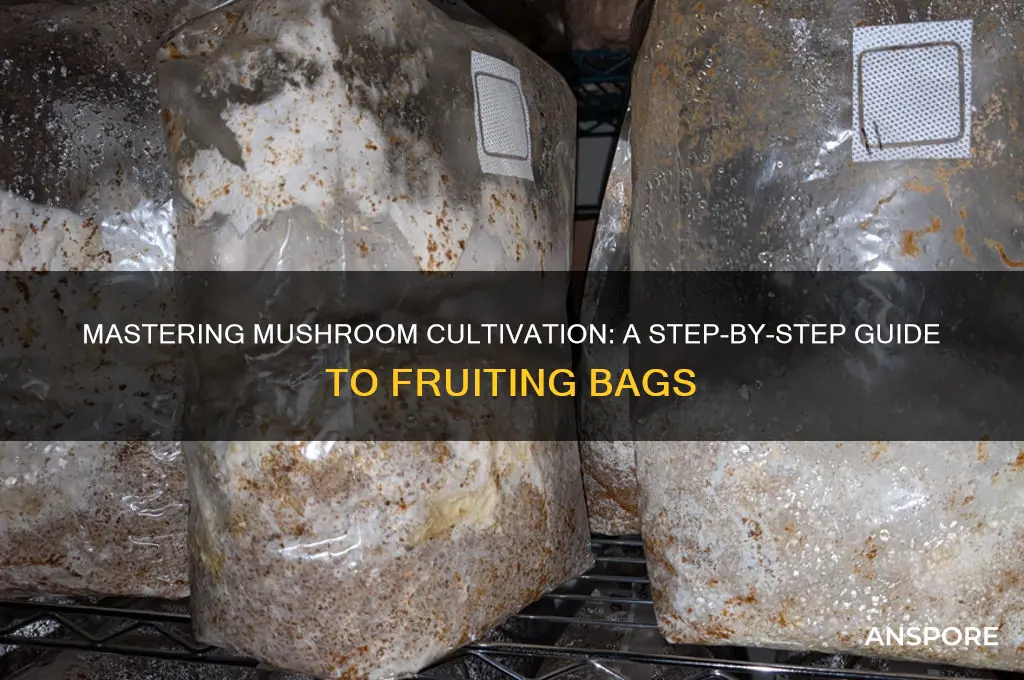

Creating a mushroom fruiting bag is a crucial step in cultivating mushrooms at home, offering a controlled environment for mycelium to produce fruit bodies. This process involves preparing a substrate—typically a mixture of grains, sawdust, or other organic materials—sterilizing it to eliminate contaminants, and inoculating it with mushroom spawn. Once the mycelium has fully colonized the substrate, the bag is moved to a fruiting chamber with optimal humidity, temperature, and light conditions to encourage mushroom growth. Proper techniques, such as maintaining sterility and monitoring environmental factors, are essential for success, making this method accessible for both beginners and experienced growers.

| Characteristics | Values |

|---|---|

| Purpose | To create an environment for mushrooms to fruit (produce mushrooms). |

| Materials Needed | Substrate (e.g., straw, sawdust, or grain), mushroom spawn, plastic bag, filter patch (tyvek or micropore tape), rubber band, pressure cooker or pasteurizer. |

| Substrate Preparation | Pasteurize or sterilize substrate to kill contaminants. |

| Spawn-to-Substrate Ratio | Typically 1:5 to 1:10 (spawn:substrate) depending on mushroom species. |

| Bag Size | Standard sizes: 5-10 lbs capacity (e.g., 6x18 inches or 8x12x24 inches). |

| Filter Patch | Allows gas exchange while preventing contamination. |

| Sterilization/Pasteurization | Sterilize for sawdust/grain substrates; pasteurize for straw substrates. |

| Inoculation | Mix spawn evenly into the substrate in a sterile environment. |

| Incubation | Keep in a dark, warm place (65-75°F) for mycelium colonization (2-4 weeks). |

| Fruiting Conditions | Introduce light, humidity (90-95%), and cooler temps (55-65°F). |

| Humidity Control | Use a humidifier or misting; ensure proper air exchange. |

| Harvesting | Harvest mushrooms when caps are fully open but before spores drop. |

| Reusability | Some bags can be reused for multiple flushes if not contaminated. |

| Common Mushroom Species | Oyster, Lion's Mane, Shiitake, and others depending on substrate. |

| Contamination Prevention | Work in a clean environment; use gloves and mask during inoculation. |

| Cost | Low to moderate, depending on substrate and equipment. |

| Timeframe | 4-8 weeks from inoculation to first harvest. |

What You'll Learn

- Substrate Preparation: Sterilize or pasteurize substrate mix (e.g., coir, vermiculite, grains) to create a nutrient base

