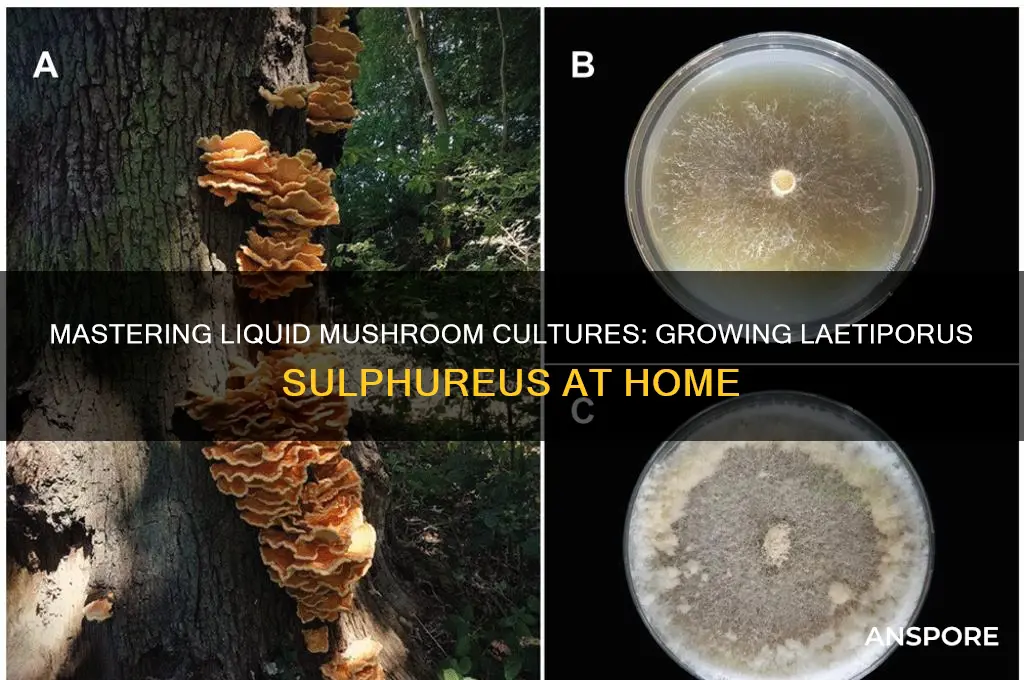

Growing liquid mushroom cultures of *Laetiporus sulphureus*, commonly known as the chicken of the woods, is an advanced mycological technique that allows for efficient propagation and cultivation of this vibrant, edible fungus. This method involves creating a sterile liquid nutrient broth, often based on malt extract or carbohydrate-rich solutions, which is then inoculated with a pure mycelium sample of *L. sulphureus*. The liquid culture facilitates rapid mycelial growth and can be stored long-term or used to inoculate bulk substrates like sawdust or straw for fruiting. Success hinges on maintaining sterile conditions throughout the process, as contamination can quickly ruin the culture. Ideal for both hobbyists and commercial growers, this technique ensures a consistent and scalable supply of *L. sulphureus* for culinary or ecological purposes.

Explore related products

What You'll Learn

- Sterilization Techniques: Proper sterilization methods to prevent contamination during the culturing process

- Substrate Preparation: Selecting and preparing nutrient-rich substrates for optimal mycelium growth

- Inoculation Process: Steps for safely introducing Laetiporus sulphureus spawn into liquid culture

- Incubation Conditions: Ideal temperature, light, and humidity for successful mycelium colonization

- Maintenance & Scaling: Tips for maintaining cultures and scaling up production efficiently

Sterilization Techniques: Proper sterilization methods to prevent contamination during the culturing process

When growing liquid mushroom cultures of *Laetiporus sulphureus*, maintaining a sterile environment is paramount to prevent contamination from bacteria, molds, or other fungi. The first critical step in sterilization is preparing your workspace. Begin by cleaning all surfaces with a 10% bleach solution or 70% isopropyl alcohol to eliminate surface contaminants. Ensure all equipment, such as glassware, stir tools, and containers, is thoroughly washed with hot water and dish soap, followed by rinsing with distilled water to remove any residues. After cleaning, autoclave all reusable tools and glassware at 121°C (250°F) for 30 minutes to achieve complete sterilization. For single-use items, consider using sterile, disposable alternatives to minimize the risk of contamination.

The next essential technique is sterilizing the growth medium. *Laetiporus sulphureus* typically thrives in a nutrient-rich liquid medium, such as malt extract or potato dextrose broth. Prepare the medium by mixing the ingredients with distilled or deionized water, then dispense it into sterile containers, such as Erlenmeyer flasks with cotton stoppers or sealed jars. Autoclave the medium at 121°C for 20–30 minutes to kill any microorganisms. Avoid overfilling the containers to prevent boil-over during sterilization, which can compromise sterility. After autoclaving, allow the medium to cool to room temperature in a clean, covered area to prevent airborne contaminants from settling.

