Creating a concrete mushroom is a unique and rewarding DIY project that combines artistry with practicality, offering a durable and decorative addition to gardens or outdoor spaces. The process involves crafting a mold, typically from materials like silicone or plastic, to shape the mushroom’s cap and stem, followed by mixing and pouring concrete into the mold. Once the concrete sets and cures, the mold is removed, revealing a sturdy mushroom structure that can be painted or left natural for a rustic look. This project not only allows for creative expression but also results in a long-lasting piece that withstands outdoor elements, making it a popular choice for garden enthusiasts and crafters alike.

| Characteristics | Values |

|---|---|

| Materials Needed | Concrete mix, water, mushroom mold (silicone or plastic), cooking oil or mold release agent, paint or sealant (optional), gloves, mixing tools, trowel, sandpaper |

| Mold Types | Silicone (reusable, flexible), plastic (single-use, affordable), custom-made (for unique designs) |

| Concrete Mix | Quick-setting concrete mix recommended for faster curing |

| Mixing Ratio | Follow manufacturer's instructions (typically 1 part concrete mix to 1 part water by volume) |

| Mold Preparation | Apply cooking oil or mold release agent to prevent sticking |

| Pouring Technique | Pour concrete mix into mold, tapping gently to remove air bubbles |

| Curing Time | 24-48 hours (depends on concrete mix and environmental conditions) |

| Demolding | Carefully remove mushroom from mold after curing, avoid forcing it out |

| Finishing | Sand rough edges with sandpaper, paint or seal for desired finish |

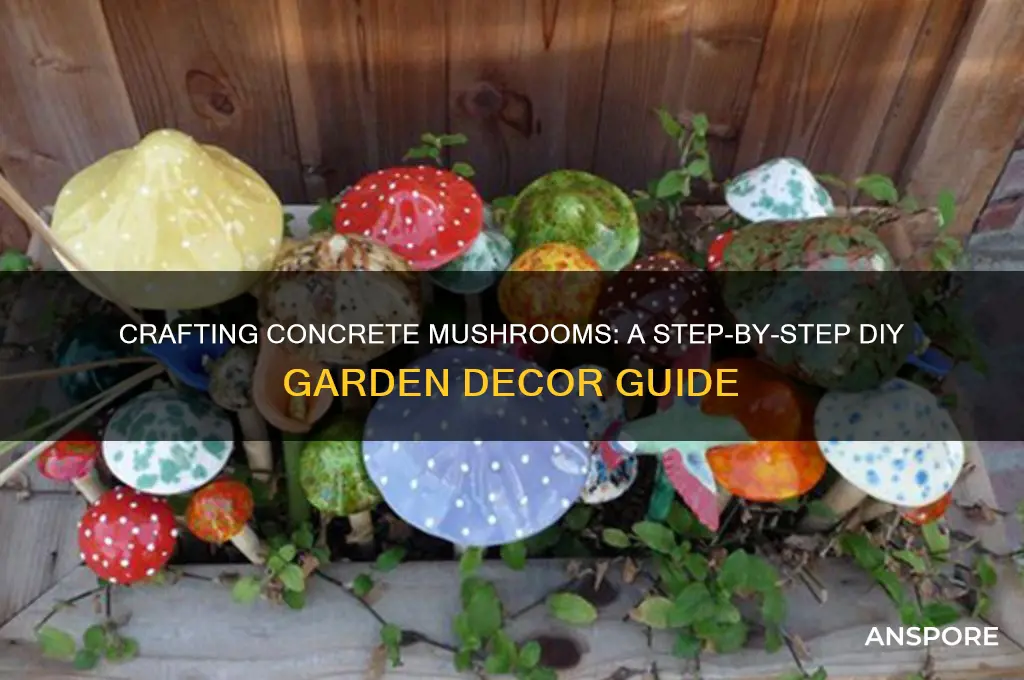

| Design Variations | Different mold shapes, colors, textures, and sizes for customization |

| Outdoor Use | Seal with outdoor-rated sealant to protect against weather |

| Cost | Low to moderate (depends on materials and mold choice) |

| Skill Level | Beginner-friendly, minimal experience required |

| Time Commitment | 1-2 days (including curing time) |

| Safety Precautions | Wear gloves, work in well-ventilated area, avoid contact with skin and eyes |

| Maintenance | Minimal, occasional cleaning and resealing if used outdoors |

Explore related products

What You'll Learn

- Materials Needed: Cement, water, sand, mold, gloves, mask, mixing tools, release agent, sealant

- Creating the Mold: Use silicone or plastic molds, ensure smooth interior, apply release agent for easy removal

