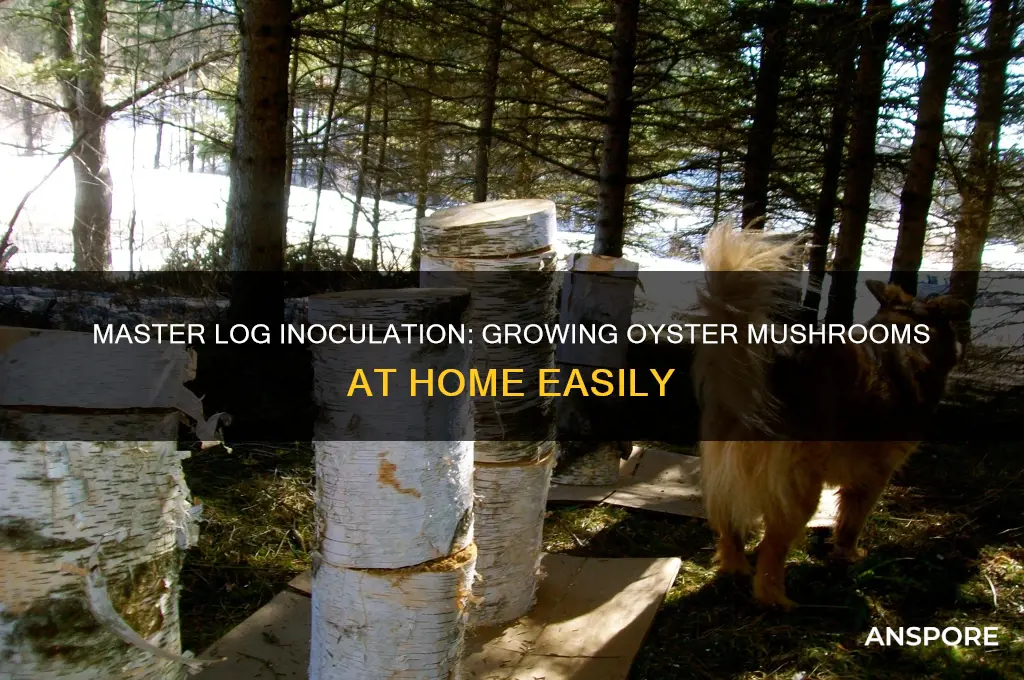

Inoculating logs with oyster mushrooms is a rewarding process that allows you to cultivate these delicious and nutritious fungi in a natural, sustainable way. By drilling holes into hardwood logs, such as oak or beech, and inserting mushroom spawn, you create an ideal environment for mycelium to colonize the wood. Over time, the mycelium breaks down the log’s cellulose, eventually producing clusters of oyster mushrooms. This method not only yields fresh mushrooms but also repurposes wood waste and supports local ecosystems. With proper preparation, patience, and care, anyone can transform logs into a thriving mushroom garden.

| Characteristics | Values |

|---|---|

| Log Selection | Hardwood logs (e.g., oak, beech, maple, poplar), 3-8 inches in diameter, freshly cut (within 1-6 months). |

| Log Preparation | Cut logs to desired length (2-4 feet), debark or score the surface for better colonization. |

| Mushroom Spawn Type | Sawdust or plug spawn of oyster mushroom (Pleurotus ostreatus). |

| Inoculation Tools | Drill with 5/16-inch bit, hammer, inoculation tool, wax or cheese wax. |

| Drill Hole Pattern | Holes spaced 6 inches apart in a diamond or spiral pattern, 1-2 inches deep. |

| Spawn Insertion | Fill each hole with spawn, tapping gently to compact. |

| Sealing Holes | Seal holes with wax to retain moisture and prevent contamination. |

| Stacking Logs | Stack logs in a shaded, humid area, off the ground (e.g., on pallets). |

| Incubation Period | 6-12 months, depending on temperature and humidity. |

| Fruiting Conditions | Soak logs in water for 24 hours, place in a cool, humid environment (55-70°F). |

| Harvesting | Harvest mushrooms when caps are fully grown but before spores drop. |

| Re-fruiting | Logs can fruit multiple times (2-5 years) with proper care. |

| Maintenance | Keep logs moist but not waterlogged; protect from extreme weather. |

| Contamination Prevention | Sterilize tools, use fresh logs, and avoid exposing spawn to contaminants. |

| Success Rate | High (80-90%) with proper technique and conditions. |

Explore related products

What You'll Learn

- Prepare Logs: Choose hardwood logs, cut to size, and drill holes for mushroom spawn

