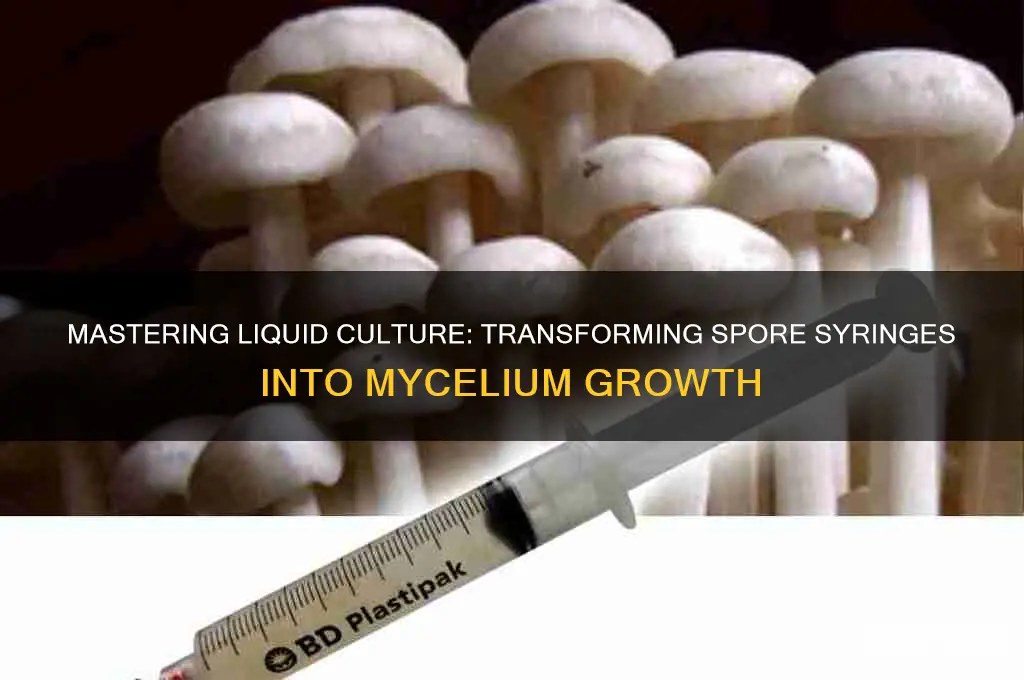

Creating a liquid culture from a spore syringe is a fundamental step in mushroom cultivation, offering a reliable method to expand mycelium for larger grows. This process involves inoculating a nutrient-rich liquid medium with spores from a syringe, allowing the mycelium to colonize the solution rapidly. The liquid culture serves as a robust and scalable way to propagate mushrooms, ensuring a higher success rate compared to direct spore inoculation. By following precise sterilization techniques and using the right ingredients, cultivators can produce a thriving liquid culture that can be used to inoculate bulk substrates, making it an essential skill for both hobbyists and professional growers.

| Characteristics | Values |

|---|---|

| Purpose | To create a liquid culture from a spore syringe for mushroom cultivation. |

| Materials Needed | Spore syringe, sterile water, sugar, agar (optional), jars, pressure cooker, alcohol, gloves, mask. |

| Sterilization Method | Pressure cooker at 15 PSI for 45-60 minutes. |

| Liquid Culture Recipe | 10-20 ml spore syringe, 200-300 ml sterile water, 5-10 grams sugar. |

| pH Level | Optimal pH range: 5.5-6.5. |

| Temperature for Incubation | 70-75°F (21-24°C). |

| Incubation Time | 7-14 days depending on species. |

| Contamination Prevention | Sterile environment, 70% isopropyl alcohol for surface sterilization. |

| Storage | Refrigerate at 2-4°C for up to 6 months. |

| Usage | Inoculate substrate or grain spawn for mushroom fruiting. |

| Success Indicators | Cloudy liquid with mycelial growth, no mold or discoloration. |

| Common Mistakes | Poor sterilization, incorrect pH, over-inoculation, improper sealing. |

| Alternative Methods | Using agar plates for isolation before liquid culture. |

| Safety Precautions | Wear gloves, mask, and work in a clean, sterile environment. |

What You'll Learn

- Sterilize equipment: autoclave jars, needles, syringes, and water to ensure a contamination-free environment

