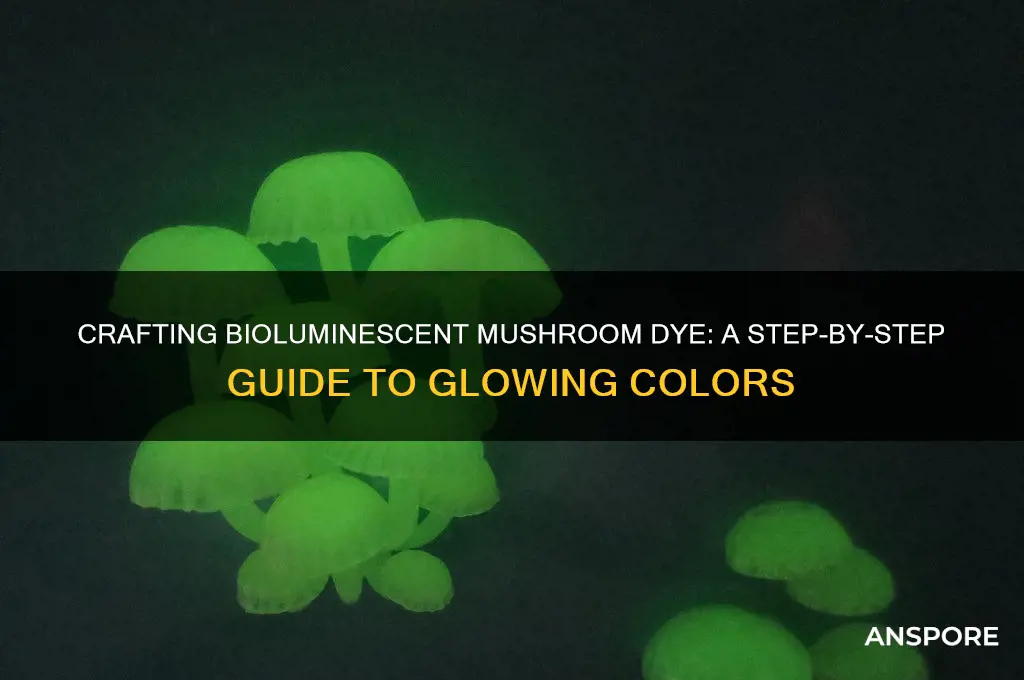

Creating glowing mushroom dye is a fascinating blend of science and art, harnessing the bioluminescent properties of certain fungi to produce a mesmerizing glow. This process involves identifying and harvesting specific mushroom species, such as *Mycena lux-coeli* or *Panellus stipticus*, which naturally emit light through a chemical reaction within their cells. Once collected, the mushrooms are carefully processed to extract their luminescent compounds, often through methods like blending or soaking in a solvent. The resulting liquid is then filtered and mixed with a stabilizing agent to enhance its glow and longevity. This dye can be applied to fabrics, paper, or other materials, creating an enchanting, otherworldly effect that glows softly in the dark. While the process requires precision and patience, the end result is a unique, eco-friendly way to bring a touch of magic to creative projects.

Explore related products

What You'll Learn

Gathering Bioluminescent Mushrooms

To begin the process of creating glowing mushroom dye, the first and most crucial step is gathering bioluminescent mushrooms. These unique fungi are the key ingredient, as they naturally produce a glowing effect due to their bioluminescent properties. Bioluminescent mushrooms are typically found in specific environments, such as damp, dark forests with rich organic matter. Before embarking on your gathering expedition, research the types of bioluminescent mushrooms native to your region, as different species may have varying levels of luminosity and suitability for dye-making. Common varieties include the Ghost Mushroom (*Omphalotus olearius*) and the Jack-O-Lantern Mushroom (*Omphalotus illudens*), both known for their vibrant green glow.

When gathering bioluminescent mushrooms, timing is essential. These fungi often emit the brightest light during the darker hours, so plan your expedition for late evening or early morning. Equip yourself with a dim red light to navigate without disrupting the mushrooms' natural glow. Red light is less likely to interfere with their bioluminescence, allowing you to spot them more easily in their natural habitat. Wear appropriate clothing, including gloves, to protect yourself from potential irritants or toxins that some mushrooms may carry. Always carry a detailed field guide or use a reliable mushroom identification app to ensure you are collecting the correct species, as misidentification can lead to ineffective dye or even harmful consequences.