- Spawn Inoculation: Mix mushroom spawn evenly into the substrate, ensuring proper colonization

- Bag Filling: Fill autoclavable bags with substrate, leaving room for expansion and air exchange

- Sterilization Process: Pressure-cook bags at 15 PSI for 1-2 hours to eliminate contaminants

- Fruiting Conditions: Maintain humidity (90-95%), light, and temperature (60-75°F) to induce mushroom growth

Substrate Preparation: Sterilize or pasteurize substrate mix (e.g., coir, vermiculite, grains) to create a nutrient base

The foundation of a successful mushroom fruiting bag lies in the substrate—a carefully prepared blend of organic materials that serve as the nutrient base for mycelial growth. Whether you're cultivating oyster, shiitake, or lion's mane mushrooms, the substrate mix is your canvas, and its preparation is an art backed by science. Coir, vermiculite, and grains are common components, each bringing unique properties to the mix. But before these materials can nurture your mushrooms, they must be sterilized or pasteurized to eliminate competing microorganisms that could hijack your harvest.

Sterilization is the more aggressive approach, typically reserved for substrates containing grains or nutrient-rich additives that attract bacteria and molds. Using a pressure cooker, heat the substrate mix to 121°C (250°F) for 60–90 minutes. This method ensures near-total elimination of contaminants but requires precision—overdo it, and you risk degrading the substrate’s nutritional value. For example, a 5-pound batch of rye grain mixed with 10% gypsum should be sterilized for 90 minutes to guarantee a clean slate for mycelium colonization. Pasteurization, on the other hand, is gentler and often sufficient for coir or straw-based substrates. Soak the material in 160°F water for 1–2 hours, then drain and cool. This method reduces but doesn’t eliminate all contaminants, relying on the mycelium’s competitive edge to outgrow rivals.

Choosing between sterilization and pasteurization depends on your substrate and mushroom species. For instance, oyster mushrooms thrive on pasteurized straw, while lion's mane prefers sterilized grain-based mixes. A comparative analysis reveals that sterilization offers higher success rates but demands more effort and equipment. Pasteurization is beginner-friendly but requires vigilant monitoring for contamination. Whichever method you choose, consistency is key—fluctuations in temperature or duration can compromise the process.

Practical tips can streamline substrate preparation. Always use distilled water to avoid chlorine or mineral interference. Pre-soak coir overnight to reduce hydration time during pasteurization. For sterilization, invest in a reliable pressure cooker with a gauge to monitor temperature accurately. Label batches with preparation dates to track freshness, as substrates lose viability over time. Finally, work in a clean environment—a HEPA filter and sterile gloves can significantly reduce contamination risks.

In conclusion, substrate preparation is a critical step that bridges the gap between raw materials and a thriving mushroom fruiting bag. Whether sterilizing or pasteurizing, the goal is to create a clean, nutrient-rich environment where mycelium can flourish. By understanding the nuances of each method and applying practical techniques, you can transform humble ingredients like coir and grains into the fertile ground your mushrooms need to grow. Master this step, and you’ll be well on your way to a bountiful harvest.

Baking Bliss: Crafting Magic Mushroom Cookies at Home

You may want to see also

Spawn Inoculation: Mix mushroom spawn evenly into the substrate, ensuring proper colonization

Spawn inoculation is the pivotal step where life begins in your fruiting bag. It’s not just mixing; it’s a delicate balance of distribution and integration. The goal is to ensure every part of the substrate is colonized by the mushroom mycelium, setting the stage for uniform fruiting. Too much spawn in one area can lead to overcrowding, while too little leaves gaps for contaminants. Think of it as seeding a garden—even dispersal is key to a healthy harvest.

To achieve this, start by preparing your substrate and spawn. For most mushroom species, a spawn-to-substrate ratio of 1:10 to 1:5 by weight works well. For example, if you have 1,000 grams of substrate, mix in 100 to 200 grams of spawn. Use a sterile tool, like a gloved hand or a sanitized spatula, to gently fold the spawn into the substrate. Avoid overmixing, as it can damage the mycelium. Aim for a marbled appearance, where the spawn is evenly distributed but not fully blended, ensuring it can spread naturally.

