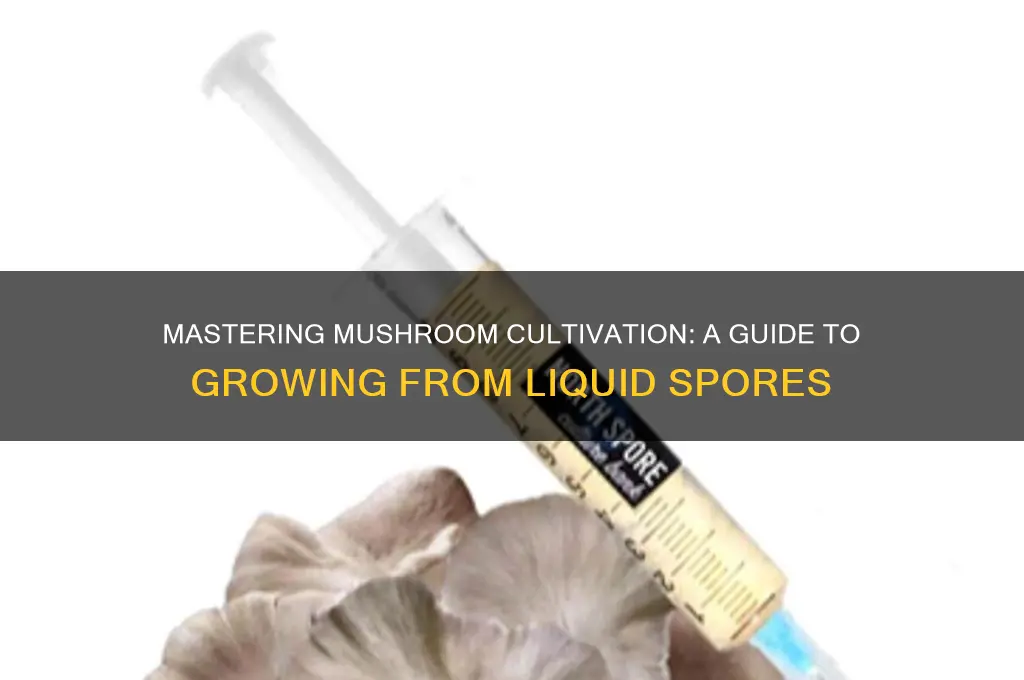

Growing mushrooms from liquid spores, also known as liquid culture, is a popular and efficient method for cultivating a variety of mushroom species. This technique involves suspending mushroom mycelium in a nutrient-rich liquid solution, which can then be used to inoculate substrate materials like grain or sawdust. Liquid spores offer several advantages, including faster colonization times, reduced contamination risks, and the ability to store the culture for extended periods. To begin, you’ll need sterile equipment, a liquid culture medium, and a source of spores or mycelium. The process starts by sterilizing the liquid medium, introducing the spores, and allowing the mycelium to grow before transferring it to the substrate. With proper care and attention to sterility, this method can yield healthy, productive mushroom crops, making it an excellent choice for both hobbyists and commercial growers.

| Characteristics | Values |

|---|---|

| Method Overview | Growing mushrooms from liquid spores involves inoculating a substrate with a liquid culture containing mushroom mycelium. |

| Liquid Spores | A suspension of mushroom mycelium in a nutrient-rich liquid medium, often sterilized. |

| Substrate Preparation | Sterilize or pasteurize a substrate (e.g., straw, sawdust, grain) to remove contaminants. |

| Inoculation | Inject or mix the liquid culture into the prepared substrate using sterile techniques. |

| Incubation | Keep the inoculated substrate in a dark, warm (70–75°F or 21–24°C) environment for mycelium colonization (1–4 weeks). |

| Fruiting Conditions | Transfer to a humid (85–95%), cooler (55–65°F or 13–18°C), and light environment to induce mushroom growth. |

| Humidity Management | Use a humidifier, misting, or a humidity-controlled chamber to maintain high humidity. |