Locating bioluminescent mushrooms requires patience and a keen eye. Look for them growing on decaying wood, tree stumps, or at the base of old trees, as these are their preferred substrates. Their glow can be subtle, appearing as a soft, ethereal light in the darkness. To confirm their bioluminescence, gently touch the mushroom or place it in a darker area to observe the glow more clearly. Avoid picking mushrooms that appear damaged, discolored, or overgrown with other organisms, as these may not yield the best results for dye-making. Aim to collect a sufficient quantity, typically around 1-2 pounds (0.5-1 kg), depending on the desired intensity of your dye.

As you gather the mushrooms, handle them with care to preserve their bioluminescent properties. Place them in a breathable container, such as a mesh bag or a basket, to prevent moisture buildup and spoilage. Avoid sealing them in airtight containers, as this can cause them to degrade quickly. If possible, use the mushrooms immediately after gathering, as their glow may fade over time. If you need to store them temporarily, keep them in a cool, dark place, such as a refrigerator, for no more than 24 hours to maintain their luminosity.

Lastly, practice responsible foraging by respecting the environment and ensuring the sustainability of the mushroom population. Only collect what you need and avoid over-harvesting from a single area. Leave some mushrooms behind to allow them to release spores and propagate for future growth. By following these guidelines, you’ll successfully gather bioluminescent mushrooms, setting the stage for the next steps in creating your glowing mushroom dye.

Delicious Gluten-Free Mushroom Sandwich: Easy Recipe for a Tasty Meal

You may want to see also

Safe Handling & Preparation

When working with materials to create glowing mushroom dye, safety should always be your top priority. The process involves handling potentially hazardous substances, so it’s essential to take precautions to protect yourself and your workspace. Begin by setting up in a well-ventilated area or using a fume hood if available. Wear personal protective equipment (PPE), including nitrile gloves, safety goggles, and a lab coat or apron, to minimize skin and eye exposure. Ensure your workspace is clean and free of clutter to avoid contamination and spills. Keep a first-aid kit nearby and familiarize yourself with emergency procedures in case of accidental exposure.

Before starting, thoroughly research the specific materials you’ll be using, such as luminescent compounds or mushroom extracts, to understand their properties and potential risks. Some substances may be toxic or irritants, so handle them with care. Always use high-quality, food-grade or non-toxic materials if the dye will come into contact with skin or be used in a sensitive environment. Measure all ingredients precisely using calibrated tools to avoid overuse or wastage. Store all chemicals in their original containers with proper labels, and never mix substances unless you are certain of their compatibility to prevent dangerous reactions.

Preparation of the mushroom material requires careful handling to avoid contamination and ensure the dye’s effectiveness. Start by selecting fresh, non-toxic mushroom species known for their bioluminescent properties or those that can be safely treated with luminescent compounds. Clean the mushrooms thoroughly under running water to remove dirt and debris, then pat them dry with paper towels. If extracting compounds, use sterile tools and containers to prevent bacterial growth. For dyes involving chemical treatments, follow a tested recipe and avoid improvising, as incorrect ratios can lead to unsafe results.

During the dye-making process, maintain a clean and organized workspace. Use heat-resistant glassware if heating is required, and never leave hot equipment unattended. Stir mixtures gently to avoid splashing, and dispose of any waste materials according to local regulations. If using luminescent chemicals, avoid inhaling powders or vapors by working in a well-ventilated area or using a mask. After completing the process, clean all tools and surfaces with appropriate solvents or disinfectants to remove any residue and prevent cross-contamination in future projects.

Finally, store your glowing mushroom dye safely to maintain its quality and prevent accidents. Use airtight, labeled containers made of materials compatible with the dye, such as glass or certain plastics. Keep the dye away from direct sunlight, heat sources, and children or pets. If the dye contains chemicals, store it in a designated area separate from food or personal care items. Always test a small sample of the dye on a discreet surface or material before full application to ensure it behaves as expected and does not cause unintended damage or reactions.

Easy Dry Mushroom Vegetable Recipe: A Flavorful, Healthy Dish Guide

You may want to see also

Extraction Process for Dye

The extraction process for creating glowing mushroom dye involves several precise steps to ensure the luminescent properties are effectively captured. Begin by selecting the appropriate bioluminescent mushroom species, such as *Mycena lux-coeli* or *Panellus stipticus*, which are known for their natural glow. Harvest the mushrooms during their peak bioluminescence phase, typically in the late evening or early morning, to maximize the concentration of luciferin and luciferase, the compounds responsible for the glow. Clean the mushrooms gently with a soft brush to remove dirt and debris without damaging the delicate structures that house the bioluminescent compounds.