One practical tip is to pre-crumble the spawn into small pieces before mixing. This helps it disperse more easily and reduces clumping. If using a bulk substrate like straw or wood chips, ensure it’s fully hydrated and pasteurized to create an ideal environment for colonization. For grain-based substrates, allow the spawn to run (fully colonize the grain) before mixing it into the bulk substrate. This two-step process increases the mycelium’s vigor and colonization speed.

Caution is critical during this stage. Work in a clean environment to minimize contamination risk. Use a still air box or a laminar flow hood if available, especially for sensitive species like oyster or lion’s mane mushrooms. Even a small introduction of competing mold or bacteria can derail the entire process. After mixing, seal the fruiting bag tightly, ensuring no air pockets remain, as they can become breeding grounds for contaminants.

The success of spawn inoculation lies in patience and precision. Once mixed, the mycelium will begin colonizing the substrate, a process that can take 2 to 4 weeks depending on the species and conditions. Maintain optimal temperature and humidity during this phase—typically 70–75°F (21–24°C) for most mushrooms. Regularly inspect the bag for signs of contamination or uneven colonization. If done correctly, you’ll soon see a white, web-like mycelium network forming, signaling that your fruiting bag is on track for a bountiful harvest.

Perfect Portobello Pairing: Crafting a Flavorful Vinaigrette Sauce Recipe

You may want to see also

Bag Filling: Fill autoclavable bags with substrate, leaving room for expansion and air exchange

The substrate is the lifeblood of your mushroom fruiting bag, and proper bag filling is a delicate balance between providing enough nutrients and allowing room for growth. Aim to fill your autoclavable bags to roughly 70-80% capacity. This leaves sufficient space for the mycelium to expand and colonize the substrate, while also ensuring adequate air exchange, which is crucial for healthy mushroom development. Overfilling can lead to anaerobic conditions, stunted growth, and even contamination.

Understanding the substrate's density is key. A loosely packed bag allows for better air circulation, preventing the substrate from becoming compacted and restricting mycelial growth. Imagine a crowded room – mushrooms need breathing space too! This is especially important for wood-loving species like oyster mushrooms, which require a more airy environment compared to manure-loving varieties like shiitake.

Filling your bags requires a systematic approach. Start by sterilizing your substrate according to your chosen mushroom species' requirements. Once cooled, work in a sterile environment to minimize contamination risk. Use a scoop or measuring cup to fill the bags, gently tapping the sides to settle the substrate without compacting it. Leave a few inches of headspace at the top of the bag, allowing for mycelial growth and preventing spillage during colonization.

Seal the bags securely, ensuring a tight closure to maintain sterility.

While the 70-80% rule is a good starting point, experimentation is key. Observe how different substrates and mushroom species respond to varying fill levels. Some growers prefer slightly fuller bags for certain varieties, while others opt for more airspace. Keep detailed notes on your experiments, noting colonization times, fruiting success, and overall yield. This data will become your personal guide to optimizing bag filling for each unique mushroom-substrate combination. Remember, successful mushroom cultivation is a journey of discovery, and bag filling is a crucial step in nurturing your fungal friends.

Brewing Wellness: A Guide to Making Mushroom Tea at Home

You may want to see also

Sterilization Process: Pressure-cook bags at 15 PSI for 1-2 hours to eliminate contaminants

Pressure-cooking fruiting bags at 15 PSI for 1-2 hours is a critical step in mushroom cultivation, ensuring a sterile environment for mycelium to thrive. This process, known as sterilization, eliminates contaminants like bacteria, mold, and competing fungi that could otherwise hijack your substrate. Without proper sterilization, your fruiting bags may fail to produce mushrooms or yield poor-quality crops. The 15 PSI pressure and 1-2 hour duration are not arbitrary; they are scientifically validated parameters that guarantee the destruction of unwanted microorganisms while preserving the substrate’s integrity.

To execute this step effectively, begin by preparing your fruiting bags with the substrate mixture, ensuring all ingredients are evenly distributed. Seal the bags loosely to allow steam penetration during sterilization. Use a reliable pressure cooker with a functioning gauge and safety release valve. Place the bags inside the cooker, ensuring they are not overcrowded, as this can lead to uneven sterilization. Once the cooker reaches 15 PSI, maintain this pressure for the full duration—1 hour for smaller bags and 2 hours for larger or denser substrates. Consistency is key; fluctuations in pressure or time can compromise the process.

A common mistake cultivators make is underestimating the importance of cooling the bags properly after sterilization. Rapid temperature changes can cause condensation inside the bags, reintroducing contaminants. Allow the pressure cooker to cool naturally to room temperature before opening it. This gradual cooling process prevents shock to the substrate and minimizes the risk of contamination. Patience here pays off, as rushing this step can undo hours of careful sterilization.

