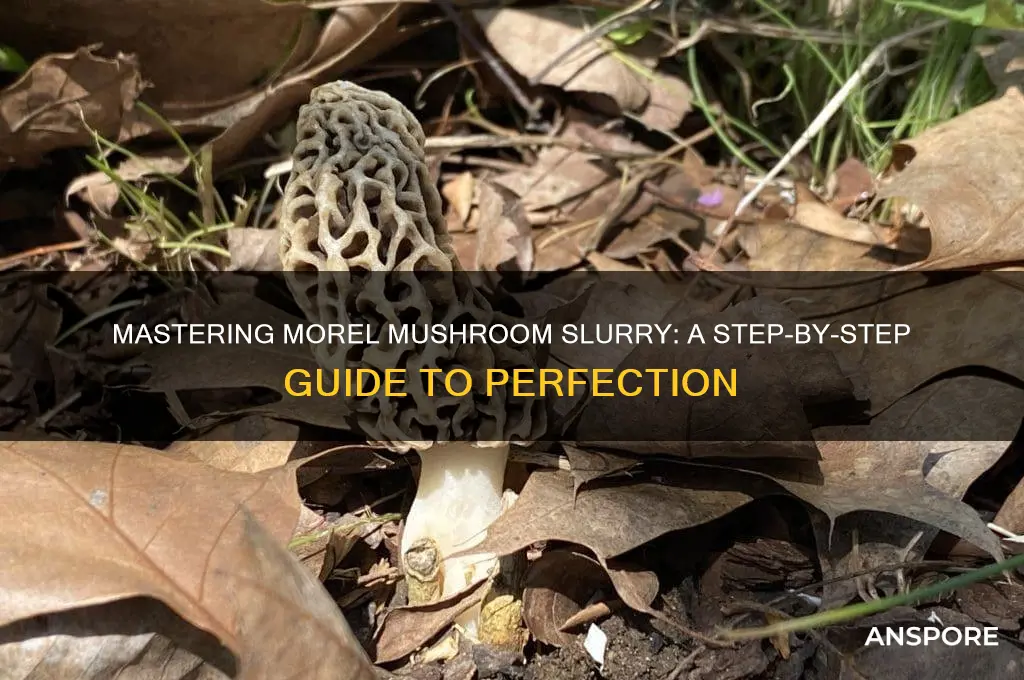

Making Morel mushroom slurry is a simple yet rewarding process that transforms these prized fungi into a versatile culinary ingredient. To begin, carefully clean fresh or rehydrated Morel mushrooms to remove any dirt or debris, ensuring their unique honeycomb-like structure remains intact. Next, blend the mushrooms into a smooth consistency using a food processor or blender, adding just enough water or broth to achieve a pourable slurry. This mixture can be used as a base for soups, sauces, or even as a flavor enhancer in dishes like risotto or pasta. The slurry captures the earthy, nutty essence of Morels, making it a fantastic way to elevate recipes with their distinctive flavor. Proper storage, such as freezing in ice cube trays, ensures the slurry remains fresh and ready for future culinary adventures.

Explore related products

$2.18

What You'll Learn

- Sterilize Substrate: Prepare and sterilize substrate materials like straw, sawdust, or grain for mushroom growth

- Spawn Inoculation: Mix sterilized substrate with mushroom spawn to initiate mycelium colonization

- Fermentation Process: Submerge colonized substrate in water, allowing natural fermentation to create slurry

- Strain and Filter: Separate liquid from solids using cheesecloth or mesh for a smooth slurry

- Storage Tips: Preserve slurry in airtight containers, refrigerated, for up to 6 months

Sterilize Substrate: Prepare and sterilize substrate materials like straw, sawdust, or grain for mushroom growth

To begin the process of sterilizing substrate materials for mushroom growth, it's essential to select the appropriate substrate, such as straw, sawdust, or grain. Each material has its unique characteristics, and the choice depends on the mushroom species you intend to cultivate. For instance, straw is commonly used for oyster mushrooms, while sawdust is preferred for shiitake mushrooms. Once you've chosen the substrate, it's crucial to prepare it by chopping or shredding it into small, uniform pieces. This increases the surface area, allowing for better absorption of nutrients and more efficient colonization by the mushroom mycelium.

