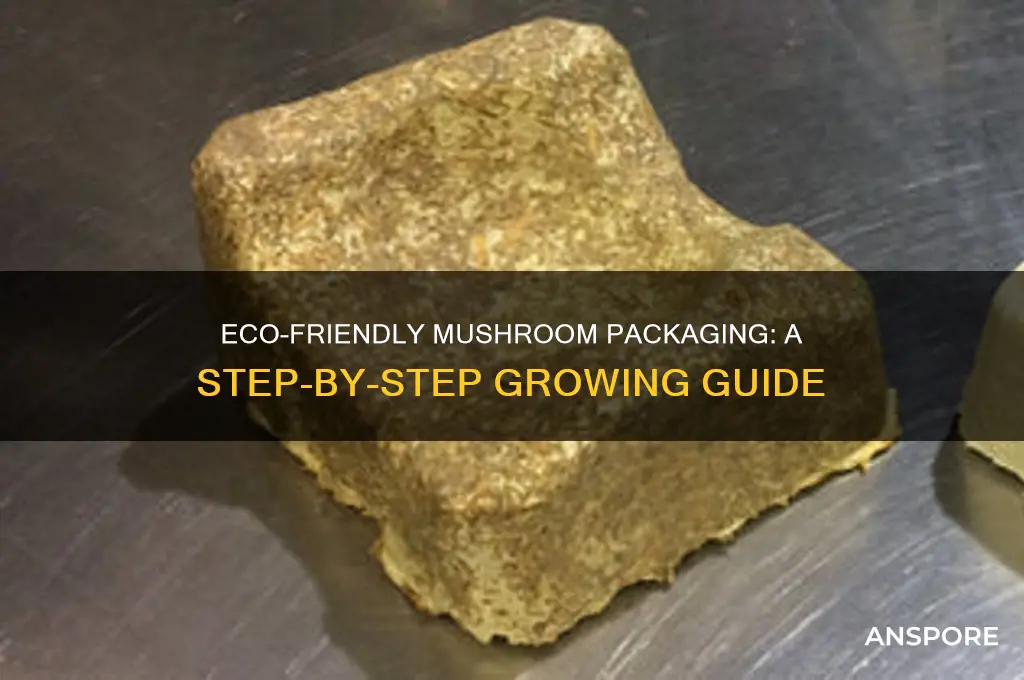

Mushroom packaging, also known as mycelium packaging, is an innovative, eco-friendly alternative to traditional foam and plastic materials, leveraging the natural growth of mycelium—the root structure of fungi—to create biodegradable and compostable products. To grow mushroom packaging, the process begins with cultivating mycelium from agricultural waste, such as corn stalks or hemp fibers, which serves as a nutrient source. The mycelium is then placed in molds shaped to the desired packaging design and allowed to grow in a controlled environment with optimal temperature, humidity, and light conditions. Over a few days, the mycelium binds the substrate together, forming a strong, lightweight, and insulating material. Once fully grown, the packaging is heat-treated to halt further growth and sterilize it, ensuring durability and safety for use. This sustainable method not only reduces reliance on harmful plastics but also utilizes organic waste, making it a promising solution for environmentally conscious packaging.

Explore related products

What You'll Learn

- Substrate Selection: Choose waste materials like sawdust, straw, or agricultural residues for mushroom mycelium growth

- Sterilization Techniques: Use heat, chemicals, or autoclaving to eliminate contaminants before inoculation

- Inoculation Process: Introduce mushroom mycelium into the substrate for colonization and packaging formation

- Growth Conditions: Maintain optimal temperature, humidity, and light levels for mycelium development

- Harvesting & Processing: Dry, shape, or compress mycelium-based material into functional packaging products

Substrate Selection: Choose waste materials like sawdust, straw, or agricultural residues for mushroom mycelium growth

When selecting a substrate for growing mushroom packaging, the focus should be on utilizing waste materials that are both sustainable and conducive to mycelium growth. Sawdust is one of the most commonly used substrates due to its availability and high cellulose content, which mushrooms thrive on. Hardwood sawdust, such as oak or beech, is preferred over softwood because it provides better nutrients and structure for mycelium colonization. Ensure the sawdust is free from contaminants like oils or chemicals, as these can inhibit growth. To prepare sawdust, it should be pasteurized or sterilized to eliminate competing microorganisms while retaining its nutritional value for the mycelium.

Straw, another excellent substrate, is particularly suitable for species like oyster mushrooms. Wheat, rye, or barley straw works well, but it must be properly prepared to remove any seeds or chaff that could introduce unwanted organisms. Soaking the straw in water and then pasteurizing it by immersing it in hot water (around 70°C) for an hour is a common method. This process softens the straw, making it easier for the mycelium to penetrate, while also reducing the risk of contamination. Straw is lightweight and easy to handle, making it ideal for packaging applications.