| Harvesting | Harvest mushrooms when the caps are fully open but before spores drop for optimal quality. |

| Sterility Requirements | High; use sterile tools, gloves, and a clean environment to prevent contamination. |

| Common Mushroom Species | Oyster, Lion's Mane, Shiitake, and other species compatible with liquid culture. |

| Equipment Needed | Sterile syringes, grow bags, pressure cooker, humidity tent, and a HEPA filter (optional). |

| Success Rate | High with proper sterilization and environmental control; 70–90% success rate. |

| Time to Fruiting | 4–8 weeks from inoculation, depending on species and conditions. |

| Cost | Moderate; initial setup costs for equipment, but reusable materials reduce long-term expenses. |

| Sustainability | Eco-friendly; substrates can be recycled, and mushrooms are a renewable resource. |

| Difficulty Level | Intermediate; requires attention to sterility and environmental conditions. |

Explore related products

What You'll Learn

- Sterilization Techniques: Properly sterilize equipment to prevent contamination during the mushroom cultivation process

- Substrate Preparation: Choose and prepare the right growing medium for optimal mushroom growth

- Inoculation Process: Inject liquid spores into the substrate using sterile techniques for successful colonization

- Incubation Conditions: Maintain ideal temperature, humidity, and light levels for mycelium development

- Fruiting Strategies: Trigger mushroom formation with proper environmental changes and care techniques

Sterilization Techniques: Properly sterilize equipment to prevent contamination during the mushroom cultivation process

Sterilization is a critical step in mushroom cultivation, especially when working with liquid spores, as it ensures a contamination-free environment for mycelium growth. The goal is to eliminate all microorganisms, including bacteria, fungi, and spores, that could compete with or harm your mushroom culture. The process begins with cleaning all equipment thoroughly before sterilization. Use a strong detergent to wash jars, lids, syringes, and any other tools to remove dirt, oils, and residues. Rinse everything with clean water and allow it to dry completely. Even a small amount of debris can interfere with sterilization, so attention to detail is essential.

One of the most effective sterilization techniques for mushroom cultivation is pressure cooking, also known as autoclaving. This method uses high-pressure steam to kill all living organisms. To sterilize substrates like grain or sawdust, place them in jars with lids loosely tightened, then process them in a pressure cooker at 15 psi (pounds per square inch) for 60 to 90 minutes. For liquid cultures or agar plates, use a similar process but ensure the containers are sealed properly to prevent contamination after sterilization. Always follow the manufacturer’s instructions for your pressure cooker to ensure safety and effectiveness.

For smaller items like syringes, scalpels, or forceps, flaming is a quick and efficient sterilization method. Hold the metal part of the tool in an open flame (e.g., from a bunsen burner or alcohol lamp) until it glows red hot. This instantly kills any microorganisms on the surface. Allow the tool to cool before use, and ensure it does not come into contact with any unsterilized surfaces. Flaming is ideal for tools used during inoculation or transferring cultures but is not suitable for substrates or larger equipment.

Chemical sterilization is another option, particularly for surfaces or items that cannot withstand heat. A 10% bleach solution (1 part bleach to 9 parts water) can be used to disinfect work areas, gloves, and external surfaces of containers. Isopropyl alcohol (70% or higher) is also effective for sterilizing tools, hands, and small items. Wipe down surfaces thoroughly and allow them to air dry. While chemical sterilization is convenient, it is less reliable than heat-based methods for substrates and should be used as a supplementary technique.

Maintaining a sterile workflow is just as important as the sterilization process itself. Work in a clean, designated area, and use a laminar flow hood if possible to create a sterile air environment. Wear sterile gloves and a face mask to minimize the introduction of contaminants. All transfers of liquid spores or mycelium should be done quickly and with minimal exposure to the open air. Properly label and date sterilized items to ensure they are used within a safe timeframe, as prolonged storage can increase the risk of contamination. By combining these sterilization techniques and practices, you can significantly reduce the risk of contamination and increase the success rate of growing mushrooms from liquid spores.

