Maintaining the correct incubation temperature is crucial for successfully growing mushrooms, as it directly impacts mycelium development and fruiting. The ideal temperature range typically falls between 70°F to 75°F (21°C to 24°C), though this can vary slightly depending on the mushroom species. Consistency is key; fluctuations can stress the mycelium or encourage contamination. To achieve this, growers often use tools like thermometers, heating pads, or incubators, ensuring the environment remains stable. Monitoring and adjusting the temperature regularly, especially during the initial colonization phase, helps promote healthy growth and maximizes yield. Proper temperature control is a fundamental aspect of mushroom cultivation, bridging the gap between amateur and successful harvests.

| Characteristics | Values |

|---|---|

| Optimal Incubation Temperature | 70-75°F (21-24°C) for most mushroom species |

| Temperature Range Tolerance | 68-80°F (20-27°C); avoid fluctuations outside this range |

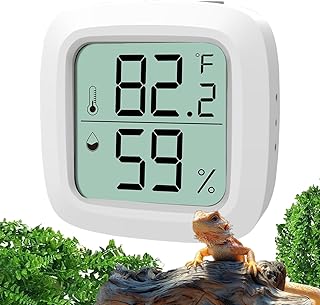

| Monitoring Tools | Digital thermometers, temperature probes, or smart sensors |

| Incubation Container | Insulated containers (e.g., coolers, incubators, or DIY setups) |

| Heat Source | Heating pads, seedling heat mats, or incandescent bulbs |

| Humidity Maintenance | 95-100% humidity; use a humidifier or misting if necessary |

| Air Exchange | Minimal air exchange; avoid drafts but ensure some ventilation |

| Light Requirements | Complete darkness during incubation |

| Duration of Incubation | 7-21 days, depending on mushroom species |

| Temperature Regulation Tips | Use a thermostat or timer to control heat sources |

| Common Issues | Overheating, mold growth due to improper humidity or temperature |

| Substrate Preparation | Sterilize or pasteurize substrate before inoculation |

| Environmental Consistency | Maintain stable conditions to prevent contamination and stress |

| Post-Incubation Care | Transfer to fruiting conditions with proper light and humidity |

| Species-Specific Variations | Some species (e.g., oyster mushrooms) may tolerate slightly higher temps |

Explore related products

What You'll Learn

- Thermostat Control: Use a reliable thermostat to regulate incubator temperature accurately and consistently

- Insulation Techniques: Apply proper insulation to minimize heat loss and maintain stable conditions

- Heat Source Placement: Position heating elements evenly to ensure uniform temperature distribution

- Monitoring Tools: Use thermometers or sensors to track temperature changes in real-time

- Humidity Balance: Maintain optimal humidity levels alongside temperature for successful mushroom incubation

Thermostat Control: Use a reliable thermostat to regulate incubator temperature accurately and consistently

Maintaining the correct incubation temperature is critical for successful mushroom cultivation, as even slight fluctuations can hinder mycelium growth or lead to contamination. Thermostat control is the cornerstone of achieving this precision. A reliable thermostat acts as the brain of your incubation system, ensuring the temperature remains accurate and consistent throughout the incubation period. When selecting a thermostat, prioritize models specifically designed for incubation purposes, as they offer finer control and are calibrated for the narrow temperature ranges mushrooms require (typically 70-75°F or 21-24°C). Avoid general-purpose thermostats, as they may lack the sensitivity needed for mushroom cultivation.

Once you’ve chosen a suitable thermostat, proper installation is key. Ensure the temperature probe is placed directly inside the incubator, away from heat sources or cold spots, to provide an accurate reading of the ambient environment. Secure the probe with insulation or tape to prevent it from touching the incubator walls, which can skew readings. Connect the thermostat to a reliable heating or cooling source, such as a space heater, heat mat, or air conditioner, depending on your setup. Calibrate the thermostat according to the manufacturer’s instructions to ensure it accurately reflects the incubator’s internal temperature. Regularly verify its accuracy using a separate thermometer to catch any discrepancies early.

