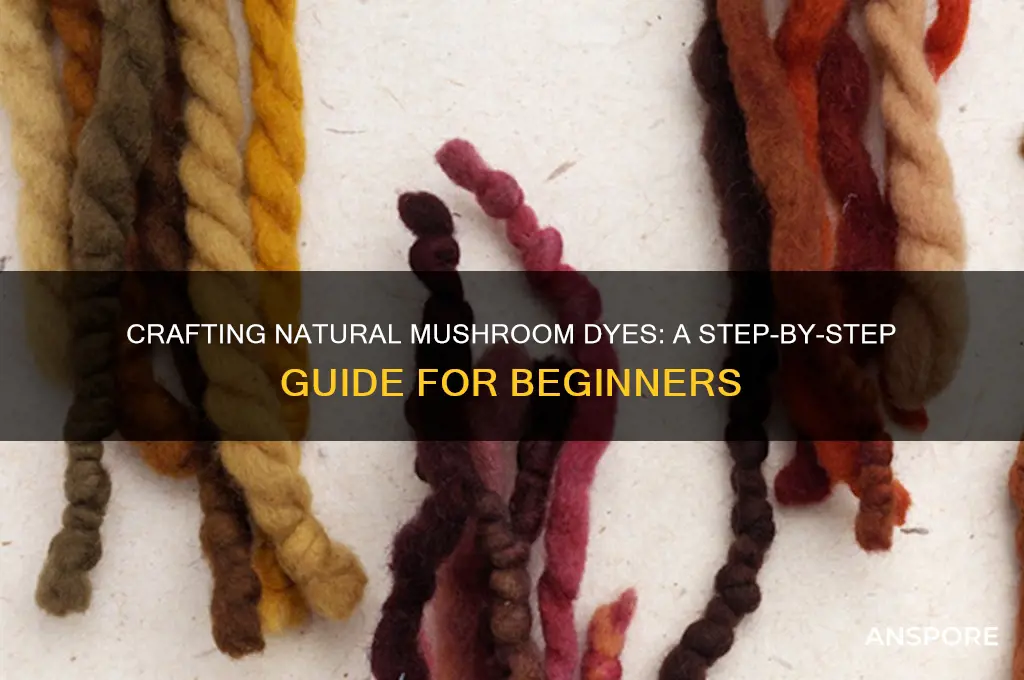

Creating dye from mushrooms is an ancient and sustainable practice that harnesses the vibrant pigments found in various fungal species. By carefully selecting, preparing, and extracting colors from mushrooms, artisans and crafters can produce natural, eco-friendly dyes in a range of hues, from earthy browns and greens to vivid yellows and reds. The process typically involves foraging for specific mushroom species, such as *Phaeolus schweinitzii* or *Hydnellum peckii*, cleaning and chopping them, and then simmering them in water to release their pigments. The resulting liquid can be used to dye fabrics, yarns, or other materials, often with the addition of mordants to fix the color. This method not only offers a unique way to connect with nature but also promotes a more sustainable alternative to synthetic dyes, preserving traditional techniques while reducing environmental impact.

| Characteristics | Values |

|---|---|

| Mushroom Species | Different mushrooms yield different colors. Common dye mushrooms include: - Phaeolus schweinitzii (yellow, orange, brown) - Hydnellum peckii (red, pink) - Cortinarius semifuscus (green) - Boletus edulis (brown, beige) - Lactarius indigo (blue) |

| Preparation | 1. Clean mushrooms thoroughly to remove dirt and debris. 2. Chop or crush mushrooms to increase surface area. 3. Soak mushrooms in water (or ammonia/vinegar solution for specific colors) for 24-48 hours. |

| Extraction Method | - Simmering: Simmer mushroom-water mixture for 1-2 hours to extract pigments. - Solar Dyeing: Place mushroom-water mixture in a clear jar and leave in sunlight for 1-2 weeks. |

| Strain & Filter | Strain the liquid through a fine mesh or cheesecloth to remove mushroom solids. |

| Fixing the Dye | Use a mordant (e.g., alum, iron, copper) to fix the dye to the fabric. Different mordants can alter the final color. |

| Dyeing Process | 1. Soak fabric in mordant solution. 2. Simmer fabric in the mushroom dye bath for 1-2 hours. 3. Rinse fabric in cold water until water runs clear. |

| Color Fastness | Mushroom dyes may fade over time, especially with exposure to sunlight. Proper mordanting improves colorfastness. |

| Sustainability | Mushroom dyeing is eco-friendly, using natural materials and producing biodegradable waste. |

| Safety | Always wear gloves and work in a well-ventilated area. Avoid ingesting mushroom dye or using toxic mushrooms. |

| Storage | Store dried mushrooms in a cool, dry place. Dye solutions can be stored in airtight containers in the refrigerator for up to 2 weeks. |

| Experimental Colors | Experiment with different mushroom combinations, mordants, and modifiers (e.g., vinegar, ammonia) to achieve unique colors. |

