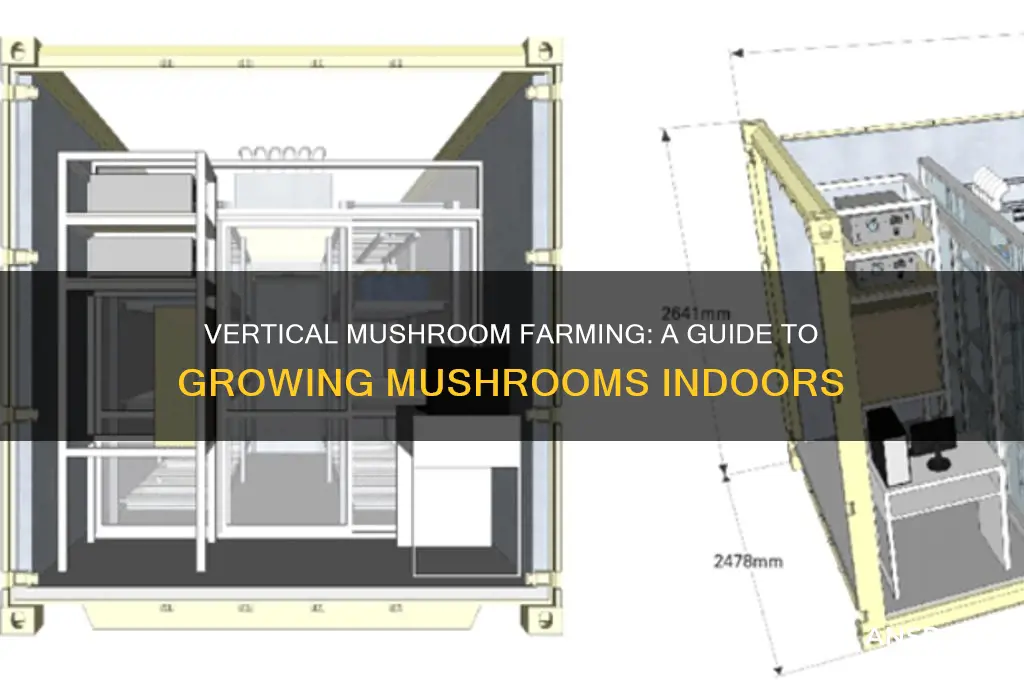

Growing mushrooms indoors vertically is an innovative and space-efficient method that allows enthusiasts and small-scale farmers to cultivate a variety of mushroom species in limited areas. By utilizing vertical farming techniques, such as stacking growing trays or shelves, growers can maximize yield while minimizing floor space. This approach is particularly beneficial for urban environments or small homes where traditional horizontal farming is impractical. Key components of successful vertical mushroom cultivation include proper substrate preparation, maintaining optimal humidity and temperature levels, and ensuring adequate air circulation. With the right setup and care, vertical indoor mushroom farming can provide a consistent and sustainable source of fresh, homegrown mushrooms year-round.

| Characteristics | Values |

|---|---|

| Space Requirements | Vertical growing saves space; can use shelves, racks, or stacked trays. Ideal for small indoor areas. |

| Substrate | Common substrates include straw, sawdust, coffee grounds, or composted manure. Must be sterilized or pasteurized to prevent contamination. |

| Mushroom Species | Oyster, lion's mane, and shiitake are popular for vertical growing due to their adaptability and fast growth. |

| Humidity | Requires 80-90% humidity. Use humidifiers, misting systems, or enclosed grow tents. |

| Temperature | Optimal range: 60-75°F (15-24°C). Varies slightly by species. |

| Lighting | Low indirect light is sufficient. No need for intense grow lights; natural light or LED strips work. |

| Air Exchange | Good airflow is essential to prevent mold and ensure healthy growth. Use fans or passive ventilation. |

| Watering | Mist substrate regularly to maintain moisture. Avoid overwatering, which can cause rot. |

| Harvest Time | Typically 2-4 weeks after spawning, depending on species and conditions. |

| Yield | Varies by species and setup, but vertical systems can produce 1-2 lbs per square foot per harvest. |

| Maintenance | Regular monitoring for pests, mold, and proper environmental conditions. Substrate needs replacement after each harvest. |

| Cost | Initial setup costs include shelving, substrate, spawn, and environmental controls. Ongoing costs are minimal. |

| Sustainability | Uses recycled materials (e.g., coffee grounds) and produces minimal waste. Energy-efficient with proper setup. |

| Scalability | Easily scalable from small home setups to larger commercial operations. |

Explore related products

What You'll Learn

Choosing the Right Mushroom Species

When choosing the right mushroom species for indoor vertical farming, it's essential to consider factors such as growth rate, space requirements, and environmental preferences. Oyster mushrooms (Pleurotus ostreatus) are a popular choice for beginners due to their fast growth, adaptability to various substrates, and ability to thrive in a wide range of temperatures (55-75°F). They also have a high yield potential, making them an efficient option for vertical setups. Another advantage of oyster mushrooms is their ability to grow on straw, coffee grounds, or sawdust, which can be easily sourced and arranged in vertical layers.

