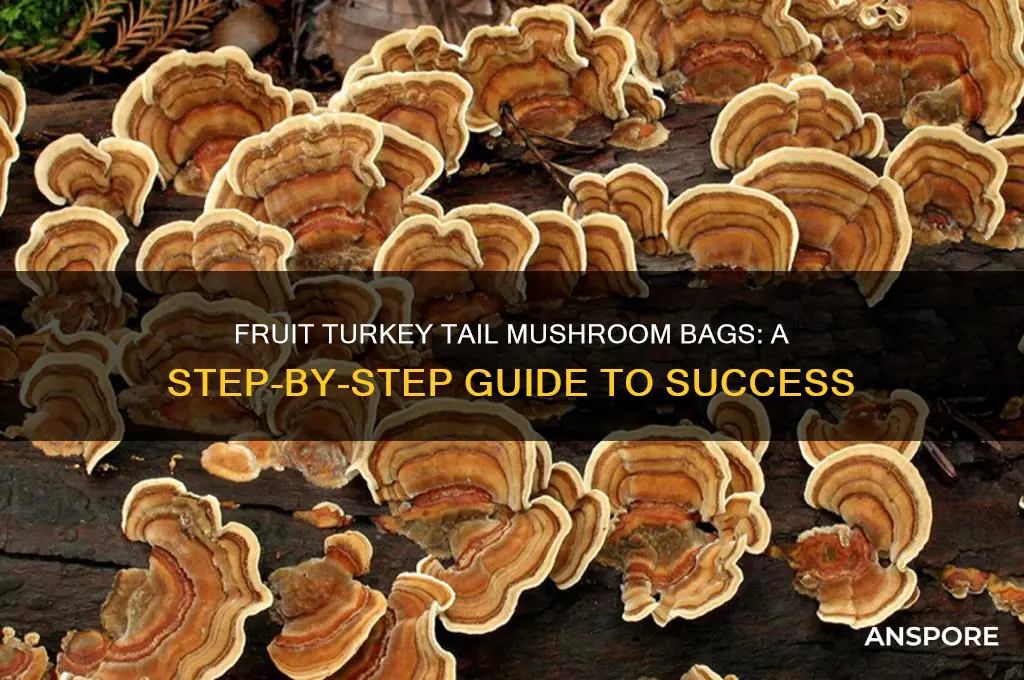

Fruiting turkey tail mushroom bags is a rewarding process that allows cultivators to grow these medicinal fungi at home. Turkey tail mushrooms, scientifically known as *Trametes versicolor*, are prized for their immune-boosting properties and vibrant, fan-like appearance. To successfully fruit these mushrooms, the mycelium-colonized substrate bags must be exposed to specific environmental conditions, including proper humidity, temperature, and fresh air exchange. This typically involves transferring the bags to a fruiting chamber or a well-ventilated area with indirect light, maintaining humidity levels around 70-90%, and ensuring temperatures range between 55°F and 70°F. Patience is key, as it can take several weeks for the mushrooms to develop, but with careful attention to these factors, cultivators can enjoy a bountiful harvest of turkey tail mushrooms.

| Characteristics | Values |

|---|---|

| Substrate Preparation | Supplemented sawdust or straw with nutrients like bran or gypsum. |

| Sterilization Method | Autoclave at 121°C (250°F) for 1-2 hours to kill contaminants. |

| Inoculation | Use turkey tail (Trametes versicolor) spawn, inject into sterilized bags. |

| Incubation Temperature | 20-25°C (68-77°F) for 4-8 weeks in dark conditions. |

| Fruiting Conditions | High humidity (85-95%), fresh air exchange, indirect light. |

| Fruiting Temperature | 15-20°C (59-68°F) to induce pinhead formation. |

| Humidity Management | Misting or humidifiers to maintain moisture; avoid waterlogging. |

| Light Requirements | Indirect natural light or low-intensity artificial light. |

| Harvest Time | Harvest when caps are fully developed but before spore release. |

| Yield per Bag | 100-200 grams of fresh mushrooms per 5-pound bag. |

| Contamination Prevention | Maintain sterile conditions during inoculation; use HEPA filters. |

| Shelf Life of Substrate | 6-12 months if stored properly in a cool, dark place. |

| Reusable Substrate | Possible after pasteurization, but yields decrease with each cycle. |

| Common Issues | Contamination by molds, insufficient humidity, or improper temperature. |

| Post-Harvest Care | Dry mushrooms at 40-50°C (104-122°F) for long-term storage. |

| Nutritional Benefits | Rich in polysaccharides (e.g., PSK and PSP) with immune-boosting effects. |

