Creating a mushroom incubator is a crucial step for cultivating mushrooms at home, as it provides the controlled environment necessary for mycelium to grow and fruit successfully. An incubator maintains optimal temperature, humidity, and light conditions, which are essential for the initial stages of mushroom cultivation. To build one, you’ll need a container (such as a plastic storage bin or a repurposed fridge), a heating element like a seedling heat mat or aquarium heater, a hygrometer and thermometer for monitoring, and a way to maintain humidity, such as a spray bottle or humidifier. Proper sterilization of the incubator and growing materials is also vital to prevent contamination. With the right setup, a mushroom incubator ensures a higher success rate and healthier mushroom yields.

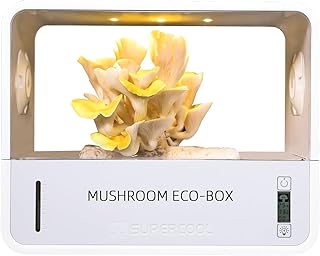

Explore related products

What You'll Learn

- Choosing the Right Container: Select a sterile, airtight container with proper ventilation for mushroom incubation

- Preparing the Substrate: Sterilize or pasteurize substrate material like straw, sawdust, or grain

- Sterilizing Equipment: Clean and sterilize all tools to prevent contamination during incubation

- Inoculating the Substrate: Introduce mushroom spawn evenly into the prepared substrate

- Maintaining Optimal Conditions: Control temperature, humidity, and light for successful mycelium growth

Choosing the Right Container: Select a sterile, airtight container with proper ventilation for mushroom incubation

When choosing the right container for your mushroom incubator, the first priority is to ensure it is sterile. Mushrooms are highly susceptible to contamination from bacteria, molds, and other fungi. Select a container that can be easily sterilized, such as one made of glass, food-grade plastic, or stainless steel. Avoid materials like wood or porous plastics, as they can harbor contaminants and are difficult to clean thoroughly. Before use, sterilize the container using a solution of bleach and water (1 part bleach to 10 parts water) or by boiling it for at least 10 minutes. Allow it to dry completely in a clean environment to prevent recontamination.

The container must also be airtight to maintain a controlled environment for mushroom incubation. An airtight seal helps regulate humidity and prevents contaminants from entering. Look for containers with secure lids, such as glass jars with rubber seals, plastic storage bins with locking lids, or specialized mushroom grow bags. Ensure there are no cracks or gaps in the container, as even small openings can compromise the sterile environment. Test the seal by filling the container with water and checking for leaks before use.

While the container needs to be airtight, it must also have proper ventilation to allow for gas exchange. Mushrooms require oxygen for growth and produce carbon dioxide as a byproduct. Incorporate passive ventilation by drilling small holes (about 1/4 inch in diameter) in the lid or sides of the container. Cover these holes with a fine mesh or microwave-safe filter paper to prevent contaminants from entering while allowing air to flow. Alternatively, use containers with built-in vents or adjustable air exchange systems for more precise control.

The size and shape of the container should align with your incubation needs. For small-scale projects, glass jars or plastic tubs work well, while larger operations may require bulk containers or specialized incubation chambers. Ensure the container is spacious enough to accommodate the substrate and allow for even colonization by the mushroom mycelium. Transparent containers are advantageous, as they allow you to monitor the growth process without disturbing the environment.

Finally, consider the durability and reusability of the container. Investing in high-quality materials will save you time and money in the long run, as you can sterilize and reuse the container for multiple grow cycles. Avoid single-use containers unless absolutely necessary, as they are less sustainable and cost-effective. By selecting a sterile, airtight container with proper ventilation, you create an ideal environment for successful mushroom incubation while minimizing the risk of contamination.

