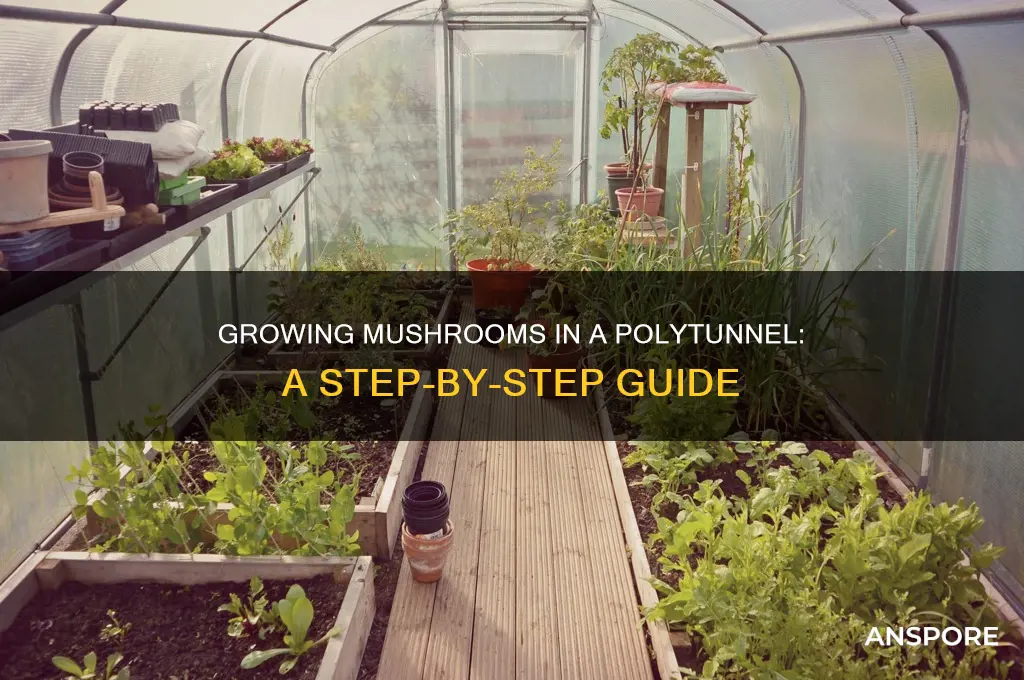

Growing mushrooms in a polytunnel offers a controlled environment that can significantly enhance yield and quality, making it an ideal setup for both hobbyists and commercial growers. A polytunnel provides the necessary humidity, temperature, and light conditions that mushrooms thrive in, while protecting them from pests and adverse weather. To begin, selecting the right mushroom species, such as oyster or shiitake, is crucial, as different varieties have specific requirements. The process involves preparing a substrate—often a mix of straw, wood chips, or compost—which is then inoculated with mushroom spawn. Maintaining optimal conditions, including consistent moisture levels and proper ventilation, is essential for successful fruiting. With careful management, a polytunnel can become a productive space for cultivating mushrooms year-round, offering a sustainable and rewarding harvest.

Explore related products

What You'll Learn

- Optimal Polytunnel Conditions: Temperature, humidity, light control for mushroom cultivation

- Substrate Preparation: Choosing and sterilizing materials for mushroom growth

- Spawn Selection: Best mushroom spawn types for polytunnel environments

- Ventilation Strategies: Maintaining air quality to prevent contamination

- Harvesting Techniques: Timing and methods for peak mushroom yield

Optimal Polytunnel Conditions: Temperature, humidity, light control for mushroom cultivation

Creating optimal conditions within a polytunnel is crucial for successful mushroom cultivation. Mushrooms thrive in specific environmental parameters, and a polytunnel offers the flexibility to control temperature, humidity, and light—key factors that influence growth, yield, and quality. Here’s a detailed guide to achieving the ideal conditions for mushroom cultivation in a polytunnel.