Sterilizing the mushroom tissue or spawn used to inoculate the liquid culture is equally crucial. Surface sterilize the *Laetiporus sulphureus* tissue by rinsing it in 70% ethanol for 1–2 minutes, followed by a brief immersion in sterile distilled water to remove any chemical residues. Alternatively, a 10% bleach solution (with a drop of Tween 20 to reduce surface tension) can be used for 2–3 minutes, followed by thorough rinsing. Once sterilized, transfer the tissue to a sterile petri dish or container using flame-sterilized forceps or a scalpel. This ensures that only the desired fungus is introduced into the liquid culture, minimizing the risk of contamination.

Proper handling of the inoculation process is another critical sterilization technique. Flame-sterilize the inoculation loop or needle by passing it through a Bunsen burner flame until it glows red, then allow it to cool momentarily before transferring a small piece of sterilized mushroom tissue to the liquid medium. Ensure the flask or container is sealed immediately after inoculation to prevent airborne contaminants from entering. Work in a laminar flow hood or a still-air box if available, as these provide a sterile environment for the transfer process. If such equipment is unavailable, perform the inoculation near an open flame to create a sterile zone.

Finally, monitor the sterilization process rigorously to ensure its effectiveness. Regularly inspect all equipment and materials for signs of contamination, such as discoloration or mold growth. If contamination is detected, discard the affected culture and sterilize the workspace and tools before restarting the process. Maintaining a strict sterilization protocol from start to finish is the key to successfully growing *Laetiporus sulphureus* liquid cultures without contamination. By following these techniques diligently, you can create an optimal environment for fungal growth while minimizing the risk of unwanted microorganisms interfering with the process.

Light's Impact on Mushroom Growth: Size Secrets Revealed

You may want to see also

Substrate Preparation: Selecting and preparing nutrient-rich substrates for optimal mycelium growth

Selecting the right substrate is critical for the successful cultivation of *Laetiporus sulphureus* (Chicken of the Woods) in liquid culture. The substrate serves as the primary nutrient source for mycelium growth and must be rich in carbohydrates, proteins, and minerals. Common substrates include hardwood sawdust, straw, or a combination of both, supplemented with nutrients like wheat bran, soy flour, or gypsum. Hardwood sawdust, particularly from oak or beech, is highly recommended due to its natural compatibility with *L. sulphureus*, which is a wood-decay fungus. Avoid softwoods like pine, as their resinous compounds can inhibit mycelial growth.

Once the substrate is chosen, it must be properly prepared to ensure sterility and optimal nutrient availability. Begin by hydrating the substrate to a moisture content of 60-70%, which can be achieved by soaking it in water for several hours. Excess water should be drained to prevent waterlogging, which can lead to contamination or anaerobic conditions. Next, the substrate must be sterilized to eliminate competing microorganisms. Autoclaving at 121°C (250°F) for 60-90 minutes is the most reliable method, ensuring all pathogens and spores are destroyed. Alternatively, pressure cooking can be used, but ensure the substrate reaches the required temperature and duration for effective sterilization.

Supplementing the substrate with additional nutrients can significantly enhance mycelium growth. Adding 10-20% wheat bran or soy flour provides extra nitrogen, which is essential for protein synthesis in the mycelium. Gypsum (calcium sulfate) can also be incorporated at a rate of 1-2% to improve substrate structure and provide essential minerals. Mix these supplements thoroughly into the hydrated substrate before sterilization to ensure even distribution. This enriched substrate will provide a balanced nutrient profile, promoting vigorous and healthy mycelial colonization.

After sterilization, allow the substrate to cool to room temperature in a clean, sterile environment to prevent contamination. Transfer the cooled substrate into sterile containers or jars, leaving enough headspace for mycelium to grow. Once the substrate is prepared, it is ready for inoculation with the *L. sulphureus* liquid culture. Proper substrate preparation is a cornerstone of successful mushroom cultivation, as it directly influences the speed and efficiency of mycelium colonization, ultimately impacting the yield and quality of the fruiting bodies.

Finally, maintain strict aseptic techniques throughout the substrate preparation process to minimize the risk of contamination. Work in a clean area, use sterile tools, and consider using a still air box or laminar flow hood when handling sterilized substrates. With a well-prepared, nutrient-rich substrate, the mycelium of *Laetiporus sulphureus* will thrive, setting the stage for a productive and healthy liquid culture system.

Discovering Morel Mushrooms: Do They Thrive in Virginia's Forests?