Agricultural residues such as corn cobs, cotton hulls, or sugarcane bagasse are also viable options, especially in regions where these materials are abundant. These residues are often considered waste products, making them a cost-effective and eco-friendly choice. However, their composition varies, so they may require supplementation with nutrients like nitrogen to support optimal mycelium growth. For example, cotton hulls can be mixed with a small amount of nitrogen-rich material like soybean meal to create a balanced substrate. Proper preparation, including chopping or grinding, ensures uniformity and accessibility for the mycelium.

When choosing a substrate, consider the mushroom species you intend to grow, as different species have varying preferences. For instance, shiitake mushrooms prefer hardwood sawdust, while oyster mushrooms are more versatile and can grow on straw or agricultural residues. Additionally, the substrate should be locally sourced to minimize transportation costs and environmental impact. By repurposing waste materials, you not only reduce the carbon footprint of your mushroom packaging but also contribute to a circular economy by transforming agricultural byproducts into valuable, biodegradable materials.

Finally, experimentation with substrate combinations can lead to optimized growth conditions. For example, blending sawdust with straw can create a substrate that balances structure and nutrient content. Always test small batches to ensure the substrate supports healthy mycelium growth before scaling up production. Proper substrate selection is critical, as it directly influences the strength, durability, and biodegradability of the final mushroom packaging product. By prioritizing waste materials, you align the process with sustainable practices while harnessing the natural capabilities of mycelium.

Growing Pink Oyster Mushrooms: A Simple Guide for Beginners

You may want to see also

Sterilization Techniques: Use heat, chemicals, or autoclaving to eliminate contaminants before inoculation

Sterilization is a critical step in growing mushroom packaging, as it ensures that contaminants such as bacteria, fungi, and other microorganisms are eliminated before inoculation. These contaminants can compete with the mushroom mycelium for nutrients, leading to failed growth or poor-quality packaging. The primary methods of sterilization include heat, chemicals, and autoclaving, each with its own advantages and applications. Heat sterilization, for example, involves exposing the substrate or growing medium to high temperatures, typically above 100°C (212°F), to kill unwanted organisms. This method is commonly used for materials that can withstand high temperatures without degradation, such as agricultural waste or sawdust. To implement heat sterilization, spread the substrate evenly on trays and place it in an oven or on a hot plate, ensuring the temperature is maintained for at least 1-2 hours to guarantee thorough sterilization.

Chemical sterilization is another effective technique, particularly for materials that may be damaged by heat. Common chemical sterilizing agents include hydrogen peroxide, bleach, or alcohol. For instance, a 3% hydrogen peroxide solution can be sprayed or poured over the substrate and allowed to sit for 30 minutes before rinsing thoroughly with sterile water to remove any residue. It’s crucial to handle these chemicals with care, wearing protective gear such as gloves and goggles, and ensuring proper ventilation. Chemical sterilization is often used for smaller-scale operations or for sterilizing tools and equipment that come into contact with the substrate. However, it’s essential to ensure that all chemical residues are removed to prevent harm to the mushroom mycelium.

Autoclaving is the gold standard for sterilization in mushroom cultivation and packaging production, as it combines heat and pressure to achieve thorough disinfection. An autoclave is a pressurized chamber that heats the substrate to temperatures between 121°C and 134°C (250°F to 273°F) for 30 to 60 minutes, depending on the load size and material. This method is highly effective for sterilizing substrates like straw, cardboard, or coffee grounds, which are commonly used in mushroom packaging. Before autoclaving, the substrate should be moistened to the consistency of a wrung-out sponge and placed in autoclavable bags or containers. After the cycle is complete, allow the substrate to cool to a safe temperature before inoculating with mushroom spawn to avoid damaging the mycelium.

For those without access to an autoclave, a pressure cooker can be used as an alternative, though it may not reach the same high temperatures. When using a pressure cooker, maintain 15 psi (pounds per square inch) for at least 45 minutes to ensure effective sterilization. Regardless of the method chosen, consistency and attention to detail are key. Always monitor temperature and time closely, as under-sterilization can lead to contamination, while over-sterilization may degrade the substrate’s nutritional value. Proper sterilization sets the foundation for successful mushroom packaging growth, ensuring a clean environment for the mycelium to thrive.

In addition to sterilizing the substrate, it’s important to sterilize all tools and equipment that will come into contact with the growing medium or mycelium. This includes gloves, scalpels, jars, and any containers used during the inoculation process. Flame sterilization is a quick and effective method for metal tools, where the tool is passed through an open flame until it glows red, killing any surface contaminants. For non-heat-resistant items, a 70% isopropyl alcohol solution can be used to wipe down surfaces. Maintaining a sterile workspace is equally vital; clean the area with disinfectant and use a laminar flow hood or HEPA filter if possible to minimize airborne contaminants. By combining these sterilization techniques, you can create an optimal environment for growing mushroom packaging, ensuring a high success rate and quality end product.

