Creating a dehydrator for mushrooms is a practical and cost-effective way to preserve their flavor and nutrients for extended periods. By removing moisture, dehydration prevents spoilage and concentrates the mushrooms' umami taste, making them ideal for soups, stews, or snacks. Building your own dehydrator can be accomplished using simple materials like a cardboard box, a heating element such as a light bulb or hairdryer, and a fan for airflow. This DIY approach allows you to control the drying process, ensuring your mushrooms are perfectly preserved while also offering a satisfying hands-on project for enthusiasts of both cooking and crafting.

| Characteristics | Values |

|---|---|

| Materials Needed | Cardboard box, wire rack, light bulb (40-60W), thermometer, fan (optional) |

| Box Size | Medium to large (e.g., 12x12x12 inches) |

| Light Bulb Type | Incandescent (40-60W) for gentle heat |

| Temperature Range | 120-140°F (49-60°C) |

| Drying Time | 6-12 hours (depending on mushroom thickness) |

| Airflow | Natural or assisted with a small fan |

| Mushroom Preparation | Clean and slice mushrooms thinly (1/4 inch or less) |

| Rack Placement | Wire racks placed inside the box for even drying |

| Monitoring | Use a thermometer to maintain optimal temperature |

| Storage | Store dried mushrooms in airtight containers in a cool, dark place |

| Cost | Low-cost DIY project (under $20) |

| Energy Efficiency | Moderate (uses a single light bulb) |

| Scalability | Can be scaled up with larger boxes or multiple units |

| Safety Tips | Avoid overheating; ensure proper ventilation to prevent mold |

| Alternative Heat Sources | Heating pad or small space heater (if light bulb is unavailable) |

| Environmental Impact | Eco-friendly, minimal energy use compared to commercial dehydrators |

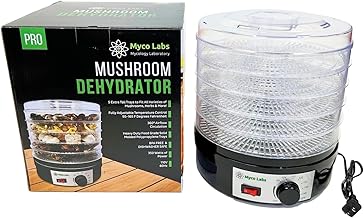

Explore related products

What You'll Learn

- Materials Needed: Gather wood, mesh screens, heating element, fan, thermostat, and insulation for construction

- Design Basics: Plan size, airflow, temperature control, and insulation to ensure efficient drying

- Assembly Steps: Build frame, install shelves, attach fan and heating element, add thermostat

- Temperature Control: Set thermostat to 120-140°F for safe, effective mushroom dehydration

- Usage Tips: Slice mushrooms evenly, place on trays, monitor drying time, and store properly

Materials Needed: Gather wood, mesh screens, heating element, fan, thermostat, and insulation for construction

To begin constructing your mushroom dehydrator, you'll need to gather several essential materials. The foundation of your dehydrator will be the wood, which serves as the frame and structure. Opt for untreated, food-safe wood such as pine or cedar to avoid any chemical contamination. You’ll need wooden boards for the sides, top, and bottom of the dehydrator, as well as smaller pieces for internal supports. Ensure the wood is cut to precise measurements to fit your desired dehydrator size, typically around 2x2 feet for a small-scale unit. The wood should be sturdy enough to hold the weight of the mushrooms and the other components.

Next, mesh screens are crucial for holding the mushrooms during the drying process. Stainless steel or food-grade plastic mesh screens are ideal, as they allow proper airflow while supporting the mushrooms. The mesh should be fine enough to prevent small mushroom pieces from falling through but large enough to permit air circulation. You’ll need multiple screens to create layers within the dehydrator, maximizing drying capacity. Ensure the mesh fits snugly within the wooden frame to avoid any gaps that could hinder airflow.

A heating element is the core component responsible for generating the warm air needed to dry the mushrooms. A simple and effective option is a low-wattage heating element, such as those found in small space heaters or specifically designed for dehydrators. The heating element should be positioned at the bottom of the dehydrator to ensure even heat distribution. It’s essential to choose a heating element with a wattage suitable for your dehydrator size, typically ranging from 250 to 500 watts for a small unit.

