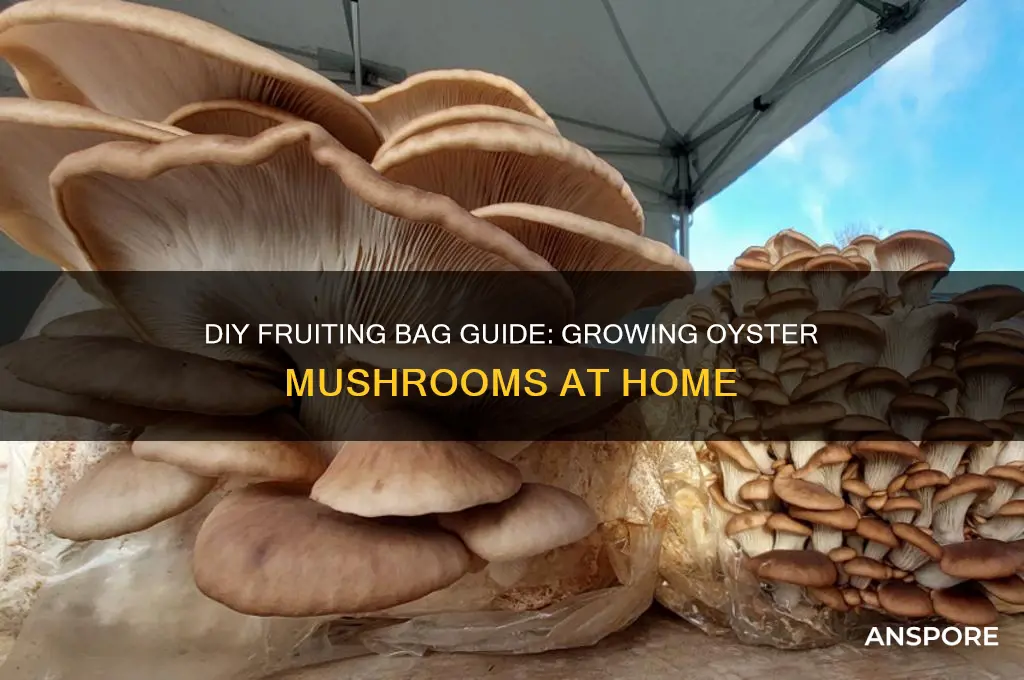

Creating a fruiting bag for oyster mushrooms is a straightforward yet crucial step in the cultivation process, allowing mycelium to transition from vegetative growth to mushroom production. To make a fruiting bag, start by preparing a substrate mixture, typically composed of pasteurized straw, sawdust, or a combination of both, supplemented with nutrients like bran or gypsum. After sterilizing or pasteurizing the substrate to eliminate contaminants, it is placed into a breathable bag, such as an autoclave bag with a filter patch, which allows for gas exchange while preventing contamination. The bag is then inoculated with oyster mushroom spawn and incubated in a dark, warm environment until the mycelium fully colonizes the substrate. Once colonization is complete, the bag is moved to a fruiting chamber with controlled humidity, light, and temperature, encouraging the mycelium to produce mushrooms. This method ensures a clean, efficient, and productive environment for growing oyster mushrooms at home or on a small scale.

Explore related products

What You'll Learn

- Materials Needed: Gather polypropylene bags, substrate, spawn, rubber bands, and a sharp knife

- Preparing Substrate: Sterilize or pasteurize straw, sawdust, or coffee grounds for optimal growth

- Inoculating Bags: Mix spawn with substrate, fill bags ¾ full, and seal tightly

- Incubation Process: Keep bags in a dark, humid place at 70-75°F for colonization

- Fruiting Conditions: Introduce light, fresh air, and misting to trigger mushroom formation

Materials Needed: Gather polypropylene bags, substrate, spawn, rubber bands, and a sharp knife

To begin creating your fruiting bags for oyster mushrooms, you'll need to gather several essential materials. Polypropylene bags are the foundation of your fruiting chamber. These bags are ideal due to their breathability, which allows for proper gas exchange while maintaining humidity. Ensure the bags are clean and free from any contaminants. You can find these bags in various sizes, but a standard 5-7 gallon capacity works well for most home growers. The polypropylene material is durable and can withstand the moisture levels required for mushroom cultivation.