Can You Grow Oyster Mushrooms in Ohio? A Complete Guide

You may want to see also

Inoculation Process: Introduce mushroom mycelium into the substrate for colonization and packaging formation

The inoculation process is a critical step in growing mushroom packaging, as it involves introducing mushroom mycelium into the substrate to initiate colonization and packaging formation. To begin, prepare the substrate by mixing agricultural waste, such as straw, hemp, or cardboard, with water to achieve a moisture content of around 60-70%. The substrate should be pasteurized or sterilized to eliminate competing microorganisms and create a favorable environment for mycelium growth. Common methods include autoclaving, steaming, or soaking the substrate in hot water. Once the substrate has cooled to a suitable temperature (around 20-25°C), it is ready for inoculation.

Next, obtain high-quality mushroom mycelium, typically in the form of spawn or liquid culture, from a reputable supplier. The mycelium should be compatible with the chosen mushroom species, such as *Pleurotus ostreatus* (oyster mushroom) or *Ganoderma lucidum* (reishi mushroom), which are popular for packaging applications. Calculate the appropriate spawn-to-substrate ratio, generally ranging from 2-5%, depending on the mycelium's vigor and the substrate's composition. Distribute the mycelium evenly throughout the substrate, ensuring thorough mixing to maximize contact between the mycelium and the substrate particles. This can be done manually or using specialized equipment, like a ribbon blender.

After inoculation, transfer the colonized substrate into molds or forms that define the desired packaging shape. These molds can be made from materials like silicone, plastic, or plaster, and should be cleaned and sterilized before use. Gently pack the substrate into the molds, applying enough pressure to create a compact and uniform structure without damaging the mycelium. Cover the molds with a breathable material, such as a fine mesh or microfiber cloth, to maintain humidity and prevent contamination while allowing for gas exchange.

Incubate the inoculated substrate in a controlled environment, maintaining optimal temperature (22-28°C), humidity (60-80%), and darkness to promote mycelium growth. Regularly monitor the colonization process, which typically takes 7-14 days, depending on the mushroom species and environmental conditions. As the mycelium grows, it will bind the substrate particles together, forming a strong and resilient material. Once fully colonized, the packaging can be removed from the molds and allowed to mature, during which the mycelium will further strengthen and dehydrate the material.

Finally, post-process the mushroom packaging as needed, which may include drying, trimming, or surface finishing. Drying can be achieved through air-drying or using low-temperature ovens to reduce moisture content and improve durability. Trim any excess material or imperfections, and apply natural coatings or treatments to enhance water resistance or aesthetic appeal. The resulting mushroom packaging is now ready for use, offering a sustainable and biodegradable alternative to traditional packaging materials. By carefully controlling the inoculation process and subsequent steps, you can create high-quality, customized packaging tailored to specific applications and requirements.

Rapid Growth of Magic Mushrooms: Cultivation Speed Explained

You may want to see also

Explore related products

$29.99 $34.59

Growth Conditions: Maintain optimal temperature, humidity, and light levels for mycelium development

Growing mushroom packaging, also known as mycelium-based packaging, requires precise control over environmental conditions to ensure successful mycelium development. The first critical factor is temperature, which directly influences the growth rate and health of the mycelium. The optimal temperature range for most mycelium species used in packaging, such as *Ganoderma lucidum* or *Pleurotus ostreatus*, is between 22°C to 28°C (72°F to 82°F). Temperatures below 20°C (68°F) can slow growth significantly, while temperatures above 30°C (86°F) may inhibit development or even kill the mycelium. Use thermometers or temperature-controlled incubators to monitor and adjust conditions, ensuring consistency throughout the growth cycle.

Humidity is another vital parameter, as mycelium thrives in a moist environment. Relative humidity levels should be maintained between 60% and 70% to support healthy growth. Lower humidity can cause the substrate to dry out, hindering mycelium colonization, while excessive moisture can lead to contamination by mold or bacteria. To regulate humidity, use humidifiers or misting systems, and ensure proper ventilation to prevent stagnant air. Regularly monitor humidity levels with a hygrometer and adjust as needed to create an ideal environment for mycelium proliferation.

Light plays a lesser but still important role in mycelium development. Unlike plants, mycelium does not require light for photosynthesis, but low levels of indirect light can stimulate growth and guide the direction of colonization. Avoid direct sunlight, as it can overheat the substrate and dry it out. Instead, provide ambient or diffused light for 12 to 16 hours daily. LED grow lights with a cool spectrum are a suitable option, as they emit minimal heat and can be easily controlled. Complete darkness is not detrimental but may result in slower or less uniform growth.

