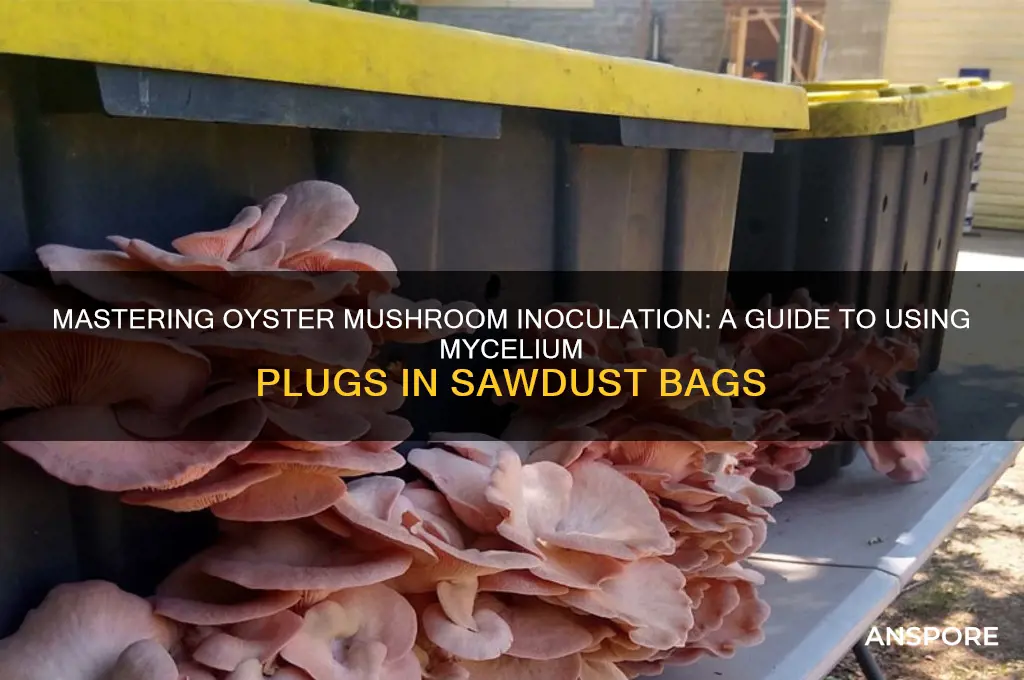

Inoculating sawdust bags with oyster mushroom mycelium plugs is a straightforward yet precise process that forms the foundation of successful mushroom cultivation. This method involves introducing the mycelium, the vegetative part of the fungus, into a nutrient-rich substrate, typically sawdust supplemented with bran or other organic materials, to encourage colonization and eventual fruiting. The process begins by preparing the sawdust substrate, sterilizing it to eliminate competing microorganisms, and then allowing it to cool to a suitable temperature. Once the substrate is ready, small holes are made in the bags, and mycelium plugs are carefully inserted, ensuring they are evenly distributed to promote uniform growth. After sealing the bags, they are placed in a controlled environment with optimal temperature and humidity to facilitate mycelium expansion. Over several weeks, the mycelium will colonize the substrate, preparing it for the fruiting stage, where oyster mushrooms will develop under the right conditions. This technique is favored by both hobbyists and commercial growers for its efficiency and scalability in producing high-quality mushrooms.

Explore related products

$16.99

What You'll Learn

- Prepare Sawdust Bags: Sterilize sawdust, moisten, pack into bags, seal, and create small holes for inoculation

- Spawn Preparation: Hydrate mycelium plugs, ensure viability, and ready for insertion into sawdust bags

- Inoculation Technique: Insert plugs into holes, seal with wax or tape, maintain sterile conditions

- Incubation Setup: Store bags in dark, humid environment at 70-75°F for mycelium colonization

- Monitoring Growth: Check bags weekly for contamination, ensure even mycelium spread, adjust conditions as needed