Next, prepare the substrate, which serves as the nutrient base for your mushrooms. Common substrates include straw, sawdust, or a mixture of both, often supplemented with materials like coffee grounds or gypsum. The substrate should be pasteurized or sterilized to eliminate competing organisms. This step is crucial for ensuring that your oyster mushrooms have a clean environment to grow. Properly prepared substrate will significantly increase your chances of a successful harvest.

Spawn is another critical component, as it contains the mycelium of the oyster mushroom. You can purchase pre-made spawn or create your own if you have the necessary equipment. The spawn should be mixed thoroughly with the substrate to ensure even colonization. High-quality spawn will accelerate the growth process and improve the overall yield. Make sure to handle the spawn carefully to avoid contamination.

Rubber bands are simple yet indispensable tools in this process. They are used to secure the polypropylene bags after filling them with the substrate and spawn mixture. Choose rubber bands that are strong and flexible to ensure a tight seal. This prevents contaminants from entering while allowing the mycelium to breathe. Properly sealed bags also help maintain the right level of humidity, which is vital for fruiting.

Lastly, a sharp knife is needed for creating small slits or holes in the polypropylene bags. These openings serve as the exit points for the mushrooms to grow. A sharp knife ensures clean cuts, reducing the risk of damaging the bag or introducing contaminants. The size and number of slits can vary, but typically, 2-4 small openings are sufficient for oyster mushrooms to fruit successfully. With these materials gathered and prepared, you’re ready to proceed with creating your fruiting bags.

Creamy Spinach & Mushroom Soup: A Delicious, Easy Recipe Guide

You may want to see also

Preparing Substrate: Sterilize or pasteurize straw, sawdust, or coffee grounds for optimal growth

Preparing the substrate is a critical step in creating a fruiting bag for oyster mushrooms, as it directly impacts the success of mushroom growth. The substrate, which can be straw, sawdust, or coffee grounds, must be properly sterilized or pasteurized to eliminate competing microorganisms and create an ideal environment for mycelium colonization. Sterilization and pasteurization are two methods used to treat the substrate, each with its own advantages depending on the resources available and the scale of your project.

Sterilization is the more thorough method, typically used for smaller batches or when working with sawdust. To sterilize sawdust, dampen it with water until it feels like a wrung-out sponge, then place it in an autoclave or a large pot with a secure lid. Steam sterilization requires heating the substrate to 121°C (250°F) for at least 1.5 hours. If using a pot, ensure it is sealed tightly to maintain pressure and temperature. For straw, sterilization can be achieved by soaking it in a hydrogen peroxide solution (3% concentration) for 12–24 hours, followed by rinsing thoroughly to remove any residue. Sterilization ensures that all contaminants are eradicated, providing a clean slate for the mushroom mycelium to thrive.

Pasteurization is a more accessible method, particularly for straw and coffee grounds, as it requires less specialized equipment. To pasteurize straw, soak it in hot water (70–80°C or 158–176°F) for 1–2 hours, then drain and cool it before use. Alternatively, you can use a pasteurization solution of hydrated lime (calcium hydroxide) mixed with water, soaking the straw for 12–24 hours. For coffee grounds, mix them with boiling water and let the mixture sit for 1–2 hours before draining excess moisture. Pasteurization reduces the microbial load without completely eliminating it, which is often sufficient for oyster mushrooms, as they are aggressive colonizers.

Regardless of the method chosen, it’s essential to allow the substrate to cool to room temperature before inoculating it with mushroom spawn. Excess moisture should also be removed to prevent waterlogging, which can hinder mycelium growth. For straw, lightly squeeze out excess water after pasteurization, and for sawdust or coffee grounds, ensure the mixture is evenly damp but not soggy. Properly prepared substrate will provide the mycelium with the nutrients and environment it needs to grow vigorously, setting the stage for a successful fruiting bag.

Finally, once the substrate is sterilized or pasteurized, it should be transferred to a clean, sterile environment for inoculation. This minimizes the risk of recontamination. Using a fruiting bag with a filter patch allows for gas exchange while keeping contaminants out. By carefully preparing the substrate, you create a foundation that supports healthy mycelium development, ultimately leading to abundant oyster mushroom yields.