- Prepare substrate: mix nutrient-rich ingredients like malt extract, dextrose, and water in jars

- Inject spores: use a sterile syringe to introduce spore solution into the prepared substrate

- Incubate culture: maintain jars at 75-80°F in a dark, clean space for colonization

- Shake vigorously: once mycelium forms, agitate liquid culture to distribute mycelium evenly

Sterilize equipment: autoclave jars, needles, syringes, and water to ensure a contamination-free environment

Sterilization is the cornerstone of successful liquid culture creation, as even a single contaminant can derail the entire process. Autoclaving, a method that uses steam under pressure to kill microorganisms, is the gold standard for sterilizing equipment like jars, needles, syringes, and water. This process ensures that every component of your setup is free from bacteria, fungi, and other microbes that could compete with or harm your spore culture. Without proper sterilization, your efforts may result in a contaminated batch, wasting time and resources.

To autoclave effectively, begin by preparing your equipment. Jars should be cleaned thoroughly and filled with distilled water, leaving enough headspace to prevent overflow during sterilization. Needles and syringes must be new and sealed to avoid introducing contaminants before the autoclaving process. Place all items in the autoclave chamber, ensuring they are not overcrowded, as proper steam penetration is crucial. Set the autoclave to run at 121°C (250°F) for at least 15 minutes, a standard cycle that guarantees sterilization. Always follow the manufacturer’s guidelines for your specific autoclave model to ensure optimal performance.

Water, a critical component of liquid culture, must also be sterilized. Distilled water is preferred due to its purity, but if unavailable, tap water can be used after boiling to remove impurities. Pour the water into jars, seal them loosely to allow steam escape, and autoclave alongside other equipment. After sterilization, allow the jars to cool completely before use, as handling hot jars can introduce contaminants or cause injury. Properly sterilized water provides a clean medium for spore germination and mycelial growth.

Caution must be exercised when handling sterilized equipment. Once removed from the autoclave, items should be treated as sterile only if they remain sealed or untouched. Any contact with non-sterile surfaces, air, or tools can reintroduce contaminants. Work in a clean, controlled environment, such as a still air box or laminar flow hood, when transferring sterilized components to your liquid culture setup. Even a single mistake in this stage can compromise the entire process, emphasizing the need for precision and care.

In conclusion, autoclaving jars, needles, syringes, and water is a non-negotiable step in creating a contamination-free environment for liquid culture. By understanding the principles of sterilization, preparing equipment correctly, and maintaining sterile conditions post-autoclaving, you can significantly increase the chances of a successful and uncontaminated culture. This meticulous approach not only saves time and resources but also lays the foundation for robust mycelial growth and future cultivation endeavors.

Unveiling the Creative Journey: How Spore Was Crafted and Developed

You may want to see also

Prepare substrate: mix nutrient-rich ingredients like malt extract, dextrose, and water in jars

Creating a liquid culture from a spore syringe begins with a critical step: preparing a nutrient-rich substrate that will nourish the mycelium as it grows. This substrate acts as the foundation for your culture, providing the essential elements needed for robust development. The key ingredients—malt extract, dextrose, and water—are mixed in jars to create a balanced environment that supports rapid colonization. Each component plays a specific role: malt extract supplies complex nutrients, dextrose provides simple sugars for energy, and water ensures hydration and fluidity. Together, they form a medium that mimics the natural conditions fungi thrive in.

To prepare the substrate, start by sterilizing your jars to eliminate contaminants. Use wide-mouth mason jars for ease of access and proper sealing. For a standard recipe, combine 20 grams of malt extract, 10 grams of dextrose, and 400 milliliters of distilled water per jar. Distilled water is preferred to avoid introducing impurities. Stir the mixture thoroughly until all solids dissolve, ensuring a uniform solution. Heat the jars in a pressure cooker at 15 PSI for 45 minutes to sterilize the substrate, killing any competing microorganisms. Allow the jars to cool completely before inoculation to prevent damaging the spore syringe’s contents.

The ratio of ingredients is crucial for optimal growth. Malt extract, derived from barley, provides amino acids, vitamins, and minerals that fungi need to flourish. Dextrose, a simple sugar, serves as a quick energy source, accelerating mycelial expansion. Too much dextrose can lead to excessive water retention, while too little may slow growth. Experimenting with slight variations in these ratios can help tailor the substrate to specific fungal species or growth conditions. For instance, some cultivators add 1–2 grams of gypsum per jar to improve structure and prevent clumping.