You may want to see also

Inoculation Process: Steps for safely introducing Laetiporus sulphureus spawn into liquid culture

Before beginning the inoculation process, ensure your workspace is clean and sterile to minimize contamination risks. Sterilize all equipment, including the liquid culture vessel, inoculation tools, and your hands, using 70% isopropyl alcohol. Prepare your liquid culture medium, typically a nutrient-rich solution like malt extract or potato dextrose broth, and sterilize it in a pressure cooker at 15 PSI for at least 30 minutes. Allow the medium to cool to room temperature in a sterile environment, such as a still air box or laminar flow hood, to prevent airborne contaminants from settling. Once cooled, inspect the vessel for any signs of contamination before proceeding to the inoculation step.

Next, prepare your Laetiporus sulphureus spawn by selecting a healthy, actively growing mycelium sample. If using grain spawn, ensure it is fully colonized and free of molds or bacteria. Sterilize the outer surface of the spawn container with alcohol wipes, and carefully open it within your sterile workspace. Using a flame-sterilized scalpel or inoculation loop, extract a small piece of the mycelium, ensuring the tool is cooled before it touches the spawn to avoid damaging the tissue. This mycelium sample will serve as the inoculant for your liquid culture, so handle it with precision to maintain sterility throughout the transfer process.

With your liquid culture medium and spawn prepared, proceed to inoculation. Remove the lid of the liquid culture vessel within the sterile workspace, and quickly but gently introduce the mycelium sample into the medium. Use a flame-sterilized inoculation tool to transfer the spawn, minimizing exposure time to prevent contamination. Once the mycelium is submerged, immediately seal the vessel with a sterile stopper or aluminum foil secured with a rubber band. Label the vessel with the date and contents for future reference, ensuring clarity for monitoring purposes.

After inoculation, place the liquid culture vessel in a controlled environment with stable temperatures between 70-75°F (21-24°C) and indirect light. Agitate the culture gently once daily to encourage even growth and nutrient distribution. Monitor the culture closely for the first 7-10 days, checking for signs of contamination such as discoloration, off-odors, or mold growth. If contamination is detected, discard the culture immediately to prevent cross-contamination. Under optimal conditions, Laetiporus sulphureus mycelium should begin visible growth within 3-5 days, gradually colonizing the liquid medium over 2-3 weeks.

Finally, once the liquid culture is fully colonized and appears homogeneous, it is ready for expansion or use in substrate inoculation. Store the culture in a cool, dark place to slow mycelial growth and prolong viability. For long-term storage, consider transferring a portion of the culture to a sterile slant or cryogenically preserving a sample. Always maintain sterile techniques during any handling or transfer to ensure the health and vitality of your Laetiporus sulphureus liquid culture for future cultivation projects.

Discovering Morel Mushrooms: Do They Thrive in New Hampshire's Forests?

You may want to see also

Explore related products

Incubation Conditions: Ideal temperature, light, and humidity for successful mycelium colonization

Incubation Conditions: Ideal Temperature for Successful Mycelium Colonization

Maintaining the correct temperature is critical for the successful colonization of *Laetiporus sulphureus* mycelium in liquid culture. This species thrives in a temperature range of 22°C to 28°C (72°F to 82°F), with the optimal temperature being around 24°C to 26°C (75°F to 79°F). Temperatures below 20°C (68°F) slow down mycelial growth, while temperatures above 30°C (86°F) can stress or kill the culture. Use a thermostat-controlled incubator or a heating pad with a thermometer to ensure stability. Avoid placing the culture near windows, vents, or areas with fluctuating temperatures, as consistency is key to preventing contamination and promoting healthy growth.

Light Requirements During Incubation

Laetiporus sulphureus mycelium does not require light for colonization in liquid culture, as it is primarily focused on nutrient absorption rather than photosynthesis. However, indirect, low-light conditions are acceptable if the culture is stored in a transparent container. Direct sunlight should be avoided, as it can raise the temperature of the liquid culture and promote the growth of contaminants like bacteria or green algae. For best results, keep the culture in a dark or dimly lit area, such as a closed cabinet or a dedicated incubation chamber, to minimize external disruptions.

Humidity Control for Liquid Cultures

While humidity is more critical for solid substrate cultivation, it still plays a role in liquid cultures of *Laetiporus sulphureus*. The primary concern is preventing evaporation, which can alter the nutrient concentration in the liquid medium. To maintain optimal conditions, seal the culture vessel with a sterile plug or aluminum foil to minimize moisture loss. If using a vented container, ensure the filter is hydrophobic to prevent contamination while allowing gas exchange. Relative humidity in the incubation area should be kept around 60-70% to discourage airborne contaminants from settling on the culture surface.

