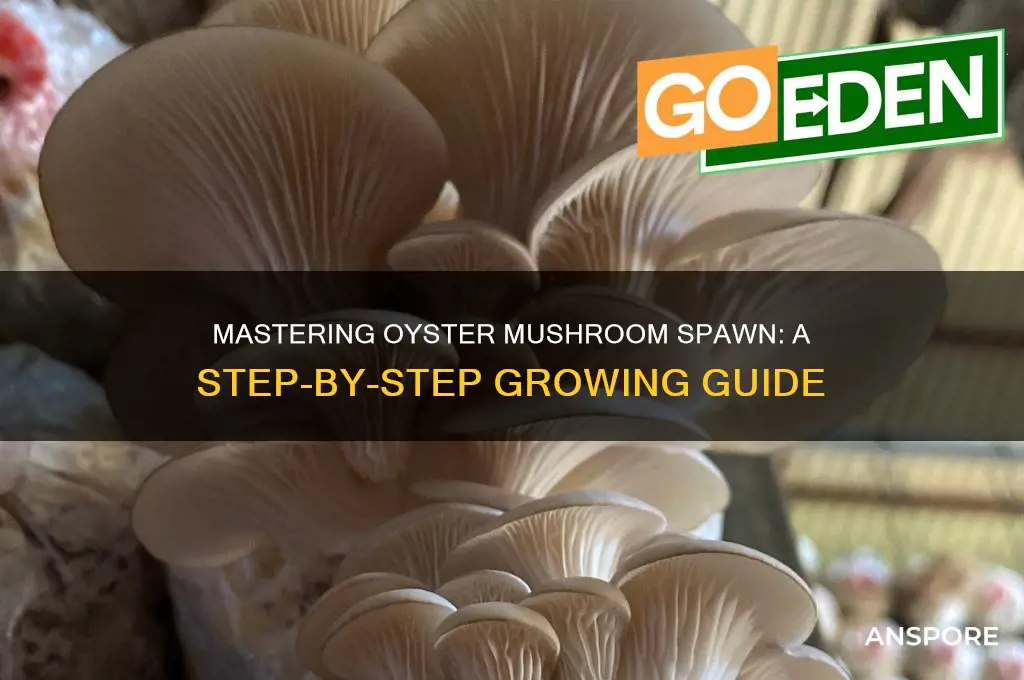

Growing oyster mushroom spawn is a fascinating and rewarding process that begins with selecting a suitable substrate, such as straw, sawdust, or coffee grounds, which serves as the nutrient base for the mushrooms. The first step involves pasteurizing or sterilizing the substrate to eliminate competing microorganisms, ensuring a clean environment for the mycelium to thrive. Next, the substrate is inoculated with oyster mushroom spawn, which can be purchased or prepared at home using grain or agar-based methods. Maintaining optimal conditions, including proper humidity, temperature (around 65-75°F), and indirect light, is crucial for the mycelium to colonize the substrate effectively. Over several weeks, the mycelium will grow and spread throughout the substrate, eventually leading to the formation of fruiting bodies—the oyster mushrooms. Patience and attention to detail are key, as successful spawn growth requires careful monitoring and adjustments to create the ideal environment for healthy mushroom development.

Explore related products

What You'll Learn

- Substrate Preparation: Sterilize or pasteurize straw, sawdust, or coffee grounds for optimal mycelium growth

- Inoculation Techniques: Use grain spawn or liquid culture to introduce mycelium to substrate

- Incubation Conditions: Maintain 70-75°F and high humidity in a dark, sterile environment

- Contamination Prevention: Sterilize tools, use gloves, and filter air to avoid mold or bacteria

- Spawn Expansion: Transfer mycelium to bulk substrate for larger mushroom yields

Substrate Preparation: Sterilize or pasteurize straw, sawdust, or coffee grounds for optimal mycelium growth

Substrate preparation is a critical step in growing oyster mushroom spawn, as it directly influences the success of mycelium colonization. The primary goal is to create a clean, nutrient-rich environment free from competing microorganisms. Straw, sawdust, and coffee grounds are commonly used substrates due to their availability and suitability for oyster mushrooms. Before inoculation, these materials must be sterilized or pasteurized to eliminate bacteria, fungi, and other contaminants that could hinder mycelium growth. Sterilization involves exposing the substrate to high temperatures (typically through autoclaving or pressure cooking) to kill all living organisms, while pasteurization reduces the microbial load without completely eradicating it, often using lower temperatures or chemical treatments.

