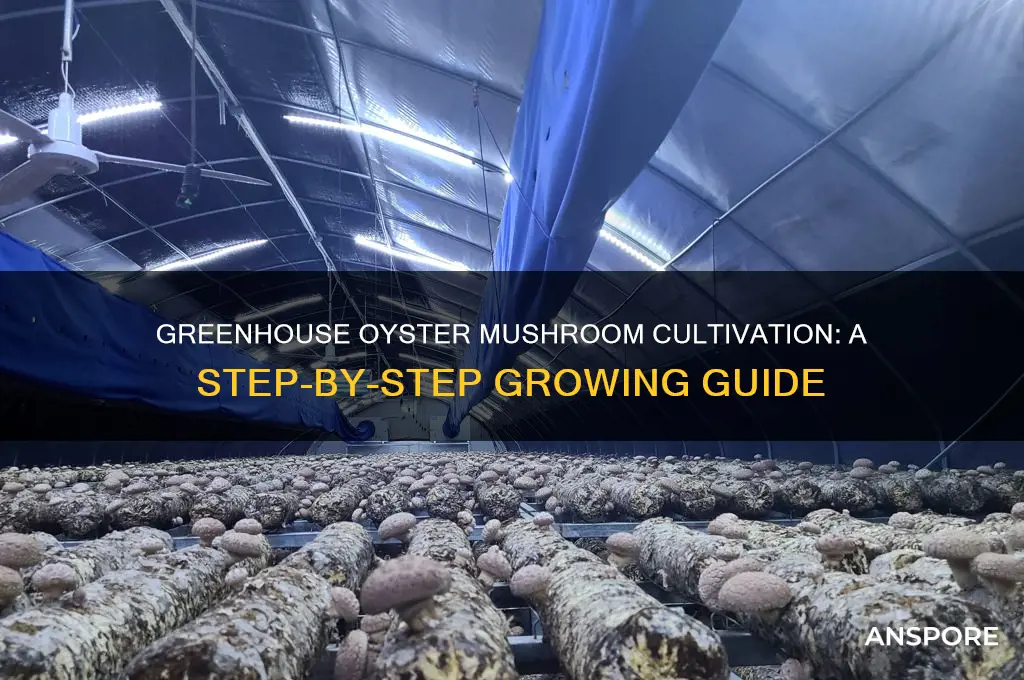

Growing oyster mushrooms in a greenhouse offers a controlled environment that optimizes their development, ensuring consistent yields year-round. To begin, select a well-ventilated greenhouse with stable temperatures between 55°F and 75°F (13°C–24°C), as oyster mushrooms thrive in cooler, humid conditions. Start by preparing a substrate, such as straw or sawdust, which is pasteurized to eliminate competing organisms and then inoculated with oyster mushroom spawn. The substrate is then placed in bags or trays, maintained at a humidity level of 80–90%, and kept in darkness during the initial colonization phase. Once the mycelium fully colonizes the substrate, introduce indirect light and slightly lower humidity to encourage fruiting. Regular misting and proper airflow are crucial to prevent contamination and promote healthy mushroom growth. With careful monitoring and maintenance, a greenhouse setup can yield multiple flushes of oyster mushrooms, making it an efficient and sustainable cultivation method.

Explore related products

What You'll Learn

Optimal greenhouse conditions for oyster mushrooms

Growing oyster mushrooms in a greenhouse requires precise control over environmental conditions to ensure optimal growth and yield. The first critical factor is temperature, which should be maintained between 60°F and 75°F (15°C and 24°C) during the incubation and fruiting stages. Oyster mushrooms are sensitive to extreme temperatures, and fluctuations outside this range can hinder mycelium development or stunt fruiting. Use thermostats and heaters or cooling systems to regulate the greenhouse temperature, especially during seasonal changes.

Humidity is another key factor, as oyster mushrooms thrive in high-humidity environments. The ideal relative humidity for fruiting is between 80% and 90%. To achieve this, install a humidifier or misting system in the greenhouse. Regularly misting the mushroom substrate and the surrounding air can help maintain the necessary moisture levels. Additionally, ensure proper ventilation to prevent the buildup of excess moisture, which can lead to mold or bacterial contamination.

Light plays a role in triggering fruiting, though oyster mushrooms do not require intense light. Provide indirect, diffused natural light or use artificial lighting with a 12-hour on/12-hour off cycle. Avoid direct sunlight, as it can overheat the greenhouse and dry out the substrate. Light exposure helps signal to the mycelium that it’s time to produce mushrooms, so consistency in lighting schedules is important.