Button mushrooms (Agaricus bisporus) are another option, but they require more specific conditions, including a cooler temperature range (55-60°F) and a more controlled environment. While they are a popular culinary mushroom, their slower growth rate and higher maintenance needs may not make them the best choice for small-scale vertical farming. However, if you have the necessary resources and expertise, button mushrooms can be a profitable crop due to their high market demand. For those interested in a more exotic option, lion's mane mushrooms (Hericium erinaceus) are gaining popularity for their unique appearance and potential health benefits. They grow well in cooler temperatures (50-65°F) and can be cultivated on supplemented sawdust or wood-based substrates, making them suitable for vertical systems.

Shiitake mushrooms (Lentinula edodes) are a gourmet option that can be grown indoors vertically, but they require a more specific substrate, such as oak or beech sawdust, and a longer growing cycle. They prefer a temperature range of 60-75°F and high humidity levels, which can be achieved in a well-designed vertical setup. When selecting a species, consider the availability and cost of substrate materials, as well as the time and resources required for preparation and maintenance. For instance, straw is a low-cost and readily available substrate for oyster mushrooms, while supplemented sawdust may be more expensive but can support a wider range of species.

In addition to substrate and environmental considerations, think about the market demand and potential profitability of the mushroom species you choose. Oyster mushrooms, for example, have a broad appeal and can be sold fresh or processed into value-added products like mushroom jerky or powder. On the other hand, specialty mushrooms like lion's mane or shiitake may command a higher price but may also have a more limited customer base. It's also crucial to research the specific requirements of each species, including their preferred pH levels, humidity, and air exchange rates, to ensure a successful and productive vertical farming system.

Lastly, consider the scalability and long-term viability of your chosen mushroom species. Some species, like oyster mushrooms, are well-suited for small-scale vertical farming and can be easily expanded as your operation grows. Others, like button mushrooms, may require a more significant initial investment and may not be as flexible in terms of scaling up or down. By carefully evaluating the characteristics and requirements of different mushroom species, you can make an informed decision that aligns with your goals, resources, and market opportunities, ultimately setting your indoor vertical mushroom farm up for success.

Mushroom Growth in Your Garden: Understanding Age and Factors

You may want to see also

Setting Up Vertical Growing Racks

To set up vertical growing racks for indoor mushroom cultivation, start by selecting a suitable space that is cool, dark, and humid, such as a basement, closet, or dedicated grow room. Ensure the area has proper ventilation to maintain air circulation and prevent the buildup of carbon dioxide. Measure the dimensions of your space to determine the size and number of racks you can accommodate. Vertical racks maximize space efficiency, allowing you to grow more mushrooms in a smaller footprint.

Next, choose or build your vertical racks. You can purchase pre-made shelving units designed for indoor gardening or construct your own using materials like PVC pipes, metal frames, or wooden shelves. The key is to ensure the racks are sturdy enough to support the weight of the growing substrate and mushrooms. Each shelf should be spaced approximately 12 to 18 inches apart to allow adequate airflow and light penetration, if supplemental lighting is used. For DIY setups, consider adding wheels to the base of the racks for easy mobility during maintenance.

Prepare the growing substrate for your mushrooms, which typically consists of a mixture of straw, sawdust, or compost, sterilized and inoculated with mushroom spawn. Place the substrate in growing containers such as trays, bags, or buckets that fit neatly onto your vertical racks. Ensure each container has proper drainage to prevent waterlogging. Arrange the containers in a staggered pattern on the shelves to optimize airflow and minimize the risk of contamination. Label each container with the mushroom variety and inoculation date for easy tracking.

Maintain optimal growing conditions by installing a humidifier and a thermometer/hygrometer to monitor humidity and temperature levels, ideally between 60-80% humidity and 55-65°F (13-18°C). Use a misting system or spray bottle to regularly hydrate the growing environment without oversaturating the substrate. If natural light is insufficient, add LED grow lights positioned above or between the racks to provide the necessary light spectrum for mushroom development.