Proper air circulation is achieved with a fan, which helps distribute warm air evenly throughout the dehydrator. A small, low-power fan, such as a computer case fan or a muffin fan, works well for this purpose. The fan should be mounted near the heating element to draw warm air upward through the mesh screens. Ensure the fan is rated for continuous operation and is securely attached to the wooden frame to avoid vibrations or noise.

To maintain the ideal temperature for drying mushrooms (around 120-140°F), a thermostat is indispensable. You can use a simple analog thermostat or a digital temperature controller, depending on your preference and budget. The thermostat should be connected to both the heating element and the fan, allowing it to regulate the temperature by turning the heat on or off as needed. Place the thermostat sensor inside the dehydrator to accurately monitor the internal temperature.

Finally, insulation is critical to retain heat and improve energy efficiency. Use foam board insulation or rigid foam panels to line the interior walls of the dehydrator. This prevents heat loss and ensures consistent drying conditions. The insulation should be secured in place with adhesive or staples, taking care not to block airflow or damage the heating element. Proper insulation will also help maintain a stable temperature, reducing the workload on the heating element and thermostat. With these materials gathered, you’ll be well-prepared to construct a functional and efficient mushroom dehydrator.

Perfectly Crispy Fried Mushrooms: Easy Recipe for Ultimate Crunch

You may want to see also

Design Basics: Plan size, airflow, temperature control, and insulation to ensure efficient drying

When designing a dehydrator for mushrooms, the first consideration is size. The dimensions of your dehydrator should align with the volume of mushrooms you plan to dry and the space available. A common DIY approach is to use a wooden or plastic box with a capacity of 1x1x2 feet, which can accommodate several trays of mushrooms. Ensure the size allows for adequate spacing between trays to promote even airflow. If you intend to scale up production, consider a modular design that allows for additional trays or sections to be added as needed.

Airflow is critical for efficient drying, as it prevents moisture buildup and ensures uniform drying across all trays. Design your dehydrator with a fan placed at the bottom or top to create a steady flow of air. A low-power computer fan or a small household fan works well for this purpose. Position the fan to draw air in from one side, pass it through the trays, and exhaust it out the opposite side. Incorporate vents or mesh screens on the intake and exhaust sides to maintain airflow while keeping insects out. Proper airflow reduces drying time and minimizes the risk of mold or uneven drying.

Temperature control is another key factor in mushroom dehydration. Mushrooms dry best at temperatures between 120°F and 140°F (49°C to 60°C). Use a thermostat-controlled heating element, such as a light bulb or heating pad, to maintain this range. For a simple setup, a 60-watt incandescent bulb can provide sufficient heat in a small dehydrator. Pair the heating element with a thermostat or a dimmer switch to regulate temperature accurately. Avoid overheating, as it can cook the mushrooms instead of drying them, compromising their texture and flavor.

Insulation is essential to retain heat and improve energy efficiency. Line the interior walls of your dehydrator with insulating material such as foam board, polystyrene, or even thick layers of cardboard. This prevents heat loss and ensures the temperature remains consistent throughout the drying process. Additionally, insulate the door or lid to minimize heat escape when checking on the mushrooms. Proper insulation not only speeds up drying but also reduces energy consumption, making your dehydrator more cost-effective to operate.

Finally, integrate these design basics into a cohesive plan. Start by sketching a layout that incorporates the size, airflow system, heating element, and insulation. Use materials like wood, plastic, or even repurposed items like old coolers or storage boxes to construct the dehydrator. Test the airflow and temperature control mechanisms before loading the trays with mushrooms. By carefully planning these elements, you can create a dehydrator that efficiently dries mushrooms while preserving their quality and nutritional value.

Mastering Chinese Mushroom Recipes: Simple Steps for Authentic Flavors

You may want to see also

Assembly Steps: Build frame, install shelves, attach fan and heating element, add thermostat

To begin building your mushroom dehydrator, start by constructing a sturdy frame that will serve as the foundation for the entire unit. Use materials like wood or PVC pipes, ensuring the dimensions are suitable for the space you have and the amount of mushrooms you plan to dehydrate. Typically, a rectangular or square shape works well. Cut the materials to size, ensuring all corners are square and edges are smooth. Assemble the frame using screws or brackets for added stability. The frame should be strong enough to support the shelves, fan, and heating element, so double-check all joints and connections before proceeding.