Prepare Sawdust Bags: Sterilize sawdust, moisten, pack into bags, seal, and create small holes for inoculation

The foundation of successful oyster mushroom cultivation lies in the meticulous preparation of sawdust bags. This process, while seemingly straightforward, demands precision and attention to detail to ensure a sterile, nutrient-rich environment conducive to mycelial growth. The first critical step is sterilizing the sawdust, a process that eliminates competing microorganisms that could hinder or destroy your mushroom crop. This is typically achieved through autoclaving, a method that subjects the sawdust to high-pressure steam at 121°C (250°F) for 60–90 minutes. Alternatively, for smaller-scale operations, pasteurization using a large pot of boiling water (90°C or 194°F for 1–2 hours) can be effective, though less reliable than autoclaving.

Once sterilized, the sawdust must be moistened to an optimal moisture content of 60–70%. This is crucial because mycelium requires water to grow, but excessive moisture can lead to contamination or anaerobic conditions. Use a spray bottle to evenly distribute water, ensuring the sawdust feels like a wrung-out sponge—moist but not dripping. Over-saturation can create water pockets, breeding grounds for unwanted bacteria and molds.

Next, pack the moistened sawdust into polypropylene bags, leaving enough space to allow for mycelial expansion. Aim to fill each bag to about 75% capacity, compacting the sawdust gently to eliminate large air pockets while maintaining enough porosity for gas exchange. Proper packing density ensures uniform colonization and prevents the sawdust from settling unevenly, which could create dry spots or overly dense areas.

Sealing the bags is a delicate balance between containment and ventilation. Use an impulse sealer to close the bags, ensuring a tight seal to prevent contamination. However, before sealing, create small holes (approximately 1–2 mm in diameter) near the top of the bag. These holes serve as inoculation points and allow for essential gas exchange during colonization. Space the holes 2–3 inches apart to maintain structural integrity while facilitating airflow.

This preparation phase is the backbone of your mushroom cultivation project. Each step—sterilization, moistening, packing, sealing, and hole creation—must be executed with care to create an environment where oyster mushroom mycelium can thrive. Skipping or rushing any step risks introducing contaminants or creating conditions unfavorable for growth. By mastering this process, you set the stage for a robust and productive mushroom harvest.

Does Clove from Valorant Use Mushrooms? Exploring Her Abilities

You may want to see also

Spawn Preparation: Hydrate mycelium plugs, ensure viability, and ready for insertion into sawdust bags

Mycelium plugs, those tiny powerhouses of fungal growth, require careful preparation before they can transform sawdust into a thriving oyster mushroom farm. Dehydrated for preservation, these plugs need rehydration to awaken their dormant mycelium. Think of it as a fungal resurrection, where water acts as the catalyst for renewed life. This crucial step, often overlooked, directly impacts the success of your inoculation.

The hydration process is deceptively simple. Submerge the plugs in room temperature, non-chlorinated water for 12-24 hours. Chlorine, a mycelium foe, can hinder growth, so consider using filtered or distilled water. Imagine the plugs as sponges, slowly absorbing moisture until they plump up, their texture transforming from dry and brittle to firm and supple. This rehydration not only reactivates the mycelium but also ensures it has the necessary moisture to colonize the sawdust substrate effectively.

While hydration is essential, viability is paramount. Before inserting plugs into sawdust bags, inspect them for signs of contamination. Mold, unusual colors, or a foul odor indicate compromised plugs and should be discarded. Healthy plugs will appear white or slightly off-white, with a faint earthy scent.

Think of this as a quality control check, ensuring only the strongest, most viable mycelium enters your growing environment. Remember, a single contaminated plug can jeopardize the entire batch. Once hydrated and deemed viable, the plugs are ready for their new home within the sawdust bags. Gently pat them dry with a clean cloth to remove excess moisture, preventing waterlogging.

