Fixing a mushroomed bolt, a common issue where the bolt head or threads expand due to over-tightening or excessive force, requires careful assessment and the right tools. Start by inspecting the bolt to determine the extent of the damage; if the mushrooming is minor, you may be able to salvage it by carefully grinding or filing down the deformed area. However, if the bolt is severely damaged or structurally compromised, it’s best to replace it entirely to ensure safety and reliability. For temporary fixes, using a bolt extractor or drilling out the bolt may be necessary, followed by cleaning the threads in the corresponding hole. Always use the correct size and grade of replacement bolt and consider applying thread locker or anti-seize compound to prevent future issues. Proper torque settings and regular maintenance can help avoid mushrooming in the first place.

| Characteristics | Values |

|---|---|

| Cause of Mushrooming | Over-tightening, using incorrect tools, low-quality bolts, or repeated assembly/disassembly |

| Tools Required | Die grinder, rotary tool, bolt extractor, hammer, punch, drill, tap and die set, safety gear (gloves, eye protection) |

| Methods to Fix | 1. Grinding: Use a die grinder or rotary tool to carefully grind down the mushroomed area until the bolt head is flush. 2. Drilling and Extracting: Drill a hole through the center of the bolt and use a bolt extractor to remove it. 3. Tapping and Replacing: If the bolt is stripped, tap the hole with a tap and die set and replace the bolt. |

| Prevention Tips | Use the correct tools, avoid over-tightening, apply thread lubricant, and use high-quality bolts |

| Safety Precautions | Wear safety gear, work in a well-ventilated area, and secure the workpiece to prevent movement |

| Difficulty Level | Moderate to difficult, depending on the severity of mushrooming and available tools |

| Cost | Low to moderate (depends on tools and replacement parts needed) |

| Time Required | 15 minutes to 1 hour, depending on the method used and the number of bolts to fix |

| Success Rate | High, if proper techniques and tools are used |

| Alternative Solutions | Replace the entire assembly or component if the bolt is inaccessible or severely damaged |

Explore related products

What You'll Learn

- Identify Mushrooming: Recognize signs of mushrooming, such as a swollen or distorted bolt head

- Safety Precautions: Wear protective gear and ensure the work area is stable and secure

- Tools Needed: Gather a grinder, die grinder, or bolt extractor for effective repair

- Grinding Technique: Carefully grind down the mushroomed area without damaging the bolt threads

- Replacement Option: If grinding fails, remove and replace the bolt with a new one

Identify Mushrooming: Recognize signs of mushrooming, such as a swollen or distorted bolt head