- Mixing Concrete: Combine cement, sand, water in 1:2:1 ratio, mix until smooth, avoid lumps

- Casting Process: Pour mixture into mold, vibrate to remove air bubbles, let cure for 24 hours

- Finishing Touches: Demold carefully, sand rough edges, seal with waterproof coating, paint if desired

Materials Needed: Cement, water, sand, mold, gloves, mask, mixing tools, release agent, sealant

To begin crafting your concrete mushroom, you’ll need cement, the primary binding material. Choose a high-quality Portland cement for durability and a smooth finish. Water is essential for mixing the cement, but use it sparingly to achieve the right consistency—a thick, paste-like mixture is ideal. Sand acts as an aggregate, providing texture and strength to the concrete. Opt for fine to medium-grained sand for a smoother surface. These three ingredients form the base of your concrete mixture, so ensure they are measured accurately for a successful project.

Next, you’ll require a mold to shape your mushroom. Silicone molds are highly recommended due to their flexibility and ease of release. You can find pre-made mushroom molds online or create your own using silicone and a 3D-printed or sculpted model. Ensure the mold is clean and dry before use. Additionally, prepare a release agent, such as cooking spray or mold release spray, to prevent the concrete from sticking to the mold. This step is crucial for achieving a clean, detailed final product.

Safety should never be overlooked, so equip yourself with gloves and a mask. Gloves protect your skin from the caustic nature of wet cement, while a mask prevents inhalation of cement dust during mixing. For mixing, gather tools like a shovel, trowel, or a mixing paddle if using a drill. These tools ensure thorough blending of the cement, sand, and water. A large mixing container, such as a wheelbarrow or plastic tub, is also necessary to accommodate the materials.

Once your mushroom is molded and cured, a sealant is essential to protect the concrete from moisture and weathering. Choose a concrete sealant suitable for outdoor use, especially if your mushroom will be displayed outside. Apply the sealant evenly with a brush or sprayer, following the manufacturer’s instructions. This final step enhances longevity and maintains the mushroom’s appearance over time.

In summary, the materials needed—cement, water, sand, mold, gloves, mask, mixing tools, release agent, and sealant—are all critical components of creating a durable and visually appealing concrete mushroom. Each item plays a specific role, from forming the structure to ensuring safety and longevity. With these materials on hand, you’re well-prepared to bring your concrete mushroom project to life.

Juicy Mushroom and Halloumi Burgers: A Step-by-Step Recipe Guide

You may want to see also

Creating the Mold: Use silicone or plastic molds, ensure smooth interior, apply release agent for easy removal

When creating a mold for your concrete mushroom, the choice of material is crucial. Silicone and plastic molds are highly recommended due to their flexibility and durability. Silicone molds, in particular, are ideal because they can withstand the weight and pressure of concrete while allowing for easy removal of the finished piece. Plastic molds are also a good option, especially for larger projects, as they are cost-effective and readily available. Ensure that the mold you select has a smooth interior surface, as this will directly affect the texture and finish of your concrete mushroom. Any imperfections or rough spots in the mold will be replicated in the final product, so take the time to inspect and smooth out the mold before use.

To achieve a smooth interior, consider sanding or polishing the mold's surface if necessary. For silicone molds, you can use a fine-grit sandpaper to gently smooth out any seams or imperfections. If you're working with a plastic mold, you might need to apply a thin layer of epoxy or resin to create a seamless surface. This step is essential, as it ensures that your concrete mushroom will have a professional, polished appearance. Additionally, a smooth mold interior facilitates the release of the cured concrete, reducing the risk of damage during the demolding process.

Before pouring the concrete mixture into the mold, it's imperative to apply a release agent to ensure easy removal. A release agent creates a barrier between the mold and the concrete, preventing them from bonding together. Common release agents include cooking oil, petroleum jelly, or specialized mold release sprays. For silicone molds, a light coating of cooking oil or mold release spray is usually sufficient. When using plastic molds, you may need to apply a thicker layer of petroleum jelly or a similar product to guarantee a clean release. Be sure to follow the manufacturer's instructions for the specific release agent you choose, as application methods may vary.

The application process for the release agent is straightforward but requires attention to detail. Use a soft brush or cloth to evenly coat the entire interior surface of the mold, ensuring complete coverage. Pay particular attention to corners, edges, and any intricate details, as these areas are more prone to sticking. Allow the release agent to dry or set according to the product instructions before proceeding with the concrete pouring. This waiting period is crucial, as it ensures that the release agent forms a stable barrier, minimizing the risk of mold damage or concrete adhesion.