Finally, organize your vertical racks for efficient workflow. Place frequently accessed items, such as harvesting tools and misting equipment, within easy reach. Allocate the lower shelves for heavier or more mature mushrooms to reduce strain during harvesting. Regularly inspect the racks for signs of contamination, pests, or uneven growth, addressing issues promptly to ensure a healthy crop. With proper setup and maintenance, vertical growing racks can significantly enhance your indoor mushroom cultivation efficiency.

Easy Guide to Growing Button Mushrooms in Bags at Home

You may want to see also

Preparing Substrate and Spawn

Growing mushrooms indoors vertically requires careful preparation of both the substrate and the spawn. The substrate serves as the nutrient base for the mushrooms, while the spawn contains the mycelium that will colonize the substrate. Here’s a detailed guide on preparing these essential components.

Selecting and Preparing the Substrate

The substrate is the growing medium for mushrooms, and its composition depends on the mushroom species. Common substrates include straw, sawdust, wood chips, or a mixture of these materials. For vertical growing, lightweight and well-draining substrates like pasteurized straw or supplemented sawdust are ideal. Begin by sourcing clean, organic material to avoid contaminants. Pasteurization is crucial to eliminate competing microorganisms. To pasteurize straw, soak it in hot water (160-180°F) for 1-2 hours, then drain and cool it to room temperature. For sawdust-based substrates, mix it with supplements like wheat bran, gypsum, or soybean meal to provide additional nutrients, then pasteurize by steaming or hydrating with boiling water. Ensure the substrate is moist but not waterlogged, as excess moisture can lead to mold or bacterial growth.

Choosing the Right Spawn

Spawn is the mycelium-inoculated material that introduces the mushroom’s fungal network to the substrate. It comes in two forms: grain spawn (mycelium grown on grains like rye or millet) or sawdust spawn. For vertical growing, grain spawn is often preferred due to its ease of mixing and higher mycelium concentration. Select a spawn strain that matches your mushroom species and growing conditions. Ensure the spawn is fresh and actively growing to maximize colonization success. If purchasing spawn, source it from a reputable supplier to avoid contamination. For advanced growers, creating your own spawn is an option, but it requires sterile techniques and a laminar flow hood to prevent contamination.

Mixing Spawn with Substrate

Once the substrate is prepared and cooled, it’s time to introduce the spawn. Work in a clean environment to minimize the risk of contamination. Break up the spawn into smaller pieces to distribute it evenly. Mix the spawn into the substrate at a ratio typically ranging from 1:5 to 1:10 (spawn to substrate), depending on the mushroom species and substrate type. Use gloved hands or sanitized tools to combine the materials thoroughly, ensuring the spawn is evenly dispersed. The goal is to create a uniform mixture that allows the mycelium to spread efficiently. After mixing, the substrate should appear lightly speckled with spawn.

Packing the Substrate into Vertical Grow Systems

Vertical growing systems often use shelves, towers, or hanging bags to maximize space. Fill the grow containers (e.g., polypropylene bags, trays, or shelves lined with plastic) with the spawn-inoculated substrate, leaving enough room for the mycelium to expand. Pack the substrate firmly but not compactly to allow air circulation, which is crucial for mycelium growth. Seal or cover the containers to retain moisture while allowing gas exchange. For bag systems, use filters or small holes to maintain airflow. Properly packed substrate ensures even colonization and supports healthy mushroom development.

Incubation and Monitoring

After preparing the substrate and spawn, the containers must be incubated in a dark, temperature-controlled environment (typically 70-75°F) to encourage mycelium growth. Monitor the substrate for signs of contamination, such as unusual colors or odors. If contamination occurs, isolate the affected container to prevent spread. Incubation times vary by species but generally range from 2-4 weeks. Once fully colonized, the substrate is ready for fruiting. Proper substrate and spawn preparation is the foundation of successful vertical mushroom cultivation, ensuring a healthy and productive harvest.

Mastering Bitter Oyster Mushroom Cultivation: A Step-by-Step Growing Guide

You may want to see also

Explore related products

Maintaining Optimal Humidity and Light

In addition to humidity, proper air circulation is essential to prevent mold and ensure even moisture distribution. Use small fans on low settings to maintain airflow without drying out the environment. Position the fans so they circulate air around the vertical growing structure but avoid direct airflow onto the mushrooms, as this can cause stress and dehydration. Balancing humidity with adequate ventilation is key to creating a healthy growing environment for your mushrooms.