Airflow is essential to prevent stagnant air and promote healthy mushroom growth. Proper ventilation ensures a steady exchange of carbon dioxide and oxygen, which the mushrooms need for respiration. Use fans or vents to maintain gentle air movement without creating strong drafts that could damage the delicate fruiting bodies. Regularly monitor airflow to avoid pockets of still air, which can encourage contaminants.

Finally, the substrate and its preparation are critical for optimal greenhouse conditions. Oyster mushrooms grow best on straw, sawdust, or coffee grounds, which should be pasteurized or sterilized to eliminate competing organisms. The substrate should be kept consistently moist but not waterlogged. Place the inoculated substrate in a well-organized manner within the greenhouse, allowing space for air circulation and easy monitoring of growth. Regularly inspect the substrate for signs of contamination or dryness, adjusting conditions as needed to support healthy mushroom development.

Exploring Alaska's Forests: Do Magic Mushrooms Thrive in the Last Frontier?

You may want to see also

Substrate preparation and sterilization techniques

Growing oyster mushrooms in a greenhouse requires careful attention to substrate preparation and sterilization to ensure a healthy and productive crop. The substrate, which serves as the nutrient base for mushroom growth, must be properly prepared and sterilized to eliminate competing organisms and create an optimal environment for mycelium development. Here’s a detailed guide on substrate preparation and sterilization techniques tailored for greenhouse cultivation.

Substrate Selection and Preparation: Begin by choosing a suitable substrate, such as straw, sawdust, or a combination of agricultural waste. Straw is commonly used due to its availability and ease of preparation. To prepare straw, chop it into 4–6 inch lengths to increase surface area for mycelium colonization. Soak the straw in water for 8–12 hours to rehydrate it, then drain and squeeze out excess moisture. This step ensures the substrate retains enough water for mushroom growth without becoming waterlogged. For sawdust-based substrates, mix it with supplements like wheat bran or cottonseed meal to provide additional nutrients. Aim for a moisture content of 60–70%, which can be checked by squeezing a handful of substrate—it should release a few drops of water but not drip.

Sterilization Techniques: Sterilization is critical to eliminate bacteria, fungi, and other contaminants that could compete with or harm the mushroom mycelium. The most common method for small-scale greenhouse operations is pasteurization, which involves heating the substrate to a specific temperature for a set duration. To pasteurize straw, place it in a large container, add hot water (180–190°F or 82–88°C), and maintain this temperature for 1–2 hours. Stir occasionally to ensure even heat distribution. For sawdust-based substrates, steam pasteurization is more effective. Use a steam generator to expose the substrate to temperatures of 160–180°F (71–82°C) for 1–2 hours. After pasteurization, allow the substrate to cool to around 80°F (27°C) before inoculation to avoid damaging the mushroom spawn.

Alternative Sterilization Methods: For larger greenhouse operations or when using sawdust blocks, pressure sterilization (autoclaving) may be necessary. This method involves placing the substrate in perforated bags and subjecting it to high pressure and temperature (15 psi at 250°F or 121°C) for 1.5–2 hours. Autoclaving ensures complete sterilization but requires specialized equipment. Chemical sterilization using lime or hydrogen peroxide is another option, though it is less common and requires careful application to avoid residual chemicals that could harm mycelium.

Post-Sterilization Handling: Once sterilized, handle the substrate with care to maintain its sterile condition. Work in a clean environment, preferably a designated area within the greenhouse, and use gloves and a face mask to minimize contamination. Transfer the cooled substrate to clean, sterilized containers or growing bags. Inoculate with oyster mushroom spawn immediately after sterilization to prevent recontamination. Seal the bags or containers with micron filters to allow gas exchange while keeping contaminants out.

Monitoring and Troubleshooting: After inoculation, monitor the substrate for signs of contamination, such as mold growth or off-odors. Proper sterilization significantly reduces this risk, but occasional issues may arise. If contamination is detected, remove the affected bags immediately to prevent spread. Maintain optimal greenhouse conditions, including temperature (65–75°F or 18–24°C) and humidity (80–90%), to support mycelium growth and fruiting. Regularly inspect the substrate during colonization to ensure even growth and address any issues promptly.

By mastering substrate preparation and sterilization techniques, you can create a robust foundation for successful oyster mushroom cultivation in a greenhouse. Attention to detail in these steps will maximize yield and minimize losses, ensuring a thriving mushroom crop.