Mastering Home Cultivation: A Guide to Growing Cubensis Mushrooms

You may want to see also

Substrate Preparation: Choose and prepare the right growing medium for optimal mushroom growth

Substrate preparation is a critical step in growing mushrooms from liquid spores, as it directly influences the success and yield of your crop. The substrate serves as the growing medium, providing essential nutrients and a suitable environment for mycelium colonization. When selecting a substrate, it's important to choose materials that align with the nutritional needs of the mushroom species you're cultivating. Common substrates include straw, wood chips, sawdust, compost, or a combination of these. For example, oyster mushrooms thrive on straw, while shiitake mushrooms prefer hardwood sawdust. Research the specific requirements of your chosen mushroom species to ensure compatibility.

Once you’ve selected the appropriate substrate, proper preparation is key to creating an optimal growing environment. Begin by pasteurizing or sterilizing the substrate to eliminate competing microorganisms that could hinder mycelium growth. Pasteurization, which involves heating the substrate to around 60-70°C (140-158°F) for an hour, is suitable for materials like straw. Sterilization, achieved by autoclaving or pressure cooking at 121°C (250°F) for 1-2 hours, is necessary for denser substrates like sawdust to ensure complete sanitation. After pasteurization or sterilization, allow the substrate to cool to a temperature between 20-25°C (68-77°F) before inoculation to avoid damaging the liquid spores.

Hydration is another crucial aspect of substrate preparation. The substrate should be moist but not waterlogged, as excessive moisture can lead to contamination or anaerobic conditions. Aim for a moisture content of 60-70% by weight, which can be achieved by soaking the substrate in water and then draining it thoroughly. For materials like sawdust, mixing it with water and squeezing it by hand until it forms a loose ball without dripping is a good indicator of proper hydration. Ensure even moisture distribution throughout the substrate to support uniform mycelium growth.

After hydration, the substrate should be placed in a suitable container, such as a grow bag, jar, or tray, depending on your cultivation method. If using grow bags, fill them loosely with the prepared substrate, leaving enough room for air circulation and mycelium expansion. Compact the substrate slightly to ensure good contact between particles but avoid packing it too tightly, as this can restrict airflow. Seal the containers properly to maintain a clean environment but consider adding a filter patch to allow gas exchange while preventing contaminants from entering.

Finally, the substrate is ready for inoculation with the liquid spores. Introduce the spore solution evenly throughout the substrate, ensuring thorough mixing to promote uniform colonization. Once inoculated, maintain the substrate in a dark, temperature-controlled environment, typically between 22-28°C (72-82°F), to encourage mycelium growth. Regularly monitor the substrate for signs of contamination and adjust environmental conditions as needed. With careful substrate preparation, you’ll create a robust foundation for healthy mushroom growth and a successful harvest.

Exploring California's Forests: Do Psilocybe Mushrooms Thrive Here?

You may want to see also

Inoculation Process: Inject liquid spores into the substrate using sterile techniques for successful colonization

The inoculation process is a critical step in growing mushrooms from liquid spores, as it involves introducing the mycelium into the substrate under sterile conditions to ensure successful colonization. Begin by preparing your workspace to maintain sterility. Clean the area thoroughly and use a laminar flow hood or a still-air box if available. Sterilize all tools, such as syringes, needles, and scalpel blades, by autoclaving or using alcohol wipes. Ensure your hands are clean and consider wearing gloves to minimize contamination. The substrate, which can be a mixture of materials like straw, sawdust, or grain, should already be pasteurized or sterilized and cooled to room temperature before inoculation.

Next, prepare the liquid spore syringe by removing it from storage and allowing it to reach room temperature. Shake the syringe gently to distribute the spores evenly in the solution. Attach a sterile needle to the syringe, ensuring the connection is secure to prevent leaks. If using multiple substrates or bags, label them clearly to avoid confusion. For each substrate bag or jar, locate the injection port or self-healing injection site, which is designed to minimize contamination when pierced. Wipe the injection site with an alcohol swab immediately before inserting the needle to further reduce the risk of contaminants entering the substrate.