Explore related products

What You'll Learn

- Preparing Substrate: Mix hardwood sawdust, bran, and gypsum, then sterilize to create a nutrient-rich base

- Inoculating Bags: Inject turkey tail mycelium into sterilized bags using a sterile syringe

- Incubation Process: Keep bags in a dark, warm (70-75°F) area for 4-6 weeks

- Fruiting Conditions: Introduce light, fresh air, and humidity (85-95%) to trigger mushroom growth

- Harvesting Mushrooms: Pick mature caps gently to avoid damaging mycelium for future flushes

Preparing Substrate: Mix hardwood sawdust, bran, and gypsum, then sterilize to create a nutrient-rich base

To begin preparing the substrate for fruiting turkey tail mushroom bags, gather your materials: hardwood sawdust, bran (such as wheat or rye), and gypsum (calcium sulfate). The hardwood sawdust serves as the primary carbon source, while the bran provides additional nutrients and helps retain moisture. Gypsum is added to regulate pH and provide essential calcium, promoting healthy mycelium growth. A typical substrate recipe might consist of 70-80% hardwood sawdust, 20-25% bran, and 1-2% gypsum by weight. Measure these components carefully to ensure a balanced mixture that meets the nutritional needs of the turkey tail mycelium.

Once you’ve measured the ingredients, combine them in a large mixing container. Thoroughly mix the hardwood sawdust, bran, and gypsum until they are evenly distributed. This step is crucial to ensure that the mycelium receives consistent nutrients as it colonizes the substrate. After mixing, lightly moisten the substrate with water to achieve a moisture content of around 60-65%. The mixture should feel like a wrung-out sponge—moist but not soggy. Proper moisture levels are essential for mycelium growth and preventing contamination.

Next, prepare the substrate for sterilization. Transfer the moistened mixture into autoclavable bags, filling them to about 75-80% capacity to allow room for expansion during sterilization. Seal the bags loosely to permit steam penetration while preventing contaminants from entering. Sterilization is a critical step to eliminate competing microorganisms that could hinder mycelium growth. Use a pressure cooker or autoclave to sterilize the bags at 15 psi (pounds per square inch) for 1.5 to 2 hours. Ensure the substrate reaches and maintains the proper temperature throughout the process to effectively kill unwanted bacteria, fungi, and spores.

After sterilization, allow the substrate bags to cool to room temperature before inoculating them with turkey tail mycelium. This cooling period is essential to prevent damaging the mycelium with excessive heat. Once cooled, the substrate will be a nutrient-rich, sterile base ready for colonization. Properly prepared substrate significantly increases the chances of successful fruiting, as it provides an optimal environment for the turkey tail mycelium to thrive and eventually produce mushrooms.

Throughout the substrate preparation process, maintain a clean and organized workspace to minimize the risk of contamination. Wear gloves and use sanitized tools when handling the substrate and bags. Attention to detail in mixing, moisturizing, and sterilizing will lay the foundation for a successful turkey tail mushroom cultivation project. With a well-prepared substrate, you’re one step closer to fruiting healthy and abundant turkey tail mushrooms in your grow bags.

Accurate Psilocybin Measurement: Techniques for Testing Magic Mushrooms

You may want to see also

Inoculating Bags: Inject turkey tail mycelium into sterilized bags using a sterile syringe

Inoculating sterilized bags with turkey tail mycelium is a critical step in the process of fruiting these mushrooms. Begin by ensuring all materials are properly sterilized to prevent contamination. The bags should be made of a durable, filter-patch equipped material, such as polypropylene, to allow for gas exchange while keeping contaminants out. Sterilize the bags using an autoclave or pressure cooker, following the manufacturer’s instructions for time and temperature. Once sterilized, allow the bags to cool to a safe handling temperature, typically around 80-90°F (27-32°C), to avoid damaging the mycelium during inoculation.

Prepare your sterile syringe by removing it from its sterile packaging and ensuring the needle is intact and free of debris. The syringe should contain the turkey tail mycelium in a liquid suspension or as a spore solution. Warm the syringe to room temperature if it has been refrigerated, as cold mycelium may not flow easily through the needle. Wipe the injection port of the sterilized bag with a 70% isopropyl alcohol wipe to further minimize the risk of contamination before inserting the needle.