Temperature Control: Mushrooms are highly sensitive to temperature fluctuations, and maintaining a consistent range is essential. Most mushroom species, such as oyster and shiitake, grow best at temperatures between 55°F and 65°F (13°C and 18°C). A polytunnel can be equipped with heating systems like electric heaters or propane heaters to maintain warmth during colder months. In warmer climates, shading or ventilation systems, such as fans or passive vents, can prevent overheating. Monitoring temperature with thermostats or digital sensors ensures that the environment remains stable, promoting healthy mycelium growth and fruiting.

Humidity Management: High humidity is critical for mushroom cultivation, as mushrooms require moisture to develop properly. Optimal humidity levels typically range from 80% to 90%. A polytunnel can be fitted with humidifiers or misting systems to increase moisture levels. Additionally, covering the growing substrate with damp materials like straw or using humidity domes can help retain moisture. Proper ventilation is equally important to prevent stagnant air and the buildup of excess moisture, which can lead to mold or disease. Regularly monitoring humidity with hygrometers allows for precise adjustments to maintain the ideal range.

Light Control: While mushrooms do not require direct sunlight for photosynthesis, they do need indirect light to trigger fruiting. A polytunnel should allow diffused natural light to enter, which can be achieved by using translucent polythene covers or shading materials. Artificial lighting, such as LED or fluorescent lights, can supplement natural light, especially during shorter winter days. Aim for 8–12 hours of low-intensity light daily to encourage pinhead formation and fruiting. Proper light control ensures that mushrooms develop uniformly without becoming leggy or underdeveloped.

Airflow and Ventilation: Adequate airflow is essential to prevent the buildup of carbon dioxide and maintain a fresh environment for mushroom growth. A polytunnel should have vents, fans, or automated ventilation systems to ensure a steady exchange of air. Proper airflow also helps regulate temperature and humidity, reducing the risk of diseases. Positioning vents strategically and using oscillating fans can create a gentle breeze that mimics natural conditions, promoting robust mushroom development.

Substrate and Environmental Integration: The growing substrate, such as straw, sawdust, or compost, should be integrated into the polytunnel’s environmental controls. For example, watering schedules must align with humidity management to keep the substrate moist but not waterlogged. Insulating the polytunnel during colder seasons can protect the substrate and mycelium from temperature extremes. By synchronizing substrate care with temperature, humidity, and light control, growers can create a harmonious environment that maximizes mushroom productivity.

In summary, optimizing a polytunnel for mushroom cultivation involves precise control of temperature, humidity, light, and airflow. Investing in monitoring tools and environmental systems ensures that conditions remain within the ideal ranges for each growth stage. With careful management, a polytunnel can provide a stable, productive space for growing high-quality mushrooms year-round.

Mastering Mushroom Cultivation: Simple Steps to Grow Your Own Fungi

You may want to see also

Substrate Preparation: Choosing and sterilizing materials for mushroom growth

Growing mushrooms in a polytunnel requires careful substrate preparation, as the substrate serves as the primary food source and environment for mushroom mycelium. The first step in substrate preparation is choosing the right materials. Common substrates include straw, wood chips, sawdust, and composted manure, depending on the mushroom species you intend to grow. For example, oyster mushrooms thrive on straw, while shiitake mushrooms prefer hardwood sawdust. Ensure the materials are free from pesticides or contaminants that could inhibit mycelium growth. Locally sourced, organic materials are ideal, as they reduce the risk of introducing harmful substances.

Once the substrate material is selected, moisture content adjustment is crucial. The substrate should be damp but not waterlogged, typically holding around 60-70% moisture. To achieve this, soak straw in water for 24 hours or spray sawdust with water until it feels like a wrung-out sponge. Excess water can be drained or squeezed out to prevent waterlogging, which can lead to anaerobic conditions harmful to mycelium. Proper moisture levels ensure the substrate is hospitable for mushroom growth while discouraging competing molds and bacteria.