Maintaining these optimal conditions requires consistent monitoring and adjustments. For instance, if temperature fluctuations occur, insulate the growing area or use heating/cooling systems to stabilize the environment. Similarly, if humidity drops, increase misting frequency or use humidity domes to retain moisture. Regularly inspect the substrate for signs of contamination or uneven growth, addressing issues promptly to ensure the mycelium develops uniformly. By carefully managing temperature, humidity, and light, you can create an environment that fosters robust mycelium growth, essential for producing durable and sustainable mushroom packaging.

Lastly, consider the substrate composition in conjunction with environmental conditions, as it directly impacts how mycelium responds to temperature, humidity, and light. The substrate should be nutrient-rich, sterile, and well-hydrated to support initial colonization. Common materials include agricultural waste (e.g., straw, sawdust, or hemp) combined with a nitrogen source like cottonseed hulls. Sterilize the substrate before inoculation to eliminate competing organisms, and ensure it is evenly moistened to facilitate mycelium spread. By integrating optimal growth conditions with a suitable substrate, you can maximize the efficiency and success of your mushroom packaging production.

Unveiling the Unique Growth Process of Lobster Mushrooms in Nature

You may want to see also

Harvesting & Processing: Dry, shape, or compress mycelium-based material into functional packaging products

Once the mycelium has fully colonized the substrate and formed a dense, cohesive network, the harvesting process begins. Harvesting mycelium-based material involves carefully removing the grown structure from its mold or growth container. This should be done gently to avoid damaging the material, as its integrity is crucial for later processing. Timing is key—harvest too early, and the material may lack strength; harvest too late, and it could become overly brittle. After harvesting, the material is typically cleaned to remove any residual substrate or contaminants, ensuring a pure product ready for the next steps.

Drying is a critical phase in processing mycelium-based material. The harvested material is placed in a well-ventilated area or a controlled drying environment, such as a dehydrator or oven, set at low temperatures (around 40-60°C). The goal is to remove moisture gradually without causing shrinkage or cracking. Drying times vary depending on thickness and humidity levels but generally take 24 to 48 hours. Proper drying not only preserves the material’s structural integrity but also prevents mold or bacterial growth during storage. Once dry, the material becomes lightweight and rigid, making it easier to handle and shape.

Shaping the mycelium material into functional packaging products requires creativity and precision. Before drying is complete, the material can be molded into desired forms using custom molds or 3D-printed shapes. For post-drying shaping, techniques like cutting, pressing, or thermoforming can be employed. Thermoforming involves heating the material slightly to make it pliable, then shaping it over a mold before cooling. This method is ideal for creating complex or curved packaging designs. Shaping should be done carefully to avoid stress points that could weaken the final product.

Compression is another method to process mycelium material, particularly for creating dense, sturdy packaging. After partial drying, the material can be compressed using hydraulic presses or rollers to achieve uniform thickness and density. Compression increases the material’s strength and reduces porosity, making it suitable for heavy-duty applications like protective packaging or structural components. Compressed mycelium can also be combined with natural binders, such as starch or cellulose, to enhance durability and water resistance.

Finally, post-processing treatments can be applied to improve the functionality and aesthetics of the packaging. Surface finishing techniques like sanding or polishing can create a smooth texture, while natural dyes or pigments can be added for color customization. To enhance water resistance, the material can be coated with plant-based waxes or oils. Quality control checks, such as testing for strength, flexibility, and biodegradability, ensure the final product meets packaging requirements. Once processed, the mycelium-based packaging is ready for use, offering a sustainable alternative to traditional materials.

Exploring New Hampshire's Forests: Do Magic Mushrooms Grow Here?

You may want to see also

Frequently asked questions

Mushroom packaging is a sustainable, biodegradable material made from mycelium (the root structure of fungi) and agricultural waste like hemp or corn stalks. It’s created by growing mycelium in molds, which binds the waste material into a sturdy, foam-like structure.

Mushroom packaging is fully compostable, breaking down in soil within weeks, and produces no toxic waste. It reduces reliance on petroleum-based plastics and minimizes carbon footprint by utilizing agricultural byproducts.

Growing mushroom packaging requires a sterile environment, a substrate (like agricultural waste), mycelium spores, and controlled temperature (around 20-25°C or 68-77°F) and humidity (60-70%). Proper ventilation and darkness during growth are also essential.

The growth process typically takes 5-10 days, depending on the mycelium strain and environmental conditions. After growth, the material is dried to halt further growth and stabilize its structure for use.