Light requirements for mushrooms are minimal, as they do not photosynthesize like plants. However, indirect, low-intensity light is necessary to signal fruiting and help mushrooms develop properly. Use LED grow lights or natural light from a nearby window, ensuring the light is not too bright or direct. Aim for 8-12 hours of light per day, mimicking a natural day-night cycle. Avoid complete darkness, as it can delay fruiting, but also prevent overexposure to light, which can dry out the growing environment.

To maintain optimal light conditions, position your vertical mushroom setup in a location with consistent, indirect light. If using artificial lighting, place the LED strips or bulbs a few feet away from the mushrooms to avoid overheating. Regularly check that the light schedule remains consistent, as disruptions can impact fruiting. Pairing proper lighting with humidity control ensures that your mushrooms receive the environmental cues they need to grow and fruit successfully.

Lastly, integrate humidity and light management into your daily maintenance routine. Check the hygrometer and adjust the humidifier or misting schedule as needed, especially during drier seasons. Inspect the lighting setup weekly to ensure bulbs or LEDs are functioning and positioned correctly. By staying vigilant and making small adjustments, you can create a stable, optimal environment for vertical mushroom cultivation, maximizing yield and quality.

Master Mushroom Growing: UK Guide to Cultivating Delicious Fungi at Home

You may want to see also

Harvesting and Post-Harvest Care

Harvesting mushrooms at the right time is crucial for both quality and yield. For vertically grown mushrooms, monitor the caps closely; they are ready to harvest when the caps have fully expanded but before the gills start to darken and release spores. Gently twist or cut the mushrooms at the base of the stem to avoid damaging the mycelium or the growing substrate. Harvesting should be done daily to ensure you catch each mushroom at its peak. If you notice any over-mature mushrooms, remove them immediately to prevent spore release, which can contaminate the growing area and reduce future yields.

After harvesting, proper post-harvest care is essential to maintain freshness and extend shelf life. Brush off any excess substrate or debris from the mushrooms using a soft brush or cloth, but avoid washing them as moisture can accelerate spoilage. Trim the stems if necessary, leaving about 1 cm of stem attached to the cap. Place the harvested mushrooms in a breathable container, such as a paper bag or a ventilated plastic container, to allow air circulation while preventing dehydration. Store them in the refrigerator at temperatures between 2-4°C (36-39°F) to slow down deterioration.

For long-term storage, consider drying or freezing the mushrooms. To dry, slice the mushrooms thinly and place them in a dehydrator at 45-50°C (113-122°F) until completely dry and brittle. Store dried mushrooms in an airtight container in a cool, dark place. For freezing, blanch the mushrooms in hot water for 2-3 minutes, then plunge them into ice water to halt the cooking process. Pat them dry, place in airtight bags, and freeze for up to 6 months. Properly preserved mushrooms retain much of their flavor and texture, making them versatile for future culinary use.

Maintaining the vertical growing system after harvest is equally important. Inspect the substrate for any signs of contamination or leftover mushroom parts, which can lead to mold or pests. If the substrate is still healthy and the mycelium is active, you may be able to induce a second or third flush by lightly misting the surface and maintaining optimal humidity and temperature. However, if the substrate is spent or contaminated, dispose of it responsibly and prepare a new batch to continue your vertical mushroom cultivation.

Lastly, keep detailed records of your harvesting and post-harvest practices, including dates, quantities, and any observations about mushroom quality or issues encountered. This documentation will help you refine your techniques over time, ensuring consistent and successful indoor vertical mushroom cultivation. Regularly clean and sanitize your harvesting tools and growing equipment to prevent cross-contamination and maintain a healthy growing environment. With proper care, your vertical mushroom garden can provide a steady supply of fresh, high-quality mushrooms for months to come.

Do Morel Mushrooms Thrive on Rock Island? Exploring Growth Conditions

You may want to see also

Frequently asked questions

Oyster mushrooms, lion's mane, and shiitake are ideal for vertical indoor growing due to their fast growth, adaptability, and high yield in small spaces.

You’ll need shelves or racks, growing bags or containers, substrate (like straw or sawdust), mushroom spawn, a humidifier or misting system, and a controlled environment with proper ventilation.

Keep humidity between 70-90% using a humidifier or regular misting. Maintain temperatures between 60-75°F (15-24°C) with a thermostat or space heater, and ensure good airflow to prevent mold.

Harvest when the caps are fully open but before the edges start to curl up. Depending on the species, this is typically 7-14 days after the mushrooms first appear. Regular harvesting encourages new flushes.