Maintaining a constant temperature in a mushroom incubator is crucial for successful mushroom cultivation, as fluctuations can hinder mycelium growth and fruiting. To achieve this, start by selecting a reliable incubator equipped with a thermostat and temperature sensor to monitor and regulate heat levels. Insulate the incubator properly to minimize heat loss and ensure even distribution. Use a heating element, such as a heating mat or lamp, and pair it with a digital temperature controller for precise adjustments. Regularly calibrate the thermostat and place the incubator in a stable environment, away from drafts or direct sunlight. Additionally, monitor humidity levels, as they often correlate with temperature, and use a hygrometer to maintain balance. Consistent monitoring and minor adjustments will help create an optimal, stable environment for mushroom growth.

| Characteristics | Values |

|---|---|

| Insulation Material | Use high-quality insulation like foam boards, reflective bubble wrap, or rigid foam to minimize heat loss. |

| Heating Source | Employ a reliable heat source such as a thermostat-controlled heating mat, space heater, or incandescent light bulb. |

| Thermostat Control | Utilize a digital thermostat or temperature controller to regulate the heating source and maintain a consistent temperature. |

| Air Circulation | Ensure proper air circulation using a small fan or ventilation system to prevent hot spots and maintain uniformity. |

| Temperature Range | Maintain the incubator temperature within the optimal range for mushroom growth, typically 68°F to 75°F (20°C to 24°C). |

| Monitoring Tools | Use a digital thermometer or hygrometer with remote sensors to continuously monitor temperature and humidity levels. |

| Humidity Control | Maintain humidity levels between 90-95% using a humidifier, misting system, or water trays, ensuring it doesn't affect temperature stability. |

| Incubator Size | Choose an appropriately sized incubator to minimize temperature fluctuations; smaller spaces are easier to control. |

| Sealing | Ensure the incubator is well-sealed to prevent external temperature influences and maintain internal conditions. |

| Calibration | Regularly calibrate temperature and humidity sensors to ensure accurate readings and control. |

| Backup Power | Have a backup power source (e.g., UPS or generator) to prevent temperature drops during power outages. |

| Substrate Preparation | Properly pasteurize or sterilize the substrate to reduce the risk of contamination, which can affect temperature control. |

| Light Exposure | Avoid direct sunlight or excessive light exposure, as it can cause temperature fluctuations. |

| Maintenance | Regularly clean and maintain the incubator to ensure all components function optimally. |

| Experimentation | Test and adjust settings to find the best configuration for your specific mushroom species and incubator setup. |

Explore related products

What You'll Learn

- Insulation Materials: Use high-quality insulation like foam or fiberglass to minimize heat loss

- Thermostat Control: Install a precise thermostat to regulate heating and cooling automatically

- Air Circulation: Maintain consistent airflow with fans to distribute temperature evenly

- Heating Elements: Choose reliable heat sources like heating pads or bulbs for stability

- Humidity Management: Control moisture levels with humidifiers or trays to support temperature balance

Insulation Materials: Use high-quality insulation like foam or fiberglass to minimize heat loss

Maintaining a constant temperature in a mushroom incubator is crucial for successful mushroom cultivation, and one of the most effective ways to achieve this is by using high-quality insulation materials. Insulation Materials: Use high-quality insulation like foam or fiberglass to minimize heat loss is a key strategy in this process. These materials act as a barrier, reducing the transfer of heat between the incubator's interior and the external environment. By minimizing heat loss, you can ensure that the temperature remains stable, creating an optimal environment for mushroom growth.

When selecting insulation materials, consider using expanded polystyrene (EPS) foam or polyurethane foam, both of which are excellent choices due to their high R-values (a measure of thermal resistance). EPS foam is lightweight, moisture-resistant, and provides consistent insulation performance. Polyurethane foam, on the other hand, offers even higher R-values and can be sprayed or injected into cavities, ensuring a seamless and airtight seal. These foams are particularly effective in preventing heat from escaping through the walls, ceiling, and floor of the incubator.