Delicious Mushroom Burgers: Tips for Flavorful, Juicy Plant-Based Patties

You may want to see also

Preparing the Substrate: Sterilize or pasteurize substrate material like straw, sawdust, or grain

Preparing the substrate is a critical step in creating a successful mushroom incubator, as it directly impacts the growth and health of your mushrooms. The substrate, which can be straw, sawdust, or grain, must be properly sterilized or pasteurized to eliminate any competing microorganisms that could hinder mushroom growth. Sterilization and pasteurization are two different processes, each suited to specific types of substrates and mushroom species. Sterilization involves killing all living organisms, including spores, using high temperatures and pressure, typically in an autoclave or pressure cooker. This method is essential for substrates like grain, which can harbor contaminants more easily. Pasteurization, on the other hand, reduces the number of harmful microorganisms without completely eliminating them, making it suitable for materials like straw or sawdust that can be damaged by full sterilization.

To sterilize grain-based substrates, begin by moistening the grains to a moisture content of around 60-70%. This can be done by soaking the grains in water for a few hours or overnight, then draining them thoroughly. Place the moistened grains into a sturdy, heat-resistant bag, such as an autoclave bag or a mason jar with a lid that allows steam to escape. Using a pressure cooker or autoclave, process the substrate at 15 psi (pounds per square inch) for 60 to 90 minutes. This ensures that all contaminants are destroyed. Allow the substrate to cool to a temperature safe for inoculation, typically around 80°F (27°C), before introducing the mushroom spawn. Sterilization is crucial for grain substrates because they provide a rich environment for both mushrooms and contaminants, making it essential to start with a completely sterile medium.

For straw or sawdust substrates, pasteurization is often the preferred method, as these materials can degrade under the harsh conditions of sterilization. To pasteurize straw, soak it in water for 24 hours to rehydrate it, then drain off the excess water. In a large container, mix the straw with hot water (around 160°F or 71°C) and maintain this temperature for 1 to 2 hours, stirring occasionally to ensure even heat distribution. Alternatively, you can use a pasteurization tunnel or a hot water bath if available. For sawdust, mix it with water to achieve a moisture content of 60-70%, then heat it in a steamer or oven at 160°F (71°C) for 2 to 3 hours. Pasteurization reduces the microbial load enough to give your mushroom mycelium a competitive advantage without damaging the substrate structure.

After pasteurization or sterilization, it’s crucial to cool the substrate to the appropriate temperature before inoculating it with mushroom spawn. Exposing the spawn to excessively hot substrate can kill it, so patience is key. Once cooled, transfer the substrate to a clean, sterile environment, such as a glove box or a laminar flow hood, if available, to minimize contamination during inoculation. Mix the spawn thoroughly into the substrate, ensuring an even distribution to promote uniform colonization. Properly prepared substrate provides the ideal foundation for healthy mycelium growth, setting the stage for a bountiful mushroom harvest.

Finally, store the inoculated substrate in a clean, humid environment within your mushroom incubator. Maintain optimal temperature and humidity levels specific to the mushroom species you’re cultivating. Regularly monitor the substrate for signs of contamination, such as mold or off-odors, and address any issues promptly. With a well-prepared and properly sterilized or pasteurized substrate, you’ll create an ideal environment for your mushrooms to thrive, ensuring a successful and productive incubation process.

Infused Garlic and Mushroom Oil: A Flavorful Homemade Recipe Guide

You may want to see also

Sterilizing Equipment: Clean and sterilize all tools to prevent contamination during incubation

Before assembling your mushroom incubator, it’s crucial to sterilize all equipment to eliminate any contaminants that could harm your mushroom mycelium. Start by gathering all tools and materials, including jars, lids, gloves, scalpels, and any surfaces that will come into contact with the substrate or mycelium. Wash everything thoroughly with hot water and dish soap to remove dirt, debris, and organic matter. Pay special attention to crevices and hard-to-reach areas, as these can harbor bacteria or mold spores. Rinse all items with clean water to ensure no soap residue remains, as it can interfere with sterilization.