Next, install the shelves inside the frame, ensuring they are evenly spaced to allow proper airflow around the mushrooms. Use food-safe materials like stainless steel or plastic-coated wire racks for the shelves. Measure the internal dimensions of the frame and cut the shelving material to fit snugly. Secure the shelves to the frame using screws or brackets, making sure they are level and can bear the weight of the mushrooms. Aim for a spacing of 4-6 inches between shelves to allow adequate air circulation, which is crucial for even dehydration.

Once the shelves are in place, attach the fan and heating element to create the necessary airflow and warmth for dehydration. Position the fan at one end of the dehydrator, typically at the bottom or top, to draw air in or push it out. Secure the fan using screws or brackets, ensuring it is firmly attached to the frame. Next, install the heating element, such as a low-wattage light bulb or a heating coil, near the fan but not directly in its airflow path. This setup ensures the air is warmed as it circulates through the dehydrator. Use heat-resistant materials and follow safety guidelines when wiring the heating element to avoid fire hazards.

After setting up the fan and heating element, add a thermostat to maintain the optimal temperature range for dehydrating mushrooms, typically between 120°F and 140°F (49°C and 60°C). Choose a thermostat with a probe that can be placed inside the dehydrator to monitor the temperature accurately. Mount the thermostat on the outside of the frame, ensuring the probe reaches the center of the unit. Connect the thermostat to the heating element and fan according to the manufacturer’s instructions, allowing it to control the power to these components. Test the thermostat to ensure it turns the heating element on and off at the desired temperature settings.

Finally, assemble any remaining components, such as a door or lid, to enclose the dehydrator and retain heat. Use a lightweight material like plywood or acrylic for the door, ensuring it fits snugly within the frame to minimize heat loss. Attach hinges and a latch to secure the door in place. If desired, add a window to the door to monitor the mushrooms without opening the dehydrator and releasing heat. Once all components are assembled, test the dehydrator by running it for a short period to ensure the fan, heating element, and thermostat are functioning correctly. With these assembly steps completed, your mushroom dehydrator is ready for use.

Easy Homemade Fresh Mushroom Sauce Recipe for Perfect Pasta Dishes

You may want to see also

Explore related products

Temperature Control: Set thermostat to 120-140°F for safe, effective mushroom dehydration

Temperature control is a critical aspect of dehydrating mushrooms, and setting your thermostat to the correct range ensures both safety and effectiveness. The ideal temperature for dehydrating mushrooms falls between 120°F and 140°F (49°C to 60°C). This range is low enough to preserve the mushrooms' nutrients and flavor while high enough to efficiently remove moisture and prevent bacterial or mold growth. Temperatures below 120°F may not dry the mushrooms thoroughly, leading to spoilage, while temperatures above 140°F can cause case hardening, where the exterior dries too quickly, trapping moisture inside and creating an environment for mold.

To achieve precise temperature control, you’ll need a thermostat-controlled heating element in your DIY dehydrator. This can be as simple as using an electric heating pad, a light bulb, or a heating element paired with a thermostat. Ensure the thermostat is calibrated correctly to maintain the 120°-140°F range consistently. If using a light bulb, choose one with the appropriate wattage (e.g., 40W to 75W) and pair it with a dimmer switch to adjust the heat output. For heating pads, select one with adjustable settings or use a separate thermostat to regulate the temperature.

Monitoring the temperature is equally important. Use a reliable thermometer or a digital temperature probe placed inside the dehydrator to ensure the heat remains within the desired range. Fluctuations in temperature can affect drying time and quality, so check the thermometer periodically, especially during the first few hours of dehydration. If your dehydrator setup allows, place the thermometer near the center of the drying trays, as this is where temperature variations are most likely to occur.