Before sterilization, the substrate must be properly hydrated to create a favorable environment for mushroom growth. Soak the prepared substrate in water for several hours or overnight, ensuring it absorbs enough moisture. The ideal moisture content varies depending on the substrate and mushroom species, but a general rule is to aim for a moisture level of around 60-70%. After soaking, drain the excess water, and squeeze out any remaining moisture to prevent waterlogging, which can lead to contamination and poor mushroom yields.

The next step is to sterilize the substrate to eliminate any competing microorganisms, such as bacteria and mold, that can hinder mushroom growth. There are several methods to sterilize substrate materials, including steam sterilization, boiling, or using a pressure cooker. Steam sterilization is a popular method, where the substrate is exposed to high-temperature steam (around 121°C or 250°F) for 1-2 hours. This can be achieved using a large pot with a lid, a steam generator, or a specialized sterilization equipment. Alternatively, boiling the substrate for 1-2 hours or using a pressure cooker at 15 psi for 45-60 minutes can also effectively sterilize the material.

When using a pressure cooker, it's essential to follow the manufacturer's instructions and safety guidelines to prevent accidents. Place the hydrated substrate in a heat-resistant container, such as a glass jar or a polypropylene bag, and seal it properly. Put the container in the pressure cooker, ensuring it doesn't touch the sides or bottom to allow for proper steam circulation. After sterilization, allow the substrate to cool down to room temperature before inoculating it with the mushroom spawn. This prevents the spawn from being damaged by high temperatures.

Proper sterilization is critical to the success of mushroom cultivation, as it creates a clean and sterile environment for the mycelium to grow. Inadequate sterilization can lead to contamination, resulting in poor yields or complete crop failure. To ensure sterilization success, monitor the process carefully, and maintain the recommended temperature and duration. Additionally, work in a clean environment, wear sterile gloves, and use sterile equipment to minimize the risk of contamination. By following these steps, you'll be well on your way to preparing a high-quality, sterilized substrate for mushroom growth, setting the stage for a successful and productive mushroom cultivation project.

After sterilization, it's essential to store the substrate properly to maintain its sterility until it's ready for use. Store the sterilized substrate in a cool, dark place, away from direct sunlight and potential contaminants. If using a pressure cooker, allow the substrate to cool down inside the cooker with the lid on, which helps maintain sterility. When handling the sterilized substrate, work quickly and efficiently to minimize exposure to the environment, and always use sterile techniques to prevent contamination. With a well-prepared and sterilized substrate, you'll provide the ideal foundation for healthy mushroom mycelium growth, ultimately leading to a bountiful harvest of delicious and nutritious mushrooms.

Creamy Mushrooms on Toast: A Quick, Flavorful Breakfast Recipe

You may want to see also

Spawn Inoculation: Mix sterilized substrate with mushroom spawn to initiate mycelium colonization

Spawn inoculation is a critical step in the process of creating a myceliated substrate, often referred to as mushroom slurry, which is essential for mushroom cultivation. This stage involves combining sterilized substrate with mushroom spawn to encourage mycelium growth and colonization. The success of this process hinges on maintaining sterile conditions to prevent contamination from competing microorganisms. Before beginning, ensure your workspace is clean and you have all necessary materials: sterilized substrate, mushroom spawn, a sterile environment (such as a laminar flow hood or still air box), and tools like gloves and a scalpel or spatula.

To start the inoculation, prepare your sterilized substrate by allowing it to cool to a temperature that is safe for the mycelium, typically around 75-80°F (24-27°C). The substrate should be moist but not waterlogged, as excess moisture can lead to contamination. Place the cooled substrate into a sterile container or bag, ensuring it is free from any contaminants. Next, introduce the mushroom spawn, which can be grain spawn or another suitable carrier colonized by mycelium. Break up any clumps in the spawn to ensure even distribution throughout the substrate.