Inject the liquid spores into the substrate with precision and care. Insert the needle through the injection port and slowly depress the plunger to release 1 to 2 milliliters of spore solution per 5 pounds of substrate. Distribute the spores evenly by injecting at multiple points, especially if the substrate is densely packed. Avoid over-injecting, as excess liquid can create anaerobic conditions that hinder mycelium growth. After each injection, withdraw the needle slowly and allow the self-healing port to seal. If using jars, seal them with lids immediately after inoculation.

Maintain sterile techniques throughout the process to prevent contamination. Work quickly but deliberately, minimizing exposure of the substrate to the open air. If contamination is suspected during inoculation, discard the affected substrate and sterilize all tools before proceeding. Once all substrates are inoculated, place them in a clean, dark environment with stable temperature and humidity levels, typically between 70-75°F (21-24°C) and 60-70% humidity. Avoid disturbing the substrates during the initial colonization phase, which can take 1 to 4 weeks depending on the mushroom species and substrate type.

Finally, monitor the substrates regularly for signs of mycelium growth, such as white, thread-like structures spreading through the material. If contamination appears, isolate the affected substrate to prevent it from spreading. Successful colonization will result in a fully white, healthy-looking substrate ready for the next stage of fruiting. Patience and attention to detail during the inoculation process are key to achieving robust mycelium growth and a bountiful mushroom harvest.

Are Poisonous Morel Mushrooms Found in Michigan? A Forager's Guide

You may want to see also

Explore related products

Incubation Conditions: Maintain ideal temperature, humidity, and light levels for mycelium development

Growing mushrooms from liquid spores requires precise control over incubation conditions to ensure optimal mycelium development. Temperature is one of the most critical factors during this stage. The ideal temperature range for most mushroom species, such as oyster or shiitake, is between 70°F to 75°F (21°C to 24°C). At this range, mycelium growth is vigorous without risking overheating or slowing down the colonization process. It’s essential to use a thermostat-controlled environment, like an incubation chamber or a modified container with a heating pad, to maintain consistency. Fluctuations outside this range can stunt growth or allow contaminants to take hold, so monitoring is key.

Humidity is equally vital during incubation, as mycelium requires a moist environment to thrive. Aim for a relative humidity of 90% or higher within the incubation space. This can be achieved by placing a humidifier nearby or using a humidity-controlled tent. Alternatively, misting the inside of the incubation container with sterile water periodically can help maintain moisture levels. However, avoid over-saturating the environment, as excess water can lead to bacterial or mold growth. Proper ventilation is also necessary to prevent stagnant air, which can be achieved by drilling small holes in the incubation container or using a fan on low speed.

Light levels during incubation are often misunderstood. Unlike plants, mycelium does not require light for photosynthesis. In fact, direct light can harm the developing mycelium or encourage green mold growth. Therefore, the incubation area should be kept in near-complete darkness. If using a transparent container, cover it with aluminum foil or store it in a dark room. Brief exposure to low light during inspections is acceptable, but prolonged light exposure should be avoided. Darkness not only protects the mycelium but also mimics its natural underground or shaded habitat, promoting healthy growth.

Maintaining these conditions consistently is crucial for successful mycelium development. Regularly monitor temperature and humidity using digital thermometers and hygrometers, and adjust as needed. Inspect the incubation container daily for signs of contamination, such as unusual colors or smells, but minimize opening it to prevent airborne spores from entering. Patience is essential, as colonization can take 2 to 4 weeks depending on the species and conditions. Once the mycelium has fully colonized the substrate, it’s ready for the next stage of fruiting, but only if the incubation conditions have been meticulously controlled.

Finally, cleanliness and sterility are paramount throughout the incubation process. Before introducing liquid spores, sterilize all equipment, including jars, lids, and tools, using an autoclave or pressure cooker. Work in a clean environment, preferably a still air box or laminar flow hood, to minimize the risk of contamination. Even small particles or airborne spores can compromise the entire batch. By combining sterile practices with optimal temperature, humidity, and light control, you create the ideal environment for mycelium to flourish, setting the stage for a successful mushroom harvest.