Consistency is just as important as accuracy when regulating incubation temperature. Set the thermostat to the optimal range for your mushroom species and avoid frequent adjustments, as these can stress the mycelium. Program the thermostat to maintain a steady temperature 24/7, as mushrooms are highly sensitive to temperature shifts, especially during colonization. If your incubator is in a location with fluctuating ambient temperatures, consider using a thermostat with a proportional-integral-derivative (PID) controller. PID controllers adjust heating or cooling incrementally, minimizing overshooting or undershooting the target temperature and providing smoother, more stable conditions.

Monitoring and maintenance are essential to ensure your thermostat continues to function reliably. Regularly inspect the thermostat, probe, and wiring for signs of wear or damage. Clean the probe periodically to remove dust or debris that could affect readings. Keep a log of incubator temperatures to track performance and identify trends or anomalies. If you notice inconsistent temperatures, recalibrate the thermostat or consult the manufacturer for troubleshooting guidance. Investing in a backup thermostat or temperature alarm can provide an additional layer of security, alerting you to failures before they compromise your mushroom culture.

Finally, integrate your thermostat control system with other environmental factors for optimal results. Humidity, airflow, and light also play crucial roles in mushroom incubation, and a well-regulated temperature enhances their effectiveness. For example, consistent temperature helps maintain proper humidity levels by reducing condensation or evaporation. Pair your thermostat with a hygrometer and consider using a controller that manages both temperature and humidity for a more integrated approach. By prioritizing thermostat control and maintaining vigilance, you’ll create a stable, nurturing environment that maximizes the chances of successful mushroom cultivation.

Porcini Mushrooms: Safe Superfood for Pregnancy?

You may want to see also

Insulation Techniques: Apply proper insulation to minimize heat loss and maintain stable conditions

Maintaining the proper incubation temperature is critical for successful mushroom cultivation, as fluctuations can hinder mycelium growth and reduce yields. Insulation techniques play a pivotal role in minimizing heat loss and ensuring stable conditions. One of the most effective methods is to use rigid foam insulation boards, such as extruded polystyrene (XPS) or polyisocyanurate (ISO), to line the walls of your incubation chamber. These materials offer high R-values, meaning they provide excellent thermal resistance, and are moisture-resistant, which is essential in the humid environment required for mushroom cultivation. Secure the insulation boards with adhesive or fasteners, ensuring there are no gaps where heat can escape.

Another practical insulation technique is to wrap the incubation container in reflective insulation, such as bubble wrap with a radiant barrier. This type of insulation reflects heat back into the chamber, reducing the workload on your heat source. For smaller setups, like shoebox or monotub incubators, lining the interior with aluminum foil or emergency blankets can also help maintain temperature by reflecting heat. Ensure the reflective side faces inward to maximize its effectiveness.

For larger incubation spaces, consider insulating the floor and ceiling in addition to the walls. If your incubation area is in a basement or on a concrete floor, place a layer of foam insulation beneath the chamber to prevent heat loss into the ground. Similarly, insulating the ceiling with foam boards or fiberglass batts can prevent heat from rising and escaping. Seal all edges and corners with insulation tape to eliminate air leaks, as even small gaps can lead to significant temperature drops.

Using insulated curtains or blankets is another versatile technique, especially for temporary or movable incubation setups. Heavy-duty thermal blankets or curtains can be draped around the incubation chamber to trap heat. These are particularly useful for maintaining temperatures in fluctuating environmental conditions, such as in a garage or shed. Ensure the blankets are securely fastened to prevent heat from escaping and to avoid disrupting the incubation environment.

Lastly, monitoring and sealing air leaks is crucial for effective insulation. Use a smoke pencil or incense stick to detect drafts around doors, vents, or seams in your incubation chamber. Seal these areas with weatherstripping, caulk, or foam sealant to prevent heat loss. For incubators with viewing windows, apply insulating window film or double-pane the glass to reduce heat transfer. By combining these insulation techniques, you can create a stable, energy-efficient environment that supports optimal mycelium growth during the incubation phase.

UA Testing: Can Mushrooms Be Detected?