For straw substrates, pasteurization is often the preferred method. Begin by chopping the straw into 4–6 inch lengths to increase surface area for mycelium attachment. Soak the straw in water for 24 hours to rehydrate it, then drain excess moisture. To pasteurize, immerse the straw in hot water (160–180°F or 71–82°C) for 1–2 hours, ensuring the temperature is maintained consistently. Alternatively, use a hydrometer to measure the specific gravity of the water, aiming for a reading of 1.02–1.03, which indicates sufficient pasteurization. After treatment, allow the straw to cool to room temperature before inoculating with spawn. Avoid over-soaking or overheating, as this can degrade the substrate’s structure and nutrient content.

Sawdust substrates typically require sterilization due to their density and higher risk of contamination. Mix the sawdust with a supplement like wheat bran or gypsum (10–20% by volume) to provide additional nutrients for mycelium growth. Moisture content should be around 60–70%, achieved by adding water gradually while mixing. Sterilize the sawdust in an autoclave at 121°C (250°F) and 15 psi for 1.5–2 hours, or use a pressure cooker for smaller batches. Ensure the substrate cools to below 80°F (27°C) before inoculation to prevent damaging the spawn. Proper sterilization is crucial for sawdust, as its compact nature can harbor contaminants more easily than straw.

Coffee grounds are an eco-friendly substrate option but require careful handling. Collect used coffee grounds and mix them with a bulking agent like straw or sawdust (50/50 ratio) to improve aeration and drainage. Pasteurization is recommended to preserve beneficial nutrients while reducing contaminants. Spread the coffee grounds on a tray and heat them in an oven at 160°F (71°C) for 1 hour, or steam them in a large pot for 30 minutes. Avoid overheating, as coffee grounds can burn easily. After pasteurization, allow the mixture to cool and equilibrate to room temperature before introducing the spawn. Coffee grounds provide a rich, nitrogen-dense substrate that oyster mushrooms thrive on when properly prepared.

Regardless of the substrate chosen, consistency in moisture and particle size is key. Ensure the substrate is evenly damp but not waterlogged, as excess moisture can lead to anaerobic conditions and contamination. After sterilization or pasteurization, transfer the substrate to a clean, sterile environment for inoculation. Work quickly to minimize exposure to airborne contaminants, and use gloves and a face mask to maintain hygiene. Proper substrate preparation sets the foundation for robust mycelium growth, ultimately leading to a successful oyster mushroom harvest.

Exploring Scotland's Forests: Do Magic Mushrooms Thrive in the Wild?

You may want to see also

Inoculation Techniques: Use grain spawn or liquid culture to introduce mycelium to substrate

Inoculation is a critical step in growing oyster mushroom spawn, as it involves introducing mycelium to the substrate to initiate colonization. Two primary methods are widely used: grain spawn and liquid culture. Grain spawn consists of sterilized grains (such as rye, wheat, or millet) fully colonized by mycelium, while liquid culture is a nutrient-rich solution containing mycelium suspended in water. Both methods have their advantages and are chosen based on the grower’s preference, scale of operation, and available resources.

When using grain spawn, the process begins with sterilizing the grains to eliminate contaminants. Once cooled, the grains are inoculated with a small amount of spawn or mycelium in a sterile environment, such as a glove box or still-air box, to prevent contamination. The grains are then incubated in a warm, dark place (around 75°F or 24°C) until fully colonized, which typically takes 10–14 days. To inoculate the substrate, the grain spawn is mixed evenly into the prepared and sterilized substrate (e.g., straw, sawdust, or coffee grounds) at a ratio of 10–20% spawn to substrate by weight. This ensures the mycelium has enough inoculation points to spread rapidly.

Liquid culture offers a faster and more efficient inoculation method, especially for larger operations. It is prepared by growing mycelium in a nutrient-rich solution, often using ingredients like malt extract, sugar, and water. The solution is sterilized, inoculated with a small piece of mycelium, and allowed to colonize for 7–10 days. During inoculation, the liquid culture is injected or sprayed directly onto the sterilized substrate using a sterile syringe or spray bottle. This method allows for even distribution of mycelium and quicker colonization compared to grain spawn. However, it requires careful handling to avoid contamination, as the liquid medium is more susceptible to bacteria and mold.