Insert the needle through the self-healing injection port of the bag, ensuring it penetrates deep enough to release the mycelium into the substrate but does not touch the sides of the bag. Slowly depress the plunger to inject 2-5 cc of mycelium, depending on the bag size and substrate volume. Aim to distribute the mycelium evenly, as this will promote uniform colonization. After injection, gently remove the needle, allowing the self-healing port to seal. Label the bag with the inoculation date and turkey tail strain for future reference.

Place the inoculated bags in a clean, humid environment with indirect light, maintaining temperatures between 70-75°F (21-24°C). Avoid direct sunlight, as it can overheat the bags and stress the mycelium. Regularly inspect the bags for signs of contamination, such as unusual colors or smells, and isolate any compromised bags immediately. Properly inoculated bags should show signs of mycelial growth within 7-14 days, indicated by white, thread-like structures spreading through the substrate.

Patience is key during the colonization phase, as turkey tail mycelium can take several weeks to fully colonize the substrate. Once colonization is complete, the bags are ready for the fruiting stage. Ensure the environment is conducive to fruiting by increasing humidity, reducing light exposure, and maintaining cooler temperatures around 60-65°F (15-18°C). Proper inoculation and care during this stage will significantly impact the success and yield of your turkey tail mushroom harvest.

Psychedelic Mushrooms: Exploring the World of Magic Fungi

You may want to see also

Incubation Process: Keep bags in a dark, warm (70-75°F) area for 4-6 weeks

The incubation process is a critical phase in fruiting turkey tail mushroom bags, as it allows the mycelium to fully colonize the substrate and prepare for pinhead formation. To begin, ensure your grow bags are fully colonized and ready for the fruiting stage. Place the bags in a dark environment, as light can inhibit the fruiting process during this initial phase. A closet, cabinet, or dedicated grow tent works well for this purpose. The key is to maintain consistent darkness to signal to the mycelium that it’s time to transition from vegetative growth to fruiting.

Temperature control is equally important during incubation. Keep the bags in a warm area where the temperature remains consistently between 70°F and 75°F (21°C to 24°C). Fluctuations outside this range can stress the mycelium and delay fruiting. Using a space heater, thermostat-controlled incubator, or even a warm room can help maintain the ideal temperature. Avoid placing the bags near drafts, vents, or windows, as these can cause temperature variations that disrupt the process.

Humidity is less critical during the incubation phase, as the bags are sealed and retain their own moisture. However, ensure the bags are not exposed to excessively dry air, as this could cause the substrate to dry out prematurely. The incubation period typically lasts 4 to 6 weeks, depending on the vigor of the mycelium and environmental conditions. During this time, the mycelium will consolidate its resources and prepare to form mushroom pins.

Patience is essential during this stage, as rushing the process can lead to poor fruiting results. Resist the urge to open the bags or disturb them unnecessarily, as this can introduce contaminants or disrupt the mycelium’s development. Instead, monitor the bags periodically for signs of contamination, such as unusual colors or smells, and address any issues promptly. Once the incubation period is complete, you’ll notice small pinheads beginning to form on the surface of the substrate, signaling that the bags are ready for the fruiting stage.

Finally, prepare for the transition to fruiting by planning your environmental setup. After incubation, the bags will require light, fresh air, and higher humidity to encourage mushroom growth. Gather the necessary equipment, such as a humidifier, fan, and light source, so you’re ready to create optimal fruiting conditions as soon as the incubation phase ends. Proper incubation sets the foundation for a successful harvest, so take the time to ensure this step is done correctly.

Discover Fast Food Chains Offering Delicious Mushroom Burgers Today

You may want to see also

Explore related products

Fruiting Conditions: Introduce light, fresh air, and humidity (85-95%) to trigger mushroom growth

To successfully fruit turkey tail mushroom bags, creating the right environmental conditions is crucial. One of the first steps is to introduce light to the growing area. Turkey tail mushrooms do not require intense light, but they do need a consistent light source to signal the transition from mycelium growth to fruiting. A simple fluorescent or LED light placed a few feet away from the bags will suffice. Aim for 12 hours of light and 12 hours of darkness daily to mimic natural conditions. Avoid direct sunlight, as it can dry out the bags and stress the mycelium.

