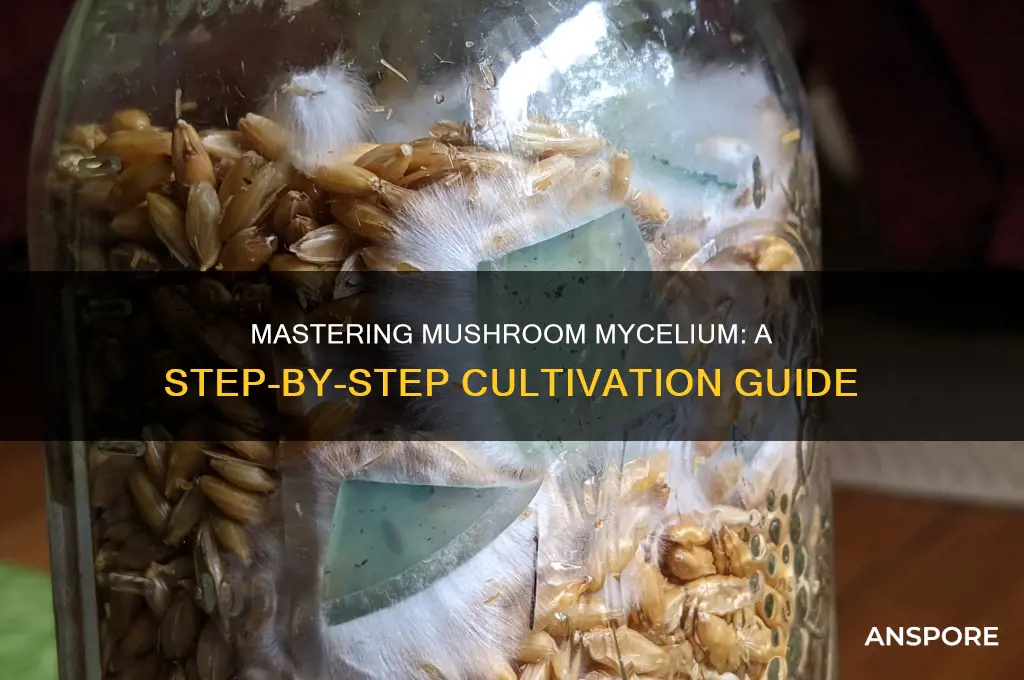

Creating mushroom mycelium is a fascinating process that forms the foundation of mushroom cultivation. Mycelium, the vegetative part of a fungus, consists of a network of thread-like structures called hyphae, which play a crucial role in nutrient absorption and growth. To make mushroom mycelium, one typically starts by sterilizing a substrate, such as grain or sawdust, to eliminate competing organisms. This substrate is then inoculated with mushroom spawn, which contains the mycelium of the desired mushroom species. Under controlled conditions of temperature, humidity, and darkness, the mycelium colonizes the substrate, breaking it down and spreading throughout. This stage requires patience, as it can take several weeks for full colonization. Once established, the mycelium can be used to grow mushrooms or transferred to a larger growing medium. Understanding this process not only unlocks the potential for sustainable mushroom production but also highlights the remarkable capabilities of fungi in ecosystems and agriculture.

| Characteristics | Values |

|---|---|

| Substrate Preparation | Sterilize or pasteurize a nutrient-rich substrate (e.g., straw, wood chips, grain, sawdust, or manure) to eliminate competing organisms. |

| Sterilization Methods | Autoclave (121°C for 30-60 minutes) or pressure cooker for small batches. |

| Pasteurization Methods | Soak substrate in hot water (70-80°C) for 1-2 hours or use a pasteurization tunnel. |

| Spawn Type | Use grain spawn (e.g., rye, wheat) or sawdust spawn inoculated with mushroom mycelium. |

| Inoculation Rate | 2-5% spawn-to-substrate ratio by weight (e.g., 2-5 kg spawn per 100 kg substrate). |

| Inoculation Process | Mix spawn thoroughly with cooled, sterilized substrate in a sterile environment (e.g., glove box or laminar flow hood). |

| Incubation Temperature | Maintain 22-28°C (72-82°F) for optimal mycelial growth. |

| Incubation Humidity | Keep substrate moisture at 50-70% to prevent drying and promote colonization. |

| Incubation Duration | 2-6 weeks, depending on mushroom species and substrate type. |

| Colonization Signs | Substrate turns white or colored (species-dependent) as mycelium spreads. |

| Contamination Prevention | Work in a clean environment, use sterile tools, and monitor for mold or bacteria. |

| Fruiting Conditions | After full colonization, expose to fruiting conditions (lower temperature, higher humidity, light exposure). |

| Common Mushroom Species | Oyster, shiitake, lion's mane, reishi, and others, each with specific substrate and environmental preferences. |

| Storage | Store colonized substrate in a cool, dark place until ready for fruiting. |

| Yield | Varies by species and substrate; e.g., oyster mushrooms can yield 0.5-1 kg per kg of dry substrate. |

| Sustainability | Mycelium production can utilize agricultural waste, promoting circular economy practices. |