Mixing the spawn and substrate requires careful technique to maintain sterility. Using sterile gloves and tools, gently combine the two components, aiming for a homogeneous mixture. Avoid overhandling, as this can introduce contaminants or damage the mycelium. If using a bag, seal it partially to allow gas exchange while minimizing the risk of contamination. For containers, cover them with a breathable material like micropore tape or a filter patch. The goal is to create an environment where the mycelium can thrive and colonize the substrate efficiently.

After mixing, place the inoculated substrate in a dark, warm environment with stable conditions to promote mycelium growth. The ideal temperature varies by mushroom species but generally ranges between 70-75°F (21-24°C). Monitor the substrate regularly for signs of contamination, such as mold or unusual colors, and discard any contaminated batches immediately. Properly inoculated substrate will show white, healthy mycelium growth within a few days to a week, depending on the species and conditions.

Once fully colonized, the substrate can be used as a base for mushroom slurry or further cultivation. This step is foundational for creating a robust mycelium network, which is crucial for successful mushroom fruiting. By following these detailed instructions for spawn inoculation, you ensure a strong start to your mushroom cultivation process, setting the stage for healthy and productive growth.

Crafting a Perfect Mario Mushroom Costume: DIY Guide for Fans

You may want to see also

Fermentation Process: Submerge colonized substrate in water, allowing natural fermentation to create slurry

The fermentation process is a crucial step in creating a mycelium-rich extract liquid (MREL) mushroom slurry. To begin, prepare your colonized substrate, which typically consists of grain or other nutrient-rich material fully colonized by mushroom mycelium. Ensure the substrate is healthy and free from contamination. Once ready, transfer the colonized substrate into a clean, food-grade container. The container should be large enough to accommodate the substrate and allow for ample water to cover it completely. Submerging the substrate in water initiates the fermentation process, so it’s essential to use filtered or distilled water to avoid introducing unwanted microorganisms or chemicals.

Next, gently submerge the colonized substrate in the water, ensuring it is fully covered. The water acts as a medium for the mycelium to release its nutrients and enzymes, creating the slurry. Seal the container with a lid or cover it with a breathable material like cheesecloth to prevent dust or contaminants from entering while still allowing gas exchange. Place the container in a warm, dark environment, ideally at room temperature (around 70-75°F or 21-24°C), to encourage natural fermentation. The warmth accelerates the process, while the darkness prevents unwanted algae growth.

Over the next 3 to 7 days, the submerged substrate will begin to break down as the mycelium releases enzymes and nutrients into the water. Stir the mixture gently once or twice daily to ensure even distribution and oxygenation, which aids the fermentation process. You’ll notice the water gradually turning into a cloudy, nutrient-rich slurry as the mycelium and substrate decompose. This slurry is the MREL, packed with beneficial compounds like polysaccharides, proteins, and other bioactive substances.

As fermentation progresses, monitor the slurry for signs of contamination, such as mold or off-odors. If any issues arise, discard the batch and start over. Proper sanitation and attention to detail are key to a successful fermentation. Once the substrate has fully broken down and the slurry appears homogeneous, typically after 5 to 7 days, the fermentation process is complete. At this stage, the slurry is ready for use or further processing, such as filtration or concentration, depending on your intended application.

Finally, strain the slurry through a fine mesh or cheesecloth to separate any remaining solid particles, leaving you with a smooth, liquid extract. Store the MREL slurry in a clean, airtight container in the refrigerator to preserve its potency. This fermented slurry can be used as a nutrient-rich additive for gardening, as a base for mushroom tinctures, or in other mycological applications. The natural fermentation process not only simplifies the extraction of mycelial compounds but also enhances their bioavailability, making it a valuable technique for mushroom enthusiasts and cultivators.

Creamy Keto Mushroom Gravy: Easy Low-Carb Recipe for Comfort Food Lovers

You may want to see also

Explore related products

Strain and Filter: Separate liquid from solids using cheesecloth or mesh for a smooth slurry

Once your mushroom mixture has steeped and the flavors have melded, it's time to separate the liquid from the solids to create a smooth, usable slurry. This crucial step ensures your final product is free of chunky mushroom pieces and has a consistent texture. Strain and Filter: Separate liquid from solids using cheesecloth or mesh for a smooth slurry.