After applying the release agent, carefully inspect the mold to confirm that it's ready for use. Check for any missed spots or uneven coverage, and address these issues before pouring the concrete. Once you're satisfied with the mold preparation, you can proceed with mixing and pouring the concrete. Remember that the quality of your mold and the effectiveness of the release agent will significantly impact the success of your project. By taking the time to create a smooth, well-prepared mold and applying a suitable release agent, you'll be well on your way to crafting a beautiful and durable concrete mushroom.

Creamy Malai Mushroom Recipe: Easy Steps for Rich, Flavorful Delight

You may want to see also

Mixing Concrete: Combine cement, sand, water in 1:2:1 ratio, mix until smooth, avoid lumps

When embarking on the task of creating a concrete mushroom, the foundation lies in mastering the art of mixing concrete. The process begins with gathering your materials: cement, sand, and water. The key to a successful mixture is adhering to the 1:2:1 ratio of cement to sand to water. This ratio ensures that the concrete is not only strong but also workable, which is crucial for molding it into the desired mushroom shape. Start by measuring out one part of cement, followed by two parts of sand, ensuring that both are dry and free from any debris. This precision in measurement is vital for achieving the consistency needed for your project.

Once you have your dry components ready, it’s time to introduce water, the final part of the 1:2:1 ratio. Gradually add one part of water to the cement and sand mixture, stirring continuously as you pour. The goal is to achieve a smooth, homogeneous consistency without any lumps. Lumps can weaken the concrete and make it difficult to mold, so it’s essential to mix thoroughly. Use a shovel or a mixing tool to combine the ingredients, ensuring that the water is evenly distributed throughout the mixture. If you notice any dry pockets of cement or sand, continue mixing until they are fully incorporated.

As you mix, pay attention to the texture of the concrete. It should be thick enough to hold its shape but still pliable enough to be molded. If the mixture appears too dry and crumbly, add a small amount of water, a little at a time, until you reach the desired consistency. Conversely, if the mixture is too wet and runny, it may not hold its shape well, so you can add a bit more sand or cement to balance it out. The key is to find the perfect balance that allows the concrete to be both strong and moldable.

Avoiding lumps is crucial for the structural integrity of your concrete mushroom. Lumps can create weak spots in the finished product, making it prone to cracking or breaking. To ensure a lump-free mixture, take your time during the mixing process. If you encounter any lumps, break them apart with your mixing tool or by hand, and continue to stir until the mixture is smooth. This step may require a bit of patience, but it is well worth the effort to ensure a high-quality end result.

Finally, once your concrete is mixed to perfection, it’s ready to be molded into the shape of a mushroom. The smooth, lump-free consistency will make it easier to work with, allowing you to achieve the intricate details of the mushroom cap and stem. Remember, the quality of your concrete mixture directly impacts the durability and appearance of your final creation. By carefully combining cement, sand, and water in the 1:2:1 ratio and ensuring a smooth, lump-free consistency, you’ll be well on your way to crafting a stunning and long-lasting concrete mushroom.

Vahchef's Mushroom Biryani: A Flavorful Step-by-Step Recipe Guide

You may want to see also

Explore related products

Casting Process: Pour mixture into mold, vibrate to remove air bubbles, let cure for 24 hours

The casting process is a crucial step in creating a concrete mushroom, as it determines the final shape, texture, and overall quality of the finished product. To begin, prepare your concrete mixture according to the desired consistency and color, ensuring it is well-combined and free of lumps. Once the mixture is ready, slowly pour it into the prepared mold, taking care to fill all the crevices and details of the mushroom shape. It is essential to work efficiently, as the concrete will start to set relatively quickly. As you pour, pay attention to the mold's capacity and avoid overfilling, as this can lead to uneven curing and potential cracks.

After pouring the mixture into the mold, the next step is to vibrate it to remove any trapped air bubbles. Air bubbles can weaken the concrete and create an uneven surface, so it's vital to eliminate them. You can use a vibrating tool, such as a concrete vibrator or even a handheld massager, to gently vibrate the mold. Start at a low setting and gradually increase the intensity, ensuring the vibration reaches all areas of the mold. This process should be done for about 2-3 minutes, or until you see the concrete mixture settle and any air bubbles rise to the surface. Be cautious not to over-vibrate, as this may cause the mold to shift or the concrete to spill out.

Vibrating the mold not only removes air bubbles but also helps consolidate the concrete, ensuring a denser and more durable final product. As the vibration settles the mixture, you may notice some excess concrete rising to the top. Carefully scrape off this excess, leaving a smooth and level surface. This step is essential for achieving a clean and professional finish on your concrete mushroom. Once you're satisfied with the vibration and leveling, it's time to let the concrete cure.

