Inoculating a substrate for mushroom cultivation is a critical step in the process of growing fungi, as it involves introducing mushroom mycelium into a nutrient-rich medium to encourage colonization and fruiting. The substrate, typically composed of materials like straw, sawdust, or grain, must be properly prepared, sterilized, or pasteurized to eliminate competing organisms and create an optimal environment for mycelial growth. Using a sterile technique, the cultivator introduces spawn (mycelium-infused material) into the substrate, ensuring even distribution to maximize colonization efficiency. Successful inoculation requires attention to detail, maintaining sterile conditions, and understanding the specific needs of the mushroom species being cultivated, ultimately setting the foundation for a healthy and productive mushroom crop.

Explore related products

What You'll Learn

- Prepare Substrate: Sterilize or pasteurize substrate (e.g., straw, wood chips) to remove contaminants

- Spawn Inoculation: Mix mushroom spawn evenly into the prepared substrate for colonization

- Sterile Technique: Use clean tools, gloves, and workspace to prevent contamination during inoculation

- Incubation Conditions: Maintain optimal temperature, humidity, and darkness for mycelium growth post-inoculation

- Contamination Prevention: Monitor for mold, bacteria, or pests; discard contaminated substrate immediately

Prepare Substrate: Sterilize or pasteurize substrate (e.g., straw, wood chips) to remove contaminants

Preparing the substrate is a critical step in mushroom cultivation, as it ensures a clean and contaminant-free environment for mycelium growth. The substrate, whether it’s straw, wood chips, or another organic material, must be sterilized or pasteurized to eliminate bacteria, fungi, and other microorganisms that could compete with or harm the mushroom mycelium. Sterilization and pasteurization are two common methods, each suited to different types of substrates and cultivation scales.

Sterilization is the more thorough of the two methods and is typically used for smaller-scale operations or substrates that require a completely sterile environment, such as grain spawn. To sterilize a substrate like straw or wood chips, begin by chopping or shredding the material into smaller, uniform pieces to ensure even treatment. Place the substrate into a sturdy, heat-resistant container, such as a pressure cooker or autoclave bag. Add water to the substrate to increase moisture content, as dry substrates do not sterilize effectively. For example, straw should be soaked in water for several hours before sterilization. Once prepared, the substrate is subjected to high temperatures—typically 121°C (250°F) for 1.5 to 2 hours in a pressure cooker or autoclave. This process kills all contaminants, including spores, ensuring a clean medium for inoculation.

Pasteurization is a milder process that reduces the number of contaminants without achieving complete sterility. It is often used for bulk substrates like straw or wood chips in larger-scale mushroom cultivation. To pasteurize, soak the substrate in water for 8 to 12 hours to rehydrate it. Then, drain the excess water and transfer the substrate to a large container or plastic bag. Heat the substrate to temperatures between 65°C and 80°C (149°F to 176°F) for 1 to 2 hours. This can be done using a hot water bath, steam, or even a compost turner. After pasteurization, allow the substrate to cool to a temperature suitable for inoculation, typically around 25°C to 30°C (77°F to 86°F). While pasteurization does not eliminate all contaminants, it significantly reduces their numbers, creating a favorable environment for the mushroom mycelium to outcompete any remaining microorganisms.

Regardless of the method chosen, proper handling of the substrate after sterilization or pasteurization is essential. Work in a clean environment, such as a still air box or a laminar flow hood, to minimize the risk of reintroducing contaminants. Allow the substrate to cool naturally, as sudden temperature changes can damage the material or create condensation, which may introduce unwanted microbes. Once cooled, the substrate is ready for inoculation with mushroom spawn, marking the next step in the cultivation process.

Choosing between sterilization and pasteurization depends on the substrate type, cultivation scale, and available equipment. For beginners or small-scale growers, pasteurization is often more practical and cost-effective, while sterilization is ideal for precision and higher success rates in controlled environments. Both methods, when executed correctly, provide a clean foundation for healthy mycelium growth and a successful mushroom harvest.

Marinating Mushrooms: Is It Worth the Effort?

You may want to see also

Spawn Inoculation: Mix mushroom spawn evenly into the prepared substrate for colonization

Spawn inoculation is a critical step in mushroom cultivation, where the mushroom spawn is introduced to the prepared substrate to initiate colonization. This process requires precision and care to ensure even distribution and optimal growth conditions. Begin by ensuring both the spawn and substrate are at the correct temperature and moisture level, typically around 70-75°F (21-24°C) and adequately hydrated but not waterlogged. The substrate should be fully pasteurized or sterilized to eliminate competing organisms that could hinder mushroom growth. Once the substrate has cooled to a safe temperature, it’s ready for inoculation.