Another highly recommended insulation material is fiberglass. Fiberglass insulation is available in batts, rolls, or loose-fill form, making it versatile for various incubator designs. It is known for its durability and ability to resist heat transfer effectively. When installing fiberglass, ensure it is fitted tightly without gaps to maximize its insulating properties. Additionally, consider using a vapor barrier with fiberglass to prevent moisture buildup, which can compromise both the insulation and the mushroom growing environment.

For incubators with limited space or unconventional shapes, rigid foam boards made of materials like polyisocyanurate or extruded polystyrene (XPS) are ideal. These boards are easy to cut and fit into tight spaces, providing a high level of insulation without adding significant bulk. Rigid foam boards are also resistant to moisture and can be paired with reflective foil facings for added thermal efficiency. This combination ensures that the incubator maintains a consistent temperature even in fluctuating external conditions.

Lastly, proper installation of insulation materials is just as important as the materials themselves. Ensure that all seams and joints are sealed to prevent air leakage, which can lead to temperature fluctuations. Use adhesive tapes or foams specifically designed for insulation to create an airtight barrier. Regularly inspect the insulation for any signs of damage or wear and replace it as needed to maintain optimal performance. By investing in high-quality insulation and installing it correctly, you can significantly reduce energy consumption and create a stable, controlled environment for mushroom cultivation.

Crimini Mushrooms: Healthy Superfood or Just a Fad?

You may want to see also

Thermostat Control: Install a precise thermostat to regulate heating and cooling automatically

Maintaining a constant temperature in a mushroom incubator is crucial for successful mushroom cultivation, as even slight fluctuations can hinder mycelium growth and fruiting. Thermostat control is one of the most effective methods to achieve this stability. Installing a precise thermostat allows for automatic regulation of heating and cooling, ensuring the incubator remains within the optimal temperature range for your mushroom species, typically between 68°F and 75°F (20°C and 24°C). This eliminates the need for manual adjustments, reducing the risk of human error and providing a consistent environment for mushroom growth.

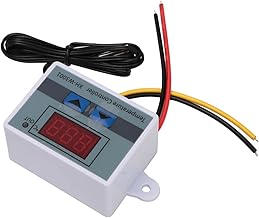

When selecting a thermostat for your mushroom incubator, opt for a digital thermostat with a temperature probe. Digital thermostats offer greater accuracy compared to analog models, often within ±1°F (±0.5°C), which is essential for mushroom cultivation. The temperature probe should be placed inside the incubator, near the growing substrate, to ensure the thermostat reads the actual environment where the mushrooms are developing. Look for a thermostat with both heating and cooling capabilities, as this allows it to activate heating elements when temperatures drop too low or trigger cooling mechanisms (such as fans or air conditioners) when temperatures rise too high.

Installation of the thermostat requires careful planning. Mount the thermostat control unit outside the incubator for easy access, while ensuring the temperature probe is securely positioned inside. Connect the thermostat to your heating and cooling devices according to the manufacturer’s instructions. For heating, options include heat mats, incandescent bulbs, or heating coils, while cooling can be achieved with exhaust fans, air conditioners, or even a simple venting system. Ensure all components are compatible with the thermostat’s voltage and amperage ratings to avoid electrical issues.

Once installed, calibrate the thermostat to ensure accurate temperature readings. Most digital thermostats have a calibration feature that allows you to adjust the displayed temperature to match a known accurate reading from a separate thermometer. Set the thermostat to the desired temperature range for your mushroom species, programming it to activate heating or cooling as needed. Many advanced thermostats also offer features like temperature alarms, logging, and programmable cycles, which can further enhance control and monitoring.

Regular maintenance is key to ensuring the thermostat system functions reliably. Periodically check the temperature probe for damage or misplacement, as this can lead to inaccurate readings. Clean the incubator’s vents and fans to prevent dust buildup, which can affect cooling efficiency. Additionally, test the heating and cooling systems independently to ensure they respond correctly to thermostat signals. By maintaining a well-calibrated and properly functioning thermostat system, you can create a stable environment that promotes healthy and consistent mushroom growth.