Explore related products

What You'll Learn

- Mushroom Selection: Identify dye-rich species like Turkey Tail, Chaga, or Lactarius for vibrant colors

- Harvesting Techniques: Sustainably gather mushrooms, ensuring no damage to mycelium or ecosystem

- Preparation Methods: Clean, chop, and simmer mushrooms to extract pigments effectively

- Fixing Colors: Use mordants like alum or iron to bind dye to fibers permanently

- Application Process: Immerse fabric or yarn in mushroom dye bath for even color absorption

Mushroom Selection: Identify dye-rich species like Turkey Tail, Chaga, or Lactarius for vibrant colors

When selecting mushrooms for dye-making, it's essential to identify species known for their vibrant color-producing properties. Turkey Tail (Trametes versicolor) is a top choice due to its abundance and the range of colors it can yield, from earthy browns to subtle greens, depending on the mordant used. This bracket fungus is easily recognizable by its fan-like shape and banded colors, often found on decaying wood in forests. Its accessibility and consistent results make it a favorite among natural dyers.

Another prized species is Chaga (Inonotus obliquus), a unique mushroom that grows primarily on birch trees. Chaga is rich in pigments that produce deep, rich browns and golden hues, making it ideal for creating warm, natural tones. Its distinct charcoal-like appearance sets it apart from other mushrooms, though it’s important to harvest sustainably, as it grows slowly and is highly valued for its medicinal properties as well.

For those seeking brighter, more vivid colors, Lactarius species are excellent choices. These milk-cap mushrooms, such as *Lactarius indigo*, are renowned for their striking blue-green pigments. When processed, they can yield colors ranging from blues to greens, depending on the pH and mordant used. Identifying Lactarius mushrooms requires careful observation, as they exude a milky latex when cut or damaged, a key characteristic of the genus.

It’s crucial to properly identify mushrooms before harvesting, as some species can be toxic or yield unsatisfactory results. Always consult a field guide or expert if you’re unsure. Additionally, consider the ecological impact of your foraging—harvest only what you need and avoid over-collecting from a single area. By selecting dye-rich species like Turkey Tail, Chaga, or Lactarius, you can unlock a palette of natural colors while engaging with the fascinating world of mycology.

Crispy Deep-Fried Portabella Mushrooms: A Step-by-Step Recipe Guide

You may want to see also

Harvesting Techniques: Sustainably gather mushrooms, ensuring no damage to mycelium or ecosystem

When harvesting mushrooms for dye-making, it’s crucial to prioritize sustainability to protect the mycelium and the surrounding ecosystem. The mycelium, the underground network of fungal threads, is the lifeb force of the mushroom, and damaging it can disrupt future growth. Always research and identify the mushroom species you intend to harvest, ensuring they are abundant and not endangered. Use a field guide or consult with a mycologist to confirm identification, as misidentification can lead to ecological harm or personal risk. Sustainable harvesting begins with knowledge and respect for the fungi and their habitats.

To gather mushrooms without harming the mycelium, avoid pulling or twisting the mushrooms from the ground. Instead, use a small knife or scissors to carefully cut the mushroom at the base of the stem. This method ensures the mycelium remains intact and can continue to grow. Leave behind any mushrooms that are too young, too old, or appear diseased, as these play vital roles in the ecosystem, such as spore dispersal or nutrient cycling. Harvest only what you need for dye-making, typically no more than 10-20% of the mushrooms in a single patch, to allow the population to thrive.

The location of your harvest is equally important. Avoid areas that are heavily trafficked or ecologically sensitive, such as wetlands or protected forests. Stick to areas where mushrooms are abundant and where your presence will not disturb wildlife or plant life. After harvesting, tread lightly and avoid compacting the soil, as this can damage the mycelium and other organisms. If possible, follow established trails or create minimal impact by spreading out your steps in open areas.

Timing is another key factor in sustainable mushroom harvesting. The best time to harvest is during dry weather, as wet conditions can increase the risk of damaging the mycelium and spreading diseases. Early morning or late afternoon is ideal, as mushrooms are typically more hydrated and easier to handle. Avoid harvesting after heavy rain, as the ground may be too soft, and the mushrooms may be waterlogged, reducing their dye-making potential.