Using Mushroom Compost: A Beginner's Guide to Boosting Garden Health

You may want to see also

Inoculation Technique: Insert plugs into holes, seal with wax or tape, maintain sterile conditions

The success of inoculating sawdust bags with oyster mushroom mycelium plugs hinges on precision and sterility. One proven technique involves inserting the plugs into pre-drilled holes, sealing them with wax or tape, and maintaining a sterile environment throughout the process. This method ensures the mycelium colonizes the substrate efficiently while minimizing contamination risks.

Steps to Master the Technique:

- Prepare the Sawdust Bags: Ensure your sawdust substrate is properly pasteurized or sterilized and cooled to around 75–80°F (24–27°C). Use a drill with a ¼-inch bit to create holes 1–2 inches apart, spaced evenly across the bag.

- Insert the Plugs: Gently press the mycelium plugs into the holes, ensuring they fit snugly. Each plug should be fully inserted, with no part exposed to the air. A 5–10 pound bag typically requires 10–15 plugs for optimal colonization.

- Seal the Holes: Melt beeswax or paraffin wax and carefully drip it over each hole to create an airtight seal. Alternatively, use sterile micropore tape, pressing it firmly to cover the plugs. Wax provides a more durable seal but requires careful application to avoid damaging the plugs.

- Maintain Sterility: Work in a clean environment, ideally a still air box or laminar flow hood. Use gloves and a mask, and sterilize all tools with alcohol before use. After sealing, store the bags in a dark, humid environment (60–70% humidity) at 70–75°F (21–24°C) for 2–4 weeks to allow colonization.

Cautions to Consider:

Avoid overheating the wax, as it can kill the mycelium. If using tape, ensure it adheres well without leaving gaps. Contamination often occurs during the sealing process, so prioritize cleanliness. Overcrowding plugs can lead to competition for resources, while too few may delay colonization.

Why This Technique Works:

By sealing the plugs, you create a microenvironment that retains moisture and protects the mycelium from airborne contaminants. The holes act as entry points for the mycelium to spread into the substrate, while the wax or tape acts as a barrier against mold and bacteria. This method balances accessibility and protection, making it ideal for both beginners and experienced growers.

Practical Tips for Success:

Label bags with the inoculation date to track progress. If using wax, practice on a test surface to perfect your technique. For larger operations, consider investing in a wax sealing tool for consistency. Regularly inspect bags for signs of contamination, such as green or black spots, and isolate affected bags immediately. With patience and attention to detail, this technique yields robust mycelium growth, setting the stage for a bountiful oyster mushroom harvest.

Mushrooms' Energy Secrets: Unveiling Their Unique Survival Strategies

You may want to see also

Explore related products

Incubation Setup: Store bags in dark, humid environment at 70-75°F for mycelium colonization

After inoculating sawdust bags with oyster mushroom mycelium plugs, the incubation phase is critical for successful mycelium colonization. This stage requires a carefully controlled environment to encourage healthy growth without contamination. The ideal setup involves storing the bags in a dark, humid space maintained at a consistent temperature of 70–75°F (21–24°C). This temperature range mimics the natural conditions oyster mushrooms thrive in, promoting rapid and uniform colonization. A dark environment is essential because light can inhibit mycelium growth, while humidity ensures the substrate remains moist, preventing dehydration that could halt colonization.

To achieve optimal humidity, aim for a relative humidity level of 60–70%. This can be maintained by placing the bags in a sealed container or room with a humidifier or by misting the bags lightly every few days. Avoid over-saturating the substrate, as excessive moisture can lead to mold or bacterial growth. Using a hygrometer to monitor humidity levels is a practical tip to ensure consistency. Additionally, ensure proper air circulation by slightly spacing the bags apart or using a small fan on low speed to prevent stagnant air, which can foster contaminants.