Once cleaned, the mushrooms must be prepared for extraction. Chop them into small, uniform pieces to increase the surface area and facilitate the release of the bioluminescent compounds. Place the chopped mushrooms into a glass or food-grade plastic container, ensuring it is clean and free from contaminants that could interfere with the extraction. Add a solvent to the container, such as ethanol or a water-based solution, depending on the desired application of the dye. Ethanol is effective for extracting luciferin and luciferase but may require additional steps to make the dye water-soluble. For a simpler process, distilled water can be used, though it may yield a less concentrated extract.

Next, initiate the extraction process by allowing the mushrooms to steep in the solvent. This can be done at room temperature for 24 to 48 hours, with occasional gentle agitation to encourage the release of the bioluminescent compounds. For a faster extraction, apply low heat (around 40-50°C) using a water bath or double boiler, but avoid boiling, as high temperatures can degrade the sensitive compounds. After steeping, strain the mixture through a fine mesh or cheesecloth to separate the solid mushroom material from the liquid extract. The resulting liquid will contain the glowing compounds and can be further concentrated if needed by gently evaporating some of the solvent.

To purify the extract and enhance its stability, consider additional steps such as filtration or centrifugation to remove any remaining particulate matter. Store the extract in a dark, airtight container at a cool temperature to preserve its luminescent properties. For longer-term storage, refrigeration is recommended. The extracted dye can now be used in various applications, such as art, textiles, or decorative purposes, where its glowing properties will be showcased.

Finally, test the dye’s luminescence by applying it to a suitable medium in a dark environment. If the glow is not as intense as desired, repeat the extraction process with a higher mushroom-to-solvent ratio or experiment with different solvents. Remember that the glow is a natural phenomenon and may vary depending on the mushroom species and extraction conditions. With patience and attention to detail, the extraction process will yield a captivating glowing mushroom dye that highlights the beauty of bioluminescence.

Creamy Mushroom Masala Recipe: Easy Steps for Rich, Flavorful Curry

You may want to see also

Explore related products

Fixing Dye to Fabric

To fix glowing mushroom dye to fabric, start by preparing the fabric. Wash the fabric in warm water with a mild detergent to remove any finishes or impurities that might interfere with dye absorption. Avoid using fabric softeners, as they can leave a residue that repels dye. After washing, rinse the fabric thoroughly and let it air dry. If you’re working with natural fibers like cotton, silk, or wool, they will generally take the dye better than synthetic fabrics. For best results, choose a fabric that is light in color or white, as this will allow the glow to show more vividly.

Once the fabric is prepared, create a dye fixative solution to ensure the glowing mushroom dye adheres permanently. A common fixative for natural dyes is alum (potassium aluminum sulfate), which helps the dye molecules bond to the fabric fibers. Dissolve 1 part alum in 16 parts warm water, stirring until fully dissolved. Submerge the fabric in this solution for at least one hour, or overnight for better results. After soaking, rinse the fabric in cool water to remove excess alum, then gently squeeze out the water without wringing the fabric to avoid distortion.

Next, prepare the glowing mushroom dye solution. Follow the recipe you’ve gathered from researching how to make glowing mushroom dye, typically involving bioluminescent mushrooms or phosphorescent pigments. Heat the dye solution gently in a large pot, ensuring it’s warm but not boiling, as high temperatures can damage the glow properties. Submerge the pre-treated fabric into the dye bath, ensuring it is fully immersed and evenly distributed. Let the fabric soak in the dye for at least 30 minutes to an hour, stirring occasionally to ensure even coloration.

After dyeing, remove the fabric from the dye bath and rinse it in cool water until the water runs clear. This step removes any excess dye that hasn’t bonded to the fabric. To further fix the dye and enhance its glow, prepare a vinegar bath by mixing 1 part white vinegar with 4 parts water. Soak the dyed fabric in this solution for 10 minutes, then rinse again with cool water. The acidity of the vinegar helps set the dye molecules into the fabric fibers, improving longevity and brightness.

