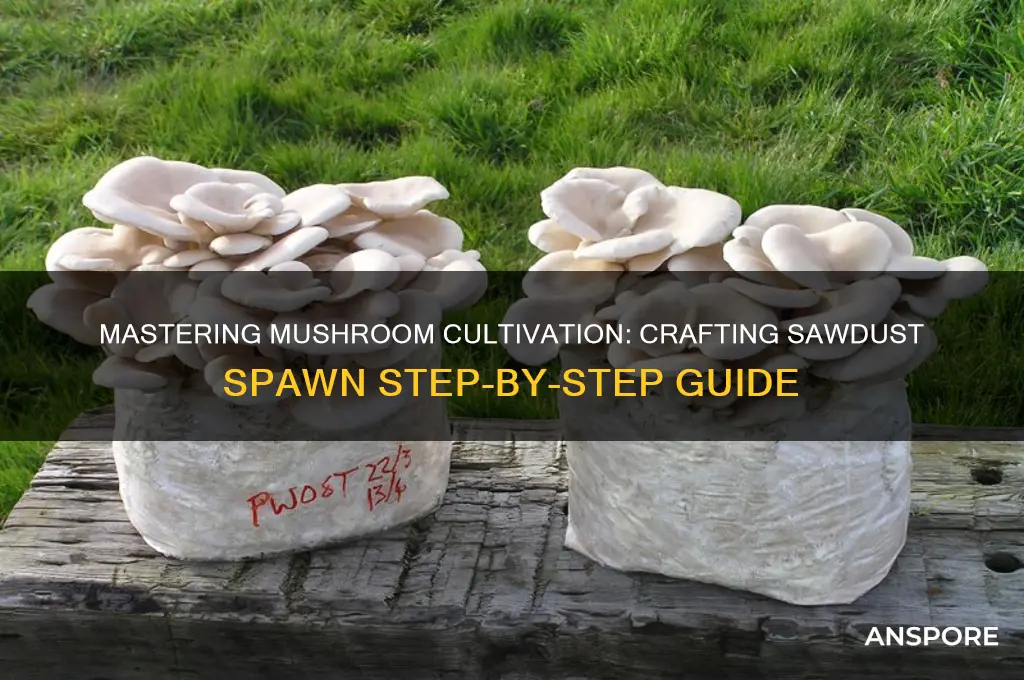

Making mushroom sawdust spawn is a crucial step in cultivating mushrooms, as it serves as the nutrient-rich substrate that mycelium colonizes before fruiting. The process begins by selecting a suitable hardwood sawdust, such as oak or beech, which is then pasteurized or sterilized to eliminate contaminants. Next, the sawdust is mixed with a supplement like wheat bran or soy hulls to provide additional nutrients for the mycelium. This mixture is then inoculated with mushroom spawn or liquid culture, ensuring even distribution. The inoculated substrate is placed in sterile bags or containers and incubated in a controlled environment, allowing the mycelium to colonize the sawdust fully. Proper sterilization, hydration, and attention to detail are key to producing high-quality sawdust spawn that will yield healthy and abundant mushroom crops.

| Characteristics | Values |

|---|---|

| Raw Materials | Sawdust (preferably hardwood like oak, beech, or poplar), mushroom mycelium culture (spawn), wheat bran or flour, calcium carbonate (optional), water. |

| Sterilization Method | Autoclave (15 psi for 1-2 hours) or pressure cooker (15 psi for 1.5-2 hours). |

| Moisture Content | 50-60% (adjust by adding water gradually). |

| pH Level | 5.5-6.5 (adjust with calcium carbonate if needed). |

| Substrate Ratio | Sawdust:wheat bran = 5:1 (by volume). |

| Inoculation Rate | 2-5% spawn to substrate (e.g., 200-500 grams spawn per 10 kg substrate). |

| Inoculation Environment | Sterile conditions (laminar flow hood or still air box). |

| Incubation Temperature | 22-26°C (72-78°F). |

| Incubation Duration | 2-4 weeks (depending on mushroom species and conditions). |

| Contamination Prevention | Sterilize all tools, use gloves, and work in a clean environment. |

| Spawn Storage | Store in a cool, dark place at 2-4°C (35-39°F) for up to 6 months. |

| Common Mushroom Species | Oyster, shiitake, lion's mane, reishi. |

| Cost | Low to moderate (depends on equipment and scale). |

| Difficulty Level | Intermediate (requires attention to sterilization and contamination prevention). |

