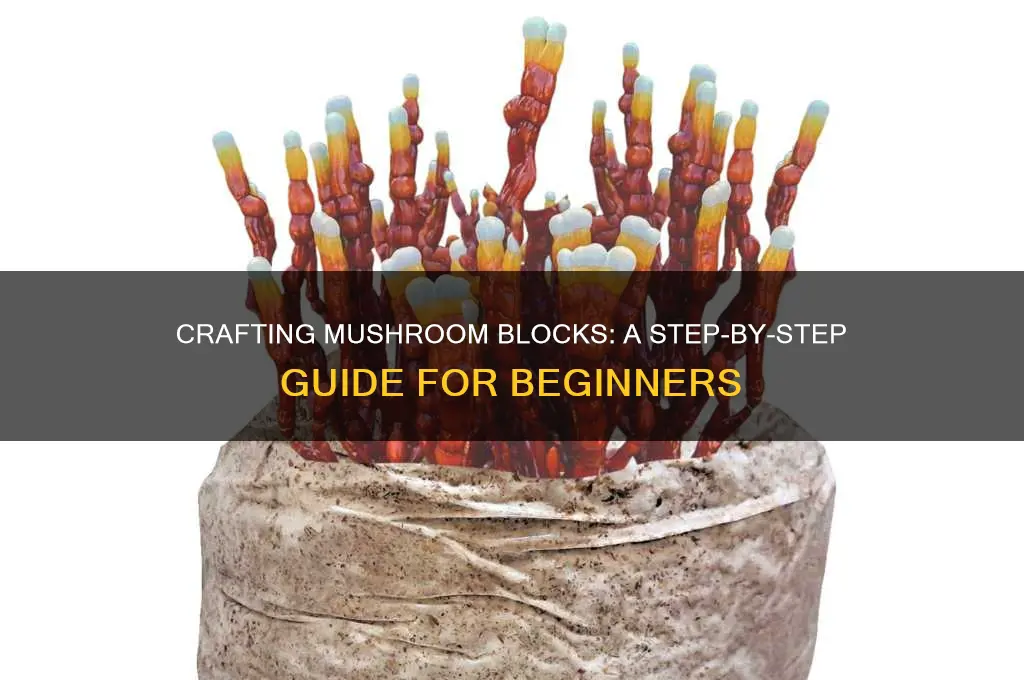

Making a mushroom block is a fascinating and rewarding process that allows you to cultivate mushrooms at home. It begins with selecting the right substrate, typically a mixture of hardwood sawdust or straw, which is then sterilized to eliminate any competing organisms. The substrate is mixed with mushroom spawn, the mycelium of the desired mushroom species, and packed into a container or bag. Proper moisture levels and environmental conditions, such as temperature and humidity, are crucial for the mycelium to colonize the block. Over several weeks, the mycelium grows throughout the substrate, and once fully colonized, the block is ready for fruiting. By maintaining optimal conditions, you can harvest fresh mushrooms directly from your homemade block, offering a sustainable and satisfying way to enjoy homegrown fungi.

| Characteristics | Values |

|---|---|

| Purpose | Substrate for growing mushrooms |

| Main Ingredients | Sawdust, straw, wood chips, or agricultural waste |

| Supplements | Wheat bran, soy hulls, gypsum, or other nutrients |

| Binding Agent | Water, lime, or natural binders like starch |

| Sterilization Method | Autoclave, pressure cooker, or pasteurization |

| Temperature Range | 50-60°C (122-140°F) for pasteurization, 121°C (250°F) for sterilization |

| pH Level | 5.5-6.5 (optimal for most mushroom species) |

| Moisture Content | 60-70% (by weight) |

| Block Size | Typically 5-10 lbs (2.3-4.5 kg) per block |

| Inoculation | Mushroom spawn (grain or sawdust-based) |

| Incubation Time | 2-4 weeks (varies by mushroom species) |

| Fruiting Conditions | High humidity (85-95%), cooler temperatures (15-25°C or 59-77°F) |

| Common Mushroom Species | Oyster, shiitake, lion's mane, reishi |

| Shelf Life | 6-12 months (if stored properly in a cool, dark place) |

| Environmental Impact | Sustainable, uses agricultural waste and reduces deforestation |

| Difficulty Level | Moderate (requires attention to sterilization and humidity control) |

Explore related products

$15.99 $19.99

What You'll Learn

- Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during the mushroom block preparation

- Prepare Substrate: Mix sawdust, straw, or grain with nutrients, ensuring proper moisture levels for mushroom growth

- Pasteurize Substrate: Heat substrate to kill harmful microbes while preserving beneficial organisms for colonization