Do Morel Mushrooms Thrive in Apple-Rich Environments? Exploring the Connection

You may want to see also

Fruiting Strategies: Trigger mushroom formation with proper environmental changes and care techniques

To successfully trigger mushroom formation from liquid spores, understanding the fruiting stage is crucial. Mushrooms require specific environmental cues to transition from mycelial growth to fruiting. The first step is to ensure your mycelium is fully colonized and healthy. Once colonization is complete, introduce a period of "pinning," where environmental changes stimulate the mycelium to form primordia (baby mushrooms). Begin by exposing the substrate to fresh air by removing any plastic wrap or opening the growing container. This increase in oxygen levels signals to the mycelium that it’s time to fruit. Simultaneously, reduce the humidity slightly to around 50-60% for 24-48 hours to further encourage pinning. This brief dry period mimics natural conditions and prompts the mycelium to initiate fruiting.

After the pinning phase, maintain optimal fruiting conditions by increasing humidity to 85-95%. This can be achieved using a humidifier, misting the container walls, or placing the substrate in a humid chamber like a shotgun fruiting chamber (a container with perlite or vermiculite to retain moisture). Proper air exchange is equally important; ensure there is adequate ventilation to prevent CO2 buildup, which can hinder fruiting. Aim for 2-3 fresh air exchanges per hour by using a filter patch or partially opening the growing container. Light exposure is another critical factor—mushrooms need indirect light to develop properly. Use a grow light or place the container near a window with natural light, ensuring it’s not exposed to direct sunlight.

Temperature control is another key aspect of fruiting strategies. Most mushroom species fruit best within a specific temperature range, typically between 60-75°F (15-24°C). Monitor the temperature closely and adjust as needed using heating mats or cooling fans. Fluctuations in temperature can also mimic natural conditions and encourage fruiting. For example, dropping the temperature by 5-10°F at night can simulate a natural day-night cycle, which some species respond to positively. Consistency in these conditions is vital; sudden changes can stress the mycelium and delay fruiting.

Hydration management is equally important during the fruiting stage. While high humidity is necessary, avoid over-saturating the substrate, as this can lead to contamination or drowning of the mycelium. Mist the mushrooms lightly 2-3 times a day, focusing on the walls of the container rather than directly on the mushrooms. If using a bulk substrate like straw or manure, ensure it retains moisture without becoming waterlogged. Regularly check for signs of contamination, such as mold or unusual colors, and address any issues immediately to protect the crop.

Finally, patience and observation are essential fruiting strategies. Mushrooms can take anywhere from a few days to several weeks to fully develop, depending on the species and growing conditions. Monitor the progress daily, noting any changes in the environment or the mushrooms themselves. If pinning stalls or mushrooms fail to develop, reassess the conditions—adjust humidity, light, or temperature as needed. With proper care and attention to these environmental factors, you can successfully trigger mushroom formation and enjoy a bountiful harvest from your liquid spore cultivation.

Exploring the Natural Habitats of Magic Mushrooms: Where They Thrive

You may want to see also

Frequently asked questions

Store liquid spores in a cool, dark place, such as a refrigerator, at temperatures between 2-8°C (36-48°F). Ensure the container is sealed tightly to prevent contamination and label it with the date and strain for future reference.

Sterilize your chosen substrate (e.g., grain, straw, or sawdust) using a pressure cooker or autoclave to kill contaminants. Once cooled, inoculate the substrate with the liquid spores in a sterile environment, such as a still air box or glove box, to avoid contamination.

The time varies by mushroom species, but generally, colonization of the substrate takes 2-6 weeks. After colonization, fruiting conditions (e.g., humidity, light, and temperature) are introduced, and mushrooms typically begin to grow within 1-3 weeks. Total time from inoculation to harvest can range from 6-12 weeks.