| Yield | Varies by species; e.g., oyster mushrooms can yield 1-2 kg per 10 kg substrate. |

| Sustainability | High (uses agricultural waste like sawdust). |

Explore related products

What You'll Learn

Sterilize sawdust substrate

Sterilization is a critical step in preparing sawdust substrate for mushroom spawn, as it eliminates competing microorganisms that could hinder mycelial growth. Without proper sterilization, contaminants like bacteria, molds, and other fungi can quickly colonize the substrate, outcompeting your desired mushroom species. This process involves subjectting the sawdust to high temperatures, typically through autoclaving or pressure cooking, to ensure all pathogens and spores are destroyed. While it may seem daunting, mastering this step is essential for successful mushroom cultivation.

Steps for Sterilizing Sawdust Substrate:

- Prepare the Sawdust Mixture: Combine sawdust with a nutrient supplement, such as wheat bran or soy hulls, in a ratio of 5:1 (sawdust to supplement). Moisture content should be around 60–70%, similar to a wrung-out sponge. Mix thoroughly to ensure even distribution.

- Pack the Substrate: Fill autoclavable bags or jars with the sawdust mixture, leaving enough headspace (about 1–2 inches) to allow steam penetration. Seal the bags loosely or use foil to cover jars.

- Autoclave or Pressure Cook: For small batches, use a pressure cooker at 15 psi (pounds per square inch) for 60–90 minutes. Larger operations require an autoclave, maintaining 15 psi for 2–3 hours. Ensure the substrate reaches a minimum internal temperature of 121°C (250°F) to kill all contaminants.

- Cool and Inoculate: Allow the substrate to cool to room temperature (22–25°C or 72–77°F) before inoculating with mushroom spawn. Premature inoculation risks killing the mycelium due to residual heat.

Cautions and Troubleshooting:

Overpacking bags or jars can prevent proper steam penetration, leading to incomplete sterilization. Conversely, underpacking wastes space and resources. Always monitor the pressure cooker or autoclave to avoid equipment failure or unsafe conditions. If contamination occurs post-sterilization, reevaluate your workflow for potential exposure points, such as unclean tools or environments.

Comparative Methods:

While autoclaving is the gold standard, alternatives like pasteurization (soaking in hot water at 65–70°C for 1–2 hours) are less effective for sawdust substrates due to their density. Pasteurization may suffice for bulk substrates like straw but falls short for sawdust, which requires the higher temperatures of sterilization to ensure a contaminant-free environment.

Practical Tips:

For hobbyists, a 16-quart pressure cooker can sterilize 5–6 quart-sized jars or 3–4 spawn bags per batch. Always use a thermometer to verify internal substrate temperature, especially when starting out. Label bags with sterilization dates to track freshness, as properly sterilized substrate can remain viable for 2–4 weeks when stored in a cool, dark place.

Mastering substrate sterilization transforms mushroom cultivation from a gamble into a science. By dedicating time to this step, you create a clean, nutrient-rich foundation for mycelial growth, setting the stage for abundant mushroom yields.

Crafting Mushroom Neptune: A Step-by-Step Culinary Adventure Guide

You may want to see also

Inoculate with mushroom mycelium

Inoculating sawdust with mushroom mycelium is the pivotal step in creating viable spawn, transforming inert substrate into a thriving fungal network. This process requires precision: use 5-10% colonized grain spawn by weight relative to your pasteurized sawdust. For example, mix 500 grams of fully colonized grain spawn with 4.5 kilograms of hydrated, pasteurized sawdust in a sterile environment. Maintain a temperature range of 70-75°F (21-24°C) to encourage rapid mycelial growth without stressing the culture.

The success of inoculation hinges on minimizing contamination. Work in a still air box or laminar flow hood to reduce airborne spores, and sterilize all tools with 70% isopropyl alcohol. After combining spawn and sawdust, seal the mixture in a spawn bag or jar, ensuring an even distribution. Avoid compacting the substrate, as mycelium thrives in oxygen-rich environments. Within 7-14 days, the sawdust should show signs of colonization, marked by white, thread-like growth.

Comparing inoculation methods reveals the advantages of using grain spawn over liquid culture. Grain spawn provides a robust, nutrient-rich inoculant that colonizes sawdust more aggressively, reducing the risk of contamination. Liquid culture, while cost-effective, often requires larger volumes and can introduce impurities if not handled meticulously. For hobbyists, grain spawn offers a higher success rate and is more forgiving for beginners.

