Creating a ceramic mushroom is a rewarding and accessible project for both beginners and experienced potters. The process begins with selecting the right clay, typically a stoneware or earthenware variety, which is then shaped using hand-building techniques or a potter’s wheel. The mushroom’s cap and stem are formed separately, with attention to detail in texture and curvature to mimic the organic look of a real mushroom. Once shaped, the pieces are joined together using scoring and slipping techniques, ensuring a strong bond. After drying to a leather-hard state, the mushroom is refined with tools to smooth edges and add intricate details like gills or surface patterns. Finally, it is fired in a kiln, often with a glaze applied to enhance color and shine, resulting in a charming, handmade ceramic mushroom perfect for decoration or functional use.

| Characteristics | Values |

|---|---|

| Materials Needed | Clay (air-dry or oven-bake), sculpting tools, acrylic paints, varnish, wire (optional), glaze (optional) |

| Difficulty Level | Beginner to Intermediate |

| Time Required | 2-4 hours (plus drying/baking time) |

| Techniques Used | Hand-building, sculpting, painting, glazing (optional) |

| Key Steps | 1. Prepare clay, 2. Shape the stem, 3. Create the cap, 4. Attach stem and cap, 5. Add details (gills, texture), 6. Dry/bake, 7. Paint/glaze, 8. Seal with varnish |

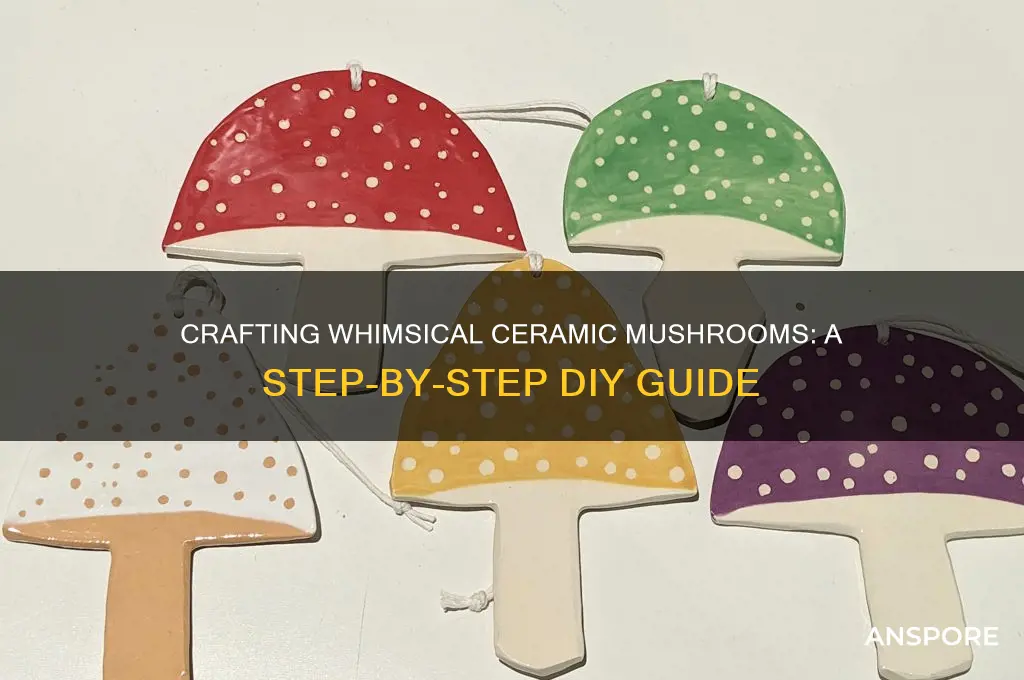

| Design Variations | Realistic, whimsical, abstract, textured, patterned |

| Tools for Details | Toothpicks, brushes, texture mats, carving tools |

| Drying/Baking | Air-dry for 24-48 hours or bake at 212°F (100°C) for 30-60 minutes (follow clay instructions) |

| Finishing Options | Acrylic paints, glaze, metallic accents, matte/gloss varnish |

| Uses | Home decor, garden ornament, gift, art piece |

| Tips | Keep clay moist, use reference images, practice shaping, experiment with colors |

Explore related products

$17.79 $21.99

What You'll Learn

- Gather Materials: Clay, tools, glaze, kiln, and mushroom reference images for accurate shaping

- Sculpt the Cap: Hand-shape or use molds to create the mushroom cap’s curved form

- Form the Stem: Roll and smooth clay into a cylindrical shape for the stem

- Assemble Pieces: Attach cap to stem using scoring, slipping, and firm pressure

- Fire and Glaze: Bisque fire, apply glaze, then final fire for a polished finish