Mastering Mushroom Cultivation in Project Ozone: A Step-by-Step Guide

You may want to see also

Inoculation process and spawn selection

The inoculation process is a critical step in growing oyster mushrooms in a greenhouse, as it involves introducing mushroom spawn into a substrate to initiate mycelium growth. To begin, select a high-quality oyster mushroom spawn, which is the foundation of a successful crop. Spawn can be purchased from reputable suppliers and is available in various forms, including grain spawn, sawdust spawn, and plug spawn. Grain spawn, typically made from rye or wheat berries, is a popular choice due to its high nutrient content and ease of use. When selecting spawn, ensure it is fresh, viable, and specifically cultured for oyster mushrooms (Pleurotus ostreatus). Avoid using wild mushroom spores or low-quality spawn, as this can lead to contamination or poor yields.

Once the spawn is selected, prepare the substrate, which is the material the mycelium will colonize. Common substrates for oyster mushrooms include straw, sawdust, coffee grounds, or a combination of these. The substrate must be pasteurized or sterilized to eliminate competing organisms and create a favorable environment for the mushroom spawn. Pasteurization involves soaking the substrate in hot water (around 60-70°C) for 1-2 hours, while sterilization requires using an autoclave or pressure cooker to achieve higher temperatures. After pasteurization or sterilization, allow the substrate to cool to a temperature between 20-25°C before inoculation to prevent damaging the spawn.

The inoculation process begins by creating a clean and sterile work environment to minimize the risk of contamination. Wear gloves and a face mask, and use a laminar flow hood or work in a clean area with minimal air movement. Open the spawn bag and gently break up any clumps to ensure even distribution. For straw or sawdust substrates, mix the spawn at a ratio of 5-10% spawn to substrate by weight. For example, use 5-10 pounds of spawn for every 100 pounds of substrate. Thoroughly incorporate the spawn into the substrate using a clean shovel or gloved hands, ensuring an even distribution throughout the material.

After mixing, transfer the inoculated substrate into growing containers, such as plastic bags, trays, or beds within the greenhouse. If using plastic bags, partially fill them with the substrate mixture, seal them with a filter patch to allow gas exchange, and incubate in a dark, warm area (20-25°C) for 2-4 weeks. During this incubation period, the mycelium will colonize the substrate, breaking down the material and preparing it for fruiting. Regularly monitor the bags for signs of contamination, such as mold or unusual colors, and remove any affected bags immediately to prevent spread.

Finally, proper spawn selection and inoculation technique are essential for a successful oyster mushroom crop in a greenhouse. Choose certified, disease-free spawn from a trusted supplier, and ensure the substrate is correctly pasteurized or sterilized before inoculation. Maintain a sterile environment during the inoculation process to minimize contamination risks. By following these steps, growers can establish a healthy mycelium network, setting the stage for abundant oyster mushroom production in the greenhouse environment.

Brown Mushrooms in PA Lawns: Causes, Concerns, and Safe Removal Tips

You may want to see also

Explore related products

Humidity and ventilation management tips

Oyster mushrooms thrive in high humidity environments, typically requiring levels between 80-90% for optimal growth. To maintain this range in a greenhouse, consider installing a humidification system such as ultrasonic humidifiers or misting systems. These tools can be programmed to activate when humidity drops below the desired threshold. Additionally, using a hygrometer to monitor humidity levels is essential, as it allows you to make real-time adjustments. Placing water-filled trays or dampened materials like burlap near the growing area can also help increase humidity naturally. However, ensure these methods do not create stagnant water, which can lead to contamination.

Proper ventilation is critical to prevent the buildup of carbon dioxide (CO2) and maintain fresh air circulation, which oyster mushrooms need for healthy growth. Install exhaust fans or vents to remove excess moisture and stale air, especially during fruiting stages when mushrooms release spores. A good rule of thumb is to exchange the greenhouse air volume at least once every hour. Pairing exhaust fans with intake vents ensures a continuous flow of fresh air while minimizing temperature fluctuations. Avoid placing vents directly over the growing substrate to prevent drying out the mycelium.

Balancing humidity and ventilation requires careful attention to airflow patterns. Position fans to create a gentle, even airflow throughout the greenhouse, avoiding direct drafts on the mushrooms, which can cause drying or abnormal growth. Oscillating fans work well for this purpose. Regularly inspect the growing area for signs of excessive moisture or dryness, such as water droplets on surfaces or shriveled mycelium, and adjust the ventilation or humidification systems accordingly. Using a combination of timers and sensors can automate this process, ensuring consistent conditions.