Practical tips can enhance your success. Label each jar with the date and contents for tracking purposes. Use a magnetic stirrer or manual agitation to ensure even mixing, avoiding hotspots where nutrients may settle. If using multiple jars, prepare the substrate in a larger batch and divide it evenly to maintain consistency. Store unused sterilized jars in a cool, dark place for up to two weeks, though inoculation should occur as soon as possible to minimize contamination risks. Proper substrate preparation is not just a step—it’s the cornerstone of a thriving liquid culture.

Can Old Yeast Develop Spores? Unveiling the Truth Behind Yeast Longevity

You may want to see also

Inject spores: use a sterile syringe to introduce spore solution into the prepared substrate

The precision of spore injection is a critical step in creating a liquid culture, where the goal is to introduce a controlled amount of spore solution into the substrate without compromising sterility. Using a sterile syringe, typically ranging from 10 to 20 milliliters in capacity, ensures that the spore solution is delivered accurately and hygienically. The syringe should be equipped with a sterile needle, preferably 18 to 20 gauge, to allow for smooth flow of the spore solution while minimizing damage to the substrate. This step requires a steady hand and attention to detail, as contamination at this stage can derail the entire process.

In practice, the injection process begins by attaching the sterile needle to the syringe in a clean, controlled environment, such as a still air box or laminar flow hood. The spore syringe is then carefully shaken to evenly distribute the spores in the solution. Next, the desired volume of spore solution—typically 1 to 2 milliliters—is drawn into the syringe. The prepared substrate, often a sterilized liquid medium like malt extract or distilled water with nutrients, is then positioned for injection. The needle is inserted into the substrate container through a self-healing injection port or a pre-drilled hole sealed with a rubber stopper. The spore solution is slowly injected, ensuring it mixes thoroughly with the substrate without causing overflow or air bubbles.

A comparative analysis of injection techniques reveals that the angle and depth of needle insertion significantly impact success. Inserting the needle at a 45-degree angle reduces the risk of damaging the substrate container, while ensuring the spore solution is deposited deep enough to mix effectively. Over-insertion can puncture the container or introduce contaminants, while shallow insertion may leave the spores inadequately dispersed. Additionally, the speed of injection matters; a slow, steady pace prevents splashing or uneven distribution, which can lead to inconsistent colonization.

Persuasively, mastering the spore injection technique is not just about following steps—it’s about understanding the biology and physics at play. Spores are resilient but require optimal conditions to germinate and thrive. By injecting them directly into a nutrient-rich, sterile substrate, you create an environment conducive to rapid growth. This method is superior to alternative approaches, such as surface inoculation, because it ensures even distribution and minimizes exposure to contaminants. For hobbyists and professionals alike, this precision is the cornerstone of successful liquid culture creation.

Finally, a practical tip to enhance this process is to label the injection site immediately after inoculation. This prevents confusion, especially when working with multiple cultures. Additionally, maintaining a sterile workflow—from cleaning the workspace with 70% isopropyl alcohol to wearing gloves and a mask—cannot be overstated. While the injection itself may take only seconds, the preparation and follow-through are what ultimately determine the success of your liquid culture. With practice, this step becomes second nature, paving the way for robust mycelial growth and fruitful yields.

Discover the Best Platforms to Play Spore: A Comprehensive Guide

You may want to see also

Incubate culture: maintain jars at 75-80°F in a dark, clean space for colonization

Once your liquid culture is prepared and inoculated with spores, the incubation phase becomes critical for successful colonization. This stage demands precision in temperature control, typically maintained between 75°F and 80°F (24°C to 27°C). Fluctuations outside this range can hinder mycelial growth or encourage contamination. Use a reliable thermometer or a temperature-controlled incubator to monitor conditions. If natural room temperature is unstable, consider placing jars on a heating mat or near a consistent heat source, ensuring it doesn't exceed the upper limit.