Gather Materials: Clay, tools, glaze, kiln, and mushroom reference images for accurate shaping

To begin your ceramic mushroom project, gathering the right materials is crucial for a successful outcome. Start by selecting a suitable clay body that aligns with your skill level and the desired finish. For beginners, air-dry clay or oven-bake polymer clay can be a great starting point, as they require less specialized equipment. However, for a more durable and professional result, consider using stoneware or porcelain clay, which need to be fired in a kiln. Ensure you have enough clay to account for potential mistakes or additional pieces, as mushrooms often come in clusters. The clay should be wedged properly to remove air bubbles, ensuring a smooth and even texture for shaping.

Next, assemble the necessary tools for sculpting and detailing your mushroom. Basic tools include a pottery needle or wire loop for cutting and shaping the stem and cap, a rib tool for smoothing surfaces, and a sponge for refining edges. For more intricate details, such as gills under the cap or texture on the stem, consider using texture tools, stamps, or even household items like forks or brushes. A wooden modeling tool can also be handy for creating precise indentations or patterns. Keep your tools organized and within reach to streamline the sculpting process.

Glaze is another essential material that will bring your ceramic mushroom to life. Choose glazes that complement the natural colors of mushrooms, such as earthy browns, reds, whites, or greens. Transparent glazes can enhance the texture and details, while opaque glazes provide a more uniform finish. If you’re new to glazing, start with underglazes, which can be applied before firing and allow for more control over color placement. Ensure you have a variety of brushes for applying glaze, including small detail brushes for intricate areas. Remember to check if your glaze is food-safe if you plan to use the mushroom as a decorative piece in a functional setting.

Access to a kiln is necessary if you’re working with traditional ceramic clay. If you don’t own one, consider renting studio time at a local pottery or ceramic arts center. Before firing, ensure your mushroom is thoroughly dried to avoid cracking. Bisque firing, the first firing, hardens the clay, making it easier to handle during glazing. The final glaze firing melts the glaze onto the surface, creating a glossy or matte finish depending on your choice. Follow the kiln’s instructions carefully, including temperature settings and firing duration, to achieve the best results.

Lastly, reference images of mushrooms are invaluable for accurate shaping and detailing. Collect high-quality photos or drawings of various mushroom species to guide your design. Pay attention to the proportions of the cap and stem, the arrangement of gills, and the texture of the mushroom’s surface. Having multiple references allows you to choose a style that suits your artistic vision, whether it’s a realistic Amanita muscaria or a whimsical, stylized design. Keep these images nearby during the sculpting process to ensure your ceramic mushroom captures the essence of its natural counterpart. With all materials gathered and prepared, you’re ready to bring your ceramic mushroom to life.

Easy Homemade Cream of Mushroom Soup Recipe: A Comforting Classic

You may want to see also

Sculpt the Cap: Hand-shape or use molds to create the mushroom cap’s curved form

To sculpt the cap of your ceramic mushroom, you'll first need to decide whether you want to hand-shape it or use a mold. Hand-shaping allows for more creativity and uniqueness, while using a mold ensures consistency and can save time. If you choose to hand-shape the cap, start by preparing a lump of clay, making sure it's moist and free of air bubbles. Wedge the clay to ensure it's pliable and ready to shape. Begin by forming a rough dome shape with your hands, gently pressing and smoothing the clay to create an even curvature.

When hand-shaping the mushroom cap, consider the type of mushroom you're trying to create. Different species have distinct cap shapes, such as convex, flat, or bell-shaped. Use your fingers and a small rib tool to refine the curve, making it more pronounced or subtle depending on your desired style. Work the clay gently to avoid distorting the shape, and periodically check the symmetry by rotating the cap and making adjustments as needed. Remember that the cap should have a smooth, organic flow, so take your time to perfect the curvature.

If you opt to use a mold for the mushroom cap, select or create a mold that matches the desired shape and size. You can make your own mold using materials like plaster or silicone, or purchase pre-made molds designed for ceramic mushrooms. Press the clay firmly into the mold, ensuring it reaches all edges and corners. Smooth the back of the clay (which will be the top of the cap) to create an even surface. Once the clay is in place, carefully remove it from the mold, making sure the curved form remains intact.

After shaping the cap, whether by hand or with a mold, it's essential to refine the edges and blend any seams. Use a sponge or damp cloth to smooth the surface, removing any fingerprints or imperfections. If you're creating a more intricate design, such as gills or a textured surface, now is the time to add those details. For gills, use a thin tool to create radial lines underneath the cap, mimicking the natural structure of a mushroom. Textures can be added using stamps, brushes, or even natural materials like leaves.

