange. The process involves harvesting the mushroom, preparing it through simmering or soaking to release its pigments, and then applying the dye to materials like wool, silk, or cotton, often with the aid of a mordant to ensure colorfastness. Beyond its aesthetic appeal, dyeing with lobster mushroom connects artisans and crafters to the natural world, blending traditional techniques with modern creativity to produce one-of-a-kind, eco-friendly textiles.

| Characteristics | Values |

|---|---|

| Mushroom Type | Lobster Mushroom (Hypomyces lactifluorum) |

| Color Produced | Orange, rust, or reddish-brown hues |

| Preparation | Clean and dry the mushroom thoroughly; grind into a fine powder |

| Mordant | Alum, iron, or copper (optional, enhances color fastness) |

| Fiber Types | Protein fibers (wool, silk) or cellulose fibers (cotton, linen) |

| Dyeing Process | Simmer mushroom powder in water for 1-2 hours; strain and add fabric; simmer for 30-60 minutes |

| Color Fastness | Moderate to good with mordant; may fade over time with exposure to sunlight |

| Sustainability | Natural, eco-friendly dye source; foraged or cultivated mushrooms |

| Safety | Non-toxic, but wear gloves to avoid skin irritation |

| Availability | Seasonal, found in coniferous forests or cultivated |

| Cost | Low to moderate, depending on sourcing method |

| Special Notes | Experiment with mordants for varied shades; pre-mordant fabric for best results |

Explore related products

What You'll Learn

- Preparation: Clean, slice, and dry lobster mushrooms thoroughly before dyeing for best color absorption

- Mordanting: Use alum or iron to fix mushroom dyes onto fabric or yarn effectively

- Extraction: Simmer mushrooms in water to release pigments for dye solution

- Dyeing Process: Immerse materials in mushroom dye bath, heat gently, and soak for hours

- Color Variations: Experiment with modifiers like vinegar or ammonia to alter dye shades

Preparation: Clean, slice, and dry lobster mushrooms thoroughly before dyeing for best color absorption

Before diving into the dyeing process, proper preparation of lobster mushrooms is crucial for achieving vibrant and long-lasting colors. The first step is to clean the mushrooms thoroughly. Lobster mushrooms can harbor dirt, debris, and insects, especially since they are often found on the forest floor. Gently brush off any visible dirt using a soft-bristled brush or a clean cloth. For stubborn particles, rinse the mushrooms briefly under cold running water, being careful not to soak them, as excess moisture can affect the dyeing process. Pat them dry with a paper towel or clean cloth to remove any surface water.

Once cleaned, the next step is to slice the lobster mushrooms. Slicing increases the surface area, allowing for better color absorption during the dyeing process. Use a sharp knife to cut the mushrooms into uniform slices, approximately ¼ to ½ inch thick. Thicker slices may retain more of the mushroom's natural structure, while thinner slices will absorb dye more quickly. Consider the desired outcome of your project when deciding on the thickness. If you plan to use the dyed mushrooms for specific crafts, such as jewelry or decorative items, slicing them consistently will ensure a more polished final product.

After slicing, it is essential to dry the lobster mushrooms completely. Moisture in the mushrooms can interfere with the dyeing process, leading to uneven color distribution or mold growth. Spread the sliced mushrooms in a single layer on a clean, dry surface, such as a wire rack or a baking sheet lined with parchment paper. Allow them to air-dry in a well-ventilated area, away from direct sunlight, which can cause fading. Depending on humidity levels, this process can take several days. For faster drying, use a food dehydrator set at a low temperature (around 100°F to 120°F) until the mushrooms are crisp and brittle to the touch.

Properly dried lobster mushrooms are ready for the dyeing process, but it’s worth noting that testing a small batch first can help ensure the desired color outcome. Since natural dyes can vary based on factors like mushroom freshness and dye concentration, experimenting with a few slices will allow you to adjust your technique before committing to a larger batch. Additionally, storing dried mushrooms in an airtight container until you’re ready to dye them will preserve their integrity and prevent contamination.