Regardless of the method chosen, maintaining sterility is paramount during inoculation. All tools, containers, and work surfaces should be sterilized using alcohol or a flame. Working in a clean environment, such as a still-air box or laminar flow hood, minimizes the risk of introducing contaminants. After inoculation, the substrate is placed in a humid, dark environment to encourage mycelium growth. Regular monitoring for signs of contamination, such as mold or off-odors, is essential to ensure successful colonization.

Both grain spawn and liquid culture techniques have their merits. Grain spawn is more forgiving for beginners and provides a physical medium for mycelium to grow, while liquid culture is ideal for experienced growers seeking faster colonization and greater efficiency. By mastering these inoculation techniques, growers can effectively introduce mycelium to the substrate, laying the foundation for a healthy and productive oyster mushroom spawn.

Mastering the Art of Growing Magic Mushroom Cakes at Home

You may want to see also

Incubation Conditions: Maintain 70-75°F and high humidity in a dark, sterile environment

To successfully incubate oyster mushroom spawn, maintaining the ideal temperature range of 70-75°F (21-24°C) is critical. This temperature window stimulates mycelial growth without causing stress or dormancy. Use a reliable thermometer or a temperature-controlled environment, such as an incubation chamber or a modified refrigerator with a heating element, to ensure consistency. Fluctuations outside this range can slow growth or lead to contamination, so monitor the temperature daily and adjust as needed.

High humidity is equally essential during incubation, as oyster mushroom mycelium requires moisture to thrive. Aim for 85-95% relative humidity to prevent the spawn from drying out, which can halt growth. Achieve this by misting the incubation area lightly with filtered or distilled water, or by using a humidifier. Alternatively, place a tray of water near the spawn to passively increase humidity. Ensure the substrate remains moist but not waterlogged, as excess moisture can promote mold or bacterial growth.

A dark environment is crucial for incubation, as light can inhibit mycelial growth and redirect energy toward fruiting prematurely. Store the spawn in a light-proof container or cover it with opaque material. If using a grow tent or room, ensure no natural or artificial light penetrates the space. Darkness encourages the mycelium to colonize the substrate efficiently, laying the foundation for a healthy mushroom crop.

Maintaining a sterile environment is paramount to prevent contamination by competing molds, bacteria, or other fungi. Before introducing the spawn, sterilize all equipment, containers, and surfaces using alcohol or a bleach solution. Work in a clean area, and consider using gloves and a face mask to minimize airborne contaminants. Once the spawn is placed in the substrate, seal the incubation container to protect it from external pollutants. Regularly inspect the setup for any signs of contamination and address issues immediately.

Finally, proper airflow is often overlooked but essential for preventing stagnant conditions that foster contamination. While the incubation area should be sealed to maintain humidity, ensure there is minimal ventilation to allow for gas exchange. Small vents or slightly cracked lids can suffice, as long as they do not compromise humidity levels. Balancing these incubation conditions—temperature, humidity, darkness, and sterility—creates an optimal environment for oyster mushroom spawn to colonize the substrate effectively.

Growing Psilocybin Mushrooms: Understanding the Timeframe for Cultivation

You may want to see also

Explore related products

Contamination Prevention: Sterilize tools, use gloves, and filter air to avoid mold or bacteria

Growing oyster mushroom spawn requires a meticulous approach to contamination prevention, as even the smallest introduction of mold or bacteria can derail the entire process. Sterilizing tools is the first critical step in maintaining a clean environment. Before use, all equipment, including knives, scissors, and containers, should be thoroughly cleaned with a 10:1 solution of water and bleach or a commercial sterilizing agent. After cleaning, tools must be rinsed with sterile water and allowed to dry completely, or better yet, sterilized in an autoclave if available. This ensures that no harmful microorganisms remain on surfaces that will come into contact with the spawn or substrate.

Using gloves is another essential practice to minimize contamination. Always wear sterile, disposable gloves when handling spawn, substrate, or any materials that will be introduced into the growing environment. Gloves act as a barrier, preventing the transfer of skin oils, bacteria, and fungi from your hands to the sensitive materials. Change gloves frequently, especially if they become torn or contaminated, and ensure hands are washed thoroughly before putting on a new pair. Nitrile or latex gloves are ideal, as they provide a good balance of dexterity and protection.

Filtering air is a often-overlooked but crucial aspect of contamination prevention. Airborne spores and particles can easily infiltrate your growing area, leading to mold or bacterial growth. Use a HEPA filter or air purifier in the room where you’re working to reduce the number of airborne contaminants. When working with exposed substrate or spawn, consider setting up a makeshift cleanroom using a laminar flow hood or a box fan fitted with a furnace filter to create a sterile airflow. This helps maintain a clean environment, especially during critical stages like inoculation.