Finally, allow the sculpted cap to firm up slightly before attaching it to the stem. This ensures it retains its shape during handling. If you're hand-building the stem, score and slip both the cap and stem surfaces where they'll join, then press them together firmly. For a more polished look, blend the joint seamlessly using a small tool or your fingers. Once the cap is securely attached, let the entire piece dry slowly and evenly to prevent cracking before firing it in the kiln.

Brewing Chaga Mushroom Tea: Simple Steps for Earthy Wellness Elixir

You may want to see also

Form the Stem: Roll and smooth clay into a cylindrical shape for the stem

To form the stem of your ceramic mushroom, begin by preparing a suitable amount of clay. Pinch off a piece of clay that feels right for the size of the mushroom you’re creating. Knead it gently to ensure it’s pliable and free of air bubbles, as this will help achieve a smooth and even shape. Place the clay on a clean, flat surface, and start rolling it between your hands. Apply even pressure as you roll, gradually shaping the clay into a rough cylindrical form. This initial rolling should be done with care to avoid tapering or uneven thickness, as the goal is to create a consistent base for the stem.

Once the clay is roughly cylindrical, transfer it to your work surface and use your palms to roll it back and forth. Keep the motion steady and controlled, applying slight pressure to refine the shape. Focus on maintaining a uniform diameter along the length of the stem, as this will ensure the mushroom looks balanced when completed. If you notice any lumps or irregularities, pause and use your fingers to smooth them out, blending the clay seamlessly into the cylindrical form. This step requires patience, as achieving a perfectly smooth stem is key to the overall aesthetic of the mushroom.

As you continue rolling and smoothing, periodically check the stem from all angles to ensure it remains symmetrical. If one end starts to taper, gently reshape it by rolling it more on that side. For added precision, you can use a flat tool or the edge of a clay rib to lightly compress and smooth the surface, removing any fingerprints or imperfections. The stem should feel firm but not overly dense, as you’ll need to attach it to the mushroom cap later. Aim for a length and thickness that proportionally complements the cap you plan to create.

Once the stem is smooth and cylindrical, take a moment to refine the ends. Slightly taper the bottom end to create a natural base, as this will mimic the organic shape of a real mushroom stem. The top end, where the cap will attach, should remain flat or slightly rounded, depending on your design. If needed, use a small tool or your finger to gently shape these areas. Ensure the clay is free of cracks or weak spots, as these could cause issues during drying or firing.

Finally, set the completed stem aside to firm up slightly while you work on the mushroom cap. This brief resting period will make the stem easier to handle during assembly. If you’re creating multiple mushrooms, repeat the process for each stem, ensuring consistency in size and shape. Properly formed stems will not only enhance the visual appeal of your ceramic mushrooms but also provide a sturdy foundation for the caps, ensuring the final pieces are both beautiful and functional.

Crafting a Delicious 1up Mushroom Cake: A Gamer's Sweet Adventure

You may want to see also

Explore related products

Assemble Pieces: Attach cap to stem using scoring, slipping, and firm pressure

To assemble the ceramic mushroom, begin by preparing both the cap and the stem for attachment. Scoring is the first crucial step in this process. Take a sharp tool, such as a needle tool or a rib, and gently scratch the surfaces of the cap and stem where they will join. Scoring creates small grooves in the clay, increasing the surface area for better adhesion. Focus on the base of the cap and the top of the stem, ensuring the scored areas are clean and free of dust. This step is essential for a strong bond, as it allows the clay particles to interlock more effectively.

Next, apply slipping to the scored areas. Slip is a thin mixture of clay and water, acting as a glue for ceramic pieces. Using a brush, generously coat both the scored surface of the cap and the stem with slip. Ensure the slip is evenly distributed and covers all the grooves created during scoring. The slip will help fuse the two pieces together as the clay dries and during firing. Be mindful not to use too much slip, as excess can create a messy joint or weaken the bond if it doesn’t dry properly.

Once both pieces are scored and slipped, carefully align the cap and stem. Position the cap onto the stem, ensuring it sits straight and centered. This step requires precision, as misalignment can be difficult to correct once the pieces are attached. Gently press the cap onto the stem, allowing the slip to act as a binding agent. Take your time to confirm the cap is level and secure before applying pressure.