During different growth stages, humidity and ventilation needs may vary. In the colonization phase, when mycelium is developing, slightly lower humidity (around 70-80%) and minimal ventilation are sufficient. However, during pinning and fruiting, increase humidity to 85-90% and enhance airflow to support mushroom development. Gradually adjust these parameters as the mushrooms mature to mimic natural conditions. For example, reducing humidity slightly during the final stages can improve cap opening and overall quality.

Lastly, insulate and seal the greenhouse to retain humidity while minimizing energy costs. Use materials like polyethylene sheeting or thermal blankets to maintain a stable internal environment. However, ensure seals are not so tight that they hinder necessary air exchange. Regularly clean and maintain all equipment, including fans, humidifiers, and vents, to prevent mold or bacterial growth. A well-managed greenhouse with precise humidity and ventilation control will significantly enhance oyster mushroom yields and quality.

Toxic Fungi on Cow Dung: Unveiling the Truth About Poisonous Mushrooms

You may want to see also

Harvesting and post-harvest handling methods

Harvesting oyster mushrooms at the right time is crucial for optimal quality and yield. Mushrooms are typically ready for harvest when the caps have fully expanded but before the edges begin to curl upward and the gills darken significantly. This stage usually occurs 5 to 7 days after the mushrooms first appear. To harvest, gently twist or cut the mushrooms at the base of the stem using a clean, sharp knife or scissors. Avoid pulling or damaging the mycelium, as this can reduce future yields. Harvesting should be done daily to ensure mushrooms are picked at their peak freshness and to encourage new flushes of growth.

After harvesting, proper post-harvest handling is essential to maintain the quality and extend the shelf life of oyster mushrooms. Begin by carefully brushing off any excess substrate or debris from the mushrooms using a soft brush or cloth. Avoid washing the mushrooms with water, as they absorb moisture quickly, which can lead to spoilage. Instead, use a damp cloth to clean them if necessary. Trim the stems to a uniform length, typically 1 to 2 centimeters, to improve their appearance and make them more marketable.

Once cleaned and trimmed, oyster mushrooms should be promptly cooled to slow down deterioration. Place them in a single layer on clean trays or in ventilated containers and store them in a cool room or refrigerator at temperatures between 2°C and 4°C (36°F to 39°F). High humidity is also important to prevent drying, so cover the mushrooms loosely with a damp cloth or store them in perforated plastic bags to maintain moisture levels. Properly stored, fresh oyster mushrooms can last up to 7 to 10 days.

For longer-term storage, consider drying or freezing the mushrooms. To dry, slice the mushrooms thinly and place them in a dehydrator at 50°C to 60°C (122°F to 140°F) until completely dry and brittle. Store dried mushrooms in airtight containers in a cool, dark place, where they can last for several months. For freezing, blanch the mushrooms in hot water for 2 to 3 minutes, cool them quickly in ice water, drain, and pack them in airtight bags or containers. Frozen mushrooms retain their quality for up to 12 months.

Finally, packaging is a critical step in post-harvest handling, especially if the mushrooms are intended for sale. Use breathable containers such as paper bags, mesh bags, or waxed cardboard boxes to allow air circulation and prevent condensation. Label the packages with the harvest date and variety of mushrooms. For commercial purposes, ensure compliance with local food safety regulations and consider adding branding or marketing materials to enhance product appeal. Proper harvesting and post-harvest handling not only preserve the quality of oyster mushrooms but also maximize their market value and consumer satisfaction.

Winter Psilocybe Mushrooms: Can They Thrive in Cold Weather?

You may want to see also

Frequently asked questions

Oyster mushrooms thrive in a greenhouse with temperatures between 55°F and 75°F (13°C and 24°C), humidity levels of 60-80%, and indirect light. Ensure good air circulation to prevent mold and maintain a slightly acidic substrate pH of 5.5 to 6.5.

Oyster mushrooms grow well on straw, sawdust, coffee grounds, or a mix of these materials. Sterilize or pasteurize the substrate to eliminate competing organisms, and supplement it with nutrients like wheat bran or gypsum for optimal growth.

Mist the mushrooms lightly 2-3 times daily to maintain humidity, but avoid overwatering, as excess moisture can cause mold. The substrate should remain moist but not soggy. Monitor conditions and adjust watering based on humidity levels.

From inoculation to harvest, oyster mushrooms typically take 4-6 weeks to grow in a greenhouse. This includes 2-3 weeks for mycelium colonization and 2-3 weeks for fruiting, depending on environmental conditions and substrate quality.