A critical caution during inoculation is avoiding over-inoculation, which can deplete nutrients prematurely and stunt mycelial growth. Stick to the 5-10% ratio and monitor the substrate’s moisture level, aiming for 60-70% field capacity. Too much moisture invites mold, while too little hinders colonization. Regularly inspect the spawn for off-colors or unusual odors, which signal contamination. If detected, discard the batch immediately to prevent cross-contamination.

Inoculating sawdust with mushroom mycelium is both art and science, demanding attention to detail and patience. By adhering to sterile techniques, precise ratios, and optimal conditions, you can reliably produce high-quality mushroom spawn. This step is the foundation for successful fruiting, ensuring a robust mycelial network capable of supporting abundant mushroom yields. Master this process, and you’ll unlock the potential of sawdust spawn for any scale of cultivation.

Savory Chicken Bacon Mushroom Pie: Easy Homemade Recipe Guide

You may want to see also

Maintain optimal temperature/humidity

Temperature and humidity are the silent conductors of the mushroom cultivation orchestra, dictating whether your sawdust spawn thrives or falters. Mushrooms, unlike plants, don't photosynthesize; they rely on mycelium, a network of thread-like cells, to absorb nutrients. This mycelium is highly sensitive to environmental conditions, particularly temperature and moisture. Deviations from the optimal range can stunt growth, invite contaminants, or even kill the spawn.

Understanding these parameters isn't just theoretical; it's the difference between a bountiful harvest and a moldy disappointment.

Maintaining the ideal temperature for mushroom spawn is a delicate balance. Most common mushroom species, like oyster mushrooms (*Pleurotus ostreatus*), prefer a temperature range between 70°F and 75°F (21°C and 24°C) during colonization. This warmth encourages mycelium to spread rapidly through the sawdust substrate. However, exceeding 80°F (27°C) can stress the mycelium, leading to slowed growth or even death. Conversely, temperatures below 65°F (18°C) can significantly slow colonization, prolonging the time it takes for your spawn to be ready for fruiting.

Think of it as a Goldilocks scenario: not too hot, not too cold, but just right.

Humidity, the other half of this environmental equation, is equally crucial. Mycelium requires moisture to grow, but too much can create a breeding ground for unwanted bacteria and molds. Aim for a relative humidity of 60-70% within your incubation environment. This can be achieved by misting the sawdust spawn lightly with water before sealing it in a humid environment, such as a plastic bag or container. Remember, the goal is to create a damp, not soaking wet, environment.

Achieving and maintaining these optimal conditions often requires some ingenuity. For temperature control, consider using a simple heating mat or placing your spawn in a warm, draft-free location. Humidity can be regulated by using a humidifier or by placing a tray of water near the spawn. Regular monitoring with a thermometer and hygrometer is essential to ensure your spawn remains within the desired range.

Consistency is key; fluctuations in temperature and humidity can disrupt the delicate balance and hinder mycelium growth.

By meticulously controlling temperature and humidity, you create an environment where your mushroom sawdust spawn can flourish. This attention to detail will be rewarded with healthy, vigorous mycelium, ready to transform your sawdust into a bountiful harvest of delicious mushrooms.

Spicy Mushroom Kadai Recipe: Easy, Flavorful Indian Curry Guide

You may want to see also

Explore related products

Seal and incubate spawn bags

Sealing and incubating spawn bags is a critical step in the mushroom cultivation process, as it creates the ideal environment for mycelium to colonize the substrate. After mixing your sawdust with mushroom spawn and moisture, the next challenge is to ensure the bags remain sterile and at the right temperature for optimal growth. This phase demands precision and patience, as any contamination or temperature fluctuation can derail your efforts.

Steps to Seal Spawn Bags: Begin by filling your autoclavable bags with the sawdust-spawn mixture, leaving enough space at the top to allow for expansion. Use a heat sealer or impulse sealer to close the bags tightly, ensuring no air pockets remain. If a sealer isn’t available, a tight knot or rubber band can suffice, though this method increases contamination risk. For added protection, some cultivators inject 0.5–1% hydrogen peroxide into the bag before sealing to create a sterile environment. Always work in a clean, sterile area, preferably a still air box or laminar flow hood, to minimize exposure to airborne contaminants.