In addition to these measures, maintaining a clean workspace is paramount. Regularly disinfect surfaces in your growing area with a suitable sterilizing agent, and ensure proper ventilation to prevent the buildup of humidity, which can encourage mold growth. Store all materials, including substrate and spawn, in sealed containers to protect them from airborne contaminants. By combining these practices—sterilizing tools, using gloves, and filtering air—you create a robust defense against contamination, significantly increasing the chances of successfully growing healthy oyster mushroom spawn.

Are Mushroom Grow Kits Legal? Exploring the Laws and Regulations

You may want to see also

Spawn Expansion: Transfer mycelium to bulk substrate for larger mushroom yields

Spawn expansion is a critical step in growing oyster mushrooms, as it allows you to increase your yield significantly by transferring the mycelium to a larger, bulk substrate. This process leverages the mycelium's ability to colonize new material, creating a robust network that will eventually produce abundant mushrooms. To begin, ensure your initial spawn is fully colonized and healthy. This typically takes 2-4 weeks, depending on the conditions and the type of spawn used. Signs of readiness include a dense, white mycelium network throughout the spawn bag or container, with no visible signs of contamination.

Once your spawn is ready, prepare your bulk substrate. Common bulk substrates for oyster mushrooms include straw, sawdust, or a mixture of both, often supplemented with materials like coffee grounds or gypsum to enhance nutrient content. The substrate should be pasteurized to eliminate competing microorganisms while retaining enough nutrients for the mycelium. Pasteurization can be done by soaking the substrate in hot water (around 65-70°C or 149-158°F) for an hour, then draining and cooling it to room temperature. Proper moisture content is crucial; the substrate should feel like a wrung-out sponge—moist but not waterlogged.

With your substrate prepared, it’s time to transfer the mycelium. Open your spawn bag or container in a clean, sterile environment to minimize the risk of contamination. Break up the colonized spawn into smaller pieces to increase the surface area for contact with the bulk substrate. Mix the spawn thoroughly into the pasteurized substrate, ensuring even distribution. Aim for a spawn-to-substrate ratio of about 1:10 to 1:20, depending on the density of your spawn. This mixture should then be placed into a clean, sterile container or bag, allowing enough space for the mycelium to grow.

After mixing, maintain optimal conditions for colonization. Keep the substrate at a temperature of 20-25°C (68-77°F) and ensure proper humidity by misting the inside of the bag or container if necessary. Avoid direct sunlight and provide adequate airflow to prevent anaerobic conditions. The mycelium will begin colonizing the bulk substrate, and within 2-4 weeks, you should see a fully colonized substrate, indicated by a dense, white network throughout the material. At this stage, the substrate is ready for fruiting.

To initiate fruiting, introduce environmental triggers such as light, fresh air, and cooler temperatures (around 15-18°C or 59-64°F). Cut open the bag or transfer the colonized substrate to a fruiting chamber, ensuring good airflow and humidity. Oyster mushrooms thrive in high humidity (85-95%), so regular misting or a humidifier may be necessary. Within 7-14 days, you should see pinheads forming, which will develop into mature mushrooms over the following 5-7 days. Harvest the mushrooms by twisting or cutting at the base, and the substrate may produce multiple flushes if properly maintained. Spawn expansion is a powerful technique that maximizes your mushroom yield, making it a cornerstone of successful oyster mushroom cultivation.

Growing Edible Mushrooms in Kenya: A Beginner's Guide to Success

You may want to see also

Frequently asked questions

The best substrate for growing oyster mushroom spawn is a mixture of straw, sawdust, or coffee grounds, as these materials provide the nutrients and structure needed for mycelium growth.

Prepare the substrate by pasteurizing or sterilizing it to eliminate competing organisms. For straw, soak it in hot water (60-80°C) for 1-2 hours, drain, and let it cool before mixing with spawn.

The ideal temperature for growing oyster mushroom spawn is between 20-25°C (68-77°F). This range promotes healthy mycelium growth without encouraging contamination.

It typically takes 2-4 weeks for oyster mushroom spawn to fully colonize the substrate, depending on factors like temperature, humidity, and substrate quality.

Reusing substrate is not recommended, as it may contain leftover mycelium or contaminants. It’s best to compost the spent substrate and use fresh material for each new spawn run.