With the pieces aligned, apply firm pressure to the joint. Use your hands or a small tool to press the cap firmly onto the stem, ensuring the scored and slipped surfaces are fully in contact. This pressure helps remove any air bubbles and creates a tight seal. Hold the pieces together for a few moments to allow the slip to begin setting. If needed, use a rib or sponge to smooth out any excess slip around the joint, creating a clean and seamless connection.

Finally, let the assembled mushroom dry slowly and evenly to avoid cracking. Place it in a safe area where it won’t be disturbed, and cover it loosely with plastic to maintain moisture during the drying process. Once dry, the mushroom will be ready for further detailing, bisque firing, and glazing. By following these steps—scoring, slipping, and applying firm pressure—you ensure a strong and durable bond between the cap and stem, resulting in a beautifully crafted ceramic mushroom.

Perfectly Crispy Fried Mushrooms: Easy Recipe for Ultimate Crunch

You may want to see also

Fire and Glaze: Bisque fire, apply glaze, then final fire for a polished finish

Once your ceramic mushroom has been shaped, dried, and is ready for its first firing, the process of bringing it to a polished, glazed finish begins. The first step is the bisque firing, a crucial stage where the piece is fired at a lower temperature to remove any remaining moisture and bind the clay particles together. This firing typically occurs at around 1830°F (999°C) and can take several hours, depending on the size of the mushroom and the kiln. It’s essential to ensure the mushroom is completely dry before bisque firing to avoid cracking or exploding in the kiln. After the firing, allow the piece to cool slowly inside the kiln to prevent thermal shock. The result is a porous, matte-finished mushroom ready for glazing.

With the bisque firing complete, the next step is to apply the glaze, which will give your mushroom its final color, shine, and durability. Choose a glaze that suits your design—whether it’s a natural earthy tone or a vibrant, whimsical color. Before glazing, lightly sand any rough spots on the mushroom’s surface to ensure a smooth finish. Dip, brush, or spray the glaze onto the piece, ensuring even coverage. Be mindful of the thickness of the glaze layer; too much can cause drips or uneven pooling, while too little may result in a patchy finish. Wipe the bottom of the mushroom clean to prevent it from sticking to the kiln shelf during the final firing. Allow the glaze to dry completely before proceeding.

The final firing, also known as the glaze firing, is where the magic happens. This firing takes place at a higher temperature, typically between 2232°F and 2345°F (1222°C and 1285°C), depending on the glaze used. During this stage, the glaze melts and bonds to the clay body, creating a glossy, waterproof surface. The kiln must be programmed to ramp up to the correct temperature gradually and then hold at that temperature for a specific duration to ensure the glaze matures properly. After the firing, the kiln must cool down slowly to avoid shocking the glaze and causing cracks or crazing. This process can take as long as the firing itself, so patience is key.

Once the kiln has cooled completely, carefully remove your ceramic mushroom. Inspect it for any defects, such as uneven glaze application or kiln marks. If the piece has turned out as desired, it’s ready for display or use. The glazed finish not only enhances its aesthetic appeal but also makes it functional, as it can now hold small items or simply serve as a decorative piece. Properly executed firing and glazing ensure your ceramic mushroom is both beautiful and durable, ready to bring a touch of handmade charm to any space.

Throughout the firing and glazing process, safety is paramount. Always wear protective gear, such as heat-resistant gloves, when handling hot kiln shelves or freshly fired pieces. Additionally, ensure proper ventilation when applying glazes, as some contain chemicals that can be harmful if inhaled. With attention to detail and care at each stage, your ceramic mushroom will emerge from the kiln as a polished, professional-quality piece that showcases your creativity and craftsmanship.

Mushroom Coffee Buzz: Energy, Focus, and Calm Explained

You may want to see also

Frequently asked questions

You will need clay (air-dry or kiln-fired), a pottery toolset (including a wire cutter, rib tool, and sponge), acrylic paints or glazes, a paintbrush, and optionally a texture tool or stamp for added detail.

For the cap, roll a ball of clay and flatten it slightly, then shape it into a dome or umbrella form. For the stem, roll a cylinder or tapered shape and attach it to the underside of the cap using scoring and slipping techniques.

Yes, use texture tools, stamps, or even natural items like leaves to press patterns into the clay before it dries. You can also carve details with a tool or add small clay pieces for gills or spots.

Air-dry clay can be left to dry naturally for 24–48 hours. For kiln-fired clay, let it dry slowly to avoid cracking, then bisque fire it, glaze if desired, and fire again according to the clay and glaze instructions.

If using acrylic paint, wait until the clay is completely dry, then apply 2–3 thin coats. For glaze, apply after the bisque firing, ensuring even coverage, and follow the manufacturer’s firing instructions for the final kiln firing.