Finally, consider giving back to the ecosystem after harvesting. One way to do this is by collecting and dispersing mushroom spores from the caps you’ve harvested. Place the caps gill-side down on a piece of paper or waxed surface in a cool, dry place for 24-48 hours. Once the spores have dropped, you can gently shake the paper over the area where you harvested to help propagate new growth. This practice supports the long-term health of the mushroom population and ensures a sustainable supply for future dye-making projects. By following these techniques, you can responsibly gather mushrooms while preserving the delicate balance of their ecosystem.

Creamy Mushroom Sauce Recipe: Easy Milk-Based Method for Rich Flavor

You may want to see also

Preparation Methods: Clean, chop, and simmer mushrooms to extract pigments effectively

To begin the process of extracting pigments from mushrooms for dye-making, it's essential to start with clean mushrooms. Gently brush off any dirt or debris from the mushroom caps and stems using a soft brush or a damp cloth. Avoid washing the mushrooms under running water, as this can cause them to absorb excess moisture and potentially dilute the pigment extraction. If the mushrooms are particularly dirty, you can quickly rinse them and pat them dry with a clean towel. Proper cleaning ensures that you're working with a pure source of pigments and prevents any unwanted particles from contaminating your dye.

Once the mushrooms are clean, the next step is to chop them into small, uniform pieces. This increases the surface area of the mushrooms, allowing for more efficient pigment extraction. Use a sharp knife to slice the mushroom caps and stems into thin strips or small cubes, roughly 1/4 to 1/2 inch in size. The finer the chop, the more pigment you'll be able to extract. If you're working with a large quantity of mushrooms, consider using a food processor to speed up the chopping process. However, be careful not to over-process the mushrooms, as this can lead to a mushy consistency that may be difficult to work with.

After chopping the mushrooms, it's time to simmer them to extract the pigments. Place the chopped mushrooms in a large pot and add enough water to cover them by about 1-2 inches. The water-to-mushroom ratio is crucial, as too little water can result in a weak dye, while too much water can dilute the pigments. Bring the mixture to a gentle simmer over medium heat, stirring occasionally to prevent sticking or burning. Maintain a low simmer for 30 minutes to 1 hour, depending on the mushroom species and the desired pigment intensity. Keep in mind that over-simmering can cause the pigments to break down, resulting in a less vibrant dye.

As the mushrooms simmer, you'll notice the water taking on the color of the pigments. This liquid, known as the dye bath, will be used to dye your chosen material. To further enhance pigment extraction, you can add a mordant to the dye bath. Mordants are substances that help fix the dye to the fabric or material, improving colorfastness and intensity. Common mordants include alum, iron, or copper sulfate, which can be added to the dye bath in small quantities (typically 10-15% of the weight of the mushrooms). Be sure to research the appropriate mordant and quantity for your specific mushroom species and desired color.

After simmering, allow the dye bath to cool before straining out the mushroom pieces. Use a fine-mesh strainer or cheesecloth to separate the liquid from the solids, reserving the dye bath for later use. The spent mushroom pieces can be composted or discarded. If desired, you can repeat the simmering process with the same mushroom pieces to extract any remaining pigments, although the resulting dye will be less intense. Once you've extracted the pigments, your mushroom dye is ready to be used on a variety of materials, from fabric and yarn to paper and wood. Remember to always test your dye on a small sample before committing to a larger project, as colors may vary depending on the mushroom species, mordant used, and material being dyed.

Rich & Creamy Mushroom Sauce: Elevate Your Pork Dishes Effortlessly

You may want to see also

Explore related products

$8.99 $18.99

Fixing Colors: Use mordants like alum or iron to bind dye to fibers permanently

When creating mushroom dyes, fixing the colors to the fibers is crucial for ensuring the hues remain vibrant and long-lasting. Mordants play a vital role in this process by chemically bonding the dye molecules to the fabric, preventing them from washing out. Common mordants used in mushroom dyeing include alum (potassium aluminum sulfate) and iron (ferrous sulfate). Alum is the most versatile and gentle, suitable for a wide range of fibers like wool, silk, and plant-based materials such as cotton or linen. It tends to brighten colors and is considered safe for both the fabric and the environment. Iron, on the other hand, darkens shades and can create dramatic, earthy tones but may weaken fibers over time, so it should be used sparingly.

To use alum as a mordant, start by preparing a mordant bath. Dissolve alum in hot water at a ratio typically ranging from 10-20% of the weight of the fiber material. For example, if you have 100 grams of fabric, use 10-20 grams of alum. Stir until fully dissolved, then add your pre-soaked fabric to the bath. Simmer the mixture for about an hour, ensuring the fabric is fully submerged and agitated occasionally. After mordanting, rinse the fabric in cool water and let it dry. This process prepares the fibers to absorb the mushroom dye more effectively and permanently.