You may want to see also

Heat Source Placement: Position heating elements evenly to ensure uniform temperature distribution

Maintaining the proper incubation temperature is critical for successful mushroom cultivation, and the placement of heating elements plays a pivotal role in achieving uniform temperature distribution. When setting up your incubation environment, it’s essential to position heat sources strategically to avoid hot spots or cold zones that could hinder mycelium growth. Start by assessing the size and shape of your incubation chamber, whether it’s a small incubator or a larger grow room. Place heating elements, such as heating pads, heat lamps, or radiant heaters, in a way that ensures even coverage across the entire space. For example, if using heating pads, distribute them evenly along the bottom or sides of the chamber, ensuring no area is left without direct or indirect heat.

In larger incubation setups, consider using multiple heat sources to maintain consistency. Position these elements at opposite ends or corners of the chamber to create a balanced heat gradient. Avoid placing all heating elements on one side, as this can lead to uneven temperatures and potentially dry out or overheat specific areas. If using heat lamps or radiant heaters, angle them to cover the incubation containers or bags uniformly, ensuring the heat is distributed rather than concentrated in one spot. Regularly monitor the temperature at various points within the chamber to confirm that the heat is evenly dispersed.

For smaller-scale operations, such as incubating mushroom spawn in jars or bags, the placement of heating elements becomes even more critical due to the limited space. Use heating pads or strips designed for incubation and place them beneath or around the containers, ensuring each jar or bag receives consistent warmth. If using a thermostat-controlled heating system, position the temperature probe in the center of the chamber to get an accurate reading of the average temperature. This helps the system adjust the heat output evenly, preventing overheating or underheating in specific areas.

Another effective strategy is to use insulation materials, such as foam boards or reflective liners, to complement the placement of heating elements. Insulation helps retain heat and reduces the workload on the heat sources, making it easier to maintain a uniform temperature. Ensure the insulation does not block the heat distribution but rather enhances it by preventing heat loss. For instance, line the walls of the incubation chamber with foam boards while leaving enough space for air circulation and heat dispersion.

Lastly, regularly rotate or rearrange the incubation containers if you notice temperature inconsistencies despite proper heat source placement. This practice helps ensure that all substrates receive equal exposure to the heat over time. Combine this with periodic temperature checks using a thermometer or thermal sensor to identify and address any emerging hot or cold spots. By meticulously positioning heating elements and monitoring their effectiveness, you can create an optimal, uniform incubation environment that fosters healthy mycelium growth and maximizes mushroom yield.

Cat Owners Alert: Are Mushrooms Safe for Cats?

You may want to see also

Explore related products

Monitoring Tools: Use thermometers or sensors to track temperature changes in real-time

Maintaining the correct incubation temperature is crucial for successful mushroom cultivation, as even slight fluctuations can hinder mycelium growth or promote contamination. To ensure precision, monitoring tools such as thermometers or sensors are indispensable. These devices provide real-time data, allowing cultivators to make immediate adjustments and maintain optimal conditions. Digital thermometers, for instance, offer accurate readings and are easy to place inside incubation chambers. For larger setups, thermocouples or probe thermometers can be strategically positioned to monitor temperature gradients, ensuring uniformity throughout the space.

When selecting monitoring tools, consider the type of sensor best suited for your incubation environment. Wireless sensors are ideal for remote monitoring, enabling cultivators to track temperatures via smartphone apps or computer dashboards. This is particularly useful for large-scale operations or when physical access to the incubation chamber is limited. For smaller setups, simple adhesive strip thermometers or dial thermometers can be affixed to the chamber walls, providing a quick visual reference. Ensure the sensors are calibrated regularly to maintain accuracy, as even small discrepancies can impact incubation success.

Placement of monitoring tools is equally important. Position sensors at multiple points within the incubation chamber to account for potential hot or cold spots. Place one sensor near the heat source to monitor its direct output, and another in the center or farthest corner to ensure even distribution. For vertical chambers, consider placing sensors at different heights to detect temperature stratification. This comprehensive approach ensures that the entire incubation space remains within the ideal temperature range, typically between 70°F to 75°F (21°C to 24°C) for most mushroom species.

Integrating real-time alerts with your monitoring system can further enhance temperature control. Many modern sensors and thermometers come with alarm features that notify cultivators when temperatures deviate from the set range. These alerts can be sent via email, text, or app notifications, allowing for swift corrective action even when away from the incubation site. This proactive approach minimizes the risk of temperature-related issues, such as slowed mycelium growth or bacterial contamination, which can be costly and time-consuming to address.

