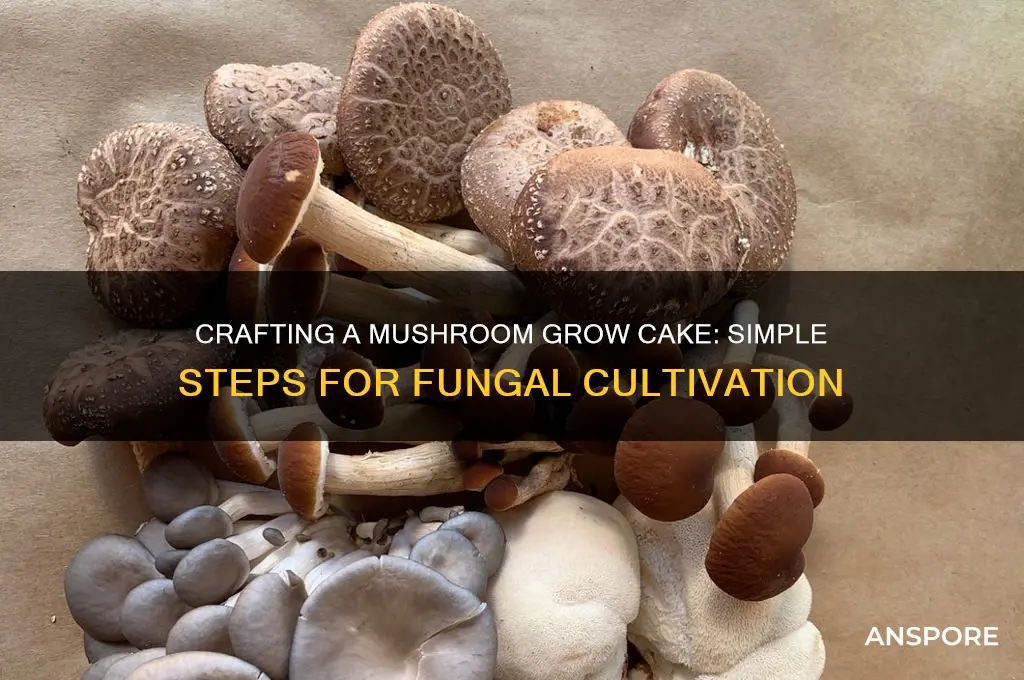

Creating a mushroom grow cake is an innovative and sustainable way to cultivate mushrooms at home, combining the art of baking with the science of mycology. This method involves mixing mushroom spawn with a nutrient-rich substrate, such as straw or sawdust, and then compacting it into a cake-like form. The grow cake provides an ideal environment for mushrooms to thrive, as it retains moisture and nutrients while allowing for proper air circulation. Whether you're a gardening enthusiast or simply curious about fungi, making a mushroom grow cake is a rewarding project that yields fresh, homegrown mushrooms with minimal effort.

Explore related products

$14.99

What You'll Learn

Choosing the Right Mushroom Species

When embarking on the journey of creating a mushroom grow cake, selecting the appropriate mushroom species is a critical first step. Different mushrooms have varying growth requirements, flavors, and textures, so your choice should align with your goals and the conditions you can provide. For beginners, oyster mushrooms (*Pleurotus ostreatus*) are often recommended due to their fast growth, adaptability to a wide range of substrates, and forgiving nature. They thrive in grow cakes and are less susceptible to contamination compared to other species. If you prefer a more gourmet option, lion's mane (*Hericium erinaceus*) is another excellent choice, known for its unique appearance and potential cognitive health benefits, though it requires slightly more precise humidity and temperature control.