In summary, the preparation of lobster mushrooms—cleaning, slicing, and drying—lays the foundation for successful dyeing. Each step is designed to optimize color absorption and ensure the longevity of the dyed material. By taking the time to prepare the mushrooms properly, you’ll set the stage for creating beautiful, naturally dyed crafts that showcase the unique hues of the lobster mushroom.

The Ultimate Guide to Heating Mushrooms

You may want to see also

Mordanting: Use alum or iron to fix mushroom dyes onto fabric or yarn effectively

Mordanting is a crucial step in the natural dyeing process, especially when working with mushroom dyes like those derived from the lobster mushroom (*Lactarius deliciosus*). Without a proper mordant, the colors may not adhere well to the fabric or yarn, resulting in faded or uneven results. Alum (potassium aluminum sulfate) and iron are two of the most commonly used mordants for mushroom dyes, each producing different effects. Alum is a gentle mordant that helps fix the dye molecules to the fibers, often brightening and stabilizing the colors. Iron, on the other hand, acts as a modifier, deepening and darkening the shades while also shifting the hue, often toward greener or grayer tones.

To mordant with alum, start by weighing your fabric or yarn. A typical ratio is 15-20% alum by weight of the fiber. Dissolve the alum in hot water, ensuring it is fully dissolved before adding the pre-washed and wetted fabric or yarn. Simmer the mixture for about an hour, stirring occasionally to ensure even exposure. After simmering, allow the fabric or yarn to cool in the mordant bath, then rinse thoroughly and let it dry. This process prepares the fibers to bond effectively with the lobster mushroom dye, enhancing colorfastness and vibrancy.

Iron mordanting requires a different approach due to its stronger effect on the dye. To use iron as a mordant, dissolve iron sulfate or ferrous sulfate in hot water, using a ratio of 5-10% by weight of the fiber. Add the pre-washed and wetted fabric or yarn to the solution and simmer for 30-45 minutes. Unlike alum, iron does not need to remain in the fibers long-term, so a shorter mordanting time is sufficient. After simmering, rinse the fabric or yarn well to remove excess iron, as leaving it in the fibers can weaken them over time. Iron mordants will significantly alter the color of the lobster mushroom dye, often creating deeper, more muted tones.

When using either alum or iron, it’s essential to pre-wash the fabric or yarn to remove any finishes or impurities that might interfere with the mordanting process. Natural fibers like cotton, wool, and silk work best with these mordants, as synthetic fibers often do not absorb natural dyes effectively. After mordanting, proceed with the dyeing process using your prepared lobster mushroom dye bath. The mordanted fibers will now be ready to absorb and retain the colors more effectively.

Experimenting with different mordant concentrations and combinations can yield unique results, allowing you to explore the full potential of lobster mushroom dyes. Always wear gloves and work in a well-ventilated area when handling mordants, as they can be irritating to the skin and respiratory system. With proper mordanting, your lobster mushroom-dyed fabrics or yarns will boast rich, lasting colors that showcase the beauty of this unique natural dye.

Is Mellow Mushroom Open on July 4th? Check Holiday Hours Here

You may want to see also

Extraction: Simmer mushrooms in water to release pigments for dye solution

To begin the process of extracting dye from lobster mushrooms, start by gathering your materials. You’ll need fresh or dried lobster mushrooms, a large stainless steel or enamel pot (avoid aluminum as it can alter colors), water, and a stove. If using dried mushrooms, rehydrate them in warm water for about 30 minutes before proceeding. Fresh mushrooms can be used directly, but ensure they are clean and free of debris. The quantity of mushrooms depends on the intensity of color desired and the amount of dye needed—generally, a 1:1 ratio of mushrooms to water by weight is a good starting point.