To mix the spawn evenly, first break up any large clumps of spawn to ensure it is as uniform as possible. This can be done by gently crumbling it with clean hands or using a sterile tool. Next, place the prepared substrate into a clean, sanitized container or directly into the growing bag or tray. Gradually add the spawn to the substrate in layers, mixing thoroughly as you go. For example, if using a 5-gallon bucket, add one-third of the substrate, then one-third of the spawn, and mix well before adding the next layer. This layering technique ensures the spawn is evenly distributed throughout the substrate, maximizing contact points for colonization.

Mixing should be done with gloved hands or sterile utensils to avoid contamination. Aim for a consistent texture where no visible clumps of spawn remain, and the mixture appears homogeneous. If using a grow bag, seal it partially to allow for gas exchange while preventing contaminants from entering. For bulk substrates, ensure the mixture is loosely packed to allow air circulation, which is essential for mycelium growth. Proper mixing at this stage significantly influences the success of colonization, as uneven distribution can lead to slow or incomplete growth.

After mixing, the inoculated substrate should be incubated in a dark, temperature-controlled environment. Maintain the incubation area at the optimal temperature range for the specific mushroom species, usually between 70-75°F (21-24°C). During this phase, the mycelium will begin to colonize the substrate, breaking down nutrients and spreading throughout the mixture. Regularly monitor the substrate for signs of contamination, such as unusual colors or odors, and address any issues promptly.

Finally, patience is key during the colonization period, which can take anywhere from 2 to 6 weeks depending on the mushroom species and environmental conditions. Once fully colonized, the substrate will appear white and densely covered with mycelium, indicating it’s ready for the next stage of fruiting. Proper spawn inoculation and substrate mixing lay the foundation for a healthy and productive mushroom harvest, making this step one of the most important in the cultivation process.

The Secret to Soaking Mushrooms: Why and How?

You may want to see also

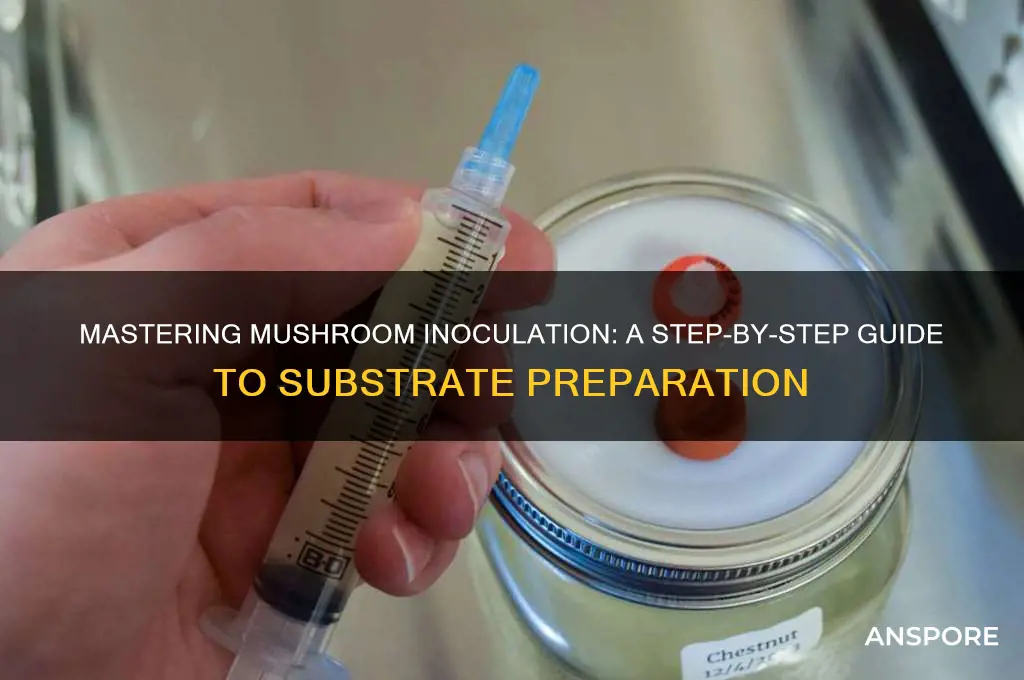

Sterile Technique: Use clean tools, gloves, and workspace to prevent contamination during inoculation

Maintaining a sterile environment is crucial when inoculating a substrate for mushroom cultivation, as contamination can ruin your entire batch. The first step in achieving this is to ensure all tools and equipment are thoroughly cleaned and sterilized. Autoclaving, a process that uses high-pressure steam to kill microorganisms, is highly effective for sterilizing tools like scalpel blades, inoculation loops, and containers. If an autoclave is not available, soaking tools in a 10% bleach solution for at least 10 minutes followed by a thorough rinse with sterile water can be a suitable alternative. Always handle sterilized tools with care to avoid recontamination.