- Sterilize Tools: Clean and sterilize all tools to prevent contamination during inoculation

- Inoculate Spawn: Fill drilled holes with oyster mushroom spawn using a special inoculation tool

- Seal Holes: Cover spawn-filled holes with wax to retain moisture and protect from pests

- Stack and Care: Stack logs in a shaded, humid area, and monitor for growth regularly

Prepare Logs: Choose hardwood logs, cut to size, and drill holes for mushroom spawn

To begin the process of inoculating logs with oyster mushrooms, the first step is to prepare the logs by selecting the right type of wood, cutting it to the appropriate size, and drilling holes for the mushroom spawn. Choose hardwood logs such as oak, maple, or beech, as these species provide the ideal environment for oyster mushrooms to thrive. Softwoods like pine are generally not recommended because they contain resins that can inhibit mushroom growth. Ensure the logs are freshly cut, ideally within a few months, to maximize the chances of successful colonization. The logs should be healthy and free from any signs of decay or insect damage.

Once you’ve selected the hardwood logs, cut them to size, typically 3 to 5 feet in length and 4 to 8 inches in diameter. This size is manageable for handling and provides ample surface area for mushroom growth. Shorter logs are easier to work with, especially if you’re a beginner, while longer logs can yield more mushrooms over time. After cutting, allow the logs to rest for a few weeks to begin the natural drying process, which helps create a suitable environment for the mushroom mycelium to establish itself.

Next, drill holes into the logs to create entry points for the mushroom spawn. Use a 5/16-inch drill bit to create holes approximately 1 to 2 inches deep, spaced 6 to 8 inches apart in a staggered pattern. This spacing ensures even distribution of the spawn while preventing overcrowding. Drill the holes at a slight upward angle to reduce the risk of water accumulation, which can lead to contamination. Aim for 20 to 30 holes per log, depending on its size, to provide ample sites for colonization.

After drilling, it’s crucial to clean the logs to remove any debris or wood chips from the holes. Use a brush or compressed air to ensure the holes are free from obstructions, as clean holes allow the spawn to be inserted easily and reduce the risk of contamination. Once cleaned, the logs are ready for inoculation with oyster mushroom spawn, setting the stage for a successful mushroom cultivation project.

Finally, consider sealing the ends of the logs with wax or a natural sealant to prevent moisture loss and protect against pests. This step is optional but can improve the longevity and productivity of the logs. With the logs properly prepared, you’re now ready to move on to the next step: inoculating them with oyster mushroom spawn.

Explore the Best Food Pairings for Morel Mushrooms

You may want to see also

Sterilize Tools: Clean and sterilize all tools to prevent contamination during inoculation

Before you begin the inoculation process, it's crucial to ensure that all tools and equipment are thoroughly cleaned and sterilized. This step is vital to prevent contamination from bacteria, fungi, or other microorganisms that could compete with or harm the oyster mushroom mycelium. Start by gathering all the tools you’ll need, such as drills, bits, inoculation tools, and any containers or surfaces that will come into contact with the logs or mushroom spawn. Wash these tools with hot, soapy water to remove dirt, debris, and organic matter. Use a scrub brush or sponge to clean hard-to-reach areas, ensuring no residue remains. Rinse the tools thoroughly to remove any soap residue, as leftover soap can interfere with the sterilization process or harm the mycelium.

After cleaning, the next step is to sterilize the tools to eliminate any remaining microorganisms. One effective method is to use a 10% bleach solution (1 part bleach to 9 parts water) to wipe down metal and plastic tools. Allow the bleach solution to sit on the tools for at least 10 minutes before rinsing them thoroughly with clean water. For heat-resistant tools like metal drills and bits, you can sterilize them by boiling in water for 10–15 minutes or using a propane torch to heat them until they are red-hot. Ensure the tools are completely dry before use, as moisture can reintroduce contaminants. Avoid using flammable materials near open flames when torching tools.

For surfaces like workbenches or inoculation stations, clean them with a disinfectant solution, such as 70% isopropyl alcohol or a 10% bleach solution. Wipe down the entire area, paying special attention to corners and crevices where contaminants might hide. Allow the disinfectant to air-dry without wiping it off to ensure maximum effectiveness. If using reusable gloves, wash them thoroughly with soap and water, then sterilize by soaking in isopropyl alcohol or boiling them for a few minutes. Always wear clean gloves during the inoculation process to avoid transferring contaminants from your hands.