For those interested in medicinal mushrooms, reishi (*Ganoderma lucidum*) or turkey tail (*Trametes versicolor*) can be grown in cakes, but they are slower to colonize and require patience. Reishi, in particular, is prized for its immune-boosting properties but is less commonly grown in cakes due to its woody texture and preference for hardwood substrates. On the other hand, shiitake mushrooms (*Lentinula edodes*) are a popular culinary choice, offering a rich, umami flavor, but they demand a more specific environment, including a period of "shock" with colder temperatures to initiate fruiting. Understanding the specific needs of each species is essential to ensure successful growth in a cake medium.

Environmental factors play a significant role in species selection. Tropical mushrooms like pink oyster (*Pleurotus djamor*) thrive in warmer, more humid conditions, making them ideal for growers in hotter climates. In contrast, species like the chestnut mushroom (*Pholiota adiposa*) prefer cooler temperatures and are better suited for temperate regions. Additionally, consider the substrate preferences of the mushroom. While most grow cakes use a grain base, some species, like the enoki (*Flammulina velutipes*), may require amendments or specific conditions to fruit successfully.

Another factor to consider is the purpose of your grow cake. If you're growing mushrooms for culinary use, focus on species with desirable flavors and textures, such as king oyster (*Pleurotus eryngii*) or pioppino (*Agrocybe aegerita*). For decorative or educational purposes, unique species like the bioluminescent *Mycena lux-coeli* could be an intriguing choice, though they are more challenging to cultivate. Medicinal growers should prioritize species with proven health benefits, such as maitake (*Grifola frondosa*), which is known for its immune-enhancing properties.

Lastly, availability of spawn and resistance to contamination are practical considerations. Common species like oyster and shiitake have readily available spawn, making them convenient for beginners. Less common species may require sourcing spawn from specialized suppliers, which can add complexity and cost. Additionally, some mushrooms, like the almond agaricus (*Agaricus subrufescens*), are more resistant to contamination, making them a safer bet for growers in less sterile environments. By carefully evaluating these factors, you can choose a mushroom species that aligns with your skills, resources, and goals for your grow cake project.

Master Indoor Enoki Mushroom Cultivation: Simple Steps for Fresh Harvests

You may want to see also

Preparing the Substrate Mixture

Once you’ve chosen your base material, it’s essential to pasteurize or sterilize it to eliminate competing organisms. Pasteurization involves soaking the material in hot water (around 160-180°F or 71-82°C) for 1-2 hours, which is sufficient for straw-based substrates. For sawdust or more dense materials, sterilization in a pressure cooker or autoclave at 15 psi for 1.5 to 2.5 hours is recommended. After pasteurization or sterilization, allow the material to cool to a temperature that won’t kill the mushroom spawn (around 75-85°F or 24-29°C). This step is crucial, as introducing spawn into hot substrate will destroy it.

Next, prepare any supplemental nutrients to enrich the substrate. Common additives include wheat bran, gypsum, or soybean meal, which provide additional nitrogen and minerals to support mycelium growth. Mix these supplements thoroughly with the base material, ensuring an even distribution. For example, a typical recipe might include 5% wheat bran and 1% gypsum by weight of the base material. Measure the ingredients carefully, as imbalances can hinder mushroom growth or lead to contamination.

Hydration is another key factor in preparing the substrate mixture. The material should be moist but not waterlogged, as excess water can create anaerobic conditions that promote harmful bacteria. Aim for a moisture content of 60-70%, which feels like a wrung-out sponge. To achieve this, gradually add water while mixing the substrate, testing the moisture level by squeezing a handful—it should release a few drops of water but not leave your hand wet.

Finally, once the substrate is properly mixed, hydrated, and cooled, it’s ready to be combined with the mushroom spawn. Layer the substrate in a growing container, such as a plastic bag or tray, and evenly distribute the spawn throughout. Seal the container to maintain humidity and provide a dark environment for the mycelium to colonize the substrate. With a well-prepared substrate mixture, you’ve laid the foundation for a successful mushroom grow cake.

Mushroom Veil Break: Does It Trigger Growth or Signal Decline?