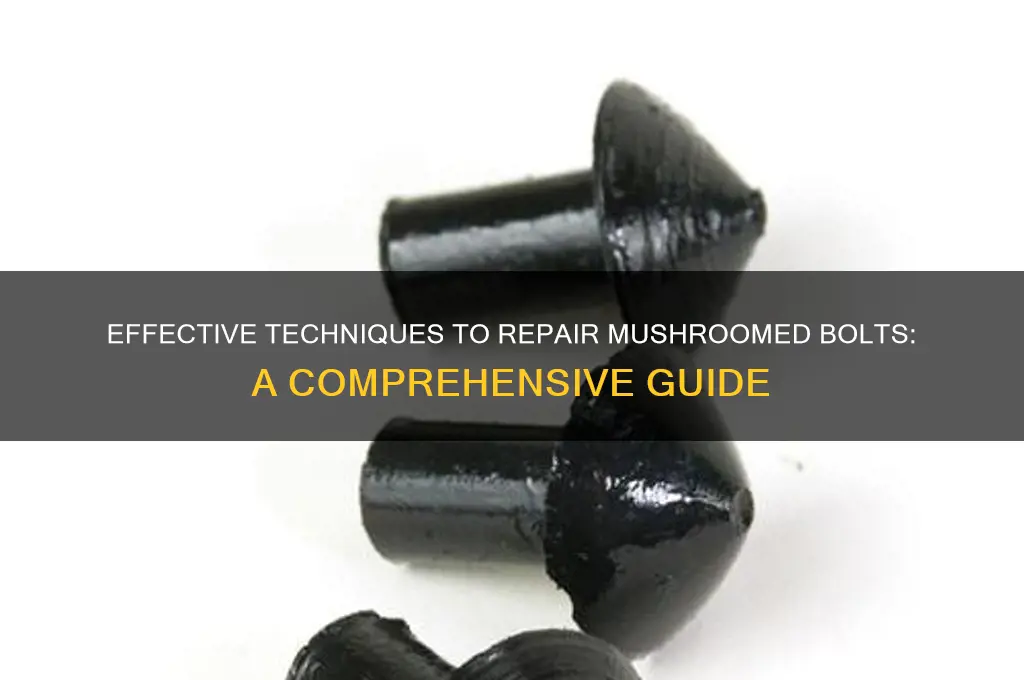

Identifying mushrooming in a bolt is the first critical step in addressing this common issue, especially in high-stress applications like automotive or machinery. Mushrooming occurs when the bolt head or nut becomes swollen, distorted, or flared outward due to excessive force or improper tightening. This deformation is often a result of over-torquing, using the wrong tools, or repeated stress on the fastener. To recognize mushrooming, start by visually inspecting the bolt head or nut. A healthy bolt head should have clean, sharp edges and a uniform shape. If you notice the edges of the bolt head are rounded, flared, or appear to have "mushroomed" outward, this is a clear sign of mushrooming. The distortion may be subtle at first, but even minor swelling can compromise the integrity of the fastener.

Another way to identify mushrooming is by examining how the bolt or nut interacts with the tool used to tighten or loosen it. If you experience difficulty engaging the wrench or socket due to the bolt head's shape, or if the tool slips more than usual, this could indicate mushrooming. The distorted shape prevents proper tool engagement, making it harder to apply torque effectively. Additionally, if you notice metal shavings or debris around the bolt head, this may be a result of the mushrooming process, as the metal is pushed outward under pressure.

Tactile inspection can also help confirm mushrooming. Run your fingers over the bolt head or nut to feel for any irregularities. A mushroomed bolt head will feel rough or uneven, with a noticeable bulge or swelling around the edges. In contrast, a properly functioning bolt head should feel smooth and consistent. If the swelling is severe, you may even see cracks or splits in the bolt head, which is a critical sign that the fastener needs immediate attention.

In some cases, mushrooming may not be immediately visible, especially if the bolt is in a hard-to-reach area or covered in grease or dirt. To ensure a thorough inspection, clean the bolt and its surrounding area before assessing its condition. Use a wire brush or compressed air to remove any debris, then examine the bolt head closely under good lighting. If you suspect mushrooming but are unsure, compare the bolt in question to a new or undamaged bolt of the same type. This side-by-side comparison can highlight the deformation more clearly.

Finally, pay attention to the performance of the bolted joint. If you notice unusual looseness, excessive play, or recurring issues with the joint, mushrooming may be the underlying cause. A mushroomed bolt head cannot distribute force evenly, leading to instability in the joint. By recognizing these signs early, you can take appropriate steps to fix or replace the mushroomed bolt before it causes further damage or failure. Regular inspections, especially in high-stress applications, are key to preventing and addressing mushrooming effectively.

Reishi Mushroom Safety for Rheumatoid Arthritis: Benefits and Risks Explored

You may want to see also

Safety Precautions: Wear protective gear and ensure the work area is stable and secure

When tackling the task of fixing a mushroomed bolt, safety precautions must be your top priority. Wear protective gear, including safety goggles to shield your eyes from metal shards or debris that may fly off during the process. Additionally, put on heavy-duty work gloves to protect your hands from sharp edges and potential slips while handling tools. If the bolt is in a noisy environment or you’re using power tools, wear ear protection to safeguard your hearing. These precautions are essential to prevent injuries and ensure a safe working experience.

Ensuring the work area is stable and secure is equally critical. Before starting, inspect the surface where you’ll be working to confirm it’s level and free from hazards like oil, grease, or loose debris that could cause slips or falls. If the bolt is located on a vehicle or machinery, make sure it’s securely supported on jack stands or blocks, and never rely solely on a jack. For bolts in elevated positions, use a stable ladder or platform, ensuring it’s placed on solid ground and locked in position. A wobbly or unstable work area increases the risk of accidents, so take the time to set it up correctly.