Finally, allow the fabric to air dry away from direct sunlight, as UV rays can degrade the glow properties. Once dry, heat-set the dye by ironing the fabric on a medium setting or tumbling it in a dryer on low heat for 10–15 minutes. This process helps lock in the dye and ensures it remains vibrant and glowing. Test the fabric’s glow in a dark room to verify the dye has taken properly. If the glow is faint, repeat the dyeing process or consider adding more phosphorescent pigment to the dye solution for a stronger effect.

Easy Fresh Mushroom Pasta Recipe: Creamy, Savory, and Quick to Make

You may want to see also

Preserving Glow Longevity

To preserve the glow longevity of your glowing mushroom dye, it's essential to understand the factors that contribute to its luminescence. The glow is typically produced by a chemical reaction involving luciferin, luciferase, and oxygen. This reaction is sensitive to environmental conditions, so controlling these factors is key to maintaining the glow. Start by ensuring that the mushrooms you use, such as *Mycena lux-coeli* or *Panellus stipticus*, are fresh and properly prepared. The extraction process should be done in a cool, dark environment to minimize degradation of the bioluminescent compounds.

Once the dye is prepared, storing it in optimal conditions is crucial for preserving its glow. Keep the dye in airtight containers to prevent exposure to oxygen, which can accelerate the degradation of the bioluminescent reaction. Store the containers in a refrigerator at temperatures between 2°C and 4°C, as lower temperatures slow down enzymatic activity and prolong the glow. Avoid freezing the dye, as ice crystals can damage the delicate enzymes and luciferin molecules. Additionally, protect the dye from light by using opaque or amber-colored containers, as light can also degrade the bioluminescent compounds.

Another effective method to enhance glow longevity is by adding stabilizers to the dye solution. Glycerol or sorbitol can be incorporated as cryoprotectants to protect the enzymes and luciferin during storage. These compounds help maintain the structural integrity of the bioluminescent proteins, ensuring they remain functional for longer periods. Similarly, including mild detergents like Tween 20 can stabilize the enzymes by preventing them from denaturing. However, use these additives sparingly, as high concentrations can interfere with the bioluminescent reaction.

The substrate on which the dye is applied also plays a significant role in preserving the glow. Porous materials like fabric or wood can absorb the dye, providing a longer-lasting glow compared to non-porous surfaces. To maximize longevity, pre-treat the substrate with a fixative solution, such as a mixture of water and a small amount of formaldehyde or a natural alternative like vinegar. This helps bind the dye molecules to the material, reducing leaching and maintaining brightness. After application, allow the dyed material to dry completely in a dark, cool environment to avoid premature activation of the bioluminescence.

Finally, minimizing exposure to environmental stressors is vital for preserving the glow. Avoid exposing the dyed material to heat, direct sunlight, or harsh chemicals, as these can degrade the bioluminescent compounds. If the dyed item needs to be washed, use cold water and a gentle, enzyme-free detergent to prevent damage to the glow components. For long-term storage of dyed items, wrap them in light-blocking fabric or store them in dark containers. By carefully controlling these factors, you can significantly extend the glow longevity of your glowing mushroom dye, ensuring it remains vibrant for weeks or even months.

Creamy Mushroom Enchilada Casserole: Easy Layered Mexican Comfort Food Recipe

You may want to see also

Frequently asked questions

To make glowing mushroom dye, you'll need bioluminescent mushrooms (like *Mycena lux-coeli* or *Panellus stipticus*), a solvent (such as ethanol or water), a mortar and pestle, a fine mesh strainer, and a container for storage.

Crush the mushrooms in a mortar and pestle to break down their cells, then mix with a solvent (ethanol or water) to extract the luciferin and luciferase compounds responsible for the glow. Strain the mixture to remove solids and collect the liquid dye.

Yes, glowing mushroom dye can be applied to fabrics, paper, or other porous materials. However, the glow is temporary and may fade over time, especially when exposed to light or heat. Fixatives like vinegar or alum can help improve adhesion.

Bioluminescent mushrooms are generally non-toxic, but it’s best to wear gloves and avoid ingesting the dye. Test a small area when applying to materials, and ensure proper ventilation during the extraction process. Always research the specific mushroom species for safety.

![MARBLERS Glow in The Dark Pigment Powder [Glow Green] 3oz (85g) | UV Glow | Non-Toxic | Blacklight Luminous Dye for Nail Polish, Resin, Acrylic Paint, Epoxy, Soap, Candle, Slime | Cruelty-Free](https://m.media-amazon.com/images/I/61hFltK3dTL._AC_UL320_.jpg)