You may want to see also

Sterilizing Equipment and Materials

When preparing to make a mushroom grow cake, sterilizing your equipment and materials is a critical step to ensure a contamination-free environment for your mycelium to thrive. Mushrooms are highly sensitive to competing microorganisms, so proper sterilization is non-negotiable. Begin by gathering all the tools and materials you’ll need, such as glass jars, a pressure cooker, substrate (like straw or sawdust), and any instruments like spoons or gloves. Ensure everything is clean before sterilization—wash all items with hot, soapy water to remove dirt, debris, and visible contaminants. This preliminary cleaning step is essential because sterilization only kills microorganisms on a clean surface; it won’t remove physical particles.

For sterilizing glass jars, which are commonly used for mushroom grow cakes, start by rinsing them thoroughly after washing to remove any soap residue. Allow the jars to air dry or dry them with a clean paper towel to avoid lint or fibers. Once dry, place the jars in a pressure cooker, ensuring they are not overcrowded to allow steam to circulate freely. Add water to the pressure cooker, following the manufacturer’s instructions, and secure the lid. Bring the cooker up to 15 psi (pounds per square inch) and maintain this pressure for at least 30 minutes. This process will kill any bacteria, fungi, or spores that could compete with your mushroom mycelium. After sterilization, allow the jars to cool inside the pressure cooker to prevent contaminants from entering as the jars cool down.

The substrate, such as straw or sawdust, also requires sterilization to eliminate competing organisms. Soak the substrate in water for a few hours to ensure it’s fully hydrated, as dry material won’t sterilize properly. Drain the excess water and place the substrate in a mesh bag or directly into the pressure cooker basket. Sterilize the substrate for 1.5 to 2 hours at 15 psi, ensuring the heat penetrates thoroughly. If using a large quantity of substrate, consider sterilizing it in batches to maintain even heat distribution. Once sterilized, allow the substrate to cool in a clean environment, covered with a lid or aluminum foil to prevent contamination.

Any tools or instruments, such as spoons, thermometers, or gloves, should also be sterilized. Metal tools can be placed directly into the pressure cooker alongside the jars or substrate for the same sterilization cycle. For items that cannot withstand high heat, such as gloves or plastic components, use 70% isopropyl alcohol to wipe them down thoroughly. Ensure the alcohol makes full contact with all surfaces and allow it to air dry completely before use. Avoid touching sterilized items with bare hands; instead, use freshly sterilized gloves or tongs to handle them.

Finally, your workspace and storage area should be as clean as possible. Wipe down surfaces with a 10% bleach solution or 70% isopropyl alcohol before beginning the process. Keep windows closed to minimize airborne contaminants, and consider using a laminar flow hood if available. After sterilization, work quickly and efficiently to minimize exposure to the environment. Proper sterilization of equipment and materials is the foundation of a successful mushroom grow cake, ensuring your mycelium has the best chance to colonize the substrate without competition.

Unveiling the Growth Secrets of Mushroom Coral: A Comprehensive Guide

You may want to see also

Explore related products

Inoculating the Cake with Spawn

Next, carefully break up the spawn into smaller pieces to increase the surface area for inoculation. Using a sanitized knife or spoon, create small incisions or holes in the grow cake, spacing them evenly across the surface and sides. These holes serve as entry points for the spawn. Gently press the spawn into the holes, ensuring it makes good contact with the substrate. Aim to distribute the spawn evenly to promote uniform colonization. Avoid compacting the substrate too much, as airflow is essential for mycelium growth.

Once the spawn is embedded, lightly mist the surface of the grow cake with sterile water to maintain humidity. Place the inoculated cake into a clean, humid environment, such as a grow chamber or a plastic container with air holes. Covering the cake with a layer of aluminum foil or a breathable material can help retain moisture while still allowing gas exchange. Keep the temperature between 70-75°F (21-24°C), as this range is optimal for most mushroom species' mycelium growth.