Iron mordants work differently and are often used post-dyeing to modify colors. To apply an iron mordant, create a solution by dissolving ferrous sulfate in hot water at a lower concentration, usually around 5-10% of the fiber weight. Submerge the dyed fabric in this solution for 15-30 minutes, then rinse thoroughly. Iron will shift colors toward darker, muted tones, such as transforming bright yellows into deep greens or softening reds into browns. Be cautious with iron, as prolonged exposure can damage delicate fibers like silk.

The order of mordanting can vary depending on the desired effect. Pre-mordanting involves treating the fabric with a mordant before dyeing, which often results in clearer, more consistent colors. Post-mordanting, or modifying the dyed fabric with a mordant like iron, allows for creative color adjustments. Experimenting with both methods can help you achieve unique results in mushroom dyeing. Always wear gloves and work in a well-ventilated area when handling mordants, as they can be irritating to the skin and respiratory system.

Finally, proper disposal of mordant solutions is essential for environmental safety. Neutralize alum solutions with baking soda before discarding, and avoid pouring iron solutions directly into waterways, as they can harm aquatic life. By mastering the use of mordants like alum and iron, you can ensure that the beautiful colors extracted from mushrooms remain permanently fixed to your fibers, creating durable and visually stunning textiles.

Mastering Mushroom Cultivation: Techniques for Growing Varied Fungal Varieties

You may want to see also

Application Process: Immerse fabric or yarn in mushroom dye bath for even color absorption

To achieve even color absorption when dyeing fabric or yarn with mushroom dye, the immersion process is a critical step. Begin by preparing your mushroom dye bath according to the recipe you’ve chosen, ensuring the color has fully extracted into the water. Once the dye bath is ready, pre-treat your fabric or yarn by soaking it in a mixture of warm water and a fixative, such as vinegar for cellulose fibers (cotton, linen) or alum for protein fibers (wool, silk). This pre-treatment helps the fibers absorb the dye more evenly. Gently squeeze out excess water from the fabric or yarn before adding it to the dye bath to avoid diluting the color.

When immersing the fabric or yarn, ensure it is fully submerged and evenly distributed in the dye bath. Use a non-reactive utensil, like a wooden spoon or stainless steel tongs, to gently push the material down and avoid trapping air bubbles, which can lead to uneven dyeing. For larger pieces of fabric, fold or scrunch it loosely rather than tightly balling it up, as this allows the dye to penetrate all areas uniformly. Keep the dye bath at a consistent temperature, typically between 180°F to 200°F (82°C to 93°C), depending on the fiber type, and avoid stirring excessively to prevent felting or tangling.

The duration of immersion depends on the desired color intensity and the type of mushroom dye used. Generally, allow the fabric or yarn to soak in the dye bath for at least 30 minutes to an hour, but it can be left longer for deeper hues. For gradient effects, you can remove portions of the fabric or yarn at different intervals. Monitor the color absorption periodically by lifting a small section with tongs and checking the shade against a white background. Be mindful that the color will appear darker when wet and will lighten slightly as it dries.

To ensure even color absorption, periodically gently agitate the fabric or yarn in the dye bath. This can be done by carefully lifting and lowering it or using a stirring motion that avoids twisting or stressing the fibers. Avoid over-handling, as this can cause uneven dye distribution or damage delicate materials. If dyeing multiple items, ensure they are not overcrowded in the bath, as this can prevent the dye from reaching all surfaces evenly.

Once the desired color is achieved, carefully remove the fabric or yarn from the dye bath using tongs or a mesh strainer. Rinse it gently in cool water until the water runs clear, being careful not to agitate the fibers excessively, as this can cause bleeding or felting. For cellulose fibers, a final rinse in a vinegar solution can help set the dye further. After rinsing, gently squeeze out excess water and allow the fabric or yarn to air dry away from direct sunlight, as UV rays can fade the color. Proper immersion and handling during the dyeing process will result in beautifully even and vibrant mushroom-dyed textiles.

Crispy Mushroom Chips: Easy Homemade Snack Recipe Guide

You may want to see also

Frequently asked questions

Mushrooms like Turkey Tail, Chaga, Reishi, and various Boletus species are commonly used for dyeing due to their rich pigments.

Clean the mushrooms, chop or grind them, and simmer in water for 30–60 minutes to extract the color. Strain the liquid to remove solids.

Both fresh and dried mushrooms work, but dried mushrooms are more concentrated and often yield stronger colors.

Natural fibers like wool, silk, cotton, and linen absorb mushroom dyes best. Pre-treat fabrics with a mordant like alum for better color adhesion.

Use a mordant (e.g., alum, iron, or copper) before dyeing to bind the color to the fabric. Follow with a vinegar or salt soak to set the dye further.