Inoculation tools, such as spawn bags or syringes, should be sterilized using an autoclave or pressure cooker if available. These devices use high heat and pressure to kill all microorganisms. If you don’t have access to an autoclave, you can sterilize syringes by boiling them in water for 15–20 minutes, ensuring they are fully submerged. For drill bits, consider using disposable ones or sterilizing them after each log to minimize cross-contamination. Keep sterilized tools in a clean, sealed container or covered area until ready for use to maintain their sterile state.

Finally, create a sterile work environment by minimizing dust and airborne particles. Inoculation should be done in a clean, enclosed space, such as a shed or garage, with windows and doors closed. Use a HEPA filter or air purifier to reduce airborne contaminants. Wear a mask and clean clothing to avoid shedding skin cells or fibers that could contaminate the logs. By meticulously cleaning and sterilizing all tools and surfaces, you significantly increase the chances of successful oyster mushroom inoculation and healthy mycelium growth.

Mushroom Coffee: Rise and Shine

You may want to see also

Inoculate Spawn: Fill drilled holes with oyster mushroom spawn using a special inoculation tool

Inoculating logs with oyster mushroom spawn is a precise process, and filling the drilled holes with spawn is a critical step that requires attention to detail. Begin by preparing your oyster mushroom spawn, ensuring it is fresh and viable. The spawn should be in a granular or sawdust form, which is ideal for insertion into the holes. A special inoculation tool, often a simple device with a cylindrical end, is used to pack the spawn tightly into the drilled holes. This tool ensures that the spawn is inserted deeply and compactly, maximizing the contact between the spawn and the log’s wood fibers, which is essential for successful colonization.

Before filling the holes, it’s important to work quickly to minimize the exposure of the spawn to contaminants. Sterilize your inoculation tool with rubbing alcohol or a flame to prevent the introduction of unwanted bacteria or fungi. Once the tool is ready, scoop a small amount of spawn and insert it into the hole, using the tool to tamp it down firmly. The goal is to fill the hole completely, leaving no gaps, as air pockets can hinder the mushroom’s growth. Repeat this process for each hole, ensuring consistency in the amount of spawn used and the depth to which it is packed.

The technique for filling the holes is straightforward but requires practice to master. Hold the inoculation tool at a slight angle to avoid damaging the log or the spawn. Apply steady pressure as you pack the spawn, but avoid excessive force, which could cause the wood to crack or splinter. If the spawn is too dry, lightly mist it with water before packing to improve its adherence to the wood. However, be cautious not to over-moisten it, as excess moisture can lead to mold or bacterial growth.

Once all holes are filled, cover each one with a piece of wax or cheese wax to seal the spawn inside. This step protects the spawn from drying out and prevents insects or other contaminants from entering the holes. The wax should be melted and applied carefully, ensuring a complete seal. Alternatively, some growers use a mixture of wax and sawdust or a specialized sealant designed for mushroom cultivation. The sealing process is as important as the inoculation itself, as it creates a stable environment for the mycelium to grow.

After inoculation and sealing, label the log with the date and type of mushroom spawn used for future reference. Store the log in a cool, shaded area with adequate humidity, such as a wooded area or a shaded part of your garden. Regularly monitor the log for signs of mycelium growth, which typically appears as white threads beneath the bark after a few months. With proper care and patience, the inoculated log will eventually produce a bountiful harvest of oyster mushrooms, making the meticulous process of filling the holes well worth the effort.

Mushroom Lakes: Underground or Not for Angler's Quest?

You may want to see also

Explore related products

$25

Seal Holes: Cover spawn-filled holes with wax to retain moisture and protect from pests

Sealing the spawn-filled holes with wax is a critical step in the log inoculation process for oyster mushrooms, as it helps retain moisture and protects the mycelium from pests and contaminants. After drilling holes into the log and filling them with mushroom spawn, you’ll need to prepare the wax for sealing. The most commonly used wax is cheese wax, which melts easily and adheres well to wood. To melt the wax, use a double boiler or a dedicated melting pot to avoid direct heat, which can cause the wax to burn. Ensure the wax is fully melted and reaches a temperature of around 160°F (71°C) for optimal application.