Once your mushrooms are prepared, place them in the pot and cover them with water. The water should just barely cover the mushrooms to ensure a concentrated pigment extraction. Place the pot on the stove and bring the mixture to a gentle simmer. Avoid boiling, as high heat can degrade the pigments and reduce the vibrancy of the dye. Maintain a low simmer for about 1 to 2 hours, stirring occasionally to ensure even extraction. The water will gradually take on the rich reddish-orange hue characteristic of lobster mushrooms, indicating that the pigments are being released.

As the mushrooms simmer, you’ll notice the liquid becoming more intensely colored. This is the dye solution forming. Keep an eye on the pot to ensure it doesn’t reduce too much; if necessary, add a small amount of hot water to maintain the initial volume. After simmering, carefully strain the mushrooms from the liquid using a fine mesh strainer or cheesecloth to capture all the pigment. The spent mushrooms can be composted or used for a second, less concentrated batch of dye if desired.

The resulting liquid is your dye solution, ready for use in coloring textiles, paper, or other materials. For a more concentrated dye, you can gently simmer the liquid further to reduce it, but be cautious not to scorch it. Allow the dye solution to cool before using it, as hot liquid can damage delicate fibers. Store any unused dye in a glass container in the refrigerator for up to a week, or freeze it for longer-term storage.

This simmering method is a simple yet effective way to extract the vibrant pigments from lobster mushrooms, providing a natural and sustainable dye option for various projects. Experiment with different simmering times and mushroom quantities to achieve the desired shade, and always test the dye on a small sample of your material before proceeding with a larger project.

Mushroom Extracts: Do They Work?

You may want to see also

Explore related products

Dyeing Process: Immerse materials in mushroom dye bath, heat gently, and soak for hours

The process of dyeing with lobster mushrooms begins with preparing the dye bath. Start by cleaning the lobster mushrooms thoroughly to remove any dirt or debris. Chop the mushrooms into small pieces to maximize the surface area, which helps release more color. Place the chopped mushrooms in a large pot and cover them with water. The ratio of mushrooms to water can vary, but a general guideline is to use about 1 part mushroom to 4 parts water. Bring the mixture to a gentle simmer, allowing the mushrooms to release their vibrant orange-red pigment into the water. This simmering process typically takes about 30–60 minutes, depending on the intensity of color desired.

Once the dye bath is prepared, strain the mushroom pieces from the liquid, reserving the colorful liquid for dyeing. If desired, you can return the mushroom pieces to the pot with fresh water to create a second, lighter batch of dye. While the dye bath cools slightly, prepare the materials you intend to dye. Natural fibers such as wool, silk, cotton, or linen work best with mushroom dyes. Scour the fabric or yarn thoroughly to remove any oils or residues, as this ensures better absorption of the dye. Wet the material with warm water and gently squeeze out excess moisture before adding it to the dye bath.

Immerse the prepared materials into the mushroom dye bath, ensuring they are fully submerged. The pot should be large enough to allow the fabric or yarn to move freely, preventing uneven dyeing. Heat the dye bath gently, maintaining a temperature between 180°F and 200°F (82°C–93°C). Avoid boiling, as high temperatures can damage both the dye and the fibers. Use a thermometer to monitor the temperature and adjust the heat as needed. Stir the materials occasionally to ensure even color distribution.

After heating, turn off the heat source and allow the materials to soak in the dye bath. The longer the soak, the deeper the color will be. Soaking times can range from a few hours to overnight, depending on the desired intensity. For lighter shades, a shorter soak is sufficient, while deeper hues require more time. Cover the pot to retain heat and prevent evaporation during the soaking period. This slow infusion process allows the natural pigments from the lobster mushroom to bond with the fibers, creating a rich, lasting color.

Once the desired color is achieved, carefully remove the dyed materials from the dye bath. Rinse them gently in cool water until the water runs clear, removing any excess dye. Avoid using hot water, as it can cause the dye to bleed or fade. After rinsing, wash the materials with a mild detergent to ensure cleanliness and further set the dye. Finally, allow the dyed items to air dry away from direct sunlight, as UV rays can affect the color. With proper care, the vibrant hues from the lobster mushroom will remain vivid and beautiful, showcasing the unique beauty of natural dyeing.