Explore related products

$15.99 $19.99

What You'll Learn

- Sterilize Substrate: Prepare grain or sawdust, sterilize to kill contaminants, ensuring a clean environment for mycelium growth

- Inoculate Substrate: Introduce mushroom spawn to sterilized substrate, allowing mycelium to colonize and spread

- Maintain Humidity: Keep environment moist to support mycelium growth, preventing drying and promoting healthy development

- Monitor Temperature: Control temperature (20-25°C) for optimal mycelium growth, avoiding extremes that hinder colonization

- Transfer to Bulk: Move colonized substrate to larger container for fruiting, encouraging mushroom formation

Sterilize Substrate: Prepare grain or sawdust, sterilize to kill contaminants, ensuring a clean environment for mycelium growth

The success of mushroom mycelium cultivation hinges on a sterile substrate, free from competing organisms that could outpace or contaminate your fungal colony. Think of it as creating a pristine, controlled environment where your desired mycelium can thrive without interference. This is where sterilization becomes paramount.

Whether you're using grain (like rye or millet) or sawdust as your substrate, the goal is the same: eliminate bacteria, molds, and other fungi that could jeopardize your harvest.

The Sterilization Process: A Delicate Dance

Imagine a microscopic battlefield where your mycelium is the hero and contaminants are the villains. Sterilization is the weapon that levels the playing field. The most common method involves pressure cooking your substrate. For grain, a ratio of 1 part grain to 2 parts water is typical. Sawdust, being drier, requires less water, around 1 part sawdust to 1.5 parts water. Aim for a temperature of 121°C (250°F) for at least 30 minutes to ensure thorough sterilization. This process, known as autoclaving, effectively kills spores and microorganisms, leaving your substrate ready for inoculation.

Remember, timing is crucial. Overcooking can damage the substrate's structure, while undercooking leaves room for contamination.

Beyond the Autoclave: Alternative Methods

While autoclaving is the gold standard, it's not the only option. For smaller batches or those without access to a pressure cooker, pasteurization can be a viable alternative. This involves heating the substrate to around 70-80°C (158-176°F) for 1-2 hours. While not as effective as sterilization, pasteurization can significantly reduce contaminant levels, especially when combined with proper sanitation practices.

The Art of Preparation: Setting the Stage for Success

Think of your substrate as the foundation of your mycelium's home. It needs to be nutrient-rich, moisture-retentive, and, most importantly, clean. Before sterilization, ensure your grain is properly hydrated and your sawdust is free from large debris. After sterilization, allow the substrate to cool to a temperature suitable for inoculation, typically around 25-30°C (77-86°F). This cooling period is crucial, as introducing spawn to hot substrate can be detrimental.

A Clean Slate for Fungal Flourishing

Sterilizing your substrate is not just a step; it's a critical investment in the success of your mushroom cultivation. By creating a clean environment, you're giving your mycelium the best possible chance to thrive, leading to healthy, abundant mushroom yields. Remember, patience and precision are key. Take the time to sterilize properly, and your mycelium will reward you with a bountiful harvest.

Do Nootropic Mushrooms Cause Psychedelic Trips? Exploring the Facts

You may want to see also

Inoculate Substrate: Introduce mushroom spawn to sterilized substrate, allowing mycelium to colonize and spread

The inoculation stage is a delicate dance, where the mushroom spawn meets its new home—the sterilized substrate. This process is akin to planting a seed, but instead of a sprout, you're nurturing the growth of mycelium, the vegetative part of the fungus. Imagine a network of tiny, thread-like roots rapidly expanding, and you'll understand the importance of this step in mushroom cultivation.

The Art of Introduction:

Inoculating the substrate is a precise operation. You'll need to introduce the mushroom spawn, typically grain or sawdust infused with mycelium, into the sterilized substrate. This substrate could be a mixture of materials like straw, wood chips, or compost, carefully prepared to provide the ideal environment for mycelial growth. The key is to ensure a thorough mix, allowing the spawn to come into contact with as much of the substrate as possible. A common technique is to layer the substrate and spawn, creating a striped pattern, which ensures even distribution. For instance, in a 5-gallon bucket, you might add 2 inches of substrate, followed by a layer of spawn, and repeat until the bucket is full.

Dosage and Timing:

The amount of spawn required varies depending on the substrate volume and the desired colonization time. A general rule of thumb is to use a spawn-to-substrate ratio of 1:10 to 1:20. For example, if you have 10 pounds of substrate, you'd need 0.5 to 1 pound of spawn. This ensures a healthy mycelial network without overcrowding. After inoculation, the mycelium will begin to colonize, and within 2-3 weeks, you should see visible signs of growth, indicating a successful inoculation.