Monitor the cake daily for signs of contamination, such as mold or unusual colors, and address any issues immediately. After 7 to 14 days, you should start to see white mycelium spreading through the cake, indicating successful colonization. Be patient, as the time required for full colonization varies depending on the mushroom species and environmental conditions. Once the cake is fully colonized, it is ready for the next steps, such as fruiting or transferring to a bulk substrate.

Finally, maintain proper humidity and airflow throughout the colonization process. If using a container, ensure it is not airtight, as stagnant air can lead to contamination. Regularly check the cake for dryness and mist it lightly if needed, but avoid overwatering, as excess moisture can cause mold. Inoculating the cake with spawn requires attention to detail and cleanliness, but with careful execution, it sets the foundation for a thriving mushroom grow cake.

Growing Mushrooms in Peat Moss: A Simple Step-by-Step Guide

You may want to see also

Maintaining Optimal Growing Conditions

Humidity is another critical factor for mushroom cultivation. During the fruiting stage, mushrooms require high humidity levels, typically between 85% and 95%. This can be achieved by misting the grow cake regularly with water or placing a humidifier in the growing area. Additionally, enclosing the grow cake in a humid chamber, such as a clear plastic container or a grow tent with a misting system, helps retain moisture. Ensure proper air exchange to prevent mold or bacterial growth, which can outcompete the mushrooms. A simple way to do this is by opening the chamber for a few minutes daily or using a small fan to circulate air without drying out the environment.

Light exposure is often overlooked but plays a significant role in mushroom development. While mushrooms do not require intense light, they need indirect, natural light or a few hours of artificial light daily to signal the fruiting process. Avoid direct sunlight, as it can dry out the substrate and harm the mycelium. A fluorescent or LED light placed a few feet away from the grow cake for 8–12 hours a day is sufficient. Darkness is also important during certain stages, so ensure the growing area can be easily covered or placed in a dark space when needed.

The substrate moisture level must be carefully managed throughout the growing process. The grow cake should feel like a wrung-out sponge—moist but not waterlogged. Overwatering can lead to anaerobic conditions, promoting mold and bacteria, while underwatering can stall mycelium growth. If the cake dries out, gently mist it with water, ensuring the moisture penetrates evenly. During the fruiting stage, maintain moisture by misting the sides of the humid chamber rather than directly spraying the mushrooms, as water droplets on caps can cause abnormalities.

Finally, air quality and ventilation are essential for healthy mushroom growth. Stagnant air can lead to carbon dioxide buildup, which inhibits fruiting. Ensure the growing area has passive airflow, such as small vents in the humid chamber or a slightly open lid. Active ventilation, like a small fan on low speed, can also help, but avoid directing it straight at the grow cake to prevent drying. Regularly inspect the growing environment for signs of contamination, such as unusual colors or smells, and address issues promptly to maintain optimal conditions for your mushroom grow cake.

DIY Magic Mushroom Cultivation: A Guide to Growing Without Kits

You may want to see also

Frequently asked questions

A mushroom grow cake is a compact, nutrient-rich substrate block designed for growing mushrooms. It’s used because it provides an ideal environment for mycelium to colonize and fruit, offering a space-efficient and controlled way to cultivate mushrooms indoors.

You’ll need a substrate (e.g., sawdust, straw, or coconut coir), a grain spawn (like rye or wheat inoculated with mushroom mycelium), a binder (such as gypsum), and a container or mold to shape the cake. Sterilization equipment (like a pressure cooker) is also essential.

The substrate must be sterilized to kill competing organisms. Place the substrate in a heat-resistant bag, moisten it slightly, and sterilize it in a pressure cooker at 15 psi for 1.5–2 hours. Allow it to cool before mixing with the grain spawn.

After the mycelium fully colonizes the cake (usually 2–4 weeks), mushrooms will begin to fruit. The first flush typically appears within 1–2 weeks after colonization, with subsequent flushes possible over several weeks, depending on care and conditions.