After cleaning, the next step is to sterilize the equipment. The most effective method for home growers is using an autoclave or a pressure cooker, as these devices can achieve the high temperatures needed to kill spores and microorganisms. Place your glass jars, lids, and metal tools into the pressure cooker, ensuring they are not overcrowded. Add water to the cooker according to the manufacturer’s instructions, typically about 1–2 cups. Secure the lid and bring the cooker to 15 psi (pounds per square inch) for at least 30 minutes. This process will sterilize the equipment by exposing it to temperatures above 250°F (121°C), effectively killing all contaminants.

For items that cannot withstand high heat, such as plastic containers or certain tools, use a 10% bleach solution or 70% isopropyl alcohol for sterilization. Submerge the items in the solution for at least 10 minutes, then remove them and allow them to air dry completely in a clean, sterile environment. Avoid touching the sterilized items with bare hands; instead, use sterile gloves or tongs to handle them. Ensure the workspace where you’re preparing the equipment is also clean and free of dust or debris.

Once sterilized, store your equipment in a clean, sealed container or plastic bag until you’re ready to use it. This prevents recontamination from airborne particles or contact with unsterilized surfaces. If using jars, keep the lids separate and only attach them in a sterile environment, such as in front of a laminar flow hood or near an open flame to create a temporary sterile field. Remember, even a small amount of contamination can ruin an entire batch, so meticulous sterilization is non-negotiable.

Finally, maintain a sterile mindset throughout the process. Work quickly and efficiently when handling sterilized equipment to minimize exposure to the environment. If you drop a tool or jar or suspect it has been contaminated, sterilize it again before use. Consistency and attention to detail in sterilizing your equipment will significantly increase the success rate of your mushroom incubation, ensuring a healthy and productive mycelium growth.

Crafting Mushroom Capsules: A Step-by-Step DIY Guide for Beginners

You may want to see also

Explore related products

Inoculating the Substrate: Introduce mushroom spawn evenly into the prepared substrate

Inoculating the substrate is a critical step in the mushroom cultivation process, as it ensures the even distribution of mushroom spawn, which directly impacts the success of your harvest. To begin, ensure your hands and all equipment are thoroughly sterilized to prevent contamination. Lay out your prepared substrate in a clean, controlled environment, ideally within the mushroom incubator you’ve set up. The substrate should be at the correct moisture level—damp but not waterlogged—to support mycelium growth. Gently break up any clumps in the substrate to create a uniform texture, which will help in achieving an even inoculation.

Next, measure the appropriate amount of mushroom spawn for your substrate volume. A general rule of thumb is to use 10-20% spawn by weight of the substrate, though this can vary depending on the mushroom species. Sprinkle the spawn evenly over the surface of the substrate, ensuring it is spread out as uniformly as possible. Avoid dumping the spawn in one spot, as this can lead to uneven colonization and reduce overall yield. For larger batches, divide the substrate into smaller sections and inoculate each section individually to maintain consistency.

Once the spawn is distributed, gently mix it into the substrate using a sterilized tool or gloved hands. The goal is to integrate the spawn throughout the substrate without compacting it. Overmixing can damage the spawn, while undermixing can leave pockets of substrate uncolonized. Aim for a thorough but delicate incorporation, ensuring every part of the substrate comes into contact with the spawn. This step is crucial for promoting uniform mycelium growth and preventing contamination.

After mixing, transfer the inoculated substrate into your incubator containers, such as sterilized jars, bags, or trays. Pack the substrate lightly, leaving enough room for air exchange, which is essential for mycelium development. Seal the containers with a breathable material, like micropore tape or a filter patch, to allow gas exchange while keeping contaminants out. Place the containers in your mushroom incubator, maintaining optimal temperature and humidity levels as per the requirements of your chosen mushroom species.

Finally, monitor the inoculated substrate closely during the initial stages of colonization. Signs of successful inoculation include the substrate turning white as the mycelium grows, typically within 7-14 days. If you notice any discoloration, unusual odors, or mold, it may indicate contamination, and the affected substrate should be removed immediately to prevent it from spreading. Patience and attention to detail during the inoculation process will significantly increase your chances of a healthy and productive mushroom harvest.