- Inoculate with Spawn: Introduce mushroom mycelium evenly into the substrate using sterile techniques

- Incubate and Fruiting: Store in a dark, humid environment until fully colonized, then induce fruiting conditions

Sterilize Equipment: Clean tools, jars, and workspace thoroughly to prevent contamination during the mushroom block preparation

Before you begin preparing your mushroom block, it’s crucial to sterilize all equipment to prevent contamination, which can ruin your entire batch. Start by gathering all the tools you’ll need, such as knives, spoons, thermometers, and any other utensils. Wash these tools thoroughly with hot, soapy water to remove dirt, debris, and organic matter. After washing, rinse them well to ensure no soap residue remains, as this can interfere with the mushroom growth process. For an extra layer of cleanliness, consider soaking the tools in a solution of 1 part bleach to 9 parts water for 10 minutes, then rinse them again with clean water. This step is essential to eliminate any potential contaminants that could compete with your mushroom mycelium.

Next, focus on sterilizing the jars or containers you’ll use for the mushroom block. Wash the jars with hot, soapy water, scrubbing the insides and lids to remove any particles. Rinse them thoroughly to ensure no soap residue is left behind. After washing, place the jars in a large pot and cover them completely with water. Bring the water to a boil and let the jars boil for at least 10 minutes to kill any bacteria, fungi, or spores. Use tongs to carefully remove the jars from the boiling water and place them upside down on a clean towel to air-dry. Avoid touching the insides of the jars or lids with your hands to maintain sterility.

Your workspace also requires thorough cleaning to prevent contamination. Wipe down all surfaces, including countertops, tables, and shelves, with a disinfectant solution or a mixture of bleach and water. Pay special attention to areas where food is prepared, as these can harbor bacteria and mold spores. After disinfecting, rinse the surfaces with clean water and allow them to air-dry completely. If possible, cover the workspace with a clean plastic sheet or use a laminar flow hood to create a sterile environment, especially if you’re working in a home setting where airborne contaminants are more likely.

In addition to cleaning, consider your clothing and personal hygiene. Wear clean clothes and avoid using fabric items like cloth aprons, as they can carry spores and bacteria. Opt for disposable gloves and a face mask to minimize the introduction of contaminants from your skin, hair, or breath. Ensure your hands are thoroughly washed with antibacterial soap before starting the process. Even small particles of skin or hair can introduce unwanted microorganisms into your mushroom block, so attention to personal cleanliness is just as important as sterilizing tools and surfaces.

Finally, prepare a sterile environment for the actual mixing and filling of the mushroom block. Use a flame, such as a kitchen torch or alcohol lamp, to sterilize the openings of jars or containers just before filling them. Quickly pass the flame over the rim and lid to kill any lingering contaminants. Work swiftly but carefully during this stage, as prolonged exposure to air increases the risk of contamination. By meticulously sterilizing your equipment, jars, and workspace, you create an optimal environment for your mushroom mycelium to thrive, ensuring a successful and uncontaminated mushroom block.

Recreate Longhorn Steakhouse Mushrooms: Easy Homemade Recipe Guide

You may want to see also

Prepare Substrate: Mix sawdust, straw, or grain with nutrients, ensuring proper moisture levels for mushroom growth

Preparing the substrate is a critical step in making a mushroom block, as it provides the necessary nutrients and environment for mushroom mycelium to grow. Start by selecting your base material, which can be sawdust, straw, or grain. Sawdust is commonly used due to its availability and ability to retain moisture, while straw is lighter and easier to handle. Grain, such as rye or wheat, is often used for faster colonization but can be more expensive. Whichever material you choose, ensure it is clean and free from contaminants to prevent competing organisms from affecting your mushroom growth.

Next, mix your chosen base material with nutrients to create a balanced substrate. Common supplements include bran, soy flour, or gypsum. For example, a typical recipe might include 5 parts sawdust, 1 part bran, and 1 part gypsum. Gypsum is particularly important as it helps regulate pH and provides calcium, which is essential for mushroom development. Thoroughly combine these ingredients in a large container, ensuring an even distribution of nutrients throughout the substrate. This step is crucial for providing the mycelium with a consistent food source as it grows.

Moisture control is another key aspect of substrate preparation. The goal is to achieve a moisture content of around 60-70%, which means the substrate should feel damp but not waterlogged. To test moisture levels, squeeze a handful of the mixture—it should hold together without dripping water. If it’s too dry, gradually add small amounts of water while mixing until the desired consistency is reached. If it’s too wet, spread the substrate out and allow it to dry slightly, or mix in additional dry material to absorb excess moisture. Proper moisture levels ensure the mycelium can spread efficiently without risking mold or bacterial growth.