Gloves are an essential part of maintaining sterility during the inoculation process. Use sterile, disposable nitrile or latex gloves to prevent the transfer of bacteria, fungi, or other contaminants from your hands to the substrate or culture. Before putting on gloves, ensure your hands are clean by washing them thoroughly with antibacterial soap. Change gloves frequently, especially if you touch non-sterile surfaces or if the gloves become torn or compromised. Additionally, avoid touching your face, hair, or any non-sterile areas while wearing gloves to maintain the integrity of the sterile field.

The workspace itself must also be meticulously cleaned and prepared. Start by cleaning all surfaces with a disinfectant, such as 70% isopropyl alcohol or a 10% bleach solution, to kill any potential contaminants. Allow the area to dry completely before proceeding. It’s beneficial to work in a laminar flow hood if available, as it provides a continuous stream of sterile air, reducing the risk of airborne contamination. If a laminar flow hood is not accessible, choose a clean, enclosed space with minimal air movement, and consider using a HEPA filter to improve air quality. Cover nearby surfaces with sterile drapes or plastic sheets to create a temporary sterile zone.

During the inoculation process, minimize the time that the substrate and culture are exposed to the open air. Work quickly and deliberately, following a planned sequence of steps to reduce the risk of contamination. Keep the substrate and culture containers closed until immediately before use, and seal them promptly after inoculation. Avoid talking, coughing, or sneezing over the workspace, as these actions can introduce contaminants. If working with multiple substrates or cultures, use separate tools for each to prevent cross-contamination.

Finally, proper waste management is a critical aspect of maintaining sterility. Dispose of all used gloves, contaminated materials, and waste in a designated biohazard bag. Seal the bag securely before removing it from the workspace to prevent the spread of contaminants. Regularly clean and disinfect the waste disposal area to maintain a hygienic environment. By adhering to these sterile techniques—using clean tools, gloves, and a well-prepared workspace—you significantly increase the chances of a successful and uncontaminated mushroom inoculation.

Mastering Mushroom Usage in Pillars of Eternity 2: Deadfire

You may want to see also

Explore related products

Incubation Conditions: Maintain optimal temperature, humidity, and darkness for mycelium growth post-inoculation

After inoculating your mushroom substrate, creating the ideal environment for mycelium growth is crucial. This stage, known as incubation, requires precise control of temperature, humidity, and light to encourage healthy mycelial colonization.

Temperature is arguably the most critical factor. Most mushroom species thrive within a specific temperature range, typically between 70-75°F (21-24°C). Deviations from this range can significantly slow down growth or even halt it entirely. It's essential to monitor the temperature consistently and make adjustments as needed. Using a reliable thermometer or a temperature-controlled environment, such as an incubation chamber or a simple setup with a heating mat, can help maintain the desired temperature.

Humidity plays a vital role in mycelium development, as it prevents the substrate from drying out and ensures the mycelium can absorb nutrients effectively. The ideal humidity range for incubation is generally between 95-100% relative humidity. This can be achieved by misting the substrate regularly or using a humidifier to maintain a consistently moist environment. However, it's crucial to avoid over-saturating the substrate, as this can lead to contamination or drowning of the mycelium. A simple way to monitor humidity is by using a hygrometer, which will help you make informed decisions about when to mist or adjust the humidity levels.

In addition to temperature and humidity, darkness is another critical component of successful incubation. Mycelium growth is typically stimulated in dark or low-light conditions, as light can inhibit growth and promote the formation of mushrooms prematurely. To ensure optimal darkness, store your inoculated substrate in a closed container or a dark room, away from direct light sources. If using a transparent container, consider covering it with a light-proof material, such as aluminum foil or black plastic, to block out any light.

Maintaining these optimal conditions requires regular monitoring and adjustments. Check the temperature and humidity levels at least twice a day, and make necessary changes to keep them within the desired range. Be patient, as mycelium growth can take several weeks, depending on the mushroom species and environmental conditions. During this period, avoid disturbing the substrate or exposing it to contaminants, as this can compromise the growth process. By providing a stable, controlled environment with the right temperature, humidity, and darkness, you'll create the ideal conditions for robust mycelium growth, setting the stage for a successful mushroom harvest.