Gas Exchange and Aeration

Proper gas exchange is essential for mycelium colonization in liquid cultures. *Laetiporus sulphureus* requires oxygen for metabolic processes, so the culture vessel should not be completely airtight. Use a loose-fitting lid or a vented cap to allow carbon dioxide to escape and oxygen to enter. Alternatively, shake the culture gently every 2-3 days to introduce oxygen and distribute nutrients evenly. Overly tight seals can lead to anaerobic conditions, which inhibit growth and may promote the production of unwanted byproducts.

Monitoring and Adjusting Incubation Conditions

Regular monitoring of incubation conditions is vital to ensure successful colonization. Check the temperature daily using a reliable thermometer or digital sensor. Inspect the culture for signs of contamination, such as discoloration, off-odors, or mold growth. If contamination occurs, discard the culture immediately to prevent spread. Adjust humidity levels by misting the incubation area if dryness becomes an issue, but avoid direct contact with the culture vessel. Patience is key, as colonization can take 2-4 weeks depending on the initial inoculum size and environmental conditions. Consistent attention to temperature, light, humidity, and gas exchange will maximize the chances of a thriving *Laetiporus sulphureus* liquid culture.

Exploring New Jersey's Forests: Do Magic Mushrooms Grow Here?

You may want to see also

Maintenance & Scaling: Tips for maintaining cultures and scaling up production efficiently

Maintaining liquid mushroom cultures of *Laetiporus sulphureus* requires consistent attention to sterility and environmental conditions. Regularly inspect cultures for contamination, such as mold or bacterial growth, and discard any compromised samples immediately. Store cultures in a cool, dark place, ideally at temperatures between 2-8°C (36-46°F), to slow metabolic activity and extend viability. Use sterile techniques when transferring cultures to fresh media, including flame-sterilizing tools and working in a laminar flow hood or still-air box to minimize airborne contaminants. Label cultures with the date and strain information to track their age and ensure timely subculturing, typically every 3-6 months, to prevent degradation.

Scaling up production efficiently begins with optimizing your workflow and resources. Prepare larger volumes of liquid culture media in advance, sterilizing it using an autoclave at 121°C (250°F) for 30 minutes. Use a magnetic stirrer or gentle shaking to ensure even distribution of mycelium during inoculation. Gradually increase batch sizes by inoculating multiple containers simultaneously, but avoid overloading your workspace to maintain sterility. Implement a staggered inoculation schedule to manage the workload and ensure a continuous supply of culture without overwhelming your capacity. Invest in reusable glass or polycarbonate containers to reduce costs and waste compared to single-use materials.

To streamline scaling, consider using a master culture system. Maintain a pristine, high-viability master culture for all transfers, reducing the risk of contamination spreading across batches. Periodically subculture the master culture to fresh media to keep it vigorous. When scaling, use this master culture to inoculate secondary cultures, which can then be expanded further. This hierarchical approach minimizes the chances of losing the entire culture to contamination while maximizing efficiency. Additionally, document each step of the process, including media recipes, sterilization times, and inoculation dates, to ensure consistency and troubleshoot issues effectively.

Efficient scaling also involves optimizing growth conditions for *Laetiporus sulphureus*. Maintain a stable incubation temperature of 22-26°C (72-78°F) and provide adequate aeration through gentle shaking or the use of baffled flasks. Monitor pH levels, as *Laetiporus* prefers a slightly acidic to neutral environment (pH 5.5-7.0). If using bioreactors for large-scale production, ensure proper oxygenation and agitation to support mycelial growth. Regularly sample cultures to assess mycelial density and viability, adjusting conditions as needed to maximize yield.

Finally, plan for contingencies to avoid setbacks. Always maintain backup cultures in case of contamination or failure. Store glycerol-preserved cultures at -20°C (-4°F) for long-term storage, ensuring genetic stability and viability for years. Train additional personnel in sterile techniques and scaling procedures to distribute the workload and reduce the risk of human error. By combining rigorous maintenance practices with strategic scaling methods, you can efficiently expand *Laetiporus sulphureus* liquid culture production while maintaining high-quality, contaminant-free mycelium.

Rapid Growth of Field Mushrooms: Unveiling Their Speedy Development

You may want to see also

Frequently asked questions

The best substrate for liquid cultures of Laetiporus sulphureus (Chicken of the Woods) is typically a mixture of malt extract, dextrose, and yeast extract (MYE) or a similar nutrient-rich medium. This provides the necessary sugars, vitamins, and minerals for mycelial growth.

Sterilize the liquid culture medium by autoclaving it at 121°C (250°F) for 20–30 minutes. Ensure all equipment, such as jars or flasks, is also sterilized to prevent contamination. After sterilization, allow the medium to cool to around 25°C (77°F) before inoculating with spawn or mycelium.

Full colonization of a liquid culture typically takes 7–14 days, depending on factors like temperature (optimal range: 22–28°C or 72–82°F) and the vigor of the mycelium. Regularly monitor the culture for contamination and ensure it is stored in a clean, sterile environment during colonization.