Sterilization or pasteurization of the substrate is the next critical step to eliminate competing organisms. For small-scale operations, pasteurization is often sufficient and less resource-intensive than sterilization. Pasteurization involves heating the substrate to 60-70°C (140-158°F) for 1-2 hours, which kills most harmful microbes while preserving beneficial microorganisms. This can be done in a large pot, steam chamber, or directly in the polytunnel using a thermometer to monitor temperature. For more sensitive mushroom species or larger operations, sterilization at 121°C (250°F) using an autoclave or pressure cooker may be necessary to ensure a completely sterile environment.

After pasteurization or sterilization, the substrate must cool to the appropriate temperature before inoculation with mushroom spawn. Introducing spawn to a hot substrate can kill the mycelium. Allow the substrate to cool to around 25-30°C (77-86°F) in a clean environment to prevent recontamination. Covering the substrate with a clean tarp or plastic sheet during cooling is essential to protect it from airborne spores and bacteria.

Finally, mixing the spawn into the substrate should be done in a clean, controlled environment to minimize contamination. Use a clean tool to evenly distribute the spawn throughout the substrate, ensuring thorough colonization. Once mixed, the substrate can be transferred to growing bags, trays, or directly into the polytunnel beds. Properly prepared and sterilized substrate provides a strong foundation for healthy mushroom growth, maximizing yield and minimizing the risk of failure in your polytunnel cultivation.

Are Tree-Growing Mushrooms Harmful? Understanding Fungal Growth on Trees

You may want to see also

Spawn Selection: Best mushroom spawn types for polytunnel environments

When selecting mushroom spawn for a polytunnel environment, it's essential to consider the unique conditions that polytunnels offer, such as controlled temperature, humidity, and light. The right spawn type can significantly impact the success and yield of your mushroom crop. Grain spawn is one of the most popular choices for polytunnel growers due to its versatility and ease of use. It consists of sterilized grains like rye, wheat, or millet that have been inoculated with mushroom mycelium. Grain spawn is ideal for a wide range of mushroom species, including oyster, shiitake, and lion's mane. Its small particle size allows for even colonization of the growing substrate, ensuring consistent growth. Additionally, grain spawn is less prone to contamination when handled properly, making it a reliable option for the controlled environment of a polytunnel.

Another excellent option for polytunnel mushroom cultivation is sawdust spawn. This type of spawn is made by inoculating sterilized hardwood sawdust with mushroom mycelium. Sawdust spawn is particularly well-suited for wood-loving mushroom species like shiitake and reishi. The advantage of sawdust spawn lies in its ability to integrate seamlessly with supplementary substrates like straw or wood chips, which are commonly used in polytunnel setups. Its fine texture promotes rapid mycelial growth, and the controlled humidity in a polytunnel helps maintain the moisture levels required for optimal colonization. However, it’s crucial to ensure proper sterilization of the sawdust to avoid contamination, as the polytunnel environment, while controlled, is not entirely sterile.

For growers looking to maximize space and efficiency in their polytunnel, plug spawn is a highly recommended choice. Plug spawn consists of small wooden dowels or plugs inoculated with mushroom mycelium, typically used for inoculating logs or stumps. However, it can also be inserted directly into pre-drilled holes in supplemented sawdust blocks or straw bales within the polytunnel. This method is particularly effective for growing shiitake and other gourmet mushrooms. The controlled climate of a polytunnel ensures that the plugs remain moist and colonize quickly, reducing the risk of contamination. Plug spawn is also a long-lasting option, allowing for staggered fruiting cycles and continuous harvests.

Liquid spawn is another viable option for polytunnel mushroom cultivation, especially for species like oyster mushrooms that grow aggressively. Liquid spawn is a suspension of mushroom mycelium in water, often used to inoculate bulk substrates like straw or pasteurized compost. Its ease of application makes it a favorite among beginners, as it can be evenly distributed throughout the substrate using simple tools like a spray bottle or by mixing it directly into the material. The high humidity levels in a polytunnel help prevent the liquid spawn from drying out, ensuring successful colonization. However, it’s important to use liquid spawn promptly after preparation, as it has a shorter shelf life compared to grain or sawdust spawn.