Once your substrate is mixed and moistened, it’s essential to pasteurize or sterilize it to eliminate any competing microorganisms. Pasteurization involves heating the substrate to around 60-70°C (140-160°F) for an hour, which is suitable for materials like straw. For sawdust or grain substrates, sterilization is often necessary, requiring temperatures of 121°C (250°F) under pressure for 1-2 hours. This step ensures a clean environment for the mushroom mycelium to thrive. After pasteurization or sterilization, allow the substrate to cool to a temperature safe for inoculation, typically around 25-30°C (77-86°F).

Finally, prepare your substrate for inoculation by transferring it into your chosen container, such as a plastic bag or jar. Pack the substrate firmly but not too tightly, leaving enough room for air exchange, which is vital for mycelium growth. Seal the container to maintain humidity and prevent contamination. With your substrate properly prepared, it’s now ready to be inoculated with mushroom spawn, marking the next phase in creating a successful mushroom block.

Creamy Spinach Dip Recipe: Recreate Mellow Mushroom's Classic Appetizer at Home

You may want to see also

Pasteurize Substrate: Heat substrate to kill harmful microbes while preserving beneficial organisms for colonization

Pasteurizing the substrate is a critical step in making a mushroom block, as it eliminates harmful microbes that could compete with or harm the mushroom mycelium while preserving beneficial organisms that support colonization. The process involves applying heat to the substrate material, typically a mixture of sawdust, straw, or other organic matter, to create an environment conducive to mushroom growth. To begin pasteurization, prepare your substrate by ensuring it is properly moistened to a consistency similar to a wrung-out sponge. This moisture level is essential because it allows heat to penetrate evenly without causing excessive steam or drying.

The most common method for pasteurizing substrate is using hot water. Fill a large container or pot with water and heat it to around 160-180°F (71-82°C). Carefully submerge the substrate in a mesh bag or porous container to allow water circulation. Maintain this temperature for 1 to 2 hours, stirring occasionally to ensure even heat distribution. A thermometer is crucial to monitor the water temperature, as overheating can kill beneficial organisms or create a hostile environment for mycelium. After pasteurization, remove the substrate and let it cool to a temperature safe for inoculation, typically around 70-80°F (21-27°C).

Another effective pasteurization technique is steam pasteurization, which is often preferred for larger batches. Use a steam generator or a large pot with a steaming rack to expose the substrate to steam at 160-180°F (71-82°C) for 1 to 2 hours. This method is more efficient at penetrating dense substrates and reduces the risk of over-saturating the material with water. Ensure the substrate is evenly spread out to allow steam to reach all parts. After steaming, allow the substrate to cool gradually while maintaining a sterile environment to prevent recontamination.

Regardless of the method chosen, timing and temperature control are key to successful pasteurization. Under-pasteurizing may leave harmful microbes intact, while over-pasteurizing can destroy beneficial organisms and nutrients. Always work in a clean environment and use sterilized tools to handle the substrate post-pasteurization. Once cooled, the substrate is ready for inoculation with mushroom spawn, marking the next step in creating a thriving mushroom block. Proper pasteurization ensures a healthy foundation for mycelium growth, increasing the likelihood of a successful harvest.

DIY Injectable Lids: Simplify Mushroom Cultivation with Easy-to-Make Solutions

You may want to see also

Explore related products

$27.99 $29.99

Inoculate with Spawn: Introduce mushroom mycelium evenly into the substrate using sterile techniques

Inoculating your mushroom block with spawn is a critical step in the cultivation process, as it introduces the mushroom mycelium into the substrate, allowing it to colonize and eventually produce mushrooms. To begin, ensure you have a sterile work environment, such as a still air box or a laminar flow hood, to minimize the risk of contamination. Gather your materials: sterilized substrate (the mushroom block), mushroom spawn (the mycelium-infused grain or supplement), gloves, a scalpel or sterile knife, and rubbing alcohol for disinfection. Before starting, disinfect your work area and tools with the alcohol to maintain sterility.

Once your workspace is prepared, carefully open the sterilized mushroom block, ensuring minimal exposure to the environment. Using your sterile knife or scalpel, create small incisions or holes in the substrate. These holes should be evenly spaced across the block to promote uniform colonization. The goal is to distribute the mycelium throughout the substrate without damaging its structure. Each hole should be just deep enough to hold a small amount of spawn, typically about 1-2 inches deep, depending on the size of your block.