Fresh air exchange is another critical factor in triggering mushroom growth. Turkey tail mushrooms thrive in environments with good air circulation, which helps prevent the buildup of carbon dioxide and promotes healthy fruiting bodies. To achieve this, ensure the growing area is well-ventilated. If using a fruiting chamber, install a small fan to gently circulate air. Alternatively, you can manually exchange air by opening the chamber for a few minutes twice a day. Proper air exchange not only supports fruiting but also reduces the risk of contamination.

Maintaining humidity levels between 85-95% is essential for turkey tail mushrooms to fruit successfully. This high humidity mimics their natural forest habitat and encourages pinhead formation. Use a humidifier or place a tray of water inside the fruiting chamber to increase moisture levels. Regularly monitor humidity with a hygrometer and adjust as needed. Misting the bags lightly with water can also help, but avoid over-saturating them, as excessive moisture can lead to mold or other issues.

The combination of light, fresh air, and high humidity works synergistically to trigger fruiting. Once these conditions are met, you should start to see tiny pinheads forming on the surface of the mushroom bags within 7 to 14 days. Be patient, as turkey tail mushrooms can take longer to fruit compared to other species. Consistency in maintaining these conditions is key to a successful harvest. Regularly inspect the bags for any signs of contamination or stress, and adjust the environment accordingly to ensure optimal growth.

Finally, it’s important to note that temperature also plays a role in fruiting, though it is less critical than the factors mentioned above. Turkey tail mushrooms prefer cooler temperatures, ideally between 60-70°F (15-21°C). Ensure the fruiting area remains within this range to support healthy mushroom development. By carefully managing light, fresh air, humidity, and temperature, you can create the ideal conditions for your turkey tail mushroom bags to fruit abundantly.

Unlocking Reishi's Power: Discover the Benefits of Mushroom Powder

You may want to see also

Harvesting Mushrooms: Pick mature caps gently to avoid damaging mycelium for future flushes

Harvesting mushrooms from turkey tail mushroom bags requires careful attention to ensure the longevity of the mycelium, which is essential for future flushes. The first step is to identify when the caps are mature and ready for harvest. Mature turkey tail mushrooms (Trametes versicolor) typically have fully developed caps with vibrant colors and a slightly curled or flattened appearance. Avoid harvesting too early, as immature mushrooms will not have reached their full potency or size. Gently inspect the caps without applying pressure to determine their readiness.

When harvesting, it’s crucial to pick the mature caps with a gentle touch to avoid damaging the mycelium beneath the surface. The mycelium is the network of fungal threads that continues to produce mushrooms in multiple flushes. Use your fingers or a small, clean tool to carefully twist or pinch the caps at their base. Pulling or tugging forcefully can disrupt the mycelium, reducing the bag’s productivity in subsequent flushes. Work slowly and deliberately to ensure each cap is removed without disturbing the surrounding substrate or fungal network.

After picking a mature cap, take a moment to observe the area for any signs of new growth or pinning mushrooms. This practice helps you understand the bag’s lifecycle and plan future harvests. If you notice small pins or primordia forming, avoid touching them to allow them to develop undisturbed. Proper harvesting techniques not only maximize the current yield but also promote a healthier environment for the mycelium to thrive and produce more mushrooms over time.

Maintaining cleanliness during the harvesting process is equally important. Ensure your hands and any tools used are sanitized to prevent contamination. Contaminants can introduce competing organisms that may harm the mycelium or reduce the bag’s fruiting potential. After harvesting, place the caps in a clean, dry container to avoid bruising or moisture buildup, which can lead to degradation.

Finally, monitor the mushroom bag post-harvest to encourage additional flushes. Turkey tail mushrooms often produce multiple flushes if the mycelium remains healthy. Maintain optimal conditions, such as proper humidity, airflow, and indirect light, to stimulate new growth. By harvesting mature caps gently and caring for the mycelium, you can enjoy a continuous supply of turkey tail mushrooms while ensuring the longevity of your fruiting bags.

Constructing a Mushroom Glove Box: A Step-by-Step Guide

You may want to see also

Frequently asked questions

To prepare the substrate, mix hardwood sawdust or straw with a small amount of bran or gypsum, pasteurize it to kill contaminants, and then let it cool before inoculating with turkey tail mycelium.

Turkey tail mushrooms require high humidity (85-95%), temperatures between 60-75°F (15-24°C), and indirect light or low-intensity LED lighting to initiate fruiting.

It typically takes 4-8 weeks for the mycelium to colonize the bag fully, followed by another 2-4 weeks for fruiting bodies to develop under optimal conditions.