Comparing this method to alternative sterilization techniques, such as using an autoclave or chemical sterilants, pressure-cooking stands out for its accessibility and reliability. Autoclaves, while efficient, are expensive and require specialized equipment, making them impractical for small-scale growers. Chemical sterilants, on the other hand, can leave residues harmful to mycelium. Pressure-cooking at 15 PSI strikes a balance, offering a cost-effective and safe solution for home cultivators. Its simplicity and effectiveness make it the go-to method for ensuring a contaminant-free fruiting environment.

In conclusion, mastering the sterilization process is non-negotiable for successful mushroom cultivation. Pressure-cooking fruiting bags at 15 PSI for 1-2 hours is a straightforward yet powerful technique that safeguards your substrate from contaminants. By following precise instructions, avoiding common pitfalls, and understanding its advantages over other methods, you can create an optimal environment for mycelium growth. This step, though seemingly technical, is within reach for any dedicated cultivator—and it’s the foundation upon which a bountiful mushroom harvest is built.

Garlic Mushroom Bruschetta: Easy Recipe for a Flavorful Appetizer

You may want to see also

Fruiting Conditions: Maintain humidity (90-95%), light, and temperature (60-75°F) to induce mushroom growth

Mushrooms thrive in environments that mimic their natural habitats, where humidity, light, and temperature converge to signal the perfect time to fruit. To replicate these conditions in a fruiting bag, you must maintain a humidity level of 90-95%, provide indirect light, and keep the temperature between 60-75°F. These parameters are not arbitrary; they are the result of years of mycological research and experimentation. For instance, humidity above 90% prevents water droplets from forming on the mushrooms, which can lead to bacterial contamination, while levels below 90% can cause the mycelium to dry out and halt growth.

Achieving the right humidity is both an art and a science. One effective method is to use a humidifier or a humidity-controlled chamber, but for those without access to such equipment, a simple DIY solution involves misting the inside of a clear plastic bag with water and sealing it around the fruiting bag. This creates a microclimate that retains moisture while allowing for gas exchange. However, be cautious not to over-mist, as excessive water can lead to mold or drowning the mycelium. A hygrometer placed inside the bag can help monitor humidity levels accurately.

Light plays a subtler but equally crucial role in mushroom fruiting. While mushrooms do not require intense light, they need a photoperiod of 8-12 hours of indirect light daily to trigger fruiting. This can be achieved with natural daylight or artificial lighting, such as LED grow lights. Avoid direct sunlight, as it can overheat the fruiting bag and dry out the mycelium. Interestingly, the color spectrum of light can also influence growth; blue light, for example, has been shown to promote fruiting in some species.

Temperature control is the backbone of successful fruiting. Most mushroom species prefer a range of 60-75°F, with slight variations depending on the species. For instance, oyster mushrooms (Pleurotus ostreatus) fruit optimally at 65-75°F, while shiitake (Lentinula edodes) prefer a slightly cooler range of 60-65°F. Consistency is key; fluctuations outside this range can stress the mycelium and delay or inhibit fruiting. Using a thermostat-controlled environment, such as a grow tent or even a repurposed refrigerator, can help maintain stable temperatures.

Finally, integrating these conditions into your fruiting bag setup requires attention to detail and patience. Start by ensuring your substrate is fully colonized before introducing it to fruiting conditions. Place the fruiting bag in a location where temperature and light can be easily regulated, and monitor humidity daily. If you notice slow growth or abnormal development, adjust one variable at a time to pinpoint the issue. For example, if pins fail to form, increase humidity slightly or extend the light period. By fine-tuning these conditions, you can create an optimal environment that encourages robust mushroom fruiting.

Thicken Cream of Mushroom Soup: Easy Tips for Richer Texture

You may want to see also

Frequently asked questions

A mushroom fruiting bag is a container filled with a substrate (like grain or sawdust) that has been fully colonized by mushroom mycelium. It is used to create a controlled environment for mushrooms to fruit, providing optimal conditions for growth and harvest.

You’ll need a sterilized substrate (e.g., grain spawn or sawdust), a grow bag with a filter patch, a pressure cooker or sterilizer, mushroom spawn, and a clean workspace. Optional items include a heat mat and humidity tent for better fruiting conditions.

Sterilize the substrate in a pressure cooker, let it cool, then mix it with mushroom spawn in a sterile environment. Place the mixture into the grow bag, seal it, and incubate in a dark, warm area until fully colonized. Once colonized, introduce light and humidity to trigger fruiting.