Next, introduce the mushroom spawn into the holes. Use a sterile spoon or your gloved hands to place a small amount of spawn into each incision. Be precise and gentle to avoid compacting the substrate, which could hinder mycelial growth. Ensure the spawn is evenly distributed across the block, as uneven inoculation can lead to patchy colonization. After filling the holes, lightly press the substrate around each spawn deposit to secure it in place, but avoid excessive pressure.

Once the spawn is introduced, seal the block to maintain humidity and protect it from contaminants. This can be done by covering the inoculation points with a sterile material, such as microwavable wax paper or parchment paper, and securing it with tape or elastic bands. Alternatively, some cultivators use self-healing injection ports for inoculation, which can be sealed after introducing the spawn. Proper sealing is crucial to prevent mold or bacteria from entering the block.

Finally, place the inoculated mushroom block in a dark, humid environment with stable temperatures, typically between 70-75°F (21-24°C), to encourage mycelial growth. Monitor the block regularly for signs of contamination or uneven colonization. With proper sterile techniques and careful inoculation, the mycelium should begin to colonize the substrate within a few days to a week, eventually leading to a fully colonized mushroom block ready for fruiting. Patience and attention to detail during this step are key to a successful mushroom cultivation project.

Brewing Bliss: A Guide to Crafting Magic Mushroom Tea at Home

You may want to see also

Incubate and Fruiting: Store in a dark, humid environment until fully colonized, then induce fruiting conditions

After preparing your mushroom block, the next critical phase is incubation and fruiting. Incubation is the process where the mycelium (the vegetative part of the fungus) colonizes the substrate within the block. To begin, place the fully colonized mushroom block in a dark, humid environment with a temperature range of 65–75°F (18–24°C). A closet, cabinet, or dedicated incubation chamber works well. Ensure the block remains undisturbed during this period, as movement can disrupt mycelial growth. Humidity is crucial; aim for 70–80% relative humidity to prevent the block from drying out. You can maintain humidity by misting the air around the block or using a humidifier, but avoid directly misting the block itself, as excess moisture can lead to contamination.

During incubation, monitor the block for signs of full colonization. This typically takes 2–4 weeks, depending on the mushroom species and environmental conditions. Full colonization is evident when the block is completely covered in white mycelium, with no visible substrate showing. If you notice any mold, off-colors, or unusual smells, it may indicate contamination, and the block should be discarded to prevent further issues. Patience is key during this stage, as rushing the process can lead to poor fruiting results.

Once the block is fully colonized, it’s time to induce fruiting conditions. Fruiting is the stage where mushrooms develop and grow. To trigger this, move the block to a well-lit area with indirect natural light or fluorescent lighting. Mushrooms need light to initiate fruiting, but direct sunlight can dry them out. Maintain a slightly cooler temperature range of 60–70°F (15–21°C) and high humidity levels (85–95% relative humidity). You can achieve this by placing the block in a fruiting chamber, such as a clear plastic container or grow tent, and regularly misting the inside walls to create a humid microclimate.

Proper airflow is also essential during fruiting. Ensure there is some ventilation in the fruiting chamber to provide fresh air while maintaining humidity. Pinheads, the tiny beginnings of mushrooms, should start to form within 5–14 days after inducing fruiting conditions. Once pinheads appear, avoid excessive disturbance, as mushrooms are sensitive during this stage. Continue to maintain humidity and light levels, and the mushrooms will grow to maturity over the next 1–2 weeks.

Finally, harvest the mushrooms when the caps are fully open but before the gills release spores. Gently twist or cut the mushrooms at the base to avoid damaging the block. After harvesting, the block may produce additional flushes of mushrooms if properly cared for. Between flushes, return the block to fruiting conditions and maintain humidity and light levels. With proper incubation and fruiting techniques, you can enjoy multiple harvests from a single mushroom block.

Easy Mushroom Biryani Recipe Using Your Electric Rice Cooker

You may want to see also

Frequently asked questions

A mushroom block is a substrate (growing medium) specifically designed for cultivating mushrooms. It is used because it provides the ideal environment for mushroom mycelium to grow and fruit, ensuring a successful harvest.

Common materials include a substrate (e.g., sawdust, straw, or wood chips), mushroom spawn, water, and sometimes supplements like bran or gypsum. You’ll also need a container (like a plastic bag or bucket) and tools for sterilization and mixing.

Sterilization is crucial to prevent contamination. The substrate can be sterilized by steaming it at 100°C (212°F) for 1-2 hours or using a pressure cooker for 1-2 hours. Ensure the substrate cools before inoculating with spawn.

The time varies by mushroom species, but typically, it takes 2-4 weeks for the mycelium to colonize the block and another 1-3 weeks for mushrooms to fruit. Optimal conditions (temperature, humidity, and light) can speed up the process.