Airflow is another factor that interacts with temperature control. Proper airflow ensures even drying and helps maintain consistent temperatures across all trays. If your dehydrator has a fan, position it to circulate air evenly without blowing directly on the mushrooms, as this can cause uneven drying. Without a fan, ensure the dehydrator has vents to allow moist air to escape and fresh air to enter, supporting the drying process while the thermostat keeps the temperature steady.

Finally, adjust the temperature based on humidity and mushroom thickness. In high-humidity environments, you may need to set the thermostat closer to 140°F to compensate for slower drying. For thinner mushroom slices, a lower temperature around 120°F is sufficient and reduces the risk of over-drying. Thicker slices may require the higher end of the range to ensure thorough dehydration. Always test your dehydrator with a small batch of mushrooms to fine-tune the temperature settings before drying larger quantities.

Crafting Perfect Grain Jars for Mushroom Cultivation: A Step-by-Step Guide

You may want to see also

Usage Tips: Slice mushrooms evenly, place on trays, monitor drying time, and store properly

When preparing mushrooms for dehydration, slicing them evenly is crucial for consistent drying. Aim for slices between ¼ to ½ inch thick, depending on the mushroom size. Uniform thickness ensures that all pieces dry at the same rate, preventing some from becoming over-dried or under-dried. Use a sharp knife and a steady hand to achieve even slices. For smaller mushrooms, consider cutting them in half or leaving them whole if they are particularly tiny. Consistency in slicing not only improves the drying process but also makes the mushrooms easier to rehydrate and use later.

Once sliced, place the mushrooms on trays designed for your dehydrator. Ensure the pieces are laid out in a single layer, avoiding overlapping or overcrowding. Proper airflow is essential for even drying, so leave a small gap between each slice. If using a homemade dehydrator, such as one made from a cardboard box or an oven, line the trays with parchment paper or mesh sheets to prevent sticking and allow air to circulate. Rotate the trays periodically during the drying process, especially if your dehydrator has uneven heat distribution, to ensure all mushrooms dry uniformly.

Monitoring drying time is key to achieving perfectly dehydrated mushrooms. The drying process typically takes 6 to 12 hours, depending on the dehydrator’s temperature and humidity levels. Start by setting the dehydrator to a low temperature, around 125°F to 135°F, to preserve the mushrooms’ flavor and nutrients. Check the mushrooms every few hours, testing for dryness by bending a piece—it should snap easily without being brittle. If they feel leathery or pliable, continue drying. Over-drying can make mushrooms too hard and difficult to rehydrate, so stay attentive during the final stages.

After the mushrooms are fully dried, store them properly to maintain their quality and extend their shelf life. Allow the mushrooms to cool completely before transferring them to airtight containers, such as glass jars or vacuum-sealed bags. Ensure there is no residual moisture, as even a small amount can lead to mold. Store the containers in a cool, dark place, like a pantry or cupboard, away from direct sunlight and heat sources. Properly stored, dehydrated mushrooms can last up to a year, making them a convenient and flavorful addition to soups, stews, and other dishes.

For added protection, consider including a silica gel packet in the storage container to absorb any excess moisture. Label the containers with the date of dehydration to keep track of freshness. When ready to use, rehydrate the mushrooms by soaking them in hot water for 15 to 20 minutes or adding them directly to recipes that involve cooking with liquid. Following these usage tips—slicing evenly, placing on trays correctly, monitoring drying time, and storing properly—ensures that your dehydrated mushrooms retain their texture, flavor, and nutritional value.

Magic Mushroom Syringe Dosage: Understanding 10ml Yield and Effects

You may want to see also

Frequently asked questions

You’ll need a cardboard box or wooden crate, a heating element (like a light bulb or heating pad), a thermometer, a fan or ventilation system, wire racks or mesh screens, and aluminum foil or reflective material to line the interior.

Use a thermometer to monitor the temperature, which should ideally be between 120°F and 140°F (49°C and 60°C). Adjust the heating element (e.g., dimmer switch for a light bulb) or ventilation to maintain the desired temperature.

Dehydration time varies but typically takes 6 to 12 hours. Mushrooms are fully dehydrated when they are brittle and snap easily. Check regularly to ensure even drying and prevent overheating.