The environment’s cleanliness is equally vital during incubation. Contaminants like mold or bacteria can outcompete the mycelium, rendering the culture unusable. Sterilize the incubation area with a 10% bleach solution or isopropyl alcohol before introducing jars. Keep the space free from dust and airborne particles by covering jars with a breathable material, such as micropore tape, which allows gas exchange while blocking larger contaminants. Regularly inspect jars for signs of contamination, such as discoloration or unusual odors, and discard any compromised cultures immediately.

Darkness is another non-negotiable requirement for optimal colonization. Light exposure can disrupt mycelial growth patterns and reduce vigor. Store jars in a completely dark space, such as a closed cabinet or a dedicated incubation chamber. If complete darkness isn’t feasible, wrap jars in aluminum foil or use opaque containers to block light. This simple step ensures the mycelium focuses energy on growth rather than phototropic responses.

Patience is key during incubation, as colonization can take 7 to 14 days, depending on the species and conditions. Resist the urge to disturb jars unnecessarily, as this introduces contamination risks and slows progress. Instead, observe growth through the jar’s sides, looking for white, fluffy mycelium spreading uniformly. Once colonization reaches 50-70% of the liquid’s surface, the culture is ready for use or expansion. Proper incubation not only ensures a healthy culture but also lays the foundation for robust fruiting in later stages.

Mastering Spore Modding: A Step-by-Step Guide to Custom Creations

You may want to see also

Shake vigorously: once mycelium forms, agitate liquid culture to distribute mycelium evenly

Agitating your liquid culture is a critical step that can make or break your mycelium’s growth trajectory. Once the mycelium begins to form—typically visible as a wispy, white network within 7 to 14 days—it tends to clump or settle at the bottom of the container. This uneven distribution starves portions of the culture of nutrients and oxygen, hindering colonization. Vigorous shaking redistributes the mycelium, ensuring every part of the liquid is inoculated and promoting uniform growth. Think of it as stirring a broth to prevent ingredients from sticking to the pan—except here, the "ingredients" are the foundation of your fungal colony.

The technique is straightforward but requires precision. Hold the sealed container firmly and shake it with a rapid, back-and-forth motion for 30 to 60 seconds. Aim for a force that mimics the intensity of mixing a protein shake, not a gentle swirl. This action breaks up mycelial clumps and suspends them evenly throughout the liquid. Repeat this process daily, especially during the first week after inoculation, when mycelium is most prone to clustering. Consistency is key—skipping this step can lead to a stalled or patchy culture, wasting valuable time and resources.

Comparing this step to other mycological practices highlights its importance. While sterile technique and nutrient balance are foundational, agitation is the active intervention that maximizes your culture’s potential. Without it, even a perfectly prepared liquid culture risks becoming a static, underperforming medium. In contrast, proper agitation mimics the natural movement fungi experience in their environment, such as water flow or soil shifts, encouraging robust growth. It’s a simple yet transformative act that bridges the gap between passive incubation and active cultivation.

For those new to liquid cultures, a practical tip is to mark the container with a line indicating the mycelium’s initial growth level. This visual reference helps you gauge progress and ensures you’re shaking vigorously enough to see noticeable redistribution. If clumps persist despite agitation, consider using a sterile magnetic stirrer or gently swirling the container in a figure-eight pattern to enhance mixing. Remember, the goal isn’t to damage the mycelium but to create an environment where it can thrive uniformly. Master this step, and you’ll set the stage for a thriving, vibrant culture ready for transfer to bulk substrate.

Does Dead Mold Still Release Spores? Uncovering the Hidden Risks

You may want to see also

Frequently asked questions

A liquid culture is a nutrient-rich solution that allows mushroom mycelium to grow rapidly in a liquid medium. Making one from a spore syringe accelerates colonization, increases yield, and reduces contamination risk compared to directly inoculating substrates with spores.

You’ll need a spore syringe, liquid culture media (e.g., light malt extract or honey water), sterile jars or containers, a pressure cooker or autoclave for sterilization, and a sterile needle or syringe for inoculation.

Prepare your liquid culture media, pour it into sterile jars, seal them with lids or foil, and sterilize in a pressure cooker at 15 PSI for 45–60 minutes. Allow to cool completely before inoculation to avoid contamination.

Wipe the spore syringe tip and jar lid with alcohol, flame the needle, and insert it through the lid or self-healing injection port. Inject 1–2 cc of spore solution into the liquid culture, seal tightly, and incubate at room temperature (70–75°F) in darkness until fully colonized.