Mushrooms and Other Decomposers: Nature's Recycling Team

You may want to see also

Air Circulation: Maintain consistent airflow with fans to distribute temperature evenly

Maintaining consistent airflow within a mushroom incubator is crucial for ensuring that temperature remains uniform throughout the growing environment. Mushrooms are highly sensitive to temperature fluctuations, and uneven heat distribution can lead to poor growth or contamination. To achieve this, strategically place fans inside the incubator to create a gentle, continuous airflow. The goal is not to generate strong winds but to promote a steady circulation that prevents hot or cold spots from forming. Position fans so that they direct air across shelves or trays rather than straight at the mushroom substrate, as direct airflow can dry out the mycelium.

The placement of fans is key to effective air circulation. Install at least one fan at the bottom of the incubator to push cooler air upward, as warm air naturally rises. Pair this with a fan at the top to pull the warm air and redistribute it downward, creating a convection loop. If the incubator has multiple shelves, consider adding smaller fans between levels to ensure air reaches all areas evenly. Avoid placing fans too close to the incubator’s walls, as this can create dead zones where air does not circulate properly. Regularly test airflow by placing a hand inside the incubator to feel for consistent movement.

Fan speed and type also play a significant role in maintaining even temperature. Use variable-speed fans to adjust airflow based on the incubator’s size and the mushrooms’ growth stage. During colonization, slower airflow is often sufficient, while fruiting stages may require slightly stronger circulation to support higher humidity and temperature demands. Opt for low-noise, energy-efficient fans to avoid disturbing the growing environment or increasing operational costs. Oscillating fans can be particularly useful for covering larger areas and ensuring air reaches all parts of the incubator.

Monitoring airflow is essential to confirm its effectiveness in maintaining a constant temperature. Use a thermometer with multiple probes placed at different heights and locations within the incubator to identify any temperature variations. If hotspots or cold spots are detected, adjust fan placement or speed accordingly. Additionally, ensure that the incubator’s intake and exhaust vents are not obstructed, as proper ventilation is critical for airflow efficiency. Regularly clean fans and vents to prevent dust buildup, which can impede airflow and affect temperature control.

Finally, integrate airflow management with other temperature control methods for optimal results. For example, combine fans with a thermostat-controlled heating or cooling system to maintain the desired temperature range. Insulate the incubator to minimize external temperature influences, reducing the workload on the fans and heating/cooling mechanisms. By prioritizing consistent airflow through thoughtful fan placement, speed adjustment, and monitoring, you can create a stable environment that supports healthy mushroom growth and maximizes yield.

Mushroom Farming: Patents and Innovation

You may want to see also

Explore related products

Heating Elements: Choose reliable heat sources like heating pads or bulbs for stability

When selecting heating elements for your mushroom incubator, reliability and stability are paramount. Heating pads are a popular choice due to their consistent heat distribution and ease of use. Opt for high-quality silicone or flexible heating pads designed for incubation purposes. These pads should have a built-in thermostat or be paired with a temperature controller to maintain precise temperatures. Ensure the heating pad covers a sufficient area of the incubator to avoid hot spots, which can negatively impact mycelium growth. Regularly inspect the pad for any signs of wear or damage to prevent malfunctions that could disrupt temperature stability.

Another effective heating option is incandescent bulbs, which provide both heat and light. Choose bulbs specifically designed for heating, such as ceramic heat emitters or low-wattage incandescent bulbs. Position the bulb at the top of the incubator to create a natural temperature gradient, with warmer air rising and cooler air settling at the bottom. Use a dimmer switch or a thermostat-controlled outlet to regulate the bulb's output and maintain a consistent temperature. Avoid using LED bulbs, as they produce minimal heat and are not suitable for this purpose.

Regardless of the heating element you choose, integrating a temperature controller is essential for stability. A digital thermostat or PID (Proportional-Integral-Derivative) controller can monitor and adjust the heat source to maintain the desired temperature within a narrow range. Ensure the controller is compatible with your heating element and calibrate it regularly for accuracy. Place temperature sensors at multiple points within the incubator to monitor variations and adjust the heating element accordingly.

When installing heating elements, prioritize safety to prevent hazards such as overheating or electrical malfunctions. Use heat-resistant materials to insulate the incubator walls and protect nearby components. Avoid overcrowding the incubator with substrates or containers, as this can restrict airflow and cause uneven heating. Regularly clean and maintain the heating elements to ensure optimal performance and longevity.