Once the wax is ready, carefully pour a small amount into each spawn-filled hole, ensuring it covers the entire surface. The goal is to create a smooth, even layer that seals the hole completely. Work quickly but carefully, as the wax will begin to solidify as it cools. Use a spoon or a dedicated tool to spread the wax if needed, but avoid disturbing the spawn underneath. Proper sealing is essential, as any gaps can allow moisture to escape or pests to enter, compromising the colonization process.

After sealing the holes, allow the wax to cool and harden completely before handling the logs. This typically takes about 15–30 minutes, depending on the ambient temperature. Once hardened, the wax forms a protective barrier that locks in moisture, which is crucial for the mycelium to thrive. It also acts as a physical barrier against insects and other pests that might otherwise damage the spawn. This step significantly increases the chances of successful colonization and fruiting.

For best results, ensure the logs are stored in a shaded, humid environment after inoculation. The wax seal will help maintain the internal moisture levels, but external conditions still play a vital role. Periodically inspect the logs to ensure the wax remains intact and reapply if any cracks or damage occur. Properly sealed logs can remain viable for several years, allowing the mycelium to fully colonize before producing oyster mushrooms.

Finally, while sealing with wax is highly effective, it’s important to use the right type and amount. Too little wax may leave gaps, while too much can be wasteful and unnecessary. Practice makes perfect, so if you’re new to the process, start with a few logs to get a feel for the technique. With patience and attention to detail, sealing the holes with wax will set the stage for a successful oyster mushroom harvest.

Fruit Mushrooms: Ideal Temperature Control

You may want to see also

Stack and Care: Stack logs in a shaded, humid area, and monitor for growth regularly

Once you’ve inoculated your logs with oyster mushroom spawn, proper stacking and care are crucial for successful colonization and fruiting. Begin by selecting a shaded area for your logs, as direct sunlight can dry them out and inhibit mushroom growth. A north-facing slope or an area under partial canopy works well. Ensure the location is naturally humid, or create humidity by placing the logs near a water source or misting them occasionally. Avoid areas prone to strong winds, as they can further dry out the logs.

Stack the inoculated logs in a way that promotes air circulation while maintaining stability. Place them in a crisscross pattern or lean them against a structure, ensuring they are secure and won’t roll. Leave a small gap between logs to allow air to flow, which helps prevent mold and encourages even colonization. Cover the stack loosely with a shade cloth or burlap to retain moisture without suffocating the logs. This setup mimics the natural environment where oyster mushrooms thrive.

Regular monitoring is essential to ensure the logs remain healthy and on track for fruiting. Check the logs every 2–3 weeks to assess moisture levels, signs of mold, or pest activity. If the logs feel dry, lightly mist them with water, focusing on the ends where moisture loss is highest. Keep an eye out for competing fungi or insects, and remove any affected areas promptly. Over time, you’ll notice the wood beginning to crack and whiten as the mycelium grows—a positive sign of colonization.

Patience is key, as it can take 6–12 months for the logs to fully colonize, depending on temperature and humidity. Once colonization is complete, soak the logs in water for 24–48 hours to stimulate fruiting. After soaking, restack them in the shaded, humid area and watch for pinheads—the first signs of mushrooms emerging. Maintain consistent moisture during this stage, as it’s critical for healthy fruiting bodies to develop.

Finally, harvest mushrooms when the caps are still convex and firm, as they’ll have the best flavor and texture. After harvesting, the logs can often fruit multiple times over 2–3 years with proper care. Continue monitoring moisture levels and soaking the logs as needed to encourage additional flushes. With attentive stacking and care, your inoculated logs will become a reliable source of fresh oyster mushrooms for years to come.

Safe and Mindful Guide to Consuming Liberty Caps Mushrooms

You may want to see also

Frequently asked questions

Hardwood logs such as oak, beech, maple, or poplar are ideal for inoculating with oyster mushrooms. Ensure the logs are freshly cut (within 2-6 weeks) and free from rot or insect damage.

Drill holes 1-2 inches deep and 6 inches apart in a diamond pattern along the log. Fill the holes with oyster mushroom spawn, then seal them with wax or cheese wax to retain moisture and protect the spawn.

It typically takes 6-12 months for oyster mushrooms to colonize the log fully, depending on environmental conditions. Fruiting (mushroom growth) usually occurs in the spring or fall when temperatures are cooler and humidity is higher.