The incubation period typically lasts 2–4 weeks, depending on factors like substrate quality and mycelium vigor. During this time, regularly inspect the bags for signs of contamination, such as unusual colors or odors. If contamination is detected, isolate the affected bag immediately to prevent it from spreading. Patience is key; rushing the process by increasing temperature or humidity can lead to suboptimal results. Instead, maintain steady conditions and allow the mycelium to colonize at its natural pace.

Comparing this setup to other mushroom cultivation methods highlights its simplicity and effectiveness. Unlike outdoor beds or trays, sawdust bags in a controlled environment minimize the risk of pests and weather-related issues. The dark, humid, and temperature-regulated space creates a microcosm of the forest floor, where oyster mushrooms naturally grow. This method is particularly advantageous for beginners, as it requires minimal equipment—a thermometer, hygrometer, and humidifier—and yields consistent results with proper care.

In conclusion, the incubation setup for inoculated sawdust bags is a delicate balance of darkness, humidity, and temperature. By maintaining 70–75°F and 60–70% humidity in a dark space, cultivators create an ideal environment for mycelium colonization. This phase demands attention to detail, from monitoring humidity levels to ensuring proper air circulation, but the reward is a robust mycelium network ready for fruiting. With patience and precision, this method transforms simple sawdust bags into thriving mushroom farms.

Exploring Ancient Greek Mushroom Use: Rituals, Remedies, and Mysteries

You may want to see also

Monitoring Growth: Check bags weekly for contamination, ensure even mycelium spread, adjust conditions as needed

Once inoculated, your sawdust bags become a delicate ecosystem where oyster mushroom mycelium strives to colonize its substrate. Weekly monitoring is crucial to ensure this process unfolds successfully. Think of it as tending a garden – neglect can lead to weeds (contamination) overtaking your desired crop.

Every seven days, inspect each bag for any signs of mold, unusual discoloration, or off-odors. Green, black, or pink growths are red flags, indicating contamination that could jeopardize your entire batch. Isolate any contaminated bags immediately to prevent spores from spreading.

Beyond contamination, observe the mycelium's progress. Ideally, you'll see a uniform white, cobweb-like growth spreading throughout the bag. Uneven colonization, where mycelium clusters in certain areas, suggests suboptimal conditions. This could be due to uneven moisture distribution, temperature fluctuations, or inadequate air exchange. Gently squeeze the bags to check for moisture levels – they should feel like a wrung-out sponge, not soggy or bone-dry.

Adjust environmental factors as needed. If mycelium growth is slow, slightly increase the ambient temperature within the recommended range (typically 70-75°F). If bags appear too dry, mist them lightly with water, ensuring not to saturate the sawdust. Conversely, if condensation is excessive, improve ventilation by poking additional holes in the bags.

Remember, patience is key. Oyster mushroom mycelium colonization can take 4-6 weeks, depending on strain and conditions. Consistent monitoring allows you to intervene at the first sign of trouble, maximizing your chances of a bountiful harvest. Treat each bag as a living experiment, learning from its unique responses to your care. This hands-on approach not only ensures successful fruiting but also deepens your understanding of the fascinating world of mushroom cultivation.

Should You Wash Shiitake Mushrooms Before Cooking? Expert Tips

You may want to see also

Frequently asked questions

Ensure the sawdust bags are properly hydrated and pasteurized before inoculation. Mix the sawdust with water to achieve a moisture content of 60-70%, then pasteurize it at 60-70°C (140-158°F) for 1-2 hours to kill competing microorganisms. Allow the bags to cool to around 25°C (77°F) before introducing the mycelium plugs.

For a standard 5-6 lb (2.3-2.7 kg) sawdust bag, use 5-10 mycelium plugs, evenly spaced across the surface. This ensures the mycelium colonizes the substrate efficiently without overcrowding.

Maintain a temperature of 22-25°C (72-77°F) and a humidity level of 60-70% in a dark or dimly lit environment. Avoid direct sunlight and ensure good air circulation. The bags should be colonized within 3-4 weeks, depending on the strain and conditions.