Lastly, consider the energy efficiency and cost-effectiveness of your chosen heating element. Heating pads generally consume less energy than bulbs and provide more uniform heat distribution. However, bulbs can be a dual-purpose solution if your mushroom species requires light exposure. Evaluate your specific needs, budget, and incubator setup to determine the most suitable heating element. By investing in reliable and stable heat sources, you can create an optimal environment for mushroom cultivation and ensure consistent yields.

Mushrooms: A Surprising Source of Daily Fiber

You may want to see also

Humidity Management: Control moisture levels with humidifiers or trays to support temperature balance

Maintaining optimal humidity levels is crucial for keeping the temperature constant in a mushroom incubator, as humidity and temperature are interconnected factors that influence each other. Humidity management involves controlling moisture levels to create a stable environment that supports mycelium growth and prevents temperature fluctuations. One effective method is using humidifiers, which can be set to maintain a specific humidity range, typically between 90-95% for most mushroom species. Humidifiers work by releasing a fine mist of water into the air, ensuring the incubator’s environment remains saturated without becoming waterlogged. When selecting a humidifier, opt for one with adjustable settings and a capacity suitable for the incubator’s size to avoid over-humidification, which can lead to condensation and temperature instability.

Another practical and cost-effective approach to humidity management is using water trays placed inside the incubator. Fill shallow trays with water and position them on the incubator’s floor or shelves. As the water evaporates, it naturally increases humidity levels, helping to maintain the desired balance. To enhance evaporation, place a fan or ventilation system near the trays to circulate air, ensuring even moisture distribution. However, monitor the trays regularly to prevent water from spilling or creating stagnant areas, which could disrupt temperature consistency. Combining water trays with a hygrometer allows for precise humidity monitoring and adjustments as needed.

For those seeking a low-tech solution, misting the incubator’s interior walls or substrate directly can temporarily boost humidity. Use a spray bottle with distilled water to avoid mineral buildup, which can harm mycelium. Misting should be done sparingly and only when humidity levels drop below the target range, as excessive misting can cause temperature drops due to rapid evaporation. Pair this method with a hygrometer to track humidity levels accurately and avoid over-misting. While misting is less precise than humidifiers or trays, it can be a useful supplementary technique in smaller incubators.

Ventilation plays a critical role in humidity management and temperature stability. Proper airflow prevents moisture from accumulating in specific areas, which could lead to localized temperature drops or mold growth. Install vents or use a small fan to maintain air circulation without causing drafts that could dry out the environment. Balancing humidity with adequate ventilation ensures that moisture is evenly distributed, supporting consistent temperature control. Regularly inspect the incubator for signs of condensation or dry spots, adjusting ventilation and humidity sources accordingly.

Lastly, monitoring and calibration are essential for effective humidity management. Use a hygrometer to track humidity levels and a thermometer to monitor temperature simultaneously, as changes in one often affect the other. Calibrate both devices regularly to ensure accuracy. If humidity levels rise too high, remove excess water from trays or reduce humidifier output. If levels drop, add more water or increase misting frequency. By actively managing humidity, you create a stable environment that minimizes temperature fluctuations, fostering healthy mushroom growth. Consistent attention to these details ensures the incubator remains an ideal habitat for mycelium development.

Toxic Mushrooms: Unveiling Their Biological Hazard Potential and Risks

You may want to see also

Frequently asked questions

The ideal temperature range for most mushroom species is between 70°F to 75°F (21°C to 24°C). To maintain consistency, use a thermostat-controlled heating system, insulate the incubator, and avoid frequent opening to prevent temperature fluctuations.

Install a reliable heating element with a thermostat, use insulation materials like foam boards, and place the incubator in a temperature-stable environment. Additionally, consider using a backup power source to ensure uninterrupted heating during power outages.

Use a digital thermometer with a probe to monitor temperature accurately. Pair it with a thermostat-controlled heating mat, space heater, or incubator with built-in temperature control. Humidity sensors and fans can also help maintain optimal conditions alongside temperature regulation.