Proper lighting is another aspect of a secure work area. If the bolt is in a dimly lit space, use portable work lights or headlamps to ensure you can clearly see what you’re doing. Poor visibility can lead to mistakes or accidents, especially when handling sharp tools or heavy equipment. Keep the area well-ventilated if you’re working indoors or in confined spaces to avoid inhaling fumes from cleaning agents or lubricants. A well-lit and ventilated workspace contributes significantly to overall safety.

Lastly, organize your tools and materials within easy reach to avoid unnecessary stretching or bending, which can lead to strain or imbalance. Keep the work area clutter-free to prevent tripping hazards and ensure you have enough space to maneuver safely. If working with power tools, double-check that they are in good condition and properly grounded to avoid electrical hazards. By maintaining a stable, secure, and organized work environment, you minimize risks and create a safer space to focus on fixing the mushroomed bolt effectively.

Julia Child's Simple Method for Cleaning Mushrooms Perfectly Every Time

You may want to see also

Tools Needed: Gather a grinder, die grinder, or bolt extractor for effective repair

When tackling the task of fixing a mushroomed bolt, having the right tools is crucial for a successful repair. A grinder is one of the essential tools you’ll need. A standard angle grinder equipped with a cutting or grinding wheel can effectively remove the mushroomed head of the bolt. This tool is powerful and versatile, allowing you to carefully grind down the deformed metal until the bolt head is flush with the surface. Ensure you use the appropriate wheel for metalwork and wear safety gear, including gloves and eye protection, to avoid injuries from flying debris.

If precision is key, a die grinder is another excellent tool to consider. Smaller and more maneuverable than an angle grinder, a die grinder offers better control, especially in tight or hard-to-reach areas. It can be fitted with a carbide burr or grinding bit to meticulously remove the mushroomed portion of the bolt without damaging surrounding components. This tool is ideal for situations where the bolt is in a delicate or confined space, as it minimizes the risk of collateral damage.

In cases where the mushroomed bolt is severely damaged or broken off, a bolt extractor becomes indispensable. A bolt extractor is designed to grip and remove broken or stuck bolts by threading into the damaged bolt and then being turned counterclockwise to extract it. There are various types of bolt extractors, including spiral flutes, reverse thread, and easy-out tools. Choose one that matches the size and thread pattern of your bolt for the best results. Always apply penetrating oil to the bolt beforehand to ease the extraction process.

While these tools are essential, it’s important to gather additional items to ensure a smooth repair. A wrench or socket set will help you apply torque evenly when removing or reinstalling bolts. Penetrating oil is vital for loosening rusted or stuck bolts, making the extraction process easier. Additionally, a wire brush or sandpaper can be used to clean the area after grinding, ensuring a smooth surface for reinstallation. Having these tools ready before you begin will streamline the repair process and increase your chances of success.

Lastly, consider the environment in which you’re working. If the mushroomed bolt is in a vehicle or machinery, ensure the area is stable and secure. For electrical components, disconnect power sources to avoid accidents. Always prioritize safety by wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask if grinding creates fine particles. With the right tools and precautions, fixing a mushroomed bolt can be a manageable task that restores functionality to your equipment.

Deadly UK Mushrooms: A Dangerous and Deadly Foray

You may want to see also

Explore related products

Grinding Technique: Carefully grind down the mushroomed area without damaging the bolt threads

When employing the Grinding Technique to fix a mushroomed bolt, precision and patience are paramount. Begin by securing the bolt firmly in a vise or clamp to ensure it remains stationary during the grinding process. This stability is crucial to avoid slipping, which could lead to uneven grinding or damage to the bolt threads. Select a grinding tool with a fine-grit wheel or a rotary tool with a grinding attachment, as these provide better control and reduce the risk of overheating the bolt. Always wear safety gear, including gloves and eye protection, to guard against debris and sparks.