Finally, document temperature data regularly to identify trends and optimize incubation conditions over time. Many digital monitoring tools include data logging features, which record temperature readings at set intervals. Analyzing this data can reveal patterns, such as consistent temperature drops during specific times of day, enabling cultivators to fine-tune their heating systems or insulation. Keeping a detailed log also provides valuable insights for troubleshooting and improving future cultivation cycles, ensuring consistent and reliable mushroom yields.

Mushrooms: Nature's Overnight Pop-Up Wonder

You may want to see also

Humidity Balance: Maintain optimal humidity levels alongside temperature for successful mushroom incubation

Maintaining optimal humidity levels is as crucial as temperature control during mushroom incubation. Mushrooms thrive in environments with high humidity, typically between 90-95%, as this mimics their natural habitat and supports mycelium growth. To achieve this, use a humidifier or place a tray of water inside the incubation chamber. Regularly monitor humidity with a hygrometer, ensuring it stays within the target range. If humidity drops, mist the walls of the chamber lightly with water or add more water to the tray. Conversely, if it’s too high, slightly ventilate the chamber or use a dehumidifier to prevent waterlogging, which can lead to contamination.

The relationship between temperature and humidity is symbiotic; changes in one can affect the other. For instance, higher temperatures can cause evaporation, lowering humidity, while cooler temperatures may reduce evaporation, raising humidity. To balance both, ensure the incubation chamber is well-insulated and use a thermostat-controlled heating mat or lamp to maintain a stable temperature. Pair this with a humidifier or water tray to keep humidity consistent. Regularly check both temperature and humidity levels, especially during extreme weather conditions, to avoid fluctuations that could stress the mycelium.

Proper airflow is essential for humidity balance without compromising sterility. Stagnant air can lead to localized high humidity and condensation, creating pockets of moisture that invite contaminants. Introduce passive airflow by slightly cracking the incubation chamber lid or using a small, sterile fan to circulate air gently. Avoid excessive airflow, as it can dehydrate the substrate and lower humidity. The goal is to create a balanced environment where air moves enough to prevent stagnation but not so much that it disrupts humidity levels.

Substrate preparation also plays a role in maintaining humidity during incubation. Properly hydrated and pasteurized substrates retain moisture better, contributing to stable humidity levels. Before inoculation, ensure the substrate is moist but not soaking wet, as excess water can lead to anaerobic conditions and contamination. After inoculation, cover the substrate with a thin layer of vermiculite or perlite, which helps retain moisture while allowing gas exchange. This layer acts as a buffer, maintaining humidity around the mycelium without oversaturating the environment.

Finally, monitor the incubation environment daily to catch and correct humidity imbalances early. Keep a log of temperature and humidity readings to identify trends and adjust your setup accordingly. For example, if humidity consistently drops overnight, consider adding more water to the tray or increasing the humidifier’s output. Conversely, if condensation frequently forms on the chamber walls, reduce the water source or improve ventilation. Consistent attention to these details ensures a stable, optimal environment for mushroom incubation, fostering healthy mycelium growth and successful fruiting.

Best Practices for Storing Psilocybin Mushrooms

You may want to see also

Frequently asked questions

The ideal incubation temperature for most mushroom species ranges between 70°F to 75°F (21°C to 24°C). However, specific species may have slightly different requirements, so always check the optimal range for the mushroom you’re growing.

Use a thermostat-controlled incubator, heating pad, or seedling heat mat to regulate temperature. Place a thermometer inside the incubation chamber to monitor and adjust as needed to avoid fluctuations.

Yes, if your room temperature naturally stays within the ideal range (70°F to 75°F). However, most environments require supplemental heating or cooling to maintain consistency, especially during seasonal temperature changes.

If the temperature is too high, it can stress the mycelium, slow growth, or even kill it. If it’s too low, growth will be extremely slow or stall entirely. Always aim to keep the temperature within the optimal range for healthy mycelium development.

Check the temperature at least once or twice a day, especially if using manual heating methods. Automated systems with thermostats require less frequent checks but should still be monitored periodically to ensure they’re functioning correctly.