Cautions and Considerations:

Sterility is paramount during this process. Any contamination can hinder mycelial growth and lead to mold or bacterial issues. Always work in a clean environment, and consider using a still air box or a laminar flow hood for more advanced setups. Additionally, maintain proper moisture levels in the substrate; too dry, and the mycelium struggles to spread; too wet, and you risk drowning the spawn. Regular misting or using a humidifier can help maintain optimal conditions.

The Waiting Game:

Once inoculated, patience is key. Mycelium growth is a gradual process, and rushing it can lead to subpar results. Keep the inoculated substrate in a warm, dark place, ideal conditions for mycelial expansion. Regularly check for signs of contamination and ensure the substrate remains undisturbed. This period is crucial for the mycelium to establish itself, and soon enough, you'll witness the fascinating transformation of substrate into a thriving mycelial network, ready for the next stage of mushroom cultivation.

This step is a critical phase in the mushroom cultivation journey, requiring attention to detail and a respectful approach to the natural processes at play. With the right techniques and care, you'll master the art of inoculation, setting the stage for a bountiful mushroom harvest.

California's Psychedelic Shift: Magic Mushrooms on the 2024 Ballot?

You may want to see also

Maintain Humidity: Keep environment moist to support mycelium growth, preventing drying and promoting healthy development

Mycelium, the vegetative part of a fungus, thrives in environments that mimic its natural habitat—damp, dark, and nutrient-rich. Humidity is the linchpin of this ecosystem. Without adequate moisture, mycelium dries out, halting growth and rendering your efforts futile. Maintaining humidity isn’t just about misting a surface; it’s about creating a microclimate where mycelium can flourish. Think of it as building a spa for your fungi—consistent, controlled, and nurturing.

To achieve this, start by monitoring humidity levels. Aim for a range of 60–70%, which is optimal for most mushroom species. Use a hygrometer to track conditions, and invest in a humidifier if your environment falls short. For smaller setups, a simple DIY solution is to place a tray of water near your growing container or use a spray bottle to mist the substrate lightly. However, avoid over-saturating the environment, as excessive moisture can lead to mold or bacterial contamination. Balance is key—enough to keep the mycelium hydrated but not so much that it drowns.

Another effective method is to use a humidity tent or chamber. This can be as simple as a clear plastic container or bag draped over your growing substrate. The enclosed space traps moisture, creating a humid environment without constant intervention. For larger operations, consider integrating a humidification system with automated controls to maintain consistency. Remember, mycelium is sensitive to fluctuations, so stability is crucial.

Finally, the substrate itself plays a role in humidity management. Materials like straw, wood chips, or sawdust naturally retain moisture, aiding in humidity regulation. Before inoculation, soak the substrate in water, then drain and pasteurize it to remove competitors while locking in moisture. This dual-purpose step not only prepares the substrate for colonization but also provides a head start on humidity control. By combining these strategies, you create an environment where mycelium can thrive, turning your growing space into a thriving fungal ecosystem.

Mastering Mushroom Curry: Shooking Techniques for Flavorful Cooking

You may want to see also

Explore related products

Monitor Temperature: Control temperature (20-25°C) for optimal mycelium growth, avoiding extremes that hinder colonization

Temperature is the silent conductor of mycelium growth, dictating the pace and success of colonization. Within the narrow range of 20-25°C, mycelium thrives, its filamentous network expanding rapidly to consume substrate nutrients. This optimal window is no accident—it mirrors the conditions of mushroom habitats in nature, where temperature stability fosters robust growth. Deviating from this range, even slightly, can slow colonization or halt it entirely, leaving your substrate vulnerable to contamination.

Consider the mechanics: mycelium is a living organism, and its metabolic processes are temperature-sensitive. At 20°C, growth is steady but not rushed, allowing for thorough substrate penetration. As temperatures approach 25°C, metabolic activity accelerates, but beyond this point, enzymes denature, and cellular stress ensues. Conversely, temperatures below 20°C slow enzyme activity, causing mycelium to grow sluggishly or enter dormancy. For instance, a drop to 15°C can extend colonization time by 50%, while a spike to 30°C may kill the mycelium outright. Precision is key—fluctuations of even 2-3°C can disrupt growth, making temperature control a non-negotiable aspect of successful cultivation.

Practical implementation requires vigilance and tools. Use a digital thermometer with a probe to monitor substrate temperature directly, as ambient air readings can be misleading. For small-scale projects, a heating pad with a thermostat or a seedling heat mat can maintain warmth in cooler environments. In warmer climates, a mini fridge converted into a growth chamber, paired with a temperature controller, ensures stability. For larger setups, consider a dedicated incubation room with a space heater or air conditioner regulated by a smart thermostat. Pro tip: insulate your growing containers with foam boards to buffer against external temperature swings, especially in drafty spaces.