Perfectly Creamy Chicken and Mushroom Pie: Easy Homemade Recipe Guide

You may want to see also

Inoculating Bags: Mix spawn with substrate, fill bags ¾ full, and seal tightly

Inoculating bags is a critical step in creating fruiting bags for oyster mushrooms, as it involves combining the mushroom spawn with the substrate to initiate mycelial growth. Begin by preparing your substrate, which is typically a mixture of straw, sawdust, or a combination of both, properly pasteurized or sterilized to eliminate competing organisms. Once the substrate has cooled to a suitable temperature (around 75-85°F or 24-29°C), it’s ready to be mixed with the oyster mushroom spawn. Use a clean, sterile environment to avoid contamination, such as a still air box or a clean room. Measure the correct ratio of spawn to substrate, usually 10-20% spawn by weight, and mix thoroughly. Ensure the spawn is evenly distributed throughout the substrate to promote uniform colonization.

After mixing, fill your grow bags ¾ full with the spawn and substrate mixture. This leaves adequate space for the mycelium to expand and for air exchange, which is essential for healthy growth. Use polypropylene or autoclavable bags with microfiltration patches to allow gas exchange while keeping contaminants out. As you fill the bags, gently pack the mixture to eliminate large air pockets but avoid compacting it too tightly, as this can restrict mycelial growth. Properly filled bags will provide the ideal environment for the mycelium to thrive and eventually fruit.

Sealing the bags tightly is crucial to prevent contamination and maintain a controlled environment for the mycelium. Use a bag sealer or an impulse sealer to create a secure, airtight seal. If using reusable bags with ties or clamps, ensure they are closed tightly and double-check for any gaps. Label each bag with the inoculation date and substrate type for tracking purposes. Once sealed, gently shake or pat the bags to further distribute the spawn and substrate mixture evenly. This step ensures that the mycelium has the best possible start in colonizing the substrate.

After sealing, place the inoculated bags in a warm, dark environment with stable temperatures between 70-75°F (21-24°C) to encourage mycelial growth. Avoid direct sunlight and extreme temperature fluctuations. The bags will enter the colonization phase, during which the mycelium will grow and spread throughout the substrate. This phase typically takes 2-4 weeks, depending on conditions and substrate type. Regularly inspect the bags for signs of contamination, such as mold or unusual colors, and remove any affected bags immediately to protect the rest.

Once the substrate is fully colonized (white and covered with mycelium), the bags are ready to be induced into fruiting. At this stage, the focus shifts from mycelial growth to creating conditions favorable for mushroom formation. Inoculating the bags correctly—by mixing spawn with substrate, filling them ¾ full, and sealing tightly—lays the foundation for a successful fruiting process. Proper execution of these steps ensures a healthy mycelial network, which is essential for abundant oyster mushroom yields.

Mastering Creamy Mushroom Perfection: Simple Steps for Rich, Velvety Delight

You may want to see also

Explore related products

Incubation Process: Keep bags in a dark, humid place at 70-75°F for colonization

The incubation process is a critical phase in cultivating oyster mushrooms, as it allows the mycelium to colonize the substrate fully. After preparing your fruiting bags, the next step is to create an optimal environment for mycelial growth. This involves maintaining specific conditions of darkness, humidity, and temperature. Place the bags in a dark area, as light can inhibit mycelium growth during this stage. A closet, cabinet, or a dedicated incubation chamber works well, ensuring that no light penetrates the space. Darkness encourages the mycelium to focus its energy on spreading throughout the substrate rather than forming mushrooms prematurely.

Humidity is another crucial factor during incubation. The environment should be consistently humid to prevent the substrate from drying out, which can halt mycelial growth. Aim for a relative humidity of around 70-80% in the incubation area. You can achieve this by using a humidifier or placing a tray of water near the bags to increase moisture levels. Alternatively, enclosing the bags in a large plastic container or tent with a humidifier can create a controlled humid environment. Regularly monitor humidity levels using a hygrometer to ensure they remain within the desired range.