To further support mycelium growth, consider using a shotgun fruiting chamber or a mushroom grow tent once the mycelium has fully colonized the substrate. These setups allow for better control over the environment during the fruiting stage, which requires slightly different conditions than incubation. However, during the initial incubation phase, focus on maintaining the optimal temperature, humidity, and darkness to encourage healthy mycelial development. With proper care and attention to these conditions, you'll be well on your way to cultivating a thriving mushroom crop. Remember, consistency and patience are key to successful mushroom cultivation, and providing the right incubation conditions is a critical step in this process.

Mushroom Coffee: What Doctors Reveal About Its Health Benefits

You may want to see also

Contamination Prevention: Monitor for mold, bacteria, or pests; discard contaminated substrate immediately

Contamination prevention is a critical aspect of successful mushroom cultivation, as even a small amount of mold, bacteria, or pests can quickly spread and ruin an entire batch. To ensure a healthy and productive grow, it's essential to monitor the substrate closely for any signs of contamination. Regular visual inspections should be conducted at least once a day, focusing on areas where contamination is most likely to occur, such as the surface of the substrate, the edges of the container, and any areas with high moisture levels. Look for discoloration, unusual textures, or any signs of fungal or bacterial growth, which may indicate the presence of contaminants.

When monitoring for mold, be aware that it can appear in various colors, including white, green, black, or brown, and may have a fuzzy or thread-like texture. Bacteria, on the other hand, often manifest as slimy or discolored patches on the substrate surface. Pests, such as mites or fungus gnats, may be visible to the naked eye or leave behind signs of their presence, such as webbing or frass (insect waste). If any of these contaminants are detected, it's crucial to act quickly to prevent further spread. Isolate the affected area and assess the extent of the contamination. If the contamination is limited to a small section, it may be possible to remove the affected substrate and salvage the rest of the batch.

However, if the contamination has spread or is severe, it's best to discard the entire substrate immediately to prevent the contaminants from spreading to other areas or future grows. When discarding contaminated substrate, ensure that it is disposed of in a way that prevents the contaminants from spreading to other areas or the environment. This may involve sealing the contaminated material in a plastic bag and disposing of it in the trash, or composting it in a separate area away from the grow space. After discarding the contaminated substrate, thoroughly clean and disinfect the affected area, including any tools or equipment that came into contact with the contaminants.

To minimize the risk of future contamination, implement strict hygiene practices in the grow space. This includes washing hands and wearing clean clothing before handling substrate or mushrooms, using disinfected tools and equipment, and maintaining a clean and organized grow environment. Additionally, consider using air filters or UV lights to reduce the presence of airborne contaminants. By being vigilant and proactive in monitoring for contamination, you can significantly reduce the risk of losing a batch to mold, bacteria, or pests. Remember that prevention is key, and it's always better to err on the side of caution when it comes to contamination.

In the event of repeated contamination issues, take a step back and assess the grow environment and practices. Identify potential sources of contamination, such as poor air circulation, high humidity levels, or inadequate sterilization of equipment. Addressing these underlying issues may require adjustments to the grow setup, such as improving ventilation, reducing humidity, or investing in more effective sterilization methods. By taking a systematic approach to contamination prevention and being prepared to adapt and improve grow practices, you can create a more resilient and productive mushroom cultivation system. Regular monitoring, strict hygiene practices, and a willingness to discard contaminated substrate immediately are essential components of a successful contamination prevention strategy.

Microwaving Mushrooms: Quick Tips for Delicious Results

You may want to see also

Frequently asked questions

The best substrate depends on the mushroom species, but common options include straw, wood chips, sawdust, or grain. Research the specific needs of the mushroom you’re growing.

Sterilize the substrate by placing it in a pressure cooker at 15 psi for 1-2 hours, or use a large pot with a tight-fitting lid to steam it thoroughly to kill contaminants.

You’ll need a sterile substrate, mushroom spawn (grain or liquid culture), a clean workspace, gloves, a scalpel or inoculation tool, and optionally, a still air box for added sterility.

Generally, use a 1:10 ratio of spawn to substrate (e.g., 1 pound of spawn per 10 pounds of substrate). Adjust based on the mushroom species and substrate type.

Colonization time varies by species and conditions but typically takes 2-4 weeks. Maintain proper temperature, humidity, and darkness to encourage healthy growth.