Begin by setting a fine-mesh strainer over a large bowl or clean pot. Cheesecloth, folded over several times for added strength, can be lined inside the strainer for an even finer filtration, capturing any tiny mushroom particles.

Carefully pour the mushroom mixture into the strainer, allowing the liquid to drain through. Use a spoon or spatula to gently press down on the mushroom solids, extracting as much liquid as possible. Be mindful not to force the solids through the strainer, as this will result in a cloudy and gritty slurry.

Patience is key during this process. Allow gravity to do most of the work, letting the liquid slowly drip through the strainer.

Once the majority of the liquid has drained, gather the edges of the cheesecloth (if using) and gently squeeze to extract any remaining liquid. Discard the spent mushroom solids, or compost them for a sustainable approach.

The resulting liquid is your mrel mushroom slurry, now smooth and ready for use in your culinary creations. Remember, the quality of your strain and filter process directly impacts the final texture of your slurry, so take your time and ensure a thorough separation for the best results.

Crafting Infected Mushroom's Signature Synth Sound: A Step-by-Step Guide

You may want to see also

Storage Tips: Preserve slurry in airtight containers, refrigerated, for up to 6 months

When it comes to preserving your freshly made myceliated grain (often referred to as "mrel mushroom slurry"), proper storage is crucial to maintain its viability and potency. The key to successful storage lies in creating an environment that minimizes contamination and slows down the metabolic activity of the mycelium. Start by selecting high-quality, food-grade airtight containers. Glass jars with tight-fitting lids or heavy-duty plastic containers are ideal choices. Ensure the containers are thoroughly cleaned and sterilized before use to prevent any unwanted bacteria or mold from compromising your slurry.

Once your containers are prepared, transfer the mrel mushroom slurry into them, leaving a small amount of headspace at the top to allow for slight expansion. It’s essential to label each container with the date of preparation and the type of mushroom strain used, as this will help you keep track of its shelf life and ensure you use the oldest batches first. After filling, seal the containers tightly to create an airtight environment, which is critical for preventing contamination and maintaining the slurry’s integrity.

Refrigeration is the next vital step in preserving your mrel mushroom slurry. Store the sealed containers in the refrigerator at a consistent temperature of around 2-4°C (36-39°F). This cooler environment significantly slows down the growth of the mycelium and reduces the risk of contamination. Avoid placing the containers in the refrigerator door, as temperature fluctuations in this area can be more frequent. Instead, opt for a stable spot on a shelf where the temperature remains constant.

To maximize the slurry’s shelf life of up to 6 months, it’s important to minimize exposure to air and light. While the airtight containers help with this, it’s also a good practice to wrap the containers in aluminum foil or store them in a dark box if your refrigerator has a lot of light exposure. Additionally, avoid frequent opening of the containers, as each time you do, you introduce the risk of contamination and temperature changes that could affect the slurry’s viability.

Lastly, periodically inspect your stored slurry for any signs of contamination, such as unusual colors, odors, or mold growth. If you notice any issues, discard the affected container immediately to prevent cross-contamination. By following these storage tips—using airtight containers, refrigerating consistently, minimizing air and light exposure, and monitoring for contamination—you can effectively preserve your mrel mushroom slurry for up to 6 months, ensuring it remains healthy and ready for use in your mushroom cultivation projects.

Creamy Mushroom Etouffee: Easy Recipe with Cream of Mushroom Soup

You may want to see also

Frequently asked questions

Mrel mushroom slurry is a liquid mixture made from fermented mushrooms, often used as a natural soil amendment to enhance plant growth, improve soil structure, and increase nutrient availability.

To make mrel mushroom slurry, mix chopped mushrooms (preferably oyster or shiitake) with water in a container, cover it loosely, and let it ferment for 2–4 weeks. Stir occasionally to prevent mold and strain before use.

While oyster and shiitake mushrooms are commonly used due to their fast decomposition and nutrient content, other edible mushrooms can also work. Avoid using wild mushrooms unless you’re certain they’re safe.

Dilute the slurry with water (1:10 ratio) and apply it directly to the soil around the base of plants or use it as a foliar spray. Apply every 2–4 weeks during the growing season for best results.