The consequences of neglect are stark. In one case study, a grower in a temperate climate overlooked temperature control during winter, resulting in a colonization time of 21 days compared to the expected 10. Another grower in a tropical region failed to cool their substrate during a heatwave, leading to mycelium death and mold takeover. These examples underscore the fragility of mycelium under temperature stress and the importance of proactive management. Even seasoned cultivators must remain vigilant, as seasonal changes or equipment malfunctions can disrupt even the most carefully planned setups.

Ultimately, temperature control is not just a step—it’s the backbone of mycelium cultivation. By maintaining 20-25°C with precision and adaptability, you create an environment where mycelium can flourish unimpeded. Think of it as nurturing a delicate ecosystem: stability breeds success, while extremes invite chaos. Whether you’re a hobbyist or a commercial grower, mastering temperature regulation transforms mycelium cultivation from a gamble into a science. Invest in the right tools, stay observant, and let temperature be your ally in the journey from spore to harvest.

Creamy Chicken and Mushroom Pie: A Step-by-Step Recipe Guide

You may want to see also

Transfer to Bulk: Move colonized substrate to larger container for fruiting, encouraging mushroom formation

Once your mushroom mycelium has fully colonized its initial substrate, it’s time to transfer it to a larger container for fruiting. This step, known as "bulk transfer," mimics the mycelium’s natural progression into a more expansive environment, triggering the formation of mushrooms. The process requires careful handling to avoid contamination and stress to the mycelium. Begin by preparing your bulk substrate—a mixture of materials like straw, wood chips, or coco coir, sterilized or pasteurized to eliminate competing organisms. Common ratios include 1 part colonized grain spawn to 3–5 parts bulk substrate, though this varies by mushroom species. For example, oyster mushrooms thrive in straw-based substrates, while shiitake prefer hardwood sawdust.

The transfer itself is a delicate operation. First, ensure your workspace is clean and, ideally, within a still air box or laminar flow hood to minimize contamination. Gently break up the colonized substrate to expose more mycelium, then mix it thoroughly with the prepared bulk substrate in the larger container. This container should have proper ventilation—small holes drilled in the sides or a filter patch to allow gas exchange while keeping contaminants out. After mixing, maintain optimal conditions: 70–75°F (21–24°C) and high humidity (85–95%). Mist the surface lightly if it dries out, but avoid overwatering, as excess moisture can lead to mold or bacterial growth.

Comparing this step to other stages of mycelium cultivation highlights its significance. While colonization focuses on mycelial growth, bulk transfer shifts the focus to fruiting conditions. Unlike the controlled, sterile environment of spawn creation, bulk fruiting requires a balance of openness and protection. For instance, while a mason jar or grow bag suffices for colonization, a larger container like a monotub or bucket allows the mycelium to expand and access more nutrients, fostering mushroom development. This transition is akin to a plant moving from a seedling pot to a garden bed—both require careful timing and preparation.

A critical caution during bulk transfer is avoiding contamination. Even a small introduction of competing organisms can derail the process. Always use sterile tools and gloves, and work quickly but methodically. If using pasteurized substrate, ensure it has cooled to below 90°F (32°C) before mixing to prevent heat damage to the mycelium. Additionally, monitor the bulk substrate for signs of contamination in the days following transfer—green or black mold, unusual odors, or slow mycelial growth indicate a problem. If caught early, contaminated areas can sometimes be removed to save the batch.

In conclusion, the bulk transfer stage is a pivotal moment in mushroom cultivation, bridging the gap between mycelial growth and fruiting. By providing the mycelium with a larger, nutrient-rich environment and maintaining optimal conditions, you encourage the formation of mushrooms. Attention to detail, from substrate preparation to contamination prevention, ensures a successful transition. With patience and care, you’ll soon see the fruits of your labor—literally—as mushrooms emerge from the bulk substrate, ready for harvest.

Delicious Longhorn Stuffed Mushrooms: Easy Recipe for Appetizer Perfection

You may want to see also

Frequently asked questions

The easiest way is to use a mushroom grow kit or purchase pre-sterilized grain spawn inoculated with mycelium. Simply follow the kit instructions, maintain proper humidity and temperature, and allow the mycelium to colonize the substrate.

You’ll need a substrate (like grain or sawdust), mushroom spores or culture, a pressure cooker for sterilization, a sterile workspace, and tools like gloves, jars, and filters to prevent contamination.

Colonization time varies by mushroom species and substrate, but it typically takes 2–4 weeks for mycelium to fully colonize grain spawn and 4–8 weeks for sawdust or straw substrates. Optimal temperature and humidity are key to speeding up the process.