Start by assessing the mushroomed area to determine the extent of the deformation. Hold the grinding tool at a slight angle, aligning it with the bolt’s longitudinal axis to maintain consistency. Gradually apply pressure and move the tool in a smooth, controlled motion along the mushroomed area. The goal is to remove the excess material without altering the bolt’s diameter or thread profile. Work in short bursts to prevent excessive heat buildup, which can weaken the bolt or cause it to lose its temper.

As you grind, frequently pause to inspect your progress. Use a thread gauge or a nut that matches the bolt’s thread size to ensure the threads remain intact and functional. If the grinding wheel begins to catch on the threads, adjust your angle or technique to avoid cutting into them. Focus solely on the mushroomed area, taking care not to grind beyond the deformed section. This targeted approach minimizes the risk of compromising the bolt’s structural integrity.

For bolts with severe mushrooming, consider using a die to re-thread the bolt after grinding. This step ensures the threads are clean and functional, especially if the grinding process has slightly altered their shape. However, if the bolt is only mildly mushroomed, careful grinding alone may suffice. Always test the bolt with a nut after grinding to confirm smooth engagement and proper fit.

Finally, clean the bolt thoroughly to remove any metal shavings or debris generated during grinding. A wire brush or compressed air can be used for this purpose. Once cleaned, apply a light coat of lubricant to the threads to prevent corrosion and ensure future ease of use. By following this Grinding Technique, you can effectively restore a mushroomed bolt to its original functionality while preserving its threads and overall strength.

Storing Mushroom Stems: Tips for Keeping Them Fresh

You may want to see also

Replacement Option: If grinding fails, remove and replace the bolt with a new one

When grinding or reshaping a mushroomed bolt proves unsuccessful, the next logical step is to consider a replacement. This option ensures the integrity of the fastening system and is often the most reliable solution for severely damaged bolts. Here's a detailed guide on how to execute this process effectively.

Assessing the Situation: Before proceeding with the replacement, it's crucial to evaluate the extent of the damage. If the bolt head is severely mushroomed, distorted, or cracked, replacement is likely the best course of action. Attempting to reuse such a bolt can compromise the safety and functionality of the assembly. Inspect the bolt carefully, and if you notice any signs of structural compromise, proceed with the removal and replacement process.

Removal Process: Start by gathering the necessary tools, including a wrench or socket set that fits the bolt head. Apply steady pressure to turn the bolt counterclockwise, ensuring you have a firm grip to prevent slippage. In some cases, the damaged bolt might be stubborn and require additional force. You can use a breaker bar or apply penetrating oil to loosen the bolt, making it easier to remove. Once the bolt is accessible, carefully unscrew it, taking note of the thread size and length for the replacement.

Selecting the New Bolt: Choosing the correct replacement bolt is essential. Match the thread size, length, and material to the original bolt. Consider the application and environment; for instance, stainless steel bolts are ideal for corrosion resistance. Ensure the new bolt meets or exceeds the strength requirements of the original. It's always a good practice to source bolts from reputable suppliers to guarantee quality.

Installation of the New Bolt: Clean the threaded hole to ensure a smooth installation. Apply a suitable thread lubricant or anti-seize compound to the new bolt's threads to facilitate assembly and prevent future corrosion. Insert the new bolt and tighten it by hand, ensuring it threads smoothly. Use a torque wrench to tighten the bolt to the specified torque value, as over-tightening can lead to new damage.

This replacement process might seem straightforward, but it is a critical task, especially in applications where bolt integrity is essential for safety. Always prioritize precision and attention to detail when working with fasteners to ensure a secure and long-lasting repair.

Mushrooms: A Meat Substitute?

You may want to see also

Frequently asked questions

A bolt mushrooms when excessive force is applied during tightening, causing the head to deform and expand, often due to overtightening or using the wrong tools.

A mushroomed bolt is typically irreparable and should be replaced to ensure structural integrity and safety.

Use the correct tools, follow torque specifications, and avoid overtightening to prevent bolts from mushrooming.

Tools like a bolt extractor, penetrating oil, and a wrench or socket set are often needed to remove a mushroomed bolt safely.