Incubation Conditions: Once sealed, the bags require a stable environment to incubate. Ideal temperatures vary by mushroom species but typically range between 70–75°F (21–24°C). Place the bags in a dark, undisturbed area, such as a closet or dedicated incubation chamber. Humidity is less critical during this phase, as the bags retain moisture internally. Incubation time depends on the species and substrate but generally lasts 2–4 weeks. Monitor for signs of contamination, such as green or black mold, and discard affected bags immediately to prevent spread.

Cautions and Troubleshooting: Contamination is the primary risk during incubation. Even a single spore can ruin an entire bag. If mold appears, it’s often due to inadequate sterilization or improper sealing. To mitigate this, double-check your sterilization process and ensure bags are sealed tightly. Another common issue is slow colonization, which may result from low temperatures or insufficient spawn-to-substrate ratio. If growth stalls, gently increase the incubation temperature by 2–3°F and ensure the area is draft-free.

Delicious Mushroom Chickpea Patties: Easy, Healthy, and Flavorful Recipe Guide

You may want to see also

Monitor for contamination signs

Contamination is the silent saboteur of mushroom cultivation, capable of undoing weeks of effort in a matter of days. Mold, bacteria, and competing fungi thrive in the same nutrient-rich, humid conditions that mushrooms require, making vigilance your first line of defense. Early detection is critical, as established contamination is nearly impossible to reverse. Regularly inspect your sawdust spawn for discoloration, unusual odors, or abnormal growths, which are telltale signs of intruders. A daily visual check, especially during the first week of incubation, can save your entire batch.

The most common contaminants include *Trichoderma* (a green mold that spreads rapidly), cobweb mold (resembling white, fuzzy patches), and bacterial blotch (slimy, discolored spots). Each has distinct characteristics: *Trichoderma* often appears as bright green patches, while cobweb mold forms a cotton-like layer. Bacterial blotch may start as small, wet spots that expand and darken. Temperature and humidity fluctuations can exacerbate these issues, so maintain a stable environment—ideally 70–75°F (21–24°C) and 60–70% humidity for most mushroom species. If you notice any anomalies, isolate the contaminated spawn immediately to prevent cross-contamination.

Prevention is just as crucial as monitoring. Sterilize your sawdust substrate thoroughly, typically by autoclaving at 15 psi for 1.5 hours or steaming for 2–3 hours. Ensure your workspace is clean, using 70% isopropyl alcohol to sanitize tools and surfaces. When inoculating, work in a still air box or a clean, draft-free area to minimize airborne spores. After inoculation, seal your spawn bags or containers tightly, but leave enough room for gas exchange without compromising sterility. These steps reduce the risk of contamination but do not eliminate the need for ongoing monitoring.

If contamination does occur, act swiftly but strategically. Small, localized issues can sometimes be salvaged by removing the affected area with a sterilized tool and sealing the wound with melted paracord or tape. However, widespread contamination often requires discarding the entire batch to protect future projects. Document each instance, noting potential causes (e.g., inadequate sterilization, improper sealing), to refine your process over time. Remember, contamination is a learning opportunity, not a failure—it sharpens your skills and deepens your understanding of this delicate craft.

Finally, adopt a mindset of patience and precision. Mushroom cultivation is as much an art as a science, and monitoring for contamination is a practice in mindfulness. Keep a log of your observations, including dates, temperatures, and humidity levels, to identify patterns and improve consistency. With time, you’ll develop an intuitive sense for what’s normal and what’s cause for concern. By staying proactive and meticulous, you’ll safeguard your sawdust spawn and set the stage for a thriving mushroom harvest.

Juicy Portobello Mushroom Burgers: A Step-by-Step Guide to Perfection

You may want to see also

Frequently asked questions

Mushroom sawdust spawn is a substrate inoculated with mushroom mycelium, typically made from sawdust mixed with nutrients like wheat bran or gypsum. It serves as a starter culture for growing mushrooms, allowing for efficient colonization of larger substrates like straw or logs.

You’ll need sawdust (preferably hardwood), a nutrient supplement (e.g., wheat bran or rice flour), gypsum (to regulate pH and structure), mushroom spawn or culture, and sterile equipment like jars, gloves, and a pressure cooker for sterilization.

Mix the sawdust, nutrient supplement, and gypsum, then moisten it with water until it feels like a wrung-out sponge. Pack the mixture into jars, seal them with lids, and sterilize in a pressure cooker at 15 psi for 1.5–2 hours to kill contaminants.

Colonization time varies by mushroom species but typically takes 2–4 weeks. Keep the jars in a warm, dark place (around 70–75°F or 21–24°C) and avoid disturbing them until fully colonized.