Lastly, brick spawn, also known as supplemented sawdust blocks, is an all-in-one solution that combines spawn and substrate in a single unit. These bricks are pre-inoculated with mushroom mycelium and often include nutrients like bran or gypsum to support growth. Brick spawn is incredibly convenient for polytunnel growers, as it requires minimal preparation—simply place the bricks on a rack or shelf, maintain proper humidity, and wait for fruiting. This option is particularly suitable for oyster mushrooms and other fast-growing species. The controlled environment of a polytunnel ensures that the bricks remain in optimal conditions, leading to high yields with minimal effort. However, brick spawn can be more expensive than other options, so it’s best suited for small-scale or hobbyist growers.

In conclusion, the best mushroom spawn type for a polytunnel environment depends on the species you’re growing, your level of experience, and your cultivation goals. Grain spawn offers versatility and reliability, sawdust spawn is ideal for wood-loving mushrooms, plug spawn provides efficiency and longevity, liquid spawn is beginner-friendly and fast-acting, and brick spawn offers convenience for small-scale operations. By carefully selecting the appropriate spawn type and maintaining the controlled conditions of your polytunnel, you can achieve successful and bountiful mushroom harvests year-round.

Mastering Mushroom Cultivation: Grow Half a Pound at Home Easily

You may want to see also

Explore related products

Ventilation Strategies: Maintaining air quality to prevent contamination

Growing mushrooms in a polytunnel requires meticulous attention to air quality to prevent contamination, as mushrooms are highly sensitive to airborne pathogens and environmental conditions. Ventilation is critical not only for maintaining optimal temperature and humidity but also for ensuring a constant supply of fresh, filtered air. A well-designed ventilation system minimizes the risk of mold, bacteria, and other contaminants while promoting healthy mycelium growth. The primary goal is to create a controlled environment where air circulates efficiently without creating drafts that could stress the mushrooms.

One effective ventilation strategy is the use of passive vents and active exhaust fans to create a balanced airflow. Passive vents, such as adjustable openings at the top or sides of the polytunnel, allow stale air to escape naturally while drawing in fresh air from intake vents positioned lower on the structure. This natural convection helps maintain a steady exchange of air without relying heavily on mechanical systems. However, passive ventilation alone may not suffice in humid or stagnant conditions, making it essential to supplement with active exhaust fans. These fans should be strategically placed to expel humid air and prevent its accumulation, which can foster contamination.

Air filtration is another crucial component of ventilation strategies. Installing HEPA filters on intake vents ensures that incoming air is free from spores, dust, and other particulate matter that could introduce contaminants. For smaller polytunnels, portable air purifiers with HEPA filters can be used to clean the air internally. Additionally, maintaining positive air pressure—where more air is pushed into the polytunnel than is extracted—can prevent external contaminants from entering through gaps or openings. This approach is particularly useful during critical growth stages when mushrooms are most vulnerable.

Monitoring and controlling humidity levels is closely tied to ventilation, as excessive moisture in the air can lead to condensation and mold growth. A dehumidifier can be integrated into the ventilation system to reduce humidity, especially during fruiting stages when moisture levels naturally rise. Pairing dehumidification with proper airflow ensures that damp air is expelled promptly, reducing the risk of contamination. It’s also important to avoid over-misting mushroom beds, as this can overwhelm the ventilation system and create pockets of stagnant, humid air.

Finally, regular maintenance and inspection of ventilation systems are essential to prevent contamination. Fans, filters, and vents should be cleaned periodically to remove dust, debris, and potential pathogen sources. Inspecting the polytunnel for gaps, tears, or damage ensures that the controlled environment remains intact. Automated systems, such as timers or sensors for fans and dehumidifiers, can help maintain consistent conditions without constant manual oversight. By combining these strategies, growers can create a clean, stable environment that supports healthy mushroom growth while minimizing the risk of contamination.