Temperature control is equally important, as it directly affects the speed and efficiency of colonization. The ideal temperature range for incubating oyster mushroom bags is 70-75°F (21-24°C). At this range, the mycelium grows vigorously without expending excess energy. Use a thermometer to monitor the temperature and make adjustments as needed. If the space is too warm, consider using fans or air conditioning to cool it down. For cooler environments, a space heater or insulation around the incubation area can help maintain the desired temperature. Consistency is key, as fluctuations can stress the mycelium and slow down colonization.

During the incubation period, which typically lasts 2-4 weeks, avoid disturbing the bags unnecessarily. Movement or handling can introduce contaminants or disrupt the mycelium’s growth. However, it’s essential to inspect the bags periodically for signs of contamination, such as mold or unusual colors. If contamination is detected, isolate the affected bag immediately to prevent it from spreading. Proper sterilization of tools and hands before handling the bags can minimize the risk of contamination during this vulnerable stage.

Patience is vital during the incubation process, as rushing can lead to poor colonization and reduced yields. Once the mycelium has fully colonized the substrate—indicated by a white, fluffy appearance throughout the bag—it’s time to move on to the fruiting stage. At this point, the bags are ready to be exposed to light, fresh air, and cooler temperatures to initiate mushroom formation. By maintaining optimal darkness, humidity, and temperature during incubation, you set the foundation for a successful and bountiful oyster mushroom harvest.

Easy Guide to Drying Fresh Shiitake Mushrooms for Longevity

You may want to see also

Fruiting Conditions: Introduce light, fresh air, and misting to trigger mushroom formation

Once your oyster mushroom mycelium has fully colonized the substrate in the grow bag, it’s time to create the ideal fruiting conditions to trigger mushroom formation. This involves introducing light, fresh air, and misting, which mimic the natural environment mushrooms thrive in. Light is essential but doesn't need to be intense; a simple 8–12 hours of indirect natural light or artificial lighting (like a fluorescent bulb) per day is sufficient. Mushrooms don't require sunlight for photosynthesis, but light signals the mycelium to begin fruiting. Avoid direct sunlight, as it can dry out the substrate and harm the mycelium.

Fresh air exchange is another critical factor for fruiting. Oyster mushrooms need oxygen to develop properly, so ensure the grow bag has small holes or slits for air circulation. If using a fruiting chamber, maintain a slightly humid environment while allowing for passive airflow. Stagnant air can lead to mold or malformed mushrooms. You can also gently fan the area once or twice a day to simulate a breeze, which encourages healthy pin formation and prevents CO₂ buildup.

Misting is the final key element to create the right humidity for fruiting. Mushrooms require high humidity (around 80–90%) to develop properly. Lightly mist the inside of the fruiting chamber or the grow bag’s surface 2–3 times a day, ensuring not to oversaturate the substrate. Use a spray bottle with clean, filtered water to avoid introducing contaminants. Misting not only maintains humidity but also provides the moisture needed for mushroom growth. Be consistent with misting, as fluctuations in humidity can stress the mycelium and hinder fruiting.

To optimize fruiting conditions, monitor the environment closely. Keep the temperature between 60–75°F (15–24°C), as oyster mushrooms are sensitive to extreme heat or cold. Combine light, fresh air, and misting with patience, as it can take 7–14 days for pins (tiny mushroom primordia) to appear. Once pins form, reduce direct misting to avoid waterlogging and focus on maintaining humidity and airflow. With the right conditions, your fruiting bag will soon be filled with clusters of oyster mushrooms ready for harvest.

Creamy Mushroom Bruschetta: A Simple, Flavorful Appetizer Recipe Guide

You may want to see also

Frequently asked questions

You will need a plastic bag (preferably breathable or with small holes), a substrate colonized with oyster mushroom mycelium, a sharp knife or scissors, and optionally, a spray bottle for misting.

First, take your colonized substrate and place it into the plastic bag. Ensure the bag is large enough to allow room for mushroom growth. Cut small slits (about 1-2 inches long) on the sides of the bag to provide ventilation and access for the mushrooms to grow out. Mist the inside of the bag lightly to maintain humidity.

Maintain a temperature range of 60-75°F (15-24°C) and humidity around 80-90%. Place the bag in a well-ventilated area with indirect light. Mist the bag occasionally to keep the environment humid, but avoid over-saturating the substrate.