Curing is a critical phase in the casting process, allowing the concrete to harden and gain strength. After vibrating and leveling, cover the mold with a plastic sheet or damp cloth to retain moisture, which is essential for proper curing. Place the mold in a cool, dry area, away from direct sunlight and extreme temperatures. Let the concrete cure for at least 24 hours; this duration ensures the mixture sets adequately and achieves its initial strength. During this time, the concrete will undergo a chemical reaction, hardening and becoming more robust.

After the initial 24-hour cure, carefully remove the plastic covering and check the concrete's progress. The surface should appear drier, and the mushroom shape should be more defined. At this point, you can gently tap the mold to release the concrete mushroom. If it doesn't come out easily, allow it to cure for a few more hours before trying again. Proper curing is essential to prevent cracking and ensure the longevity of your concrete creation. Once demolded, your concrete mushroom can be further cured for several days to reach its maximum strength, ready for display or use in your garden or outdoor space.

Zesty Lemon Mushroom Recipe: A Quick, Flavorful, and Easy Dish

You may want to see also

Finishing Touches: Demold carefully, sand rough edges, seal with waterproof coating, paint if desired

Once your concrete mushroom has fully cured, typically after 24 to 48 hours, it’s time to carefully demold it. Start by gently tapping the sides and bottom of the mold to loosen the concrete. If the mold is made of silicone, flex it slightly to help release the mushroom. Avoid forcing the mold apart, as this can damage the delicate details of your creation. Slowly and patiently remove the mold pieces, ensuring no part of the concrete gets stuck. If the mushroom has a stem and cap molded separately, take extra care when separating these sections to avoid breakage. Once demolded, inspect the mushroom for any initial imperfections or areas that need attention.

After demolding, you’ll likely notice rough edges or uneven surfaces where the mold seams were. Use sandpaper to smooth these areas, starting with a medium grit (around 120-grit) and progressing to a finer grit (220-grit or higher) for a polished finish. Pay special attention to the edges of the mushroom cap and the base of the stem, as these areas often require the most sanding. Be mindful not to sand too aggressively, as concrete can be delicate when freshly cured. Wipe away dust with a damp cloth after sanding to prepare the surface for sealing.

Sealing your concrete mushroom is crucial to protect it from moisture and weathering, especially if it will be displayed outdoors. Apply a waterproof concrete sealer using a brush or spray bottle, ensuring even coverage over the entire surface. Pay attention to crevices and detailed areas, as these spots can be prone to water absorption. Allow the first coat to dry according to the manufacturer’s instructions, then apply a second coat for added protection. A properly sealed mushroom will maintain its appearance and structural integrity for years to come.

If you wish to add color or personality to your mushroom, painting is the next step. Use outdoor acrylic paints or concrete-specific paints for durability. Start by applying a base coat and let it dry completely. For a more realistic look, consider adding shades of red, brown, or white to mimic natural mushroom colors. Use small brushes for detailed areas, such as the gills or spots on the cap. If you prefer a more whimsical design, feel free to experiment with bright colors or patterns. Once the paint is dry, apply a clear, waterproof sealant over the painted surface to protect your artwork.

Finally, inspect your finished concrete mushroom for any last-minute touch-ups. Ensure all edges are smooth, the sealant is evenly applied, and the paint is vibrant and chip-free. If you’ve created a multi-piece mushroom (e.g., a separate stem and cap), securely attach the pieces using a strong adhesive suitable for outdoor use. Place your mushroom in its desired location, whether it’s a garden, patio, or indoor space, and admire your handiwork. With proper care, your concrete mushroom will be a charming and durable addition to any setting.

Delicious Mushroom Lasagna: A Step-by-Step Recipe Guide

You may want to see also

Frequently asked questions

You will need concrete mix, water, a mold (silicone or plastic), a mixing container, a trowel, gloves, a wire brush, and optionally, paint or sealant for finishing.

You can use a silicone mold specifically designed for mushrooms or create your own by sculpting a mushroom shape from clay or modeling material, then casting it with silicone.

A fine-grained concrete mix or cement mix with sand works best for detailed shapes like mushrooms. Avoid coarse aggregates for a smoother finish.

It typically takes 24–48 hours for the concrete to set, but full curing can take up to 28 days. Keep it moist and covered during the initial curing period.

Yes, once fully cured, you can paint it with outdoor acrylic paint or use a sealant to protect it from weather. Allow the paint to dry completely before sealing.