Creamy Mushroom Chicken Recipe: Easy Steps for a Rich, Flavorful Dish

You may want to see also

Maintaining Optimal Conditions: Control temperature, humidity, and light for successful mycelium growth

Maintaining optimal conditions within a mushroom incubator is crucial for successful mycelium growth. Temperature control is the cornerstone of this process, as mycelium thrives in specific temperature ranges depending on the mushroom species. For most common varieties, such as oyster or shiitake mushrooms, the ideal temperature ranges between 70°F and 75°F (21°C to 24°C). To achieve this, use a thermostat-controlled heating element, such as a seedling heat mat or a small space heater with a thermostat. Place a digital thermometer inside the incubator to monitor temperature fluctuations and adjust the heating source accordingly. Insulation, such as foam boards or reflective materials, can help maintain a stable temperature by reducing heat loss.

Humidity is another critical factor, as mycelium requires a consistently moist environment to grow. Aim for a relative humidity level between 80% and 90% inside the incubator. This can be achieved by incorporating a humidifier or placing a tray of water with a fan to distribute moisture evenly. Alternatively, use a humidity controller connected to a misting system for precise regulation. To prevent waterlogging, ensure proper air circulation by installing small vents or using a computer fan. Regularly monitor humidity levels with a hygrometer and adjust the system to avoid dry spots or excessive moisture, which can lead to contamination.

Light control is often overlooked but plays a subtle yet important role in mycelium growth. While mycelium does not require intense light, a consistent low-light environment can help signal the transition to fruiting. Use a timer-controlled LED light strip or a small fluorescent bulb to provide 12–16 hours of indirect light daily. Avoid direct sunlight, as it can overheat the incubator and dry out the substrate. For species that require specific light triggers for fruiting, such as certain gourmet mushrooms, research their light requirements and adjust the lighting schedule accordingly.

Maintaining cleanliness and sterility is essential to prevent contamination, which can thrive in the same conditions as mycelium. Regularly sanitize the incubator’s interior with a 10% bleach solution or alcohol wipes, especially before introducing new spawn. Use airtight filters, such as HEPA filters or microfiber cloth, over vents to allow air exchange while blocking contaminants. Always handle materials with clean hands or gloves, and ensure all tools and substrates are sterilized before use.

Finally, monitor the incubator’s conditions daily and keep a log of temperature, humidity, and any observations. This data will help you identify trends and make adjustments to optimize growth. Be patient, as mycelium colonization can take several weeks. With consistent attention to temperature, humidity, light, and cleanliness, your mushroom incubator will provide the ideal environment for robust mycelium development, setting the stage for a successful mushroom harvest.

Creamy Keto Mushroom Gravy: Easy Low-Carb Recipe for Comfort Food Lovers

You may want to see also

Frequently asked questions

You’ll need a container (like a plastic storage bin or aquarium), a heating element (such as a seedling heat mat or incandescent bulb), a thermometer/hygrometer, a spray bottle, and a substrate (like sterilized grain or sawdust) for mushroom spawn.

Use a thermostat to control the heating element, aiming for a temperature range of 70–75°F (21–24°C), which is ideal for most mushroom species. Monitor with a thermometer to ensure consistency.

Mushrooms thrive in high humidity, typically between 85–95%. Use a hygrometer to monitor levels and mist the incubator walls or use a humidifier if needed.

Clean the incubator with a 10% bleach solution or isopropyl alcohol, rinse thoroughly, and allow it to dry completely. Ensure all tools and substrates are also sterilized to prevent contamination.

Check daily to monitor temperature, humidity, and signs of contamination. Mist as needed to maintain humidity, but avoid opening the incubator excessively to prevent mold or bacteria from entering.

![Boomer Shroomer Inflatable Monotub Kit, Mushroom Growing Kit Includes a Drain Port, Plugs & Filters, Removeable Liner [Patent No: US 11,871,706 B2]](https://m.media-amazon.com/images/I/61K9zwzRQxL._AC_UL320_.jpg)