Calm Slumber: Post-Mushroom Relaxation Techniques

You may want to see also

Color Variations: Experiment with modifiers like vinegar or ammonia to alter dye shades

Lobster mushrooms (*Hypomyces lactifluorum*) are renowned for their vibrant orange-red hues, which can be extracted to create natural dyes. However, the colors obtained directly from the mushroom may not always align with your desired shade. This is where modifiers like vinegar and ammonia come into play, offering a way to experiment with color variations. By adjusting the pH of the dye bath, these household substances can shift the tones of your lobster mushroom dye, allowing for a range of outcomes from softer pastels to deeper, more intense colors.

Using Vinegar to Modify Dye Shades: Vinegar, being acidic, can brighten and lighten the colors extracted from lobster mushrooms. To incorporate vinegar, start by preparing your dye bath as usual by simmering the mushrooms in water. Once the dye has been extracted, strain the liquid and divide it into separate containers if you’re working with multiple batches. Add 1-2 tablespoons of white vinegar per quart of dye liquid, stirring gently to mix. The acidic nature of vinegar will shift the dye toward yellower or more muted tones, depending on the fabric or fiber being dyed. Test on small samples first to observe how the color changes, as vinegar can also affect the absorption of the dye into the material.

Using Ammonia to Modify Dye Shades: Ammonia, on the other hand, is alkaline and can deepen or intensify the colors derived from lobster mushrooms. To use ammonia, ensure you work in a well-ventilated area and wear gloves, as it can be harsh on the skin and respiratory system. After preparing your dye bath, add 1 teaspoon of clear household ammonia per quart of dye liquid, stirring carefully. The alkaline environment created by ammonia can shift the dye toward richer, more reddish tones. Be cautious with the amount of ammonia used, as too much can alter the fabric’s texture or damage delicate fibers. Always test on a small piece of material before dyeing larger items.

Combining Modifiers for Unique Effects: For more nuanced color variations, consider combining vinegar and ammonia in controlled amounts. Start by treating one batch of dye with vinegar and another with ammonia, then blend the two in different ratios to achieve intermediate shades. This technique allows for a broader spectrum of colors, from warm oranges to deep rusts. Keep detailed notes on the quantities of modifiers used and the resulting colors to replicate successful combinations in future projects.

Testing and Documenting Results: Experimentation is key when working with natural dyes and modifiers. Always test your dye batches on small swatches of the fabric or fiber you intend to dye, as different materials may react uniquely to both the dye and the modifiers. Document each experiment by labeling samples with the type and amount of modifier used, the dyeing time, and the resulting color. This systematic approach will help you refine your techniques and achieve consistent, reproducible results in your lobster mushroom dyeing projects.

Mushroom Magic: Beef Bourguignon's Perfect Fungi Partners

You may want to see also

Frequently asked questions

A lobster mushroom is a unique culinary fungus formed by a parasitic ascomycete (Hypomyces lactifluorum) infecting a Russula or Lactarius mushroom. While primarily known for its seafood-like flavor, it also contains pigments that can be used for natural dyeing, producing earthy tones like orange, brown, or tan.

Clean the mushrooms thoroughly to remove dirt and debris. Chop them into small pieces to maximize surface area, then simmer in water for 30–60 minutes to extract the pigments. Strain the liquid to create your dye bath, and reserve the mushroom pieces for composting or other uses.

Lobster mushroom dye works best on natural fibers like wool, silk, cotton, and linen. Pre-treat the fabric with a mordant (such as alum or iron) to help the dye bind effectively. Avoid synthetic materials, as they typically do not absorb natural dyes well.

Experiment with mordants to alter the color. For example, alum may yield warmer orange tones, while iron can shift the dye toward darker browns or grays. Additionally, modifying the pH of the dye bath with vinegar (acidic) or baking soda (alkaline) can subtly change the final color.