Do Mushrooms Thrive Under Trees? Exploring the Forest Floor Ecosystem

You may want to see also

Harvesting Techniques: Timing and methods for peak mushroom yield

Harvesting mushrooms at the right time is crucial for maximizing yield and ensuring the best quality. In a polytunnel, where environmental conditions can be controlled, mushrooms typically mature faster than in outdoor settings. The ideal time to harvest is when the caps are fully expanded but before the gills start to darken and release spores. For button mushrooms, this means harvesting when the cap is still slightly convex and the veil is just beginning to break. For larger varieties like portobellos, wait until the cap is fully open and the gills are visible but not yet releasing spores. Regular monitoring is essential, as mushrooms can reach this stage quickly, often within 24 to 48 hours after the first signs of fruiting.

The method of harvesting also plays a significant role in peak yield. Always use a sharp knife or blade to cut the mushroom at the base of the stem, avoiding pulling or twisting, which can damage the mycelium and reduce future yields. Handle the mushrooms gently to prevent bruising, as damaged mushrooms deteriorate quickly and can affect the overall quality of the harvest. After harvesting, immediately place the mushrooms in a cool, dry area or refrigerate them to preserve freshness. Proper harvesting techniques not only ensure the best yield from the current crop but also encourage healthy mycelium growth for subsequent flushes.

Timing is key to achieving multiple flushes in a polytunnel. After the initial harvest, the mycelium will often produce additional mushrooms in what are known as "flushes." To encourage this, maintain optimal growing conditions, including consistent humidity (around 85-95%) and temperature (13-18°C for most varieties). Lightly mist the growing area daily to keep the substrate moist but not waterlogged. Typically, the second flush appears 1-2 weeks after the first, and subsequent flushes may follow at similar intervals. Be prepared to harvest each flush at its peak to avoid over-maturity and spore release, which can contaminate the growing environment.

For peak yield, it’s important to manage the polytunnel environment meticulously during the harvesting period. Ensure proper air circulation to prevent the buildup of carbon dioxide, which can stunt mushroom growth. Regularly inspect the substrate and remove any overripe or spoiled mushrooms to prevent mold or pests. Additionally, keep the polytunnel clean and sanitized to avoid contamination that could reduce yields. By maintaining these conditions and following precise harvesting techniques, you can optimize the productivity of your mushroom crop in a polytunnel.

Finally, record-keeping is an often-overlooked but valuable practice for maximizing yield. Keep a log of harvesting times, environmental conditions, and mushroom quality for each flush. This data will help you identify patterns and adjust your techniques for better results in future cycles. For example, if you notice that mushrooms harvested earlier in the day have a longer shelf life, you can plan your harvesting schedule accordingly. Consistent monitoring and adaptation based on observed trends will ensure that your polytunnel mushroom cultivation remains efficient and productive.

Affordable Mushroom Cultivation: Startup Costs for Beginners Explained

You may want to see also

Frequently asked questions

Mushrooms thrive in a controlled environment with consistent humidity (80-90%), temperatures between 55-65°F (13-18°C), and indirect light. Ensure good air circulation and use a substrate like straw, wood chips, or compost, depending on the mushroom species.

Use a misting system or humidifier to keep humidity high. Cover the growing substrate with a damp cloth or plastic sheet initially to retain moisture. Regularly monitor humidity with a hygrometer and ventilate as needed to prevent mold or bacteria growth.

Oyster mushrooms, shiitake, and lion's mane are popular choices due to their adaptability and fast growth. Button mushrooms (Agaricus bisporus) can also be grown but require more precise conditions, including a casing layer and controlled CO2 levels.

![Boomer Shroomer Inflatable Monotub Kit, Mushroom Growing Kit Includes a Drain Port, Plugs & Filters, Removeable Liner [Patent No: US 11,871,706 B2]](https://m.media-amazon.com/